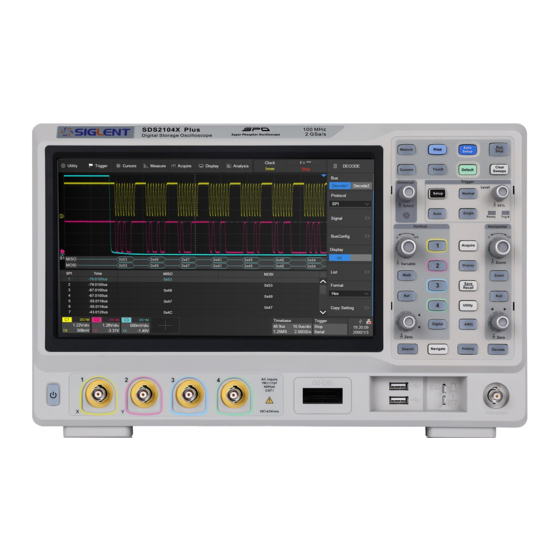

SIGLENT SDS2000X Plus Series Service Manual

Digital oscilloscope

Hide thumbs

Also See for SDS2000X Plus Series:

- User manual (335 pages) ,

- User manual (324 pages) ,

- Quick start manual (39 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for SIGLENT SDS2000X Plus Series

- Page 1 SDS2000X Plus Series Digital Oscilloscope Service Manual SM0102XP-E01A...

-

Page 2: Table Of Contents

SDS2000X Plus Series Digital Oscilloscope Service Manual Contents CONTENTS ..........................2 GENERAL SAFETY SUMMARY..................4 ......................4 AFETY ERMS AND YMBOLS ....................... 5 ORKING NVIRONMENT ......................6 OOLING EQUIREMENTS AC P ........................... 7 OWER ....................8 OWER AND GROUND CONNECTIONS .......................... - Page 3 SDS2000X Plus Series Digital Oscilloscope Service Manual DISASSEMBLY PROCEDURES..................48 ..................48 AFETY ONSIDERATION AND AUTIONS ..........................49 OOLS ISTS ......................50 ISASSEMBLY ROCEDURES ................50 6.3.1 To Remove the Rear Cover and Knobs ..............52 6.3.2 To Remove the Power Supply Module and Fan ..............

-

Page 4: General Safety Summary

SDS2000X Plus Series Digital Oscilloscope Service Manual General Safety Summary This chapter contains information and warnings that must be followed to keep the instrument operating under the appropriate safety conditions. In addition to the safety precautions specified in this section, you must also follow recognized safety procedures. -

Page 5: Working Environment

SDS2000X Plus Series Digital Oscilloscope Service Manual Working Environment This instrument is intended for indoor use and should be operated in a clean, dry environment with an ambient temperature range of 0 ° C - 40 ° C. Temperature Operating: 0 ℃ to +40 ℃... -

Page 6: Cooling Requirements

SDS2000X Plus Series Digital Oscilloscope Service Manual Degree of Pollution: II Degree of Ingress Protection: IP20 Note: Installation (Overvoltage) Category II refers to the local distribution level, which applies to equipment connected to the mains supply (AC power source). -

Page 7: Ac Power

SDS2000X Plus Series Digital Oscilloscope Service Manual ventilation it is required to leave a 15 cm (6 inch) minimum gap around the sides of the instrument. CAUTION: Do not block the ventilation holes located on both sides of the scope. -

Page 8: Power And Ground Connections

SDS2000X Plus Series Digital Oscilloscope Service Manual Power and ground connections The instrument includes a grounded cord set containing a molded three- terminal polarized plug and a standard IEC320 (Type C13) connector for making line voltage and safety ground connection. The AC inlet ground terminal is connected directly to the frame of the instrument. -

Page 9: Calibration

SDS2000X Plus Series Digital Oscilloscope Service Manual Calibration The recommended calibration interval is one year. Calibration should be only performed by qualified personnel. Cleaning Clean only the exterior of the instrument, using a damp, soft cloth. Do not use chemicals or abrasive elements. Under no circumstances allow moisture to penetrate the instrument. - Page 10 SDS2000X Plus Series Digital Oscilloscope Service Manual Warning: Any use of the scope in a manner not specified by the manufacturer may impair the instrument’s safety protection. This instrument should not be directly connected to human subjects or used for patient monitoring.

