Subscribe to Our Youtube Channel

Summary of Contents for IWAKI PUMPS MDM Series

- Page 1 IWAKI Magnetic Drive Pump MDM Series (Asia Edition: English) Instruction Manual Read this manual before use of product...

-

Page 2: Table Of Contents

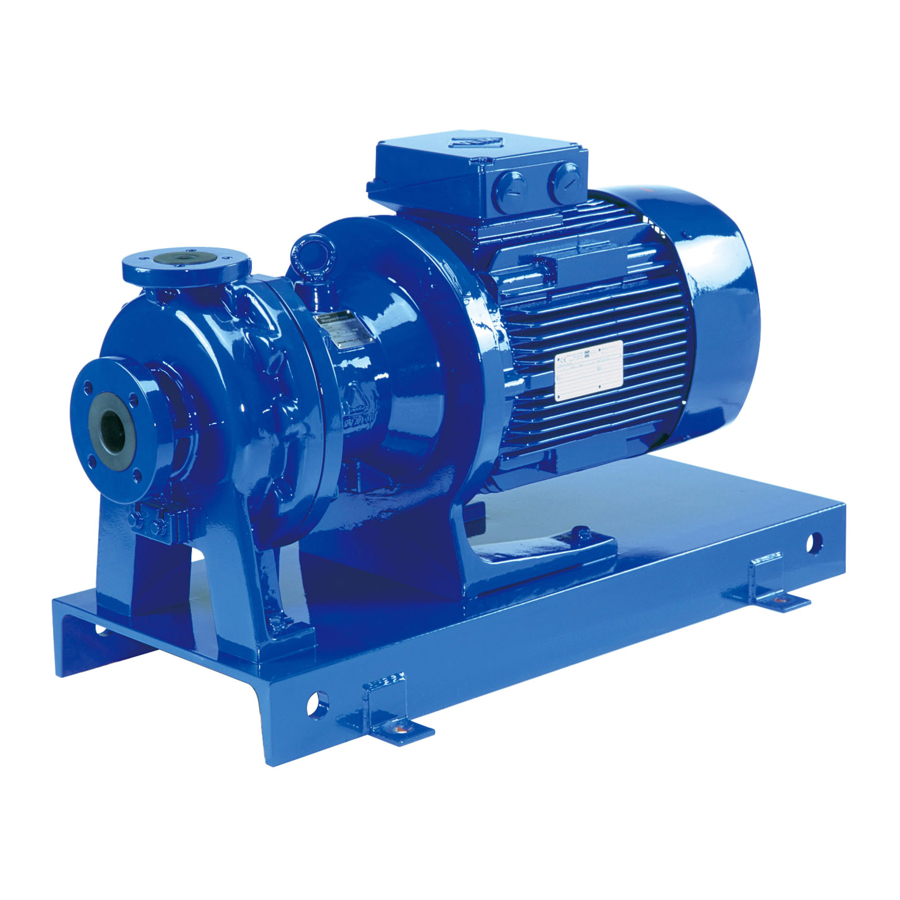

Thank you for selecting IWAKI Magnetic Drive Pump MDM Series. This instruction man- ual, which is divided into five sections, namely "Safety", "Outline of Product", "Installation", "Operation" and "Maintenance", deals with the correct handling and operation procedures for the pump. To make maximum use of the pump and to ensure safe and long time opera- tion of the pump, please read this manual thoroughly and carefully prior to operating the pump. -

Page 3: Safety Section

SAFETY SECTION For the Safe and Correct Handling of the Pump ● Before use of the pump, read carefully this "Safety Section" to prevent accidents and to avoid the damage or loss of other assets. ● Observe and abide by the instructions described in this "Safety Section". These instructions are very important for protecting pump users or other persons from hazard or from loss of assets. - Page 4 Safety Section WARNING ● Magnet field danger The magnet drive pumps contain very strong magnets. The strong magnet field could adversely affect persons who are assisted by electronic devices such as pacemakers etc. ● A lways turn off power supply prior to maintenance works etc. Pay special attention so that no other operator turns on by mistake the power supply while someone is working on the pump.

- Page 5 Safety Section CAUTION ● Attention to magnetic force This pump employs strong magnets. Special attention must be paid not to be injured by attracting force of magnets. Follow the procedure "Disassembling and Assembling" when the maintenance works are done. ● Do not run pump dry Do not run pump dry (without liquid). If the pump run dry, heat is generated by rub- bing, which causes pump damage.

