Subscribe to Our Youtube Channel

Summary of Contents for HADEF 43/86E-Liftboy

- Page 1 Installation, Operating and Maintenance Instructions HADEF Electric Wire Rope Winch Type 43/86E-Liftboy 5.52.288.00.01.06 Rev.06...

-

Page 2: Table Of Contents

Heinrich de Fries GmbH Heinrich de Fries GmbH, Gauss Str. 20, D-40235 Düsseldorf Heinrich De Fries GmbH will be named HADEF in the following text. Original operating- and maintenance instructions in German language. Translation in other languages is made of the German original. -

Page 3: Information

Wire rope ........................18 Limit switch for wire rope path (as option) ..............18 Slack rope switch (as option) ..................18 Safety check ..................18 Functional test ................. 19 11.1 Checks before the initial start-up ................. 19 Maintenance ..................19 12.1 General ........................... -

Page 4: Indications To Determine The Used Part Of The Theoretical Usage Life

“winches, lifting and pulling devices”. NOTICE! Commitment A general overhaul may only be performed by HADEF or by a specialized company, authorized by HADEF. Safety Warning notice and symbols Warnings and notice are shown as follows in these instructions: This means that there is a high risk that leads, if it is not avoided, to death or severe injury. -

Page 5: Requirements For The Operating Personnel

However, in everyday operation this degree of safety can only be achieved if all measures required are taken. It falls within the duty of care of the owner/user of the devices to plan these measures and to check that they are being complied with. Complete the operating and installation instructions by any instructions (regarding supervision or notifications)that are important for the special kind of use of the equipment, i.e. -

Page 6: Basic Safety Measures

The permissible ambient temperature when operating the devices: Device classification for Power unit Explosive atmosphere Not explosive atmosphere according to ATEX Manual -20° C/+50° C -20° C/+40° C Motor -20° C/+40° C -20° C/+40° C ) * Devices in this category have been specially modified and labeled by the manufacturer DANGER! The ambient temperature must not be exceeded! Vertical lifting and lowering of unguided loads, horizontal movement of loads and inclined movement of... -

Page 7: Transport And Storage

Do not use a hoist that is defective, pay attention to any abnormal noise it makes during operation. Stop working immediately in case of disturbances and remedy failures. Any damage and faults must be reported to a responsible supervisor immediately. If the unit is put into motion, any persons in the immediate vicinity must be informed by calling to them! Please pay attention to the regulations for load carrying devices UVV for both positive and non-positive methods of attaching loads. -

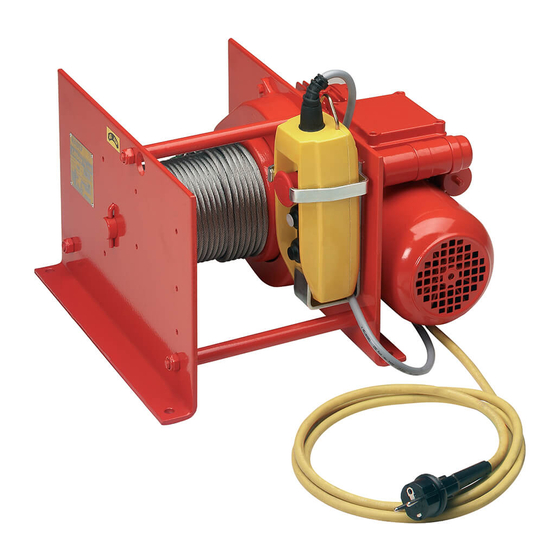

Page 8: Description

It is not permitted to use the unit in an area at risk from explosion! Design HADEF electric wire rope winches for stationary use are fitted with holes for installation. The housing is made of steel plate. The two housing halves are connected by threaded bolts and distance tubes. The rope drum between the two housing halves offers wire rope exits in several directions. -

Page 9: Functions

Functions The lifting gear are operated by pressing the push buttons on the control switch. The spring-pressure brake installed in the electric motor of the lifting gear prevents the independent lowering of the load after the push button has been released. Important components Standard 3-phase current motor Standard AC motor at 125 -2000 kg load capacity. -

Page 10: Technical Data

Pressure roller (as option) The pressure roller prevents the skipping of rope windings, when the unloaded rope will on- or unwinded. respective rope layers will pressed functionally correct . Illustration 1 DANGER! The following is not allowed: Disengaging under load. Manipulation of the disengaging device. -

Page 11: Installation

Alternating current 230V - 50Hz Capa- Wire rope Wire Capa- Wire rope Wire Rope nec. nec. min. Mechanism Motor- Current Noise Weight city storage rope city storage rope layers wire breaking group output consumption emission * without speed speed rope ø load wire rope approx. -

