Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Eaton Hydrokraft PVW 250

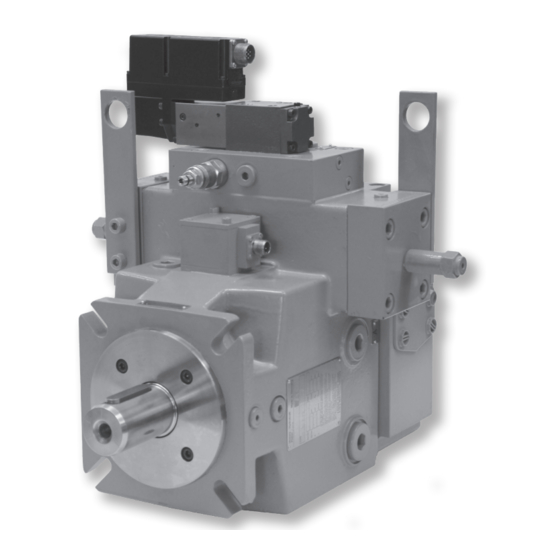

- Page 1 Hydrokraft Operation Manual PVW 250+360...

-

Page 2: Table Of Contents

6.15 Other installation torque specification ............29 HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... - Page 3 12. PROPER DISPOSAL ..............34 HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com...

-

Page 4: General Safety Instructions

2.4 Intended use Eaton Germany GmbH does not assume any guarantee or liability for errors in these instructions or any subsequent Eaton Hydrokraft axial piston pumps are developed and damages in relation with the delivery manufactured in accordance with the state of technology and the safety-related directives of MD 2006/42/EC. - Page 5 Make sure the system is at zero pressure • Malfunction of elements. • Avoid endangering caused by adjacent installations • Pollution of the hydraulic medium. • Make sure that the pressure has been • completely relieved. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com...

- Page 6 For this reason, the expert staff must wear ear protection when exposed to health-damaging noise emission. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com...

-

Page 7: Product Description

Through-drive enables multiple pump installations • from a single shaft. Multiple pump combinations are ES - Displacement adjustment via electric motor also available. Integrated pilot pump, filter and pressure relief • valves available. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... - Page 8 Product Description Typical section of open loop PVW pump Definition of shaft direction of rotation, swash angle direction and actuator piston movement Optically indicated swash angle Pressure control setting HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com...

-

Page 9: Description Of Available Control Options

– Connection plate for DF-control – Pressure compensator, main stage – Pressure compensator, pilot stage Circuit shown is just an example, other options available. For circuit of individual pumps please contact technical support HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... - Page 10 – Pressure and power compensator, main stage – cover plate – Power compensator, pilot stage Circuit shown is just an example, other options available. For circuit of individual pumps please contact technical support. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com...

- Page 11 – Pilot pressure relief valve – Pilot oil filter – Proportional control valve – Pilot pump Circuit shown is just an example, other options available. For circuit of individual pumps please contact technical support. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com...

- Page 12 – Connection plate for proportional valve – Proportional relief valve – Pilot pump Circuit shown is just an example, other options available. For circuit of individual pumps please contact technical support. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com...

- Page 13 – Adapter plate ST-control – Propotional control valve L3.1 L8 L5 ML L1 L2 Circuit shown is just an example, other options available. For circuit of individual pumps please contact technical support. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com...

- Page 14 – Gauge port, case pressure – Basic pump – Electric Motor for ES-control Circuit shown is just an example, other options available. For circuit of individual pumps please contact technical support. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com...

-

Page 15: Nameplate And Identification

= Max. pressure to ISO 5598:2008 With “Type” short form of modelcode pump is not uniquely identifiable. Please use always Part No. or Serial Number for communication with Hydrokraft customer support. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... -

Page 16: Technical Data

5000 ISO splined shaft only Larger displacement/higher speed on request only. Contact Eaton Technical Support. System oil viscosity between 20-40cSt is recommended for optimal volumetric efficiency Case flushing oil viscosity between 40-50cSt is recommended for optimal bearing life and mechanical efficiency Lifetime of shaft seal is depending on shaft speed of the pump, fluid, case drain pressure and others. - Page 17 3688 ISO splined shaft only p Larger displacement/higher speed on request only. Contact Eaton Technical Support. System oil viscosity between 20-40cSt is recommended for optimal volumetric efficiency Case flushing oil viscosity between 40-50cSt is recommended for optimal bearing life and mechanical efficiency Lifetime of shaft seal is depending on shaft speed of the pump, fluid, case drain pressure and others.

