Summary of Contents for SCHUNK AOV-MC

- Page 1 Translation of Original Operating Manual Assembly and Operating Manual AOV-MC Media changer for orbital sander...

- Page 2 Imprint Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Technical changes: We reserve the right to make alterations for the purpose of technical improvement. Document number: 1461420 Version: 01.00 | 01/02/2021 | en...

-

Page 3: Table Of Contents

Electrical connection .................. 19 Start-up ........................ 20 Notes on teaching-in .................. 20 Pick up sanding discs .................. 20 Check for presence of sanding discs.............. 25 Remove sanding discs.................. 27 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... - Page 4 Assembly drawings ..................... 37 EU Declaration of Conformity AOV-MCH.............. 40 10 Certificate of Conformity AOV-MF5 / -MF6 ............. 41 11 Declaration of incorporation AOV-MRA .............. 42 12 Annex to Declaration of Incorporation .............. 43 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

-

Page 5: General

Dangers for persons! Non-observance can lead to irreversible injury and even death. CAUTION Dangers for persons! Non-observance can cause minor injuries. CAUTION Material damage! Information about avoiding material damage. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 6: Definition Of Terms

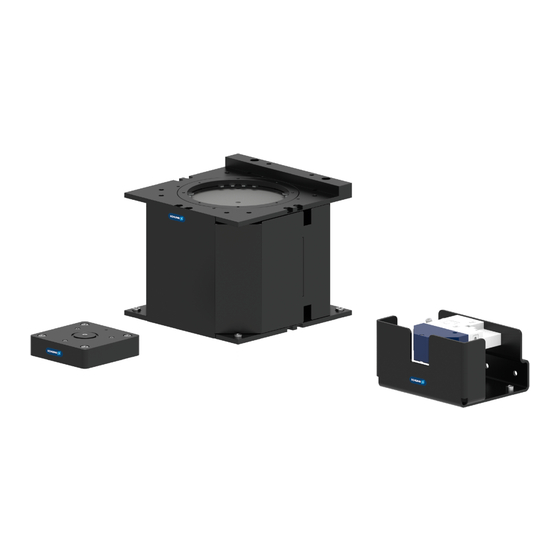

1.3 Scope of delivery The scope of delivery includes • Components of the media changer for orbital sander in the version ordered • Assembly and Operating Manual 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 7: Basic Safety Notes

Use of unauthorized spare parts Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction. • Use only original spare parts or spares authorized by SCHUNK. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 8: Ambient Conditions And Operating Conditions

Due to its technical training, knowledge and experience, service personnel of the manufacturer is able to perform the delegated the manufacturer tasks and to recognize and avoid possible dangers. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 9: Personal Protective Equipment

• Do not recommission the product until the malfunction has been rectified. • Test the product after a malfunction to establish whether it still functions properly and no increased risks have arisen. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 10: Disposal

Falling loads may cause serious injuries and even death. • Stand clear of suspended loads and do not step into their swiveling range. • Never move loads without supervision. • Do not leave suspended loads unattended. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 11: Protection During Commissioning And Operation

Before starting up the machine or automated system, check that the EMERGENCY STOP system is working. Prevent operation of the machine if this protective equipment does not function correctly. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 12: Notes On Particular Risks

During operation, flying chips and dirt particles can cause eye injuries. Always wear appropriate personal protective equipment, • particularly protective goggles. Take suitable protective measures to secure the danger zone. • 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 13: Technical Data

Technical data 3 Technical data Designation AOV-MC Nominal operating pressure [bar] 4.1-6.2 Pressure medium Compressed air (clean, dry, filtered (≤ 5 µm), oil-free) 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 14: Design And Description

Media retaining gasket Media storage Through holes for mounting Media remover Needle gripper Plate with Through holes for mounting "Retract needle" air connection "Extend needle" air connection Needle stroke adjustment 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 15: Description

Media checker Through holes for mounting Media detection piston Sensor connection 4.2 Description Automatic sanding disc changer for mounting and removing sanding discs and checking the change procedure 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 16: Assembly

The media must be inserted with the Velcro side facing upwards. 3. Connect media remover to compressed air supply, Pneumatic connection 18]. 4. Connect media checker, Electrical connection 19]. 5. Teach-in components, Start-up 20]. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 17: Mechanical Connection

The media checker and the media feeder can be mounted in all orientations. The media remover must be mounted in such a way that the media used can fall down by gravity. Item Mounting AOV-MC Through hole for mounting 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 18: Pneumatic Connection

• Use a 5/2 directional control valve to control the two air connections. "Retract needle" air connection "Extend needle" air connection Item Mounting AOV-MRA Hose connection [mm] Hose connection [mm] 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 19: Electrical Connection

Proximity switch on the media checker • Type of switching: PNP • Switching function: Closer • Connector: M8 Wire strand Designation Brown +10 to 30 VDC Blue Black Output 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 20: Start-Up

0.6 cm (view A). The nearest edge of the backer pad should be at a distance ✓ b of approx. 1.2-2.5 cm from the alignment rail (view B). 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... - Page 21 3. Move the sander linearly along the alignment rail until the backer pad is level with the opening. The orbit pattern of the sander is deflected accordingly. ✓ 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

