Summary of Contents for INGENIA Triton Go

- Page 1 Triton Go Product Manual Edition 05/29/2017 For the most up to date information visit the online manual. INGENIA-CAT S.L. 8-14 MARIE CURIE, ADVANCED INDUSTRY PARK 08042 BARCELONA...

-

Page 2: Table Of Contents

1 Table of Contents Table of Contents General Information Manual revision history ............................. 5 Disclaimers and limitations of liability ......................5 Contact ................................5 Safety Information About this manual.............................. 7 Warnings................................7 Precautions ................................ 7 Product Description Triton part numbering ............................8 Specifications.............................. - Page 3 7.2.5 Power supply wiring recommendations......................58 7.2.5.1 Wire section ..............................58 7.2.5.2 Wire ferrules ..............................58 7.2.5.3 Wire length ............................... 59 Motor and shunt braking resistor........................59 7.3.1 AC and DC brushless motors ........................... 59 7.3.2 DC motors and voice coils actuators ......................60 7.3.3 Motor wiring recommendations ........................

- Page 4 CAN wiring recommendations ........................110 7.7.4 EtherCAT interface ............................111 Safe Torque Off (STO) ............................ 112 Dimensions Triton Go with CAN (TRI-x/48-C-C) ........................ 115 Triton Go with EtherCAT (TRI-x/48-E-C) ......................116 Application Software Configuration ..............................118 Applications..............................118 Arduino ................................118...

-

Page 5: General Information

S.L.. Such information is supplied solely for the purpose of assisting users of the product in its installation. INGENIA-CAT S.L. rejects all liability for errors or omissions in the information or the product or in other documents mentioned in this document. ... - Page 6 Triton Go Product Manual | General Information Telephone: +34 932 917 682 E-mail: hello@ingeniamc.com site: www.ingeniamc.com mailto:HELLO@INGENIAMC.COM http://www.ingeniamc.com/ INGENIA | 05/29/2017...

-

Page 7: Safety Information

Triton Go Product Manual | Safety Information 3 Safety Information 3.1 About this manual Read carefully this chapter to raise your awareness of potential risks and hazards when working with the Triton Servo Drive. To ensure maximum safety in operating the Triton Servo Drive, it is essential to follow the procedures included in this guide. -

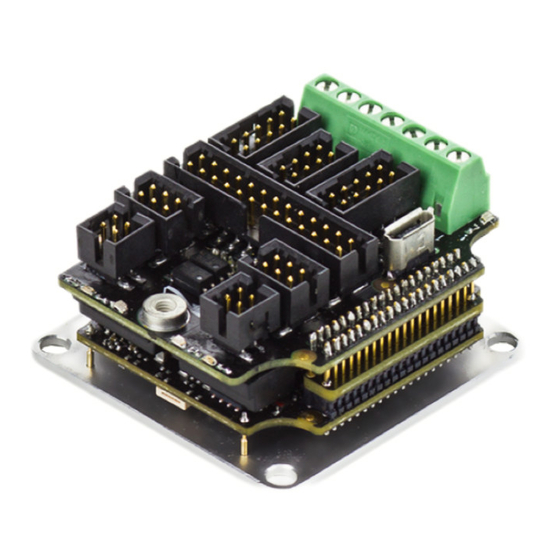

Page 8: Product Description

Triton Go Servo Drive is provided with several general purpose inputs and outputs designed for 5 V TTL logic but tolerant up to 24 V and fully rugged. By using these inputs and outputs it is possible to implement alarm signals, connect digital sensors, activate external devices (LEDs, actuators, solenoids, etc.). Some of the digital and... - Page 9 Triton Go Product Manual | Product Description Product Ordering part number Status Image ACTIVE TRI-7/48-C-P Triton Core ACTIVE TRI-4/48-C-P ACTIVE TRI-1/48-C-P ACTIVE TRI-7/48-E-P ACTIVE TRI-4/48-E-P ACTIVE TRI-1/48-E-P http://doc.ingeniamc.com/display/TR/Triton+Core+Product+Manual INGENIA | 05/29/2017...

-

Page 10: Specifications

• TRI-8/48-C-C → TRI-7/48-C-C • TRI-2/48-C-C → TRI-4/48-C-C • TRI-0.5/48-C-C → TRI-1/48-C-C • TRI-8/48-E-C → TRI-7/48-E-C • TRI-2/48-E-C → TRI-4/48-E-C • TRI-0.5/48-E-C → TRI-1/48-E-C 4.2 Specifications A list of features of the Triton Go Servo Drive is shown next. INGENIA | 05/29/2017... - Page 11 Triton Go Product Manual | Product Description Electrical and power specifications Part number → TRI-1/48-y-C TRI-4/48-y-C TRI-7/48-y-C Power supply voltage +8 V to +48 V Transient peak voltage 65 V Internal DC bus capacitance 20 µF Minimum motor inductance 200 µH (Triton still can control motors with lower inductances.