-

Page 18: Transport And Storage

For exact mass data contact your Eaton Hydrokraft Technical Support team or weight pump separately before lifting. For dimension information please have a look in appropriate documentation (installation drawing, product catalogue) HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... -

Page 19: Storage

4.2.1. Corrosion protection ex works standard wooden box (seafreight packaging) • Eaton Hydrokraft axial piston units are tested with mineral possible storage time ca. 24-36 months • oil HLP 46 acc. DIN 51524 T2 by default. The oil film kept inside the unit covering all internal parts provides an 4.2.3.3 Storage outdoor... -

Page 20: Assembly And Installation

Defective bonding, aging, mechanical defaults may cause burst of flexible lines. WARNING! Defective flexible lines must be replaced immediately Flexible lines from unknown manufacturers or • incomplete identification should not be used HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... -

Page 21: Relief Valves

Refer to # 5.14 / 5.15. Below tank installation is the preferred installation • position, i.e. outside of tank below the minimum oil level in hydraulic reservoir. Minimum suction pressure is defined with 1 bar absolute. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... -

Page 22: Case Drain And Case Pressure

Lifetime of shaft seal is depending on shaft speed of the between shoe and piston and might affect/decrease pump, fluid, case drain pressure and others. For max. lifetime of this combination allowable values please refer to Ch 3.4 “Technical data” . HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... -

Page 23: Suction Line

HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... -

Page 24: Shaft Coupling - Immersed Pump

This shaft seal pressure can be measured at port L8. Shaft seal pressure can be limited by diameter of • orifice, depending on pressure level in flushing supply line = 0.01 x Qpump = 0.025 x Qpump HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... -

Page 25: Active Bearing Flushing - W-Design

PF/VW 250 PF/VW 360 Case pressure case (overpressure) n = 1200 rev/min n = 1500 rev/min n = 1800 rev/min HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... -

Page 26: Comissioning

(special application conditions above standard ratings may You should proceed to a visual inspection of all flex- • be possible, but would need written approval from Eaton ible lines before taking into operation. Defective Wehrheim to become valid) bonding, aging, mechanical defaults may cause burst of flexible lines. -

Page 27: Hydraulic Fluids

In general, the susceptibility to temperature and contamination is significantly higher than with standard mineral oils. In line with Eaton Germany GmbH T&C warranty conditions covering use of HFDR/HFDU/HEES fluids, fluid-related damage is excluded. 6.6 Filtration filtration and cleanliness levels for extending the life of axial piston pumps and other system components are listed. -

Page 28: Commissioning At Low Temperature

6.12 Stopping the pump When stopping the E-motor, system should be depres- surized. Otherwise pressurized oil might drive E-motor in opposite direction, creating massive cavitation damage inside the pump. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... - Page 29 µ .= 0,125 STEEL Stud Form (Picture) Size MA (Nm) MA (Nm) G 1/8 G 1/4 G 3/8 G 1/2 G 3/4 G 11/4 G 11/2 HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com...

-

Page 30: Other Installation Torque Specification

2.) Lubricate O-ring with light coating of hydraulic 6.15.2 Validity oil or compatible lubricator! These references are not under control of Eaton change 3.) Inspect components to ensure that male and management. female port threads and sealing surfaces are free of burrs, nicks and scratches or any foreign 6.15.3 References... -

Page 31: Troubleshooting

27. Pilot pressure too low < 28. Electrical solenoid < problems 29. Loosened fittings < 30. Dried or worn seals or < < < O-rings 31. Line breakage < < < HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... - Page 32 7.12 Excessive pressure above maximum pump rating: Check that oil viscosity and oil type are as per fluid Check relief or regulator valve maximum setting. recommendations. See chp.: 3.4 Technical data • 6.5 Hydraulic fluids • HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com...

- Page 33 Inspect for correct size, and check for kinked or • crimped hose. Check valve in regard of function and cleanliness, espe- cially valve orifices repair or replace valves. Malfunction usually caused by high sediment level or oil oxidation. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com...

-

Page 34: Maintenance And Repair

Phone: +49 (0) 6081 103 0 (switchboard) 8.4 Repair Eaton Germany GmbH provides a complete range of service and repair. If it is required Eaton Germany GmbH can provide a complete offer for service and repair. HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... -

Page 35: Extension And Converting

Make sure the system is pressure-free • assistance. Make sure the temperature of the Hydrokraft pump is • cold enough to touch safe. Use a collector to collect resigning hydraulic fluid • HYDROKRAFT OPERATION MANUAL PVW 250+360 E-PUIO_II001-E April 2021 www.eaton.com... - Page 36 Am Joseph 16 D-61273 Wehrheim Tel: +49 (0) 6081 103 302 Fax: +49 (0) 6081 103 342 © 2021 Eaton Eaton is a registered trademark. All Rights Reserved Publication No. E-PUIO-II001-E All trademarks are property April 2021 of their respective owners.

Need help?

Do you have a question about the Hydrokraft PVW 250 and is the answer not in the manual?

Questions and answers