-

Page 6: Outline Of Product

OUTLINE OF PRODUCT ......1. Unpacking and inspection ..........2. Model code ....... 3. Conditions to be used ....4. Structure and names of parts - 4 -... -

Page 7: Unpacking And Inspection

1. Unpacking and inspection After unpacking of the pump, check the following points. (1) If the product is ordered one. Check model code, discharge capacity, discharge pressure, voltage which are written on nameplate of pump and motor to see if they conform to your order. -

Page 8: Model Code

2. Model code MDM40 - 150 1 E KK F 075 J - D 2 H 9 10 11 1 Pump discharge bore Suction Discharge 25: 40 × 25 40: 50 × 40 50: 65 × 50 65: 80 × 65 2 Nominal impeller diameter: 100 - 225 (mm) 3 Impeller range: 1: Low head impeller type 2: High head impeller type (Available for MDM25 and MDM40) 3: High head impeller type (Available for MDM25 only) -

Page 9: Conditions To Be Used

Note 1) The code "E", "P" and "N" represents main materials. 2) For temperature range of each chemical liquid, refer to Chemical Resistant Table on booklet "Technical Information on MDM Series". 3) For liquid temperature below zero deg. C and above 120 deg. C, please contact IWAKI because detailed operating condition must be considered for these temperature ranges. -

Page 10: Structure And Names Of Parts

4. Structure and names of parts 500.3 554.5 554.6 554.3 400.1 901.5 908.1 901.6 100.2 100.1 901.3 903.1 400.3 122.2 554.4 901.4 314.1 314.2 500.2 122.1 554.2 400.2 901.2 500.1 554.1 901.1 159.1 554.7 314.4 314.3 901.7 Parts name Q'ty Parts name Q'ty 100.1... -

Page 11: Installation

INSTALLATION ..........5. Installation ............6. Piping ......... 7. Electrical wiring ........... 8. Protection - 9 -... -

Page 12: Installation

5. Installation Example of recommended piping 1 Discharge pipe 2 Discharge valve 3 Check valve 4 Pressure gauge 5 Motor 6 Pump 7 Flexible joint 8 Vacuum gauge 9 Suction pipe 10 Suction valve Within 11 Gate valve 12 Air vent piping 13 Pipe support 1. -

Page 13: Piping

6. Piping 1. Tightening of pipe flange Table below shows the bolt size and tightening torque for the connection of pipe flange to pump flange. Tightening torque is the figure when metallic flange and rubber gasket are used. Bolt size Tightening torque 78.4 N ·... - Page 14 3. Suction piping (1) Flooded suction Flooded suction is recommended. (2) Pipe diameter Pipe diameter should be larger than pump inlet bore. (3) Shortest piping Employ less bends and shortest piping length. (4) Straight piping Employ straight pipe just before pump inlet port. Pump inlet bore 50A or smaller : Straight pipe of 500 mm or longer Pump inlet bore 65A or larger : Straight pipe of 8 times as larger than inlet port For the easy pump dismantling and maintenance, install a removable short length pipe of 300mm or so in straight...

-

Page 15: Electrical Wiring

(3) Gate valve Install the gate valve in discharge piping to adjust flow rate and to protect motor from over loading. If the check valve is also installed, recommended arrangement is : Pump → Check valve → Gate valve (4) Pressure gauge Install a pressure gauge in discharge piping to check the operating conditions such as discharge head etc. -

Page 16: Operation

OPERATION ......9. Precautions on operation ......... 10. Operation (Starting) .......... 11. Pump stopping - 14 -... -

Page 17: Precautions On Operation

9. Precautions on operation CAUTION ● Never operate pump dry or with suction side valve closed. ● Dry running possible model (CF type of carbon bearing) can run dry (completely no liquid in pump) continuously one hour max. However rubbing parts are worn in a short time which will result in pump damage in the worst case if pump runs dry continuously exceeding one hour or if it runs dry repeatedly although it is short time. -

Page 18: Operation (Starting)

10. Operation (Starting) 1. Fully close discharge valve and fully open suction valve. 2. Fill liquid into pump • In case of flooded suction, confirm if suction valve is fully opened. • In case of suction lift, prime to fill liquid into suction piping. 3. -

Page 19: Maintenance

Maintenance ........12. Troubleshooting ..... 13. Maintenance & inspection ....14. Disassembling & assembling ......... 15. Repair parts list ........... 16. Mass of pump - 17 -... -

Page 20: Troubleshooting

12. Troubleshooting Symptom on pump Troubles Cause Check & countermeasures When disch. valve When disch. valve closed opened Liquid Press. gauge & vac- • Lack of priming • Stop pump and reple- can not be uum gauge indicate liquid nish pump with liquid sucked zero. - Page 21 Symptom on pump Troubles Cause Check & countermeasures When disch. valve When disch. valve closed opened Discharge Pressure gauge & Pressure is high but • Too high actual • Check actual head of capacity is vacuum gauge indi- vacuum is normal. head or too large discharge piping and small.