- Page 12 Triton Go Product Manual | Product Description Motion control specifications Supported motor types • Rotary brushless (trapezoidal and sinusoidal) • Linear brushless (trapezoidal and sinusoidal) • DC brushed • Rotary voice coil • Linear voice coil Power stage PWM frequency 20 kHz (default)

- Page 13 Triton Go Product Manual | Product Description Supported target sources • Network communication – USB • Network communication – CANopen • Network communication – RS-485 • Network communication – EtherCAT • Standalone (execution from internal EEPROM memory) • Analog inputs • Step and Direction (Pulse and Direction) •...

- Page 14 Triton Go Product Manual | Product Description Protections • User configurable: • DC bus over-voltage • DC bus under-voltage • Drive over-temperature • Drive under-temperature • Over-current • Overload (I • Short-circuit protections: • Phase to DC bus • Phase to phase •...

- Page 15 Triton Go Product Manual | Product Description CANopen Available. Non-isolated (1 Mbps by default). 120 Ω termination not included on board. CiA-301, CiA-303, CiA-305, CiA-306 and CiA-402 compliant. EtherCAT Available (magnetics included) Environmental and mechanical specifications Part number → TRI-x/48-C-C TRI-x/48-E-C Cold plate temperature •...

-

Page 16: Hardware Revisions

USB 2.0, EtherCAT, CAN or RS485 serial interface and does not indicate the air temperature, but the temperature of the PCB. Above 110 ºC the Triton Go automatically turns off the power stage and stay in fault state avoiding any damage to the drive. The Fault LED will be activated and latched until temperature decreases below this threshold. -

Page 17: Power Losses Calculation (Heat Dissipation)

Some parts of the Triton Go can exceed 110 ºC during operation, especially at high load levels. Do not touch the Triton Go during operation and wait at least 5 minutes after turn off to allow a safe cool down. -

Page 18: Current Ratings

Triton Go Product Manual | Product Description 4.4.2 Current ratings Power losses cause the drive to increase its temperature according to: As power losses have a positive correlation with the motor RMS current, when the ambient temperature rises, the output current must be limited to avoid an excessive drive temperature (T <... - Page 19 Triton Go Product Manual | Product Description Temperature > With 1.2 ºC/W heatsink attached. Considering 90 % of stabilization maximum time temperature. This graphic shows the maximum current with respect to coldplate temperature, assuming a 1.2 ºC/W heatsink attached. This graphic shows the maximum current with respect to ambient temperature, also assuming a 1.2 ºC/W heatsink attached.

-

Page 20: System Temperature

Triton Go Product Manual | Product Description Current derating The current derating graph is only indicative and is based on thermal tests performed in a climatic chamber where there was enough room for natural air convection. Each application may reach different ratings depending on the installation, ventilation and/or housing. -

Page 21: Architecture

• Temperature range can be increased by providing forced cooling with a fan. Always ensure electrical isolation between live parts and the heatsink. 4.5 Architecture This diagram represent the main hardware elements of Triton Go, and how they relate to each other. INGENIA | 05/29/2017... - Page 22 Triton Go Product Manual | Product Description INGENIA | 05/29/2017...

-

Page 23: Connectors Guide

Triton Go Product Manual | Connectors Guide 5 Connectors Guide This chapter details the Triton Go Servo Drive (TRI-x/48-y-C) connectors and pinout. For a pin header board option please refer to the Triton Core product manual. http://doc.ingeniamc.com/display/TR/Triton+Core+Product+Manual INGENIA | 05/29/2017... -

Page 24: Supply, Shunt And Motor Connector

Triton Go Product Manual | Connectors Guide 5.1 Supply, shunt and motor connector P1 Connector 7 position, 3.5 mm pitch rising cage clamp terminal block. Phoenix Contact 1751293 Function Signal 1 PH_A Motor phase A (Positive for DC and voice coils) PH_B... -

Page 25: Milli-Grid Connectors Mating

(see page 52) 5.2 Milli-Grid connectors mating All Triton Go Servo Drive signal and communication connections are based in Molex Milli-Grid™ 2 mm pitch connectors. Multi-core crimped cables can be used for wiring inputs, outputs feedbacks and communications. Multi-core crimped cable mating Description Molex Milli-Grid™... - Page 26 Triton Go Product Manual | Connectors Guide Pre-assembled wires Description Black 26 AWG pre-crimped jumper cable (50.8 mm). Note: there are many lengths and clours available at Digi-Key Part Molex 0503948051-02-B6 number Distributor Digi-Key 0503948051-02-B6-ND codes Connection and disconnection of connectors Take special care when disconnecting cables.

-

Page 27: Halls And Motor Temperature Connector

Triton Go Product Manual | Connectors Guide Halls and motor temperature connector P2 Connector 10 pin 2 row Milli-Grid™ 2 mm pitch header. Molex 87832-1006 Function Signal Cable shield connection (Internally connected to drive mounting plate) +5V_OU 5 V 200 mA max (shared with other connectors) - Page 28 Triton Go Product Manual | Connectors Guide HALL_1 Hall sensor input 1 (analog and digital) HALL_2 Hall sensor input 2 (analog and digital) GND_D Ground HALL_3 Hall sensor input 3 (analog and digital) Notes • The drive includes 1 kΩ pull-up resistors to the halls inputs. They are enabled when digital halls are selected.

