Summary of Contents for matev FPS-FZW-Kioti CS 2520

- Page 1 -FZW-Kioti CS 2520 Operating Manual matev GmbH Modifications and errors excepted! Nürnberger Str. 50 Version: 5/10/2021 D-90579 Langenzenn Reference number: BA-FPS-FZW-32441 Phone: +49 (0) 9101 90870...

- Page 2 Order numbers Order no. Designation 131 9017 Front PTO shaft 131 9018 Universal joint shaft guard Page 2...

-

Page 3: Table Of Contents

Table of contents Table of contents ........................3 1 Introduction .......................... 5 2 About this operating manual ....................6 3 Technical data ........................7 Front PTO shaft ......................7 4 General safety notices ......................7 Depiction of safety information ................... 7 Intended use ....................... - Page 4 Table of contents 13 EC Declaration of Conformity .................... 19 Page 4...

-

Page 5: Introduction

Introduction Welcome to the matev family and thank you for purchasing a product from matev GmbH; we appreciate your trust. You have acquired a quality product, if contrary to expectations you should have problems with the implement, contact your responsible sales partner. -

Page 6: About This Operating Manual

About this operating manual Read this entire manual carefully before operating this machine for the first time. Keep this manual where it is easily accessible. This will enable you to refer to important infor- mation and handling instructions as needed. When the machine is delivered the owner receives instruction regarding operation and maintenance of the machine from his sales partner. -

Page 7: Technical Data

Technical data Front PTO shaft Drive shaft 1” 15-piece PTO input 2000 rpm CCW Ground clearance (see Fig.5) 135 mm - 140 mm General safety notices This chapter summarizes regulations and information that must be observed in connection with machines. Depiction of safety information The safety information in the text is combined with pictograms and signal words which to- gether indicate the severity of the expected risk... -

Page 8: Instructions For The Owner

• Intended use also comprises the exclusive use of original replacement parts and ad- ditional equipment or such components and equipment that meet the manufacturer’s technical requirements. • Unauthorized modifications to the implements will void any liability on the part of the manufacturer. -

Page 9: Warning Pictograms

Warning pictograms Warning pictograms point out dangers that cannot be counteracted by means of safety measures. Strict observance of the pictograms is necessary to prevent severe injuries or death. Danger! Missing warning notices must be replaced immediately. Do not operate the machine if warning notices are missing. You can order warning pictograms with the spare parts numbers specified in chapter 4.5. -

Page 10: Safety Devices

Implement is suitable for a PTO shaft speed of 2000 rpm only! Mainly mid-mount, front-end or independent engine PTO shafts. Implement is suitable for counterclockwise PTO shaft rotation only! (CCW) The specified direction of rotation always refers to the view of the end of the PTO shaft from the front (Fehler! Verweisquelle konnte nicht gefunden werden. - Page 11 Guard on the machine Universal joint shaft guard Protective pot for front PTO shaft Fig. 2: Safety device for front PTO shaft PTO shaft speed 2000 rpm / CCW Order no.: V0 003 109 Caution! Tighten screws Order no.: V0 002 965 Warning pictogram “Drive shaft”...

-

Page 12: Equipment

Equipment Front power system Basic machine, hydraulics, coupling support CAT 0, upper link, lower link Suspension system for original Kioti Hydraulic kit, mount Exhaust muff for original Kioti mid-mount mower Muff, muff adapter, hose clamps, suction hose Universal joint shaft guard Protective tubes, front and rear mounts, tightening strap Page 12... -

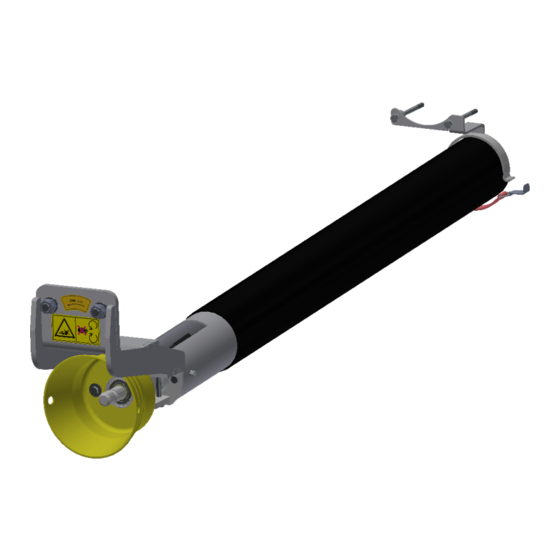

Page 13: Front Pto Shaft

Front PTO shaft Universal joint shaft, drive shaft, protective pot, mount Operation of the front PTO shaft During operation of the front power system, always observe the following safety information Comply with the instructions in the operating manual provided by the manufac- turer of the universal joint shaft Mounting the front PTO shaft Switch off the tractor, remove the ignition key and set the hand brake before... - Page 14 To mount the front PTO shaft, pre-assemble the drive shaft with the drive shaft mount and the protective pot, as well as the rear protective tube mount. (see assembly manual) 1. Insert the universal joint shaft through the protective tube and press the locking pin (locking ring) on the outer fork.

-

Page 15: Ground Clearance

Ground clearance Fig. 5: Ground clearance of drive shaft Maintenance Safety during maintenance Personal injury and material damage to the tractor and implements can occur. Before each use of implements, inspect all safety-related components and hy- draulic connections. Make sure that the front PTO shaft is not engaged when carrying out mainte- nance tasks. -

Page 16: Maintenance

After the first 20 hours of operation check all screw and bolt connections. Subject the implement to regular maintenance. Maintenance To ensure serviceability and compliance with occupational safety requirements, the following tasks must be carried out after each use. • Cleaning the machine. -

Page 17: Repair

GmbH does not provide any disposal services. Guarantee The general terms and conditions of matev GmbH apply. List of illustrations Fig. 1: Definition of orientation and direction of rotation ................6 Fig. 2: Safety device for front PTO shaft ....................11 Fig. -

Page 18: List Of Tables

Fig. 5: Ground clearance of drive shaft ....................15 List of tables Table 1: Screw tightening torques ......................16 Page 18... - Page 19 The manufacturer matev GmbH Nürnberger Str. 50 90579 Langenzenn declares that the machine FPS-FZW-Kioti CS 2520 complies with the provisions of Directive 2006/42/EC and with the national statutory regulations for its implementation. The signer is authorized to compile the technical documents.

Need help?

Do you have a question about the FPS-FZW-Kioti CS 2520 and is the answer not in the manual?

Questions and answers