-

Page 22: Maintenance & Inspection

13. Maintenance & inspection Warning • Magnetic force is very strong. Pay attention when you handle the magnet capsule or driving magnet so that fingers can not be injured by attraction of magnets. • The persons who are assisted by electronic devices such as pacemakers etc. are prohibited to approach the magnet capsule and drive magnet. -

Page 23: Disassembling & Assembling

2. Wear limit of bearing and spindle (Time to be replaced) Unit: mm Bearing inner dia. Spindle outer dia. Model New one Wear limit New one Wear limit MDM25-1 MDM25-2, MDM40-1, MDM50-1 MDM25-3, MDM40-2, MDM65-1 Note1. When the clearance between bearing inner dia. and spindle outer dia. exceeds 1 mm, replace by new ones. Carbon bearing (CF) type: Replace by new one either spindle or bearing which is worn more (normally it is bearing) . - Page 24 1. Disassembly of pump casing (1) Remove hex. bolts (901.3) and drain plate (122.1) to drain liquid inside. For the type without drain, disassemble the pump after the liquid inside is neutralized or the pump is cleaned by water. Warning If all the hex.

- Page 25 (7) Then, remove rear casing (158) from rear casing cover (159). If rear casing is hard to remove, remove it by turn- ing. Pay attention not to drop the impeller (230)/magnet capsule (859) unit which is located in the rear casing. 2.

- Page 26 (3) Remove impeller fixing pin (942) of upper part of mag- net capsule by pushing it by screw driver or like. (4) Remove impeller (230) from magnet capsule (859). If it is hard to remove, slightly strike the impeller back side with plastic hammer.

- Page 27 4. Replacement of spindle (1) Spindle (210) is slightly pressed into rear casing (158). Pull out the spindle by a hand. If it is hard to pull it out, pull it out by shaking it right and left. (2) Wipe off the stain at spindle inserted part of rear casing and insert the spindle.

- Page 28 6. Assembling Assemble the pump in reverse procedures paying attention to the following points. ● Replacement of gasket Do not fail to replace the gasket by new one. Pay attention so that it cannot be forgotten to be put or it can be mounted correctly without twist or bite.

-

Page 29: Repair Parts List

15. Repair parts list - 27 -... - Page 30 - 28 -...

- Page 31 - 29 -...

- Page 32 - 30 -...

- Page 33 - 31 -...

- Page 34 - 32 -...

- Page 35 MDM25 Impeller parts list Impeller Motor Q'ty/ Parts code No. Model Parts name size code power unit MDM0046 MDM0067 MDM0067 Impeller MDM0047 MDM0068 MDM0068 MDM0048 MDM0069 MDM0069 MDM0049 MDM0070 MDM0070 MDM0050 MDM0071 MDM0071 MDM0051 MDM0072 MDM0072 MDM0052 MDM0073 MDM0073 MDM0084 MDM0109 MDM0109 MDM0628...

- Page 36 Impeller Motor Q'ty/ Parts code No. Model Parts name size code power unit MDM0147 MDM0171 MDM0187 230+ Impeller ass'y MDM0148 MDM0172 MDM0188 314.2 MDM0149 MDM0173 MDM0189 MDM0150 MDM0174 MDM0190 MDM0151 MDM0175 MDM0191 MDM0152 MDM0176 MDM0192 MDM0153 MDM0177 MDM0193 MDM0154 MDM0178 MDM0194 MDM0641 MDM0646...

- Page 37 Impeller Motor Q'ty/ Parts code No. Model Parts name size code power unit MDM0858 MDM0777 MDM0923 230+ Impeller ass'y MDM0859 MDM0778 MDM0924 314.2 MDM0860 MDM0779 MDM0925 5.5kW MDM0756 MDM0788 MDM0934 230+ Impeller/magnet 5.5kW MDM0757 MDM0789 MDM0935 310+ capsule ass'y 5.5kW MDM0758 MDM0790 MDM0936...

- Page 38 Impeller Motor Q'ty/ Parts code No. Model Parts name Remarks size power unit PKK-H Impeller and magnet capsule 5.5kW MDM0812 230+ Impeller/magnet can not be separated because capsule ass'y they are welded each other. 5.5kW MDM0813 5.5kW MDM0814 5.5kW MDM0815 5.5kW MDM0816 5.5kW...

- Page 39 Impeller Motor Q'ty/ Parts code No. Model Parts name Remarks size power unit PKK-H 5.5kW MDM0836 230+ Impeller/magnet 5.5kW MDM0837 310+ capsule ass'y 5.5kW MDM0838 314.2+ 5.5kW MDM0839 314.4+ 5.5kW MDM0840 859+ 5.5kW MDM0841 5.5kW MDM0842 5.5kW MDM0843 7.5kW MDM0836 7.5kW MDM0837 7.5kW...