-

Page 29: Absolute Encoder Connector

Triton Go Product Manual | Connectors Guide 5.4 Absolute encoder connector P3 Connector 8 pin 2 row Milli-Grid™ 2 mm pitch header. Molex 87832-0806 Function Signal Cable shield connection (Internally connected to drive mounting plate) +3.3V_OUT +3.3 V 200 mA max for absolute encoder... - Page 30 Triton Go Product Manual | Connectors Guide DATA- Absolute encoder DATA negative signal input Notes • The Triton is compatible both with 5 V and 3.3 V level absolute encoders. The input accepts also single ended signals, in this case, connect clock and data positive signals only.

-

Page 31: Incremental And Sin-Cos Encoder Connector

Triton Go Product Manual | Connectors Guide 5.5 Incremental and Sin-Cos encoder connector P4 Connector 10 pin 2 row Milli-Grid™ 2 mm pitch header. Molex 87832-1006 Function Signal Cable shield connection (Internally connected to mounting plate) +5V_OUT 5 V 200 mA max (shared with other connectors) - Page 32 Triton Go Product Manual | Connectors Guide ENC_Z- Differential Encoder: Index- input ENC_Z+ Single ended digital encoder: Index input Differential digital encoder: Index+ input Notes • See Feedback connections for further information about different feedbacks wiring. (see page 64) Do not confuse with Halls connector Halls and encoder connectors have the same number of pins.

-

Page 33: Usb Connector

Triton Go Product Manual | Connectors Guide 5.6 USB connector P5 Connector 5 pin vertical micro-USB connector. Wurth Electronics 614105150721 Function Signal 1 USB_SUPPL USB +5 V supply input. Used to power logic circuits when no external power supply is available. USB D-... - Page 34 Triton Go Product Manual | Connectors Guide Notes • Avoid applying excessive lateral forces to the USB connector. • Micro-USB connection allows drive configuration using Motion Lab or downloading latest firmware revision • Shorter USB cables are preferred whenever possible for minimal EMI. • Please see Communications...

-

Page 35: I/O And Leds Connector

Triton Go Product Manual | Connectors Guide 5.7 I/O and LEDs connector P6 Connector 26 pin 2 row Milli-Grid™ 2 mm pitch header. Molex 878322620 Function Signal Cable shield connection (Internally connected to mounting plate) GND_D Ground HS_GPI1- / High speed digital differential input 1-... - Page 36 Triton Go Product Manual | Connectors Guide GPI1 General purpose single ended digital input 1 GPI2 General purpose single ended digital input 2 GPI3 General purpose single ended digital input 3 GPI4 General purpose single ended digital input 4 GPO1 Digital output 1 (open collector with weak pull-up to 5 V, can be...

- Page 37 Triton Go Product Manual | Connectors Guide Notes • LED outputs are open collector with a 220 Ω resistor in series for current limiting. However the output is tolerant to 30 V and can be used with panel indicators powered at 12V or 24V, just ensure current does not exceed 25 mA.

- Page 38 Triton Go Product Manual | Connectors Guide Part 3M 3625/26-30M number Distributo Mouser 517-3625/26 r code Farnell 2065102 Notes Easy wiring Ribbon cable is the easiest and lowest cost option. Multi-core crimped cable mating Description 2.00mm Pitch, Milli-Grid™ Receptacle Housing, 26 Circuits, with Center Locking Ramp and Side Polarization Keys.

-

Page 39: Rs485 Interface Connector

Triton Go Product Manual | Connectors Guide Notes • Triangle on the bottom left indicates pin 1. • See Milli-Grid connectors mating for further information about crimping terminals and (see page 25) cables. Clean wiring Crimped single cables makes wiring cleaner and is a preferred option for volume applications. - Page 40 Triton Go Product Manual | Connectors Guide RS485 receive data - (should be connected to master TX-) RS485 transmit data - (should be connected to master RX-) Notes • The Triton does not include any termination resistors to the RX or TX signals.

-

Page 41: Safe Torque Off (Sto) Connector

Triton Go Product Manual | Connectors Guide 5.9 Safe Torque Off (STO) connector P8 Connector 6 pin 2 row Milli-Grid™ 2 mm pitch header. Molex 878320628 Function Signal STO_COMMON Safe Torque Off common (optocoupler LEDs cathode, ISOLATED). GND_D Ground (not isolated) STO_1... - Page 42 Triton Go Product Manual | Connectors Guide Notes • To bypass the STO protection, add 3 x 2 mm pitch jumpers (Sullins Connector SPN02SVEN-RC between pins 1-2, 3-4, 5-6. • See Safe Torque Off (STO) for operation information. (see page 112) ...