-

Page 11: First Steps

SIGLENT shall not be responsible for any defect, damage, or failure caused by any of the following: a) Attempted repairs or installations by personnel other than SIGLENT. -

Page 12: Maintenance Agreement

The oscilloscope's firmware has been thoroughly tested and is presumed to be functional. Nevertheless, it is supplied without warranty of any kind covering detailed performance. Products not made by SIGLENT are covered solely by the warranty of the original equipment manufacturer. -

Page 13: Document Conventions

SDS2000X Plus Series Digital Oscilloscope Service Manual Document Conventions For convenience, text surrounded by a box border is used to represent the button of the front panel. For example, Print represents the "Print" button on the front panel. Italicized text with shading is used to represent the touchable or clickable menu/button/region on the touch screen. -

Page 14: Prepare Information

SDS2000X Plus Series Digital Oscilloscope Service Manual Prepare Information Before initiating performance verification or any adjustments, it is recommended the user follow these procedures. The following topics are discussed in this chapter. How to perform functional checks How to operate four standard interface tests ... - Page 15 SDS2000X Plus Series Digital Oscilloscope Service Manual Figure 1 Connect the power cord CAUTION: To avoid electric shock, make sure that the instrument is correctly grounded to the earth before connecting AC power. Press the Power button located at the lower-left corner of the front panel and note that several buttons will be lit for about 6 seconds simultaneously until the boot screen appears.

-

Page 16: Probe Compensation

SDS2000X Plus Series Digital Oscilloscope Service Manual 4.1.2 Probe Compensation When a probe is used for the first time, you should compensate it to match the input channel of the oscilloscope. Non-compensated or poorly compensated probe may increase measurement inaccuracy or error. The probe compensation procedures are as follows: 1. -

Page 17: Auto Setup

SDS2000X Plus Series Digital Oscilloscope Service Manual 4.1.3 Auto Setup Press the Auto Setup button to enable the waveform auto setting function. The oscilloscope will automatically adjust the horizontal time base, vertical scale, and trigger mode according to the input signal to obtain an optimum waveform display. -

Page 18: Self-Calibration

SDS2000X Plus Series Digital Oscilloscope Service Manual 4.1.4 Self-Calibration The self-calibration program can quickly calibrate the oscilloscope to reach the best working state and the most precise measurement. It is recommended to perform a self-calibration if the change of ambient temperature is more than 5 ℃. -

Page 19: Interface Test

SDS2000X Plus Series Digital Oscilloscope Service Manual Interface Test The SDS2000X Plus series oscilloscope is designed with four standard interfaces: USB Host, USB Device, LAN, and Pass/Fail. Connecting to other instruments via these interfaces enables the oscilloscope to achieve additional capabilities. -

Page 20: Usb Device Test

SDS2000X Plus Series Digital Oscilloscope Service Manual Figure 3 USB drive detected 4.2.2 USB Device Test To test if the USB Device interface is operating correctly. Tools: A computer with a USB interface A standard USB cable (Type AB) ... - Page 21 SDS2000X Plus Series Digital Oscilloscope Service Manual of the NI software interface and immediately the “USBTMC” device symbol is displayed. 4. Click “Open VISA Test Panel” option button, and then the following Interface will appear. Next, click the “Input/Output” option button and click the “Query”...

-

Page 22: Lan Port Test

SDS2000X Plus Series Digital Oscilloscope Service Manual 4.2.3 LAN Port Test Use to test if the LAN interface operates correctly when connected with NI Visa software. Tools: A computer with a LAN interface A standard LAN cable ... - Page 23 SDS2000X Plus Series Digital Oscilloscope Service Manual 1. Connect the oscilloscope to the computer using a LAN cable via the LAN interface ports. 2. Run NI-MAX software. Click “Device and Interface” at the upper left corner of the NI software interface and select the “LAN” device symbol.

