Graco Husky 3300e Manual

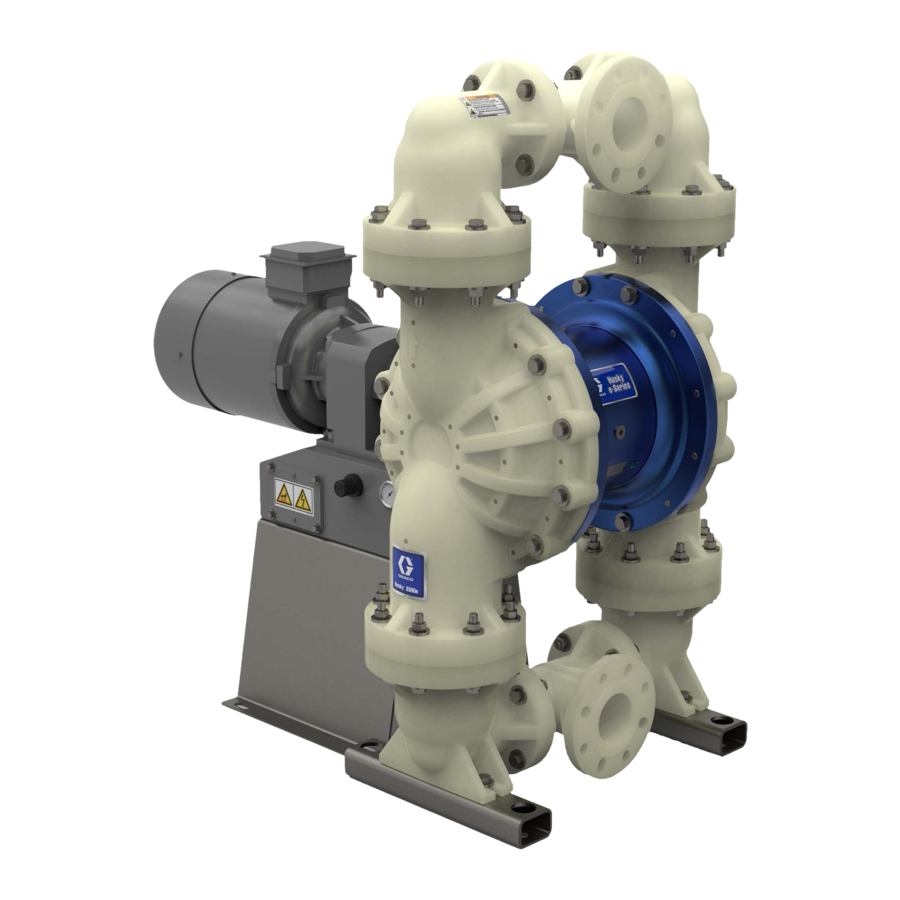

Electric-operated diaphragm pump

Hide thumbs

Also See for Husky 3300e:

- Operation (38 pages) ,

- Manual (38 pages) ,

- Repair parts (38 pages)

Table of Contents

Advertisement

Quick Links

Operation

Husky™ 3300e

3300e

Husky™

Husky™

3300e

Electric

Electric

Electric - - - Operated

Operated Diaphragm

Operated

3 3 3 - - - Inch

Inch pumps

pumps with

with electric

electric drive

Inch

pumps

with

electric

atmospheres or or or hazardous

hazardous (classified)

atmospheres

atmospheres

hazardous

Important

Important Safety

Important

Safety Instructions

Safety

Read all warnings and instructions in this manual and in your

Repair/Parts manual. Save

Maximum Working Pressure: 80 psi

(0.55 MPa, 5.5 bar)

Diaphragm Pump

Diaphragm

drive for

for fluid

fluid transfer

transfer applications.

drive

for

fluid

transfer

(classified) locations

locations unless

(classified)

locations

Instructions

Instructions

Save

Save all all all instructions.

instructions.

instructions.

PROVEN QUALITY. LEADING TECHNOLOGY.

Pump

Pump

applications. Not

Not approved

approved for

applications.

Not

approved

unless otherwise

otherwise stated.

stated. For

unless

otherwise

stated.

3A7036D

for use

use in in in explosive

explosive

for

use

explosive

For professional

professional use

use only.

only.

For

professional

use

only.

EN

Advertisement

Table of Contents

Summary of Contents for Graco Husky 3300e

- Page 1 Operation Husky™ 3300e 3300e Husky™ Husky™ 3300e 3A7036D Electric Electric Electric - - - Operated Operated Diaphragm Operated Diaphragm Pump Diaphragm Pump Pump 3 3 3 - - - Inch Inch pumps pumps with with electric electric drive drive for for fluid fluid transfer transfer applications.