-

Page 43: Ethercat Connectors (Tri-X/48-E-C)

Triton Go Product Manual | Connectors Guide 5.10 EtherCAT connectors (TRI-x/48-E-C) P9-P10 Connectors 2x ECAT connectors are 4 pin 2 row Milli-Grid™ 2 mm pitch header. Molex 878320406 The network GND spacer is a SMD mounted female spacer. Wurth Electronics 9774015151R Function... - Page 44 Triton Go Product Manual | Connectors Guide Transmit Data- line. Colour typ: Orange TX_D- RX_D- Receive Data- line. Colour typ: Green Notes • Use ring terminal to connect the cable shield or to the system enclosure if needed. • The EtherCAT is fully isolated, magnetics are included on board of TRI-x/48-E-C. The TRI-x/48-E-P (Triton core, with pin headers) has the PHY interface accessible without isolation.

- Page 45 Triton Go Product Manual | Connectors Guide Image Part number MOLEX 19324-0001 Distributor codes Mouser 538-19324-0001 Digi-Key WM9605-ND RJ-45 Connectors Descripti As a standard, EtherCAT uses the same phisical layer and RJ-45 connectors as Ethernet. This is a suggested wall connector, others might be valid too.

-

Page 46: Can Connectors (Tri-X/48-C-C)

Triton Go Product Manual | Connectors Guide 5.11 CAN connectors (TRI-x/48-C-C) P9-P10 Connectors 2x CAN connectors are 4 pin 2 row Milli-Grid™ 2 mm pitch header. Molex 878320406 Function Signal CAN OUT (P9) CAN_TERM 120 Ω termination resistor connected between this pin and pin 4... - Page 47 Triton Go Product Manual | Connectors Guide CAN_GND CAN ground CAN_L CAN bus line dominant low CAN_H CAN bus line dominant high Notes • The CAN bus must always be terminated at the ends with 120Ω. This termination is included on Triton.

-

Page 48: Signalling Leds

Triton Go Product Manual | Signalling LEDs 6 Signalling LEDs Triton Go Servo Drive provides information through 6 signalling LEDs: • Supply and operation: 2 LEDs (one of them bi-color) next to the Supply, shunt and motor connector. • CANopen communication: 2 LEDs next to the CAN/EtherCAT connectors (shared with EtherCAT option). -

Page 49: Can Signalling Leds (Only Tri-X/48-C-C)

Triton Go Product Manual | Signalling LEDs Colour Meaning SHUN Blue LED is turned on when the supply voltage is greater than the maximum voltage configured by the user. Configuration required This signal will only work if the braking resistor output is configured as active. -

Page 50: Ethercat Signalling Leds (Only Tri-X/48-E-C)

Triton Go Product Manual | Signalling LEDs RUN LED state* Concept Description The device is switched off Blinking Pre-operational The device is in state PREOPERATIONAL Single flash Stopped The device is in state STOPPED Operational The device is in state OPERATIONAL *See a detailed description of the states in the next table: * Possible LED states... - Page 51 SAFE-OPERATIONAL Single flash Local error OPERATIONAL Double flash Watchdog timeout Application controller failure For high severity errors inside the Triton Go Servo Drive, an special LED state has been developed: Status Signalling RUN LED state ERROR LED state Internal error...

-

Page 52: Wiring And Connections

Triton Go Product Manual | Wiring and Connections 7 Wiring and Connections Proper wiring, and especially grounding and shielding, are essential for ensuring safe, immune and optimal servo performance of Triton Go Servo Drive. Next pages show detailed connection recommendation as well as technical details of each interface. •... - Page 53 Use good quality plated screws that won’t oxidize or lose conductivity during the expected lifetime. Note that the PE terminal is internally connected with the Triton Go Servo Drive standoffs. • For achieving low impedance connections, use wires that are short, thick, multistrand cables or preferably conductive planes. PE wire section should be, at least, the same as power supply cables.

- Page 54 Triton Go Product Manual | Wiring and Connections If a simplified wiring is required, the following shielding priority can be applied: 1. Shield the motor cables, which are the main high-frequency noise source. 2. Shield the feedback signals, which are sensitive signals usually coming from the motor housing.

-

Page 55: Power Supply

Triton Go Product Manual | Wiring and Connections 7.2 Power supply The Triton Go Servo Drive is supplied from the Supply, shunt and motor connector, using the same terminal for logic and power supply (8 V to 48 V ). An internal DC/DC converter provides circuits with appropriate voltages as well as regulated 5 V and 3.3 V output voltages to supply feedback sensors and I/O. -

Page 56: Power Supply Connection

Lambda supply recommended for TRI-7/48-y-C, 500 W 7.2.2 Power supply connection Triton Go logic and power supply are provided through the same terminal. All Triton Go versions support an input voltage of +9 V to +48 V. Twisted cables Twisted power supply cables are preferred to reduce electromagnetic emissions and increase immunity. -

