Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Rice Lake MASTER Bulkslide

- Page 1 MASTER Bulkslide Flow Measurement Operation Manual August 6, 2021 PN 206443 Rev A...

- Page 2 All information contained within this publication is, to the best of our knowledge, complete and accurate at the time of publication. Rice Lake Weighing Systems reserves the right to make changes to the technology, features, specifications and design of the equipment without notice.

-

Page 3: Table Of Contents

Load Cell ..................10 Technical training seminars are available through Rice Lake Weighing Systems. - Page 4 Bulkslide Operation Rice Lake continually offers web-based video training on a growing selection of product-related topics at no cost. Visit www.ricelake.com/webinars www.RiceLake.com Visit our website...

-

Page 5: Introduction

Do not operate or work on this equipment unless this manual has been read and all instructions are understood. Failure to follow the instructions or heed the warnings could result in injury or death. Contact any Rice Lake Weighing Systems dealer for replacement manuals. -

Page 6: Installation

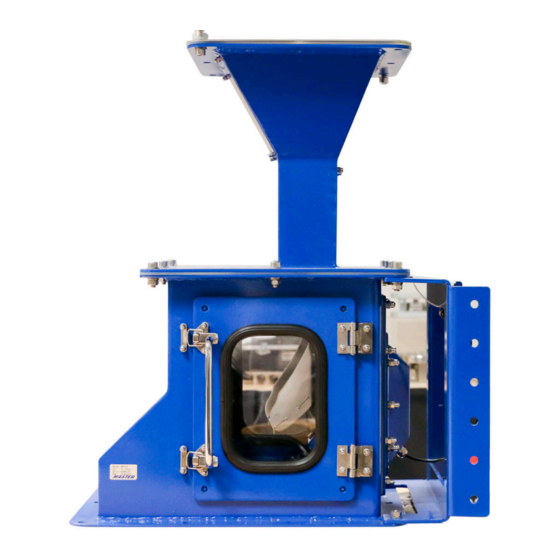

Immediately after unpacking, visually inspect the bulkslide to ensure all components are included and undamaged. The shipping crate should contain the unit and an installation manual. If any parts were damaged in shipments, notify Rice Lake Weighing Systems and the shipper immediately. -

Page 7: Storage

• Must be sufficient clearance to open the housing doors toward the inside of the meter • Must be sufficient clearance to be able to open the rear sensor cover for maintenance © Rice Lake Weighing Systems ● All Rights Reserved... -

Page 8: Installing The Bulkslide

Bulkslide Operation Installing the Bulkslide Use the following steps to install the Bulkslide feeder. 1. Fix the discharge flange to the material feeder. 2. Establish the material supply using the Master feeder or the customer feeder. 3. Make sure that the support structure is free from vibration. Welding currents can damage the load cell so weld with extreme caution making sure that no welding current flows Note through the flow volume meter. -

Page 9: Operation (Feeder Types)

• Bulk material flows in a purely vertical direction without impact • No air flow must be present Spiral Conveyor Conveying Speed Arrangement Low Speed < 40 rpm High Speed > 40 rpm Table 3-1. Spiral Conveyor Types © Rice Lake Weighing Systems ● All Rights Reserved... -

Page 10: Rotary Valve

Bulkslide Operation Rotary Valve Conveying Speed Arrangement Low Speed <20 rpm High Speed > 20 rpm Table 3-2. Rotary Valve Types www.RiceLake.com Visit our website... -

Page 11: Conveyor Belts

Operation (Feeder Types) Conveyor Belts Conveying Speed Arrangement Slow, constant movement up to 1 m/s Slow, variable movement High speed from 1 to 4 m/s Table 3-3. Conveyor Belt Types © Rice Lake Weighing Systems ● All Rights Reserved... -

Page 12: Direct Drop From A Silo/Container

Bulkslide Operation Direct Drop From a Silo/Container Maximum 1/2 A Figure 3-1. Direct Drop Type The opening on the feeder gate must be no wider than half the straight unimpeded inflow section (Figure 3-1, #A) on a direct drop from a silo or container. A larger opening can result in overload and damage to the meter. Make sure that material does not hit the feeder slide and make sure that there is never a backlog as these forces can result in overload and damage to the meter. -

Page 13: Maintenance

3. Dismantle the material feeder. 4. Transport the Bulkslide without vibration is possible. Disposal Any excess materials should be disposed of in accordance to state and local regulations and if possible, recycle. © Rice Lake Weighing Systems ● All Rights Reserved... -

Page 14: Technical Data

Bulkslide Operation Technical Data Min. Throughput MaxThroughput Particle Size Weight Including Type [m3/h] [m3/h] [mm] Load Cell [kg] Intake Funnel [kg] BF006 BF012 BF024 BF050 2 x 10 BF100 2 x 20 BF200 2 x 20 BF400 2 x 20 BF600 2 x 30 Table 4-2. - Page 16 Specifications subject to change without notice. Rice Lake Weighing Systems is an ISO 9001 registered company. 230 W. Coleman St. • Rice Lake, WI 54868 • USA U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0)26 472 1319...

Need help?

Do you have a question about the MASTER Bulkslide and is the answer not in the manual?

Questions and answers