-

Page 24: Pass/Fail Out Test

SDS2000X Plus Series Digital Oscilloscope Service Manual 4.2.4 Pass/Fail out Test To test the Mask Test function and signal output by viewing on another oscilloscope. Tools: A second oscilloscope Two BNC cables Steps: 1. Turn on the SDS2000X Plus oscilloscope. - Page 25 SDS2000X Plus Series Digital Oscilloscope Service Manual Figure 5 Mask Test Interface All data points of waveform must be inside the mask to pass the test. Even a single point outside the mask will cause a failure. 1. Connect the Pass/Fail output signal (on the rear panel) to the input terminal of another oscilloscope.

- Page 26 SDS2000X Plus Series Digital Oscilloscope Service Manual Figure 6 Pulse Waveform 26 / 70 WWW.SIGLENT.COM...

-

Page 27: Performance Test

SDS2000X Plus Series Digital Oscilloscope Service Manual Performance Test This chapter explains testing the oscilloscope to verify performance specifications. For accurate test results, please let the test instruments and the oscilloscope warm-up 30 minutes before testing. Below is the required equipment for the test:... - Page 28 SDS2000X Plus Series Digital Oscilloscope Service Manual 9500B SDS2000X Plus SDS2000X-E GPIB CH3 CH4 BNC CABLE Figure 7 Connecting test instruments for DCG\Offset SDS2000X Plus 9500B GPIB BNC CABLE Figure 8 Connecting test instruments for Clock\Trigger Delay 9500B SDS2000X Plus...

- Page 29 SDS2000X Plus Series Digital Oscilloscope Service Manual Figure 10 Connecting test instruments for Input impedance The figures below show the interconnections between the test equipment and PC to Ext Trigger test: GPIB BNC CABLE Figure 11 Connecting test instruments for Ext Trigger Delay\ Ext Trigger Level...

- Page 30 SDS2000X Plus Series Digital Oscilloscope Service Manual Verify Test Results To verify whether or not a test passes (i.e. whether the readings are within the appropriate limits), it is necessary to record the readings in the Performance Test located in the Test Record.

-

Page 31: To Verify Dc Gain Accuracy

SDS2000X Plus Series Digital Oscilloscope Service Manual To Verify DC Gain Accuracy DC Gain Accuracy Slope = LINEST(V error1 error5 Setting1 Setting5 Note: “V ” represents the DC voltage output level setting. Setting “V ” represents the difference between the output setting and the error measurement. -

Page 32: To Verify Offset Accuracy

SDS2000X Plus Series Digital Oscilloscope Service Manual Table 3 DC Gain Accuracy Volt/Div DC voltage output levels DC Gain Accuracy error 10 V/div 30 V,15V ,0,-15 V,-30 V ±3% ±3% 5 V/div 15 V, 7.5 V,0,-7.5 V,-15 V ±3% 2 V/div 6 V,3 V,0,-3 V,-6 V ±3%... - Page 33 SDS2000X Plus Series Digital Oscilloscope Service Manual This test verifies the non-interleaved mode Offset Accuracy of all the channels. Steps: 1. Set the 9500B output to on. 2. Connect all channels of the oscilloscope to 9500B as shown in Figure 7.