Page 57: Battery Supply Connection

Isolated power supplies For safety reasons, it is important to use power supplies with full galvanic isolation. 7.2.3 Battery supply connection Next figure shows a simplified wiring diagram for the Triton Go Servo Drive supplied from a battery. Motor braking current Motor braking can cause reverse current sense and charge the battery. -

Page 58: Power Supply Wiring Recommendations

Triton Go Product Manual | Wiring and Connections 7.2.5 Power supply wiring recommendations Wire section The minimum wire section is determined by the current consumption and the allowed voltage drop across the conductor. It is preferred to use wide section stranded wires to reduce impedance, power losses and ease the assembly. -

Page 59: Wire Length

0.5 mm (20 AWG) Wire length • The distance between the Triton Go Servo Drive and the power supply should be minimized when possible. Short cables are preferred since they reduce power losses as well as electromagnetic emissions and immunity. • For best immunity use twisted and shielded 2-wire cables for the DC power supply. This becomes crucial in long cable applications. -

Page 60: Dc Motors And Voice Coils Actuators

Triton Go Product Manual | Wiring and Connections Common-mode choke In order to minimize EMI that can affect sensitive signals, the use of a motor choke is recommended. The objective of the motor choke is to block the common mode current to the motor and cables. - Page 61 Triton Go Product Manual | Wiring and Connections Common-mode choke In order to minimize EMI that can affect sensitive signals, the use of a motor choke is recommended. The objective of the motor choke is to block the common mode current to the motor and cables.

-

Page 62: Motor Wiring Recommendations

The minimum wire section is determined by the motor current. It is preferred to use wide section stranded wires to reduce impedance, power losses and ease the assembly. Insulator size should not exceed 5 mm (connector pitch). Following table indicates recommended section for the Triton Go Servo Drive: Connection... -

Page 63: Wire Length

Triton Go Product Manual | Wiring and Connections Next table shows a choke that fits the Triton Go Servo Drive specifications and has a great performance at low frequencies. Type Manufacturer Reference Low frequency ferrite Laird Technologies LFB360230-300 Wire length • The distance between the Triton Go Servo Drive and the motor should be minimized when possible. Short cables are preferred since they reduce power losses as well as electromagnetic... -

Page 64: Feedback Connections

7.4 Feedback connections The Triton Go Servo Drive has multiple connectors (Halls, motor temperature and analog feedback connector, Absolute encoder connector and Incremental and Sin-Cos encoder connector) dedicated to the following feedback options: •... -

Page 65: Digital Halls Interface

Digital halls can be used for commutation, position and velocity control. Resolution using these sensors is much lower than using encoders. Triton Go can use single ended Hall sensors to drive the motor with trapezoidal commutation, but not with sinusoidal commutation. ... - Page 66 Triton Go Product Manual | Wiring and Connections Number of inputs ESD capability IEC 61000-4-2 (ESD) ± 30 kV (air), ± 30 kV (contact) Voltage range 0 ~ 5 V Maximum voltage range -0.5 ~ 5.5 V Maximum recommended working 1 kHz frequency 1st order filter cutting frequency (-3dB)

-

Page 67: Analog Halls Interface

7.4.2 Analog Halls interface The Triton Go Servo Drive can operate with analog Hall sensors (also known as linear halls) as feedback option. Signals provided by these sensors are typically 5 V peak-to-peak sinusoidal signals, with 2.5 V offset and a phase... - Page 68 Triton Go Product Manual | Wiring and Connections shift of 120 degrees. These sensors can be used for a fine positioning of the rotor. Triton Go analog halls inputs main features are shown in next table: Specification Value Type of inputs Non-isolated...

-

Page 69: Digital Incremental Encoder

Triton Go Product Manual | Wiring and Connections 7.4.3 Digital Incremental Encoder Triton Go can use single ended or differential digital incremental encoder inputs (also known as quadrature incremental encoders) for velocity and/or position control, as well as commutation sensor. The encoder provides incremental position feedback that can be extrapolated into precise velocity or position information. - Page 70 Digital encoders are especially useful in applications where low-speed smoothness is the objective. The Triton Go Servo Drive has one differential digital encoder interface, with optional index signal input. Index (Z) is a single pulse per revolution signal that indicates an absolute position. Next table lists digital encoder inputs main features. ...

- Page 71 Triton Go Product Manual | Wiring and Connections Next figure shows the circuit model of the digital encoder inputs. INGENIA | 05/29/2017...

-

Page 72: Digital Encoders With Single Ended 24 V Outputs

Triton Go Servo Drive can also interface single ended digital encoders with output voltages higher than 5 V, for instance 24 V PLC level encoder. With the use of series connected limiting resistors, Triton Go is able to read encoder counts correctly while the inputs are correctly protected. - Page 73 Input impedance 220 Ω resistive differential. 100 pF capacitive. 1 kΩ to GND Resolution 10 bits Next figure shows how to connect a Sin-Cos encoder to Triton Go Servo Drive. Refer to Feedback wiring recommendations for more information about connections and wires. ...