Page 12: Selection Of Wire Ropes

Selection of wire ropes Wire ropes acc. to EN 12385-4 - Lifting ropes Stainless wire ropes and special wire ropes are available on request. Diameter and nec. minimum breaking load must be acc. to the data mentioned in the table in chapter "Technical Data"... -

Page 13: Winding Up Of Wire Rope

Winding up of wire rope The wire rope must always be winded up tensioned. When the last wire rope layer is winded onto the drum, the flanged wheel must exceed the top layer by at least 1 1/2 times of the wire rope diameter. NOTICE! According to validated regulations and accident prevention regulations, the wire rope length must be chosen so that at least 2 rope layers remain on the drum when the wire rope is unwinded. -

Page 14: Operation

Operation Only people that are familiar with the operation of the lifting devices and cranes may be entrusted with their operation. They must be authorized by the employer for the operation of the equipment. The employer must ensure that the operating instructions are available near the equipment and that they are accessible for the operating personnel. -

Page 15: Disengaging Clutch (As Option)

Disengaging clutch (as option) The drum is disengaged through a switch button situated at the gear shaft. engaged (A) disengaged (B) In order to release the switch, pull it out approx. 10 mm against the pressure of the spring (1) and turn it 90° to the left, - anti- clockwise (2). -

Page 16: Commissioning

Commissioning General Should the unit be used in Germany: Please observe the validated, national accident prevention regulations. For other countries: Inspections as above. Please observe the national rules and regulations and the instructions in this manual! NOTICE! Hoists up to 1000 kg capacity and without motor-driven trolleys of hoisting unit must be tested by a “qualified person”... -

Page 17: Gear

9.2.4 Wiring diagram Wiring diagrams are situated in the terminal box or can be requested from HADEF by metioning of serial number. 9.2.5 Assignment recommendation of line cross-sections and fuses Assignment of line cross-sections and fuses must be done acc. to VDE0100. -

Page 18: Wire Rope

Wire rope Wire ropes must be free from corrosion, dirt or damage. They must be lubricated before commissioning. No lubrication shortens the lifetime of the wire rope and the maintenance intervals. WARNING! It is not allowed to use plastic wire ropes or plastic-coated wire ropes. Limit switch for wire rope path (as option) The limit switch (if exist) must be adjusted before commissioning and after maintenance work has been made. -

Page 19: Functional Test

Functional test 11.1 Checks before the initial start-up Check lifting by moving up/down and slow/fast without load. Suspend the nominal load and check the function of the brake. Maintenance 12.1 General All monitoring, servicing and maintenance operations are to ensure correct functioning of the equipment; they must be effected with utmost care. -

Page 20: Overload Protection

12.3.3 Adjusting the air gap View "X" on the brake. 1 Loosen the locking screws (6) by half a turn. 2 Turn the cap screws (8) into the magnetic body (9) anti-clockwise. 3 By turning the locking screws (6) clockwise, move the magnetic body (9) towards the anchor plate (10) using a feeler gauge until nominal air gap “a”... -

Page 21: Slack Rope Switch (As Option)

Make sure that 2-3 rope layers remain on the drum in the lowest load position. Adjustment for "lifting" is done analogous. Afterwards drive carefully to the end positions to check correct adjustment. Illustration 17 Pictures may differ from the actual design. 12.6 Slack rope switch (as option) 12.6.1... -

Page 22: Periodic Checks

13.2 Periodic checks Independently from the regulations of the individual countries, lifting devices must be checked at least yearly by a qualified person or licensed qualified person regarding its functional safety. 13.3 Wire rope Adequate performance of the servicing and monitoring work acc. to the validated, national regulations “Basics for cable drives –... -

Page 23: Gearbox

14.2 Gearbox The worm gear is maintenance free. The teeth of the spur gear for winches from 250 kg pulling rope force and up must be re-lubricated at least once a year. Lubricant recommended: grease Renolit FEP2 14.3 Electric motor For the motor it is sufficient to keep the cooling airways clean and monitor the roller bearing and its lubrication status. -

Page 24: Remedy

Remedy Problem* Unit Cause Remedy No main power Check connection to mains supply Unit cannot be switched on Electric Hoists exchange 2 phases Phase sequence not correct (with low voltage control) (see waring note at the plug) Fuse burnt out Replace the fuse Defective switching unit in the control button switch Replace the switching unit... -

Page 25: Decommissioning

Decommissioning WARNING! It is essential that the following points are observed in order to prevent damage to the equipment or critical injury when the device is being decommissioned: It is mandatory that all steps for decommissioning the machine are carried out in the indicated sequence: First secure the working area for decommissioning, leaving plenty of space.

Need help?

Do you have a question about the 43/86E-Liftboy and is the answer not in the manual?

Questions and answers