Table of Contents

Advertisement

Quick Links

INSTALLATION AND MAINTENANCE INSTRUCTIONS

BEAM1224A, BEAM1224SA

Single-ended Reflected Type Projected

Beam Smoke Detector

Specifications

General

Range:

Sensitivity:

Spacing:

Response Time:

Trouble Conditions:

Test/Reset Features:

Indicators:

Environmental

Temperature:

Humidity:

Mechanical

Shipping Weight:

Shipping Size:

Mounting:

Wiring:

Adjustment Angle:

Paintable Trim Ring:

D400-73-00

16 to 230 Feet (5 to 70m)

230 to 328 Feet (70 to 100m) using optional accessory BEAMLRK

25% to 50% Total Obscuration in 6 levels

Level 1 = 25%

Level 2 = 30%

Level 3 = 40%

Level 4 = 50%

Level 5 = 30% to 50% (Acclimate)

Level 6 = 40% to 50% (Acclimate)

30 to 60 Feet (9.1 to 18.3 m)

Alarm: 20 seconds typical

Trouble: 30 seconds typical

Beam Blockage (96% or More Obscuration)

Improper Initial Alignment

Self-compensation limit reached (service needed)

In Alignment mode

Integral Sensitivity Test Filter (BEAM1224SA only)

Sensitivity Filter (Incremental scale on reflector)

Local Alarm Test Switch

Local Alarm Reset Switch

Remote Test and Reset Switch Capability

(compatible with RTS451/RTS451KEYA)

Alarm:

Trouble:

Remote Output, Local LED (yellow)

Normal Operation:

Alignment Aids: Optical Gunsight (coarse adjustment)

Relays:

Sensitivity:

–22°F to 131°F (–30°C to 55°C)

Note: For applications below 32°F (0°C), see Special Applications section of this manual

10% to 93% RH Noncondensing

Complete unit:

15" × 10.5" × 6.5" (381 mm × 267 mm × 165 mm)

Wall only without optional accessories

Plug-in Terminal Blocks (12 to 22AWG)

±10° Horizontal and Vertical

May be painted using enamel or acrylic type paints

6581 Kitimat Rd. Unit 6 Mississauga, Ontario L5N 3T5

Remote Output, Local LED (red)

Blink Pattern Indicates Trouble Diagnostics

Local LED (flashing green once every 5 sec)

00 to 99 Digital Display (fine adjustment)

Alarm; Trouble

Digital Display Readout in Percent Obscuration

3.9 lbs. (1.77 kg)

1

1-800-SENSOR2, Télécopieur : 905-812-0772

WWW.SYSTEMSENSOR.CA

I56-2541-00R

Advertisement

Table of Contents

Summary of Contents for System Sensor BEAM1224A

- Page 1 INSTALLATION AND MAINTENANCE INSTRUCTIONS BEAM1224A, BEAM1224SA Single-ended Reflected Type Projected 6581 Kitimat Rd. Unit 6 Mississauga, Ontario L5N 3T5 Beam Smoke Detector 1-800-SENSOR2, Télécopieur : 905-812-0772 WWW.SYSTEMSENSOR.CA Specifications General Range: 16 to 230 Feet (5 to 70m) 230 to 328 Feet (70 to 100m) using optional accessory BEAMLRK Sensitivity: 25% to 50% Total Obscuration in 6 levels Level 1 = 25% Level 2 = 30% Level 3 = 40% Level 4 = 50% Level 5 = 30% to 50% (Acclimate) Level 6 = 40% to 50% (Acclimate) Spacing: 30 to 60 Feet (9.1 to 18.3 m) Response Time: Alarm: 20 seconds typical...

-

Page 2: Before Installing

No additional equipment is needed for alignment General Description of the beam. System Sensor Model BEAM1224A/BEAM1224SA is a long range p rojected b eam s moke d etector d esigned t o p rovide o pen Each detector contains one Form A (normally open) con- area protection. It is to be used with ULC-listed, separately sup-... -

Page 3: Approved Accessories

The BEAMSMK allows System Sensor reflected beam detec- shipping warehouses, enclosed parking facilities, sporting tors to be mounted when surface wiring is used. This kit must arenas and stadiums, concert halls, barns, or stables. Some be used when mounting the transmitter/receiver unit with the of these environments might be considered to hostile for multi-mount kit (BEAMMMK). spot-type smoke detectors. If the environment is consid- ered to be hostile then the colder alarm threshold settings RTS451/KEYA should be used. - Page 4 NOTE: P rojected beam smoke detectors should always In the case of peaked or sloped ceilings, codes may specify be mounted to stable mounting surfaces. See the spacing of detectors by using horizontal spacing from the MOUNTING LOCATION section for details. peak of the roof or ceiling. Figures 3 and 4 show the spacing for both the shed type and peaked type sloped ceilings. Some fire codes specify spacing on a given center-to-center distance between detectors under ideal conditions. This On smooth ceilings, beam smoke detectors should gener-...