-

Page 74: Absolute Encoder Interface

Triton Go Product Manual | Wiring and Connections 7.4.5 Absolute encoder interface The Triton Go has an Absolute encoder connector that can be used as position and velocity feedback element. This sensor generates digital data that represent the encoder actual position. From the position information, speed and direction of motion is calculated. The position is not lost even if the encoder is powered down, this means it is not necessary to move to a reference position as with incremental type encoders. -

Page 75: Digital Input Feedback - Pwm Encoder

7.4.6 Digital input feedback - PWM encoder Triton Go Servo Drive can also use a PWM encoder connected through the I/O and LEDs connector as a feedback element. A PWM encoder provides a Pulse Width Modulated (PWM) signal with a duty cycle proportional to the angle (position) of the rotor. This feedback can be interfaced through the high-speed digital input 1 (HS_GPI1). - Page 76 Both differential and single-ended PWM encoders can be used. Further specifications about the PWM input can be found in I/O connection section (see page 79) Next figure illustrates PWM feedback input for different rotor positions: Next figures illustrates how to connect differential and single ended PWM encoders to the Triton Go Servo Drive: INGENIA | 05/29/2017...

-

Page 77: Analog Input Feedback

Triton Go Servo Drive can also use analog feedback systems connected through the I/O connector. From the voltage level of one analog input, the position or velocity of the rotor can be calculated. The Triton Go have 2 analog inputs that can be used for feedback input, each one with a different input range. The input used as feedback can be selected by software. Further specifications about the analog inputs input can be found... -

Page 78: Dc Tachometer

The Triton Go Servo Drive can use a DC tachometer for velocity feedback through the I/O connector. a DC tachometer provides an analog signal whose voltage level is proportional to the rotor speed. Next figure illustrates how to connect a DC tachometer with differential output to the Triton Go Servo Drive. 7.4.8 Feedback wiring recommendations Signal distortion and electrical noise is a common problem in feedback signals. -

Page 79: I/O Connections

(see page 87) • 4 x 5 V non-isolated digital outputs (GPO1, GPO2, GPO3, GPO4). (see page 90) Apart from the general purpose inputs, Triton Go has a dedicated analog input for measuring the motor temperature . (see page 95) ... - Page 80 Triton Go Product Manual | Wiring and Connections Specification Value Number of inputs 4 (GPI1, GPI2, GPI3, GPI4) Type of input Single ended. Low-pass filtered. ESD protected ESD capability IEC 61000-4-2 (ESD) ± 30 kV (air), ± 30 kV (contact) Input current 0.17 mA @ 5 V; 1 mA @ 15 V High level input voltage 4 V <...

- Page 81 Non-isolated I/O Triton Go Inputs and outputs are not isolated. The ground of the Triton Go Servo Drive and the ground of the devices connected to I/Os must be the same. Otherwise inputs or outputs may be damaged. Triton Go Servo Drive general purpose inputs can be used for connecting three-wire sensors. Next figures illustrate the connection of PNP and NPN three-wire sensors in input GPI1 (same wiring can be used for GPI2, GPI3 and GPI4).

-

Page 82: High-Speed Digital Inputs Interface (Hs_Gpi1, Hs_Gpi2)

The high-speed (HS) non-isolated digital inputs are ready for 5 V levels but are 24 V tolerant. Next table show their electrical specifications. Defect logic value Triton Go high-speed inputs are default low-level (OFF). When no signal or load is connected, the board will detect a logic low. Specification Value... - Page 83 Triton Go Product Manual | Wiring and Connections Input current 0.17 mA @ 5 V; 0.5 mA @ 15 V High level input voltage (HS_GPI+ - HS_GPI-) > 150 mV Low level input voltage (HS_GPI+ - HS_GPI-) < -600 mV Maximum working input voltage ±24 V...

- Page 84 Non-isolated I/O Triton Go Inputs and outputs are not isolated. The ground of the Triton Go Servo Drive and the ground of the devices connected to I/Os must be the same. Otherwise inputs or outputs may be damaged. Next figures illustrate how to connect high-speed differential and single ended signals to HS_GPI1 (same wiring can be used for HS_GPI2).

- Page 85 Triton Go Product Manual | Wiring and Connections Triton Go Servo Drive high-speed digital inputs can be used for connecting three-wire sensors. Next figures illustrate the connection of PNP and NPN three-wire sensors in input HS_GPI1 (Same wiring can be used for HS_GPI2). Pin 16 (+5V_OUT) can be used as a supply source.

- Page 86 Triton Go Product Manual | Wiring and Connections HS_GPI pull-up resistors Pull-up resistors ensure the desired logic state when the sensor (transistor or relay) is in off-state. NPN pull-up resistor value must be chosen in order to ensure a positive value in the differential receiver while consuming low current.