-

Page 2: Table Of Contents

Operation ............18 Dimensions ............26 Tighten Fasteners ........18 Technical Data ........... 35 Initial Configuration (AC with VFD) ....18 Flush the Pump Before First Use ....18 Graco Standard Husky Pump Warranty....38 Related Related Related Manuals Manuals Manuals... -

Page 3: Warnings

Warnings Warnings Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. - Page 4 Warnings WARNING PRESSURIZED PRESSURIZED PRESSURIZED EQUIPMENT EQUIPMENT EQUIPMENT HAZARD HAZARD HAZARD Fluid from the equipment, leaks, or ruptured components can splash in the eyes or on skin and cause serious injury. • Follow the Pressure Pressure Relief Pressure Relief Procedure Relief Procedure Procedure when you stop spraying/dispensing and before...

- Page 5 Warnings WARNING THERMAL THERMAL THERMAL EXPANSION EXPANSION HAZARD EXPANSION HAZARD HAZARD Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure due to the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

-

Page 6: Configuration Number Matrix

Configuration Number Matrix Configuration Configuration Configuration Number Number Matrix Number Matrix Matrix Check the identification plate (ID) for the Configuration Number of your pump. Use the following matrix to define the components of your pump. 3300A 3300A - - - EA04AA1TPTPTP 3300A EA04AA1TPTPTP - - - - - - EA04AA1TPTPTP... - Page 7 Configuration Number Matrix Fluid Fluid Fluid Covers Covers and Covers Seat Seat Seat Material Material Material Ball Ball Material Ball Material Material Diaphragm Diaphragm Material Diaphragm Material Material Manifold/Seat Manifold/Seat Manifold/Seat Manifolds O O O - - - Rings Rings Manifolds Manifolds Rings...

-

Page 8: Ordering Information

Operated Diaphragm Diaphragm Diaphragm Pump Pump Pump Selector Selector Selector Tool Tool at at at Tool www.graco.com www.graco.com www.graco.com. . . Search for Selector. To Order Order Replacement Order Replacement Parts Replacement Parts Parts Please call call your your distributor. -

Page 9: Installation

Lower the installed position of the pump selecting and installing system components. Contact relative to the liquid level in the supply. your Graco distributor for assistance in planning a system to suit your needs. Always use Genuine b. Reduce the friction length of the suction Graco Parts and accessories. - Page 10 Installation Figure 1 Typical Installation for pumps without a compressor System System Components System Components Components Required Required Required Components Components Not Components Not Supplied Supplied Supplied Fluid inlet port Power cord to VFD Fluid outlet port Grounded, flexible air supply line Mounting feet Bleed-type master air valve (when closed, relieves air pressure between valve and pump)

- Page 11 Installation Figure 2 Typical installation of a pump with compressor System System Components System Components Components Required Required Required Components Components Not Components Not Supplied Supplied Supplied Fluid inlet port Power cord to VFD Fluid outlet port Power cord to compressor Mounting feet Grounded, flexible fluid supply line Air inlet port...

-

Page 12: Mount The Pump

Mounting pump without Gearmotor A pump without a Graco gearbox and motor will require a mounting platform to provide support for the customer-supplied motor and gearbox To avoid serious injury or death from toxic fluid or and provide alignment with the pump alignment... -

Page 13: Ground The System

Insert one end of a 12–gauge minimum ground wire behind the ground screw and tighten the screw securely. Connect the clamp end of the grounding wire to a true earth ground. A ground wire and clamp, Part 238909, is available from Graco. 3A7036D... -

Page 14: Air Line

Installation Air Line Line Fluid Supply Supply Line Line Line Fluid Fluid Supply Line 1. Connect a grounded, flexible fluid hose (K) to Models Models Models that that Include that Include a a a Compressor: Include Compressor: Compressor: the fluid inlet port. The port on pumps with An air line is already connected from the compressor aluminum, stainless steel, or cast iron fluid to the pump air inlet. -

Page 15: Electrical Connections

Use a motor soft starter or a VFD in the electrical circuit for all installations (not supplied). VFDs can be purchased through Graco. See recommended VFD kits on page 36. Wire Wire... - Page 16 2. Open the access cover on the VFD. qualified electrician and comply with all local codes and regulations. 3. For a Graco VFD, perform the following: a. Wire one lead to terminal 4 on the rail. Connect the power supply wires to the VFD, as b.

- Page 17 Follow these instructions to wire Graco Compressor 2. Install wiring system with proper connections (i.e. 24Y544 (120V) or 24Y545 (240V). conduit/fittings, power cable/cable grip) to the...

-

Page 18: Operation

Operation Operation Operation Operation 3. Place the suction tube (if used) in fluid to be pumped. NOTE: If fluid inlet pressure to the pump is more NOTE: NOTE: than 25% of outlet working pressure, the ball check valves will not close fast enough, resulting in inefficient pump operation. -

Page 19: Pressure Relief Procedure

Operation Pressure Relief Relief Procedure Procedure Pump Shutdown Shutdown Pressure Pressure Relief Procedure Pump Pump Shutdown Follow the Pressure Relief Procedure whenever you see this symbol. At the end of the work shift and before you check, adjust, clean, or repair the system, follow the Pressure Relief Procedure, page This equipment stays pressurized until pressure is relieved manually. -