-

Page 34: To Verify Time Base Accuracy

SDS2000X Plus Series Digital Oscilloscope Service Manual Slope Zero Volt/Div Offset error input(V) 10 V/div 35 V,30 V,0,-3 0V,-35 V ±1.5% ±1.202 ±1.5% ±0.602 5 V/div 30 V,25 V,0,-25 V,-30 V ±1.5% ±0.242 2 V/div 20 V,10 V,0,-10 V,-20 V ±1.5%... -

Page 35: To Verify Trigger Delay

SDS2000X Plus Series Digital Oscilloscope Service Manual 1. Connect the selected channel of the oscilloscope to the 9500B. 2. Set the oscilloscope Volts/Div to 100 mV/div. 3. Set the oscilloscope Sec/Div to 50 ms/div. 4. Set the Memory Depth to 20Mpts. -

Page 36: To Verify Ext Trigger Delay

SDS2000X Plus Series Digital Oscilloscope Service Manual 3. Set the impedance of the 9500B to 50 Ω, frequency to 1 kHz, and amplitude to 0.6 V. 4. Set the oscilloscope Volts/Div to 100 mV/div. 5. Set the oscilloscope Sec/Div to 2 ns/div, trigger source is the selected channel. -

Page 37: To Verify Ext Trigger Level

SDS2000X Plus Series Digital Oscilloscope Service Manual amplitude to 0.6 V. 4. Set the oscilloscope Volts/Div to 100 mV/div. 5. Set the oscilloscope Sec/Div to 2 ns/div. 6. Set the oscilloscope trigger source to EXT, the trigger slope to Rising, and the trigger level to 0. - Page 38 SDS2000X Plus Series Digital Oscilloscope Service Manual 9500B with a BNC T connector, as shown in Figure 11. 2. Set the oscilloscope Sec/Div to 50 us/div. 3. Set the oscilloscope Volts/Div to 150 mV/div, trigger source to EXT, trigger slope to positive, and coupling mode to DC.

-

Page 39: To Verify Noise Floor

SDS2000X Plus Series Digital Oscilloscope Service Manual 18. Disconnect the test connection. To Verify Noise Floor This test checks the noise floor of the analog channels and varies from models. In this test, do not connect any testing devices to the oscilloscope. -

Page 40: To Verify Bandwidth

SDS2000X Plus Series Digital Oscilloscope Service Manual 7. Set the oscilloscope Volts/Div to the others in the table above, and repeat steps 3 to 5. To Verify Bandwidth This test checks the bandwidth of all analog channels. In the test, the impedance of 9500B should be set to be the same as analog channels, 50 Ω,... -

Page 41: To Verify Bandwidth Limit

SDS2000X Plus Series Digital Oscilloscope Service Manual 1. Every time the frequency is changed, it is recommended to adjust the Sec/Div to a proper value to display a complete waveform. 2. Record the Peak-Peak measurement of the waveform. 3. Set the oscilloscope Volts/Div to the setting choices, and repeat step 2 to step 7. - Page 42 SDS2000X Plus Series Digital Oscilloscope Service Manual Steps: 1. Connect channel 1 of the oscilloscope to the 9500B via the active head, as shown in Figure 9. 2. Set the oscilloscope Volts/Div to 100 mV/div, the Sec/Div to 50 ms/div, and set the BW Limit button to 20 MHz.

-

Page 43: T Overify Trigger Sensitivity

SDS2000X Plus Series Digital Oscilloscope Service Manual 1. Calculate the dB value at the frequency point. If the value Check if the value is in the limited range. 2. Check the other channels in the same way as in step1 to step 8. - Page 44 SDS2000X Plus Series Digital Oscilloscope Service Manual 7. Record the (hardware-measured) frequency which is on the top right of the screen, and check that it is in the specified trigger range listed in Table 8. Set the oscilloscope trigger slope to Negative, repeat steps 5 to 7.

-

Page 45: T Overify Input Impedance

SDS2000X Plus Series Digital Oscilloscope Service Manual 7. Set trigger slope to Negative, repeat steps 4 to 6. 8. Set frequency of the 9500B to the oscilloscope’s bandwidth frequency, amplitude to 300 mV. Repeat steps 3 to 7. In step 5, the range changes to [-150 mV, 150 mV]. - Page 46 SDS2000X Plus Series Digital Oscilloscope Service Manual Table 12 Input Impedance data Impedance Range Coupling and Channel impedance type 1176000~1224000 Ω 0.1V/div AC/1 MΩ 0.2V/div,2V 980000~1020000 Ω /div DC/1 MΩ 980000~1020000 Ω DC(AC)/50 Ω 49.15~50.85 1 MΩ 980000~1020000 Ω 50 Ω...