-

Page 87: Analog Inputs Interface (An_In1, An_In2)

7.5.3 Analog inputs interface (AN_IN1, AN_IN2) Triton Go Servo Drive has two 12-bit analog inputs, a single ended one (AN_IN1) and a differential one (AN_IN2). Each one of them has a different input voltage range. Next table summarizes the main features of the analog... - Page 88 Triton Go Inputs and outputs are not isolated. The ground of the Triton Go Servo Drive and the ground of the devices connected to I/Os must be the same. Otherwise inputs or outputs may be damaged. Next figure illustrates how to connect an analog single ended source to the Triton Go Servo Drive analog input 1. INGENIA | 05/29/2017...

- Page 89 Triton Go Product Manual | Wiring and Connections Next figure shows how to interface differential and single ended voltage sources to the differential analog input 2. The differential analog input is typically used as a command source or feedback signal. INGENIA | 05/29/2017...

-

Page 90: Digital Outputs Interface (Gpo1, Gpo2,Gpo3,Gpo4)

7.5.4 Digital outputs interface (GPO1, GPO2,GPO3,GPO4) Triton Go Servo Drive has four digital non-isolated outputs. Digital outputs are based on an open drain MOSFET with a weak pull-up to 5 V, and are 24 V tolerant and short-circuit protected. Next table shows their main... -

Page 91: Wiring Of 5V Loads

Non-isolated I/O Triton Go Inputs and outputs are not isolated. The ground of the Triton Go Servo Drive and the ground of the devices connected to I/Os must be the same. Otherwise inputs or outputs may be damaged. Wiring of 5V loads Loads that require 5V as high-level voltage can be connected directly to the digital output. -

Page 92: Wiring Of 24V Loads

Triton Go Product Manual | Wiring and Connections Wiring of 24V loads Loads that require 24V as high-level voltage can also be interfaced with GPO. For this option, an external power supply is needed. The load can be connected with a pull-up to 24V or directly switched with the GPO. Next figures show two example connections to GPO1 (same wiring could be used for GPO2, GPO3 or GPO4). ... - Page 93 Triton Go Product Manual | Wiring and Connections Interfacing inductive loads The switching of inductive loads (like relays or motor brakes) can cause inductive kicking, that is a sudden voltage rise when the current through the inductor is falls to zero. In order to avoid this voltage rise, it is recommended to place a diode in anti-parallel with the load (known as freewheeling...

-

Page 94: Motor Brake Output (Gpo1, Gpo2, Gpo3, Gpo4)

Electromechanical brakes are needed in critical applications where the disconnection of the motor or a lack of electric braking could be dangerous or harmful (i.e. falling suspended loads). Triton Go Servo Drive can use the digital outputs (GPO1, GPO2, GPO3 and GPO4) as a brake output. This output consists on an open drain MOSFET (1 A and 24 V). -

Page 95: Motor Temperature Input (Motor_Temp)

7.5.6 Motor temperature input (MOTOR_TEMP) The Triton Go has a dedicated analog input for measuring the motor temperature, which can be found in the Halls, motor temperature and analog feedback connector. The motor temperature input is... -

Page 96: Command Sources

800 Hz 7.6 Command sources The target or command sources are used for setting a reference for position, velocity or torque controllers. Triton Go Servo Drive supports the following command sources: • Network communication interface (USB, CANOpen, RS-485 or EtherCAT) (see page 97) •... -

Page 97: Network Communication Interface

Lab suite, the user can configure and save instructions to this 1 Mb (128K x 8bit) EEPROM, allowing Triton Go Servo Drive to work in standalone mode. In this mode, there is no need of any external command source. Programs or macros composed with Motion Lab suite allow to configure position, velocity or torque targets and to interface with general purpose inputs and outputs. -

Page 98: Analog Input

Position, velocity or torque targets can also be controlled trough an analog signal. Any general purpose analog input can be used as command source. Triton Go Servo Drive has two 12-bit analog inputs, a single ended one with 0 V to 5 V range (AN_IN1) and a differential one with +/-10 V range (AN_IN2). Refer to... -

Page 99: Step And Direction

HS_GPI2 is used for Direction input. Refer to I/O Connections for further specifications about high- (see page 79) speed digital inputs. Next figures illustrate how to connect a single ended and differential step and direction command source to the Triton Go Servo Drive. INGENIA | 05/29/2017... -

Page 100: Pwm Command

Triton Go Product Manual | Wiring and Connections 7.6.5 PWM command PWM command source sets a position, velocity or torque target from the duty cycle value of a PWM signal. PWM command has to be interfaced with the high-speed digital input 2 (HS_GPI2). Further details about this input can be seen in I/O Connections... -

Page 101: Single Input Mode

Triton Go Product Manual | Wiring and Connections Single input mode Single input mode is based o the use of a PWM signal whose duty cycle sets the target position, velocity or torque. A duty cycle of 50% corresponds with a target of 0 rad, 0 rpm or 0 N·m, and higher or lower values indicate the target in a different rotating direction. -

Page 102: Dual Input Mode

Triton Go Product Manual | Wiring and Connections Dual input mode Dual input mode uses two signal lines, a PWM signal whose duty cycle sets the target position, velocity or torque, and a Direction signal that indicates the rotation direction (i.e., logic low or "0" for clockwise rotation and logic high or "1"... -