- Page 40 MDM40 Impeller parts list Impeller Motor Q'ty/ Parts code No. Model Parts name PKK/NKK size power unit MDM0215 MDM0239 MDM0239 Impeller MDM0216 MDM0240 MDM0240 MDM0217 MDM0241 MDM0241 MDM0218 MDM0242 MDM0242 MDM0219 MDM0243 MDM0243 MDM0220 MDM0244 MDM0244 MDM0221 MDM0245 MDM0245 MDM0222 MDM0246 MDM0246 MDM0654...

- Page 41 Impeller Motor Q'ty/ Parts code No. Model Parts name size power unit MDM0740 MDM0764 MDM0764 Impeller MDM0741 MDM0765 MDM0765 MDM0742 MDM0766 MDM0766 MDM0743 MDM0767 MDM0767 MDM0744 MDM0768 MDM0768 MDM0745 MDM0769 MDM0769 MDM0746 MDM0770 MDM0770 MDM0747 MDM0771 MDM0771 MDM0853 MDM0772 MDM0918 230+ Impeller ass'y MDM0854...

- Page 42 Impeller Motor Q'ty/ Parts code No. Model Parts name size power unit 18.5kW MDM0861 MDM0796 MDM0942 230+ Impeller/magnet 18.5kW MDM0862 MDM0797 MDM0943 310+ capsule ass'y 18.5kW MDM0863 MDM0798 MDM0944 314.2+ 18.5kW MDM0864 MDM0799 MDM0945 314.4+ 18.5kW MDM0865 MDM0800 MDM0946 859+ MDM40-2 18.5kW MDM0866...

- Page 43 Impeller Motor Q'ty/ Parts code No. Model Parts name Remarks size power unit PKK-H 18.5kW MDM0820 230+ Impeller/magnet 18.5kW MDM0821 capsule ass'y 18.5kW MDM0822 18.5kW MDM0823 18.5kW MDM0824 18.5kW MDM0825 18.5kW MDM0826 18.5kW MDM0827 1.5kW-4P MDM0804 2.2kW-4P MDM0804 3.7kW-4P MDM0812 5.5kW-4P MDM0820 5.5kW...

- Page 44 Impeller Motor Q'ty/ Parts code No. Model Parts name Remarks size power unit PKK-H 18.5kW MDM0848 230+ Impeller/magnet 18.5kW MDM0849 310+ capsule ass'y 18.5kW MDM0850 314.2+ MDM40-2 18.5kW MDM0851 (for high 314.4+ temp. type of 1.5kW-4P MDM0828 859+ PKK) 2.2kW-4P MDM0828 3.7kW-4P MDM0836...

- Page 45 MDM50 Impeller parts list Impeller Motor Q'ty/ Parts code No. Model Parts name size power unit Impeller MDM0379 MDM0481 MDM0481 MDM0475 MDM0482 MDM0482 MDM0476 MDM0483 MDM0483 MDM0477 MDM0484 MDM0484 MDM0478 MDM0485 MDM0485 MDM0479 MDM0486 MDM0486 MDM0480 MDM0487 MDM0487 MDM0669 MDM0674 MDM0674 230+ Impeller ass'y...

- Page 46 MDM65 Impeller parts list Impeller Motor Q'ty/ Parts code No. Model Parts name size power unit Impeller MDM0289 MDM0317 MDM0317 MDM0290 MDM0318 MDM0318 MDM0291 MDM0319 MDM0319 MDM0292 MDM0320 MDM0320 MDM0293 MDM0321 MDM0321 MDM0294 MDM0322 MDM0322 MDM0295 MDM0323 MDM0323 MDM0683 MDM0689 MDM0689 230+ Impeller ass'y...

-

Page 47: Mass Of Pump

16. Mass of pump Total mass with motor & base- Total mass with motor & with- Model Output (kW) Mass of Motor (kg) plate (kg) out baseplate (kg) MDM25-1 MDM25-2 MDM-25-3 18.5 MDM40-1 MDM40-2 18.5 MDM50-1 MDM65-1 Note 1. Motor mass is based on TEFC outdoor motor made by HITACHI. Note 2. - Page 48 IWAKI Norge AS TEL : (47)23 38 49 00 FAX : 23 38 49 01 China IWAKI Pumps (Guandong) Co., Ltd. TEL : (86)750 3866228 FAX : 750 3866278 Singapore IWAKI Singapore Pte. Ltd. TEL : (65)6316 2028 FAX : 6316 3221 China GFTZ IWAKI Engineering &...

Need help?

Do you have a question about the MDM Series and is the answer not in the manual?

Questions and answers