- Page 47 SDS2000X Plus Series Digital Oscilloscope Service Manual When checking the EXT trigger channel, it is the same as checking the analog channel. Record the reading displays on the screen of the 9500B, and check to verify it is within the specified range in Table 12.

-

Page 48: Disassembly Procedures

SDS2000X Plus Series Digital Oscilloscope Service Manual Disassembly Procedures This chapter describes how to remove major parts from the SDS2000X Plus series oscilloscope. Safety Consideration and Cautions Only qualified personnel should perform the disassembly procedures. Disconnect the power before you begin to remove or replace the parts. -

Page 49: Tools Lists

SDS2000X Plus Series Digital Oscilloscope Service Manual CAUTION REMOVE POWER TO AVOID DAMAGE Remove power before you start to disassemble or replace parts. DO NOT disassemble or replace parts with the power on. Damage to the components may occur. Tools Lists Use these tools to remove or replace the modules in the oscilloscope: ... -

Page 50: Disassembly Procedures

SDS2000X Plus Series Digital Oscilloscope Service Manual Disassembly Procedures This section describes how to remove the modules in the oscilloscope in detail. To install the removed parts or replace a new part, follow the instructions in reverse order. 6.3.1 To Remove the Rear Cover and Knobs... - Page 51 SDS2000X Plus Series Digital Oscilloscope Service Manual screws). 3. Lift the rear cover up and off carefully. WWW.SIGLENT.COM 51 / 70...

-

Page 52: To Remove The Power Supply Module And Fan

SDS2000X Plus Series Digital Oscilloscope Service Manual 6.3.2 To Remove the Power Supply Module and Fan Figure 14 To remove the power supply module and Fan Steps: 1. Remove the four PM3*6 screws outside the Power Supply Module housing . -

Page 53: To Remove The Front Panel And Rubber Keypad

SDS2000X Plus Series Digital Oscilloscope Service Manual 6.3.3 To Remove the Front Panel and Rubber Keypad Figure 15 To remove the front panel and rubber keypad Steps: 1. Remove the three PM3*6 screws on the front of the panel. 2. Remove the eleven PM3*6 screws outside the rear metal module. -

Page 54: To Remove The Keyboard And Probe Interface Board

SDS2000X Plus Series Digital Oscilloscope Service Manual 6.3.4 To Remove the Keyboard and Probe Interface Board Figure 16 To remove the keyboard and probe interface board. Steps: 1. Unplug the connecting cable from the mainboard. 2. Remove the two PM3*6 screws on the probe interface board. -

Page 55: To Remove The Acquisition Board

SDS2000X Plus Series Digital Oscilloscope Service Manual 6.3.5 To Remove the Acquisition board Figure 17 To remove the acquisition board Steps: 1. Remove the five BNC nuts and gaskets on the front side of the metal frame. 2. Remove the ten PM3*6 screws on the acquisition board. -

Page 56: To Remove The Lcd Module And Lcd Interface Board

SDS2000X Plus Series Digital Oscilloscope Service Manual 6.3.6 To Remove the LCD Module and LCD Interface Board Figure 18 To remove the LCD module and LCD interface board Steps: 1. Remove the five PM3*6 screws on the LCD module. 2. Disconnect the cable between the LCD and LCD interface board. -

Page 57: Solving General Problems

If not, contact SIGLENT for further instructions. If it is, try to upgrade to the latest firmware to solve the problem. If the display is still stuck at the logo screen, contact SIGLENT for further instructions. If there is no trace display WWW.SIGLENT.COM... - Page 58 User Manual. Turn on the associated channel again and press the Auto Setup key. If there is still no trace displayed, contact SIGLENT for further instructions. If the baseline trace drift out of specification ...