-

Page 5: Mounting Locations

Mounting Locations adjustment of the transmitter/receiver unit. If the perpen- Beam detectors require a stable mounting surface for dicular plane of the reflector cannot be mounted within 10° proper operation. A surface that moves, shifts, vibrates, or of the optical line of sight then the multi-mount kit can be warps over time will cause false alarm or trouble condi- used for the reflector. See BEAMMMK instructions. -

Page 6: Wiring Installation Guidelines

When installing the beam smoke detector in applications where Light sources of extreme intensity such as sunlight and hal- the head unit will be mounted to either a wall or the ceiling ogen lamps, if directed at the receiver, can cause a dramatic using the multi-mount kit (BEAMMMK) flexible conduit will be signal change resulting in fault and alarm signals. To prevent used. The surface mount kit (BEAMSMK) and multi-mount kit this problem direct sunlight into the transmitter/receiver... -

Page 7: Installation / Alignment

Pre-Alignment Checklist The alignment of the BEAM1224A/BEAM1224SA is divided into four steps: coarse alignment, fine adjustment, final gain • I nsure that both the detector and reflector are mounted adjustment, and final verification. It is necessary for all four securely to stable surfaces. -

Page 8: Step 1. Coarse Alignment

• C omplete any wiring dressing to minimize movement to the “electronic amplifier gain” setting. When this occurs it will detector once the alignment procedure is completed. be indicated by the dual digital readout as “- -”. When this • I nsure that the appropriate number of reflectors are occurs, cease any further adjustment until the display again used for the installed distance. Distances between 230 reads a number value. - Page 9 Step 4. Final Verification electronic gain each time a value of 90 is achieved. This step is required to insure the detector has been setup When this occurs the detector resumes with less elec- correctly and will detect smoke at the proper sensitivity tronic gain than previously when 90 was achieved.

-

Page 10: Sensitivity Selection

Figure 11. Alignment Adjustment Locations Figure 13. Housing Screw Locations ALIGNMENT MIRROR ALIGNMENT GUNSIGHT ALIGNMENT POSITION INDICATOR SCREW SCREW LOCATIONS LOCATIONS DIGITAL SIGNAL STRENGTH READOUT HORIZONTAL OPTICS ADJUSTMENT LOCK-DOWN SCREWS RESET SWITCH C0264-00 C0266-00 VERTICAL ADJUSTMENT Figure 12. Coarse Alignment Procedure Sensitivity Selection The detector has six sensitivity selections. Each of these selec- tions is only acceptable over a specific distance separation... - Page 11 Disable the zone or system undergoing maintenance to prevent unwanted alarms. Detectors must be tested after installation and following periodic maintenance. The sensitivity of the BEAM1224A/ BEAM1224SA may be tested as follows: MOVE TEST CARD TO DESIRED AMOUNT OF OBSCURATION...

-

Page 12: Maintenance

4 of the Installation/Alignment procedure to insure that the ammonia. pathway between the detector and reflector is clear. 3. N otify the proper authorities that the system is back on Note: For the BEAM1224A this test does not satisfy the line. requirements of NFPA72 and/or ULC for periodic maintenance Painting and sensitivity verification of beam type detectors. For the... -

Page 13: Appendix I. Operation Modes And Troubleshooting Guide

Appendix I. Operation Modes and Troubleshooting Guide D400-73-00 I56-2541-00R... - Page 14 D400-73-00 I56-2541-00R...

-

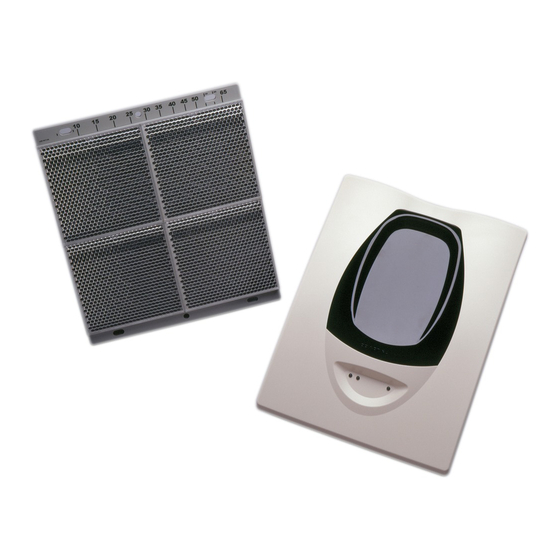

Page 15: Appendix Ii. Detector Drilling Template

Appendix II. Detector Drilling Template 6.190 ″ 4.345 ″ Scale = 1:1 D400-73-00 I56-2541-00R... - Page 16 D400-73-00 I56-2541-00R...

-

Page 17: Appendix Iii. Reflector Drilling Template

Appendix III. Reflector Drilling Template 5.512 ″ ( 140mm ) 8.465 ″ ( 215mm ) Scale = 1:1 D400-73-00 I56-2541-00R... -

Page 18: Three-Year Limited Warranty

Please refer to insert for the Limitations of Fire Alarm Systems FCC Statement This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful inter- ference, and (2) this device must accept any interference received, including interference that may cause undesired operation. Note: T his equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to...

Need help?

Do you have a question about the BEAM1224A and is the answer not in the manual?

Questions and answers