Page 20: Vfd Operation

Control Panel Panel Panel NOTE: NOTE: NOTE: This information is specific to Graco’s VFD. For complete information about another manufacturer’s VFD, see the manufacturer’s instructions supplied with the VFD. STOP • The control panel display shows the status of the motor. -

Page 21: Maintenance

Maintenance Maintenance Maintenance Maintenance Flushing Flushing and Flushing and Storage Storage Storage To avoid injury from fire, explosion, or electric shock, all electrical wiring must be done by a qualified electrician and comply with all local codes To avoid injury from fire, explosion, or electric shock, always ground equipment and waste and regulations. -

Page 22: Torque Instructions

Torque Instructions Torque Instructions Instructions Torque Torque Instructions If fluid cover or manifold fasteners have been 1. Start all fluid cover screws a few turns. Then, turn loosened, it is important to torque them using the down each screw just until head contacts cover. following procedure to improve sealing. - Page 23 Torque Instructions Stainless Steel Steel Pumps Pumps Stainless Stainless Steel Pumps 1. Left/Right Fluid Covers 2. Manifolds Torque bolts 5-12 to 40-45 ft-lb (54-60 N•m) Torque bolts to 40-45 ft-lb (54-60 Torque bolts 1-4 to 110-120 in-lb N•m) (12–13 N•m) SIDE VIEW TOP/BOTTOM VIEW Polypropylene,...

-

Page 24: Performance Charts

Performance Charts Performance Charts Charts Performance Performance Charts Test Test Test Conditions: Conditions: Conditions: The pump was tested in water with 3. Set the VFD frequency corresponding to the the inlet submerged. desired flow rate. Flow rates will increase with outlet pressure lower than 10 psi (0.7 bar) and How to to to Use Use the... - Page 25 Performance Charts How to to to Calculate Calculate Your Your System’s System’s Net Net Positive Positive Suction Suction Head Head – – – Available Available Calculate Your System’s Positive Suction Head Available (NPSHa) (NPSHa) (NPSHa) For a given flow rate, there must be a minimum of your system must be greater than the NPSHr to fluid head pressure supplied to the pump to prevent prevent cavitation and therefore increase efficiency...

-

Page 26: Dimensions

Dimensions Dimensions Dimensions Dimensions Aluminum pump with compressor 3A7036D... - Page 27 Dimensions Aluminum pump without compressor 3A7036D...

- Page 28 Dimensions Table 1 1 1 Dimensions Dimensions for for Aluminum Aluminum Pumps Pumps Table Table Dimensions Aluminum Pumps Gearbox Gearbox Gearbox and and Motor Motor Code Motor Code Code – – – Dimensions Dimensions shown Dimensions shown shown in in in inches inches (cm) inches (cm)

- Page 29 Dimensions Polypropylene pump with compressor 3A7036D...

- Page 30 Dimensions Polypropylene pump without compressor 3A7036D...

- Page 31 Dimensions Table 2 2 2 Dimensions Dimensions for for Polypropylene Polypropylene Pumps Pumps Table Table Dimensions Polypropylene Pumps Gearbox Gearbox and Gearbox and Motor Motor Motor Code Code – – – Dimensions Code Dimensions Dimensions shown shown in in in inches shown inches (cm) inches...

- Page 32 Dimensions Stainless steel pump with compressor 3A7036D...

- Page 33 Dimensions Stainless steel pump without compressor 3A7036D...

- Page 34 Dimensions Table 3 3 3 Dimensions Dimensions for for Stainless Stainless Steel Steel Pumps Pumps Table Table Dimensions Stainless Steel Pumps Gearbox Gearbox Gearbox and and Motor Motor Code Motor Code Code – – – Dimensions Dimensions shown Dimensions shown shown in in in inches inches (cm) inches...

-

Page 35: Technical Data

Technical Data Technical Data Data Technical Technical Data Husky Electric Electric Double Double Diaphragm Diaphragm Pump Pump Husky Husky Electric Double Diaphragm Pump Metric Metric Metric Maximum fluid working pressure 80 psi 0.55 MPa, 5.5 bar Air pressure operating range 20 to 80 psi 0.14 to 0.55 MPa, 1.4 to 5.5 bar... - Page 36 Technical Data Gear Ratio 11.88 Voltage 3–phase 230V / 3–Phase 460V Maximum Amperage Load 20.0 A (230V) / 10.0 A (460V) Leak Sensor Contact Ratings: State Normally closed Voltage 240V Max (AC/DC) Current 0.28 A max at 120 VAC 0.14 A max at 240 VAC 0.28 A max at 24 VDC 0.07 A max at 120 VDC Power...

- Page 37 California Proposition 65 Weights Weights Weights Pump Material Motor/Gearbox Standard ATEX AC Flame- No Gear- proof AC motor Fluid Center Section Section Aluminum Aluminum Polypropylene Aluminum Aluminum Stainless Steel Fluid Temperature Temperature Range Range Fluid Fluid Temperature Range NOTICE NOTICE NOTICE Temperature limits are based on mechanical stress only.

-

Page 38: Graco Standard Husky Pump Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Husky 3300e and is the answer not in the manual?

Questions and answers