-

Page 59: Troubleshooting

SDS2000X Plus Series Digital Oscilloscope Service Manual Troubleshooting This chapter contains information and procedures for troubleshooting general hardware failures. Safety Consideration and Cautions Only qualified personnel should perform troubleshooting procedures. Disconnect the power cord whenever possible. DO NOT try to troubleshoot if visible damage is detected on the power supply module and the acquisition board, return it to SIGLENT for further repair. -

Page 60: Required Equipment

Troubleshooting Flowchart The following flowchart describes how to troubleshoot the oscilloscope in the most general case. This does not guarantee a 100% recovery of all possible hardware failures. Contact SIGLENT if you cannot solve the problem. 60 / 70 WWW.SIGLENT.COM... - Page 61 SDS2000X Plus Series Digital Oscilloscope Service Manual Begin Test Power Supply Module Replace Power Good? Supply Module Test Main Board Replace Main Good? Board Test LCD Good? Replace LCD WWW.SIGLENT.COM 61 / 70...

-

Page 62: To Check The Power Supply Module

SDS2000X Plus Series Digital Oscilloscope Service Manual To Check the Power Supply Module Disconnect all the external cables and devices from the front and back panel. Disconnect the power cord of the oscilloscope. Remove the rear plastic cover and metal cover following the instructions in chapter Disassembly Procedures. -

Page 63: To Check The Acquisition Board

SDS2000X Plus Series Digital Oscilloscope Service Manual To Check the Acquisition Board This guide is based on the acquisition board revision C (labeled SDY8.007.181C). Future revision will be compatible unless described differently. 8.5.1 Acquisition Board SDY8.007.181C 8.5.1.1 Acquisition Board Drawing ... - Page 64 SDS2000X Plus Series Digital Oscilloscope Service Manual confirmed that the power supply module is in good condition. Power up the acquisition board by pushing the front panel power button. In most cases, you can hear the relays click if the acquisition board power up successfully.

- Page 65 SDS2000X Plus Series Digital Oscilloscope Service Manual AVCC5V_AWG ±0.1V ���� ���� T101 AVEE-5V ±0.1V ���� ���� TP39 VCC3V3_PLL 3.3V ±0.2V ���� ���� TP47 VCC3V3_CH 3.3V ±0.2V ���� ���� AVCC1V9 1.9V ±80mV ���� ���� T111 VCC5V_VBUS ±0.25V ���� ���� TP136 VCC12V5 12.5V...

- Page 66 SDS2000X Plus Series Digital Oscilloscope Service Manual Figure 22 Test points for the Acquisition board power supplies (continued) 8.5.1.3 Check the clock There are 4 clock oscillators and associated fanout buffers on board to source different circuitries. Each of them serves one or more function. The voltage compliance of all the clock under test is LVCMOS33.

-

Page 67: To Check The Lcd

SDS2000X Plus Series Digital Oscilloscope Service Manual Figure 23 Test points for clock To Check the LCD Reconnect the power cable to the acquisition board after you have confirmed that the power supply module is in good condition. ... -

Page 68: To Check The Lcd Signal

SDS2000X Plus Series Digital Oscilloscope Service Manual Figure 24 Test points for the LCD power supplies If the power supply is out-of-specification, double-check with LCD cable disconnected. If the power supply is still out-of-specification, replace the acquisition board. If the power supply is good when the LCD cable is disconnected, replace the LCD panel or the LCDI board (the board between the acquisition board and the LCD panel). - Page 69 SDS2000X Plus Series Digital Oscilloscope Service Manual LCD_DATA2_N/P LCD DATA signal. J32 PIN16/18 LVDS Always active LCD_CLK_N/P LCD reference clock, J32 PIN19/21 LVDS typically 50MHz If the signal is active, replace the LCD panel. If the signal is stuck, double-check with LCD cable disconnected. If the signal still stuck, replace the acquisition board.

- Page 70 SDS2000X Plus Series Digital Oscilloscope Service Manual 70 / 70 WWW.SIGLENT.COM...

Need help?

Do you have a question about the SDS2000X Plus Series and is the answer not in the manual?

Questions and answers