- Page 22 Align the backer pad exactly over the opening 5. Check whether the orbit pattern has been deflected accordingly. A 20° inclination in the direction of the alignment rail ✓ improves the pickup process. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

- Page 23 Stack with sanding discs is pressed down, pause briefly in this position 9. Lift the sander. The stack in the feeder slides forward for the next pickup. ✓ 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

- Page 24 11. Move the sander to the starting position "HOME". The pickup process is complete. ✔ The next process involves checking media presence. ✔ 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

-

Page 25: Check For Presence Of Sanding Discs

The hard Velcro side on the backer pad and the soft Velcro ✓ side on the media checker are separated. The LED on the sensor lights up ✓ 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... - Page 26 Move the backer pad away from the media checker 4. Wait briefly so that the media checker can process the signal. 5. Move the sander to the starting position "HOME". 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

-

Page 27: Remove Sanding Discs

Contact checkers A = View from above, B = View from the side 2. Move the sander towards the media remover until the backer pad touches the remover. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... - Page 28 The needles are hooked onto the backer pad. ✓ The orbit height of the sander can change depending on the ✓ combination of backer pad and sanding disc. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

- Page 29 Distance for removing the sanding disc 6. Retract needles. 7. Reset the nominal operating pressure to the preset value. 8. Move the sander to the starting position "HOME". 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

-

Page 30: Troubleshooting

Clean dirt off surface. The interface is not receiving a signal from Check cable for damage. the sensor. Check that the cable is connected correctly. Sensor is damaged. Change sensor. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 31: Sanding Discs Are Not Removed

The needle stroke is not set correctly. Readjust needle stroke. Sanding disc and backer pad are interlocked. Add additional step in the process: sanding over a bar or edge. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 32: Maintenance

Disassembly and assembly 33]. Check the glide for damage and wear, replace if necessary, Disassembly and assembly 33]. as required Send damaged products to SCHUNK for repair. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 33: Disassembly And Assembly

6. Check retaining gasket (6) for damage and replace if necessary. Align the through hole on the retaining gasket (6) with the ✓ through hole on the support bracket (7) 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... - Page 34 4. Loosen the fitting screw (4) and remove the spring (2) and spacer (3) from the spring bracket (1). 5. Insert spacer (3) into new spring (2). 6. Fasten spring (2) with fitting screw (4) in spring bracket (1). Max. tightening torque: 1.4 Nm ✓ 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

-

Page 35: Replace The Velcro Disc On The Media Checker

1. Loosen screw (1) with 2 mm hexagon socket wrench. 2. Remove damaged or worn Velcro disc (2). 3. Clean dirt off surface. 4. Place new Velcro disc (1) and tighten screw (1) with 2 mm hexagon socket wrench. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 36: Replace Needles

4. Follow the instructions in the "Needle Kit" spare parts package. 5. Mount the needle gripper (4). 6. Disassemble the media remover from the application. 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 37: Assembly Drawings

Maintenance 8.6 Assembly drawings Media feeder AOV-MF5 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... - Page 38 Maintenance Media feeder AOV-MF6 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

- Page 39 Maintenance Media checker AOV-MCH Media remover AOV-MRA 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

-

Page 40: Eu Declaration Of Conformity Aov-Mch

Signed for and on behalf of: SCHUNK GmbH & Co. KG p.p. Ralf Winkler; Head of Technology & Engineering, Mechanics Gripping Systems Lauffen/Neckar, January 2021 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 41: Certificate Of Conformity Aov-Mf5 / -Mf6

Risk assessment and risk reduction Person authorized to compile the technical documentation: Robert Leuthner, Address: see manufacturer's address Lauffen/Neckar, January 2021 p.p. Ralf Winkler; Head of Technology & Engineering, Mechanics Gripping Systems 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 42: Declaration Of Incorporation Aov-Mra

Person authorized to compile the technical documentation: Robert Leuthner, Address: see manufacturer's address Lauffen/Neckar, January 2021 p.p. Ralf Winkler; Head of Technology & Engineering, Mechanics Gripping Systems 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... -

Page 43: Annex To Declaration Of Incorporation

Risks due to falling or ejected objects 1.3.4 Risks due to surfaces, edges or angles 1.3.5 Risks related to combined machinery 1.3.6 Risks related to variations in operating conditions 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420... - Page 44 1.5.15 Risk of slipping, tripping or falling 1.5.16 Lightning Maintenance 1.6.1 Machinery maintenance 1.6.2 Access to operating positions and servicing points 1.6.3 Isolation of energy sources 1.6.4 Operator intervention 1.6.5 Cleaning of internal parts 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

- Page 45 Supplementary essential health and safety requirements for machinery intended for underground work Supplementary essential health and safety requirements for machinery presenting particular hazards due to the lifting of persons 01.00 | AOV-MC | Assembly and Operating Manual | en | 1461420...

- Page 48 Translation of Original Operating Manual SCHUNK GmbH & Co. KG Clamping and gripping technology Bahnhofstr. 106 - 134 D-74348 Lauffen/Neckar Tel. +49-7133-103-0 Fax +49-7133-103-2399 info@de.schunk.com schunk.com Folgen Sie uns I Follow us...

Need help?

Do you have a question about the AOV-MC and is the answer not in the manual?

Questions and answers