Page 103: Encoder Following Or Electronic Gearing

Encoder following command source is used tor drive two motors to the same position. The encoder (or an auxiliary encoder) of the master motor is read by the Triton Go Servo Drive and used as position target. A gearing ratio between the motors (input counts to output counts ratio) can be configured via software. -

Page 104: Communications

CANopen and another communication interface can be used simultaneously. 7.7.1 USB interface Triton Go Servo Drive supports Universal Serial Bus (USB), a standard interface for connecting peripheral devices to a host computer. The following table shows main USB interface specifications: Specification... -

Page 105: Usb Powered Drive

• Use shielded cable with the shield connected to PC end. Shield of micro USB connector is not connected on Triton Go. • Do not rely on an earthed PC to provide the Triton Go Servo Drive earth connection. The drive must be earthed through a separate circuit. - Page 106 Supported Termination resistor 120 Ω termination resistor on RX channel Next figure illustrates how to connect Triton Go Servo Drive with a host in a point to point configuration. Termination resistor The use of termination resistors at the RX side of each differential pair (120 Ω between RX+ and RX- of both host and slave) is essential for correct operation of the RS485 communication. For long cable...

-

Page 107: Multi-Point Connection Using Daisy Chain

Ω termination resistor in the RX side is required. For long distances (> 10 m) it is required in RX and TX sides. Triton Go includes a termination on the RX line (activated through a jumper) allowing direct daisy chain wiring for short links. -

Page 108: Canopen Interface

Triton Go it is not needed to connect CAN connector GND again, as this could cause ground loop issues. Since Triton Go has two CAN connectors, wiring from previous device and to next device can be done using different connectors (CAN IN and CAN OUT). Pins 2, 3 and 4 of those connectors are connected pin-to-pin. - Page 109 GND line in CAN devices is used for equaling potential between master and slaves, but is not used for data transmission, as the line is fully differential. For this reason, if the host device shares supply GND with Triton Go it is not needed to connect CAN connector GND again, as this could cause ground loop issues.

-

Page 110: Can Interface For Pc

CAN interface for PC Ingenia Motion Lab suite is able to communicate with the Triton Go Servo Drive through CANopen interface. For this purpose, a CAN transceiver for PC is required. Motion Lab is compatible with the following CAN transceivers: Kvaser, Peak-System, IXXAT, Vector and Lawicel. -

Page 111: Ethercat Interface

Triton Go Product Manual | Wiring and Connections 7.7.4 EtherCAT interface Triton Go Servo Drive with EtherCAT (TRI-x/xx-E-C) variant provides access to the EtherCAT fieldbus system. EtherCAT is an isolated bus suitable for hard and soft real-time requirements in automation technology, test and measurement and many other applications. ... -

Page 112: Safe Torque Off (Sto)

The Triton Go STO works with negative logic, deactivating the power stage by default. In order to activate the power stage, and therefore allow the motor operation, two differential inputs must energized. These inputs activate two optocouplers connected in series that enable the Triton Go power stage operation. - Page 113 Triton Go Product Manual | Wiring and Connections STO firmware notification An STO stop is notified to the control DSP and creates a fault that can be read externally, however its performance is totally independent from control or firmware. When the STO is not connected it is virtually impossible to apply power to the drive.

- Page 114 Triton Go Product Manual | Wiring and Connections Overriding STO In applications where the STO will not be used, this function can be disabled with the use of three standard 2 mm jumpers. The connection of pins 1-2, 3-4 and 5-6 will activate the optocouplers and enable the power stage operation.

-

Page 115: Dimensions

The Triton Go Servo Drive is available in 2 versions with different dimensions: TRI-x/48-C-C (Triton Go with CAN) and TRI-x/48-C-E (Triton Go with EtherCAT). Both have a 43 mm x 45 mm footprint, 23.5 mm height and 4 x Ø 3.3 mm holes in a 37 mm x 37 mm square for M3 screws mounting. -

Page 116: Triton Go With Ethercat (Tri-X/48-E-C)

3D model and PDF 3D for this variant. Note that the model is simplified: it does not show all the internal components, but does show the major volumes. 8.2 Triton Go with EtherCAT (TRI-x/48-E-C) All dimensions are in mm. All tolerances ≤ ±0.2 mm. http://ingeniamc.com/support/triton... - Page 117 Triton Go Product Manual | Dimensions 3D Model For further detail, download the STEP 3D model and PDF 3D for this variant. Note that the model is simplified: it does not show all the internal components, but does show the major volumes. http://ingeniamc.com/support/triton...

-

Page 118: Application Software

Before configuring your drive for a new application make sure you have upgraded to the latest firmware revision. Applications If you want to make your own application to communicate with the Triton Go and develop standalone or multiaxis systems you can use the multi-platform library MCLIB Arduino To start an Arduino based project easily, connect using the serial... -

Page 119: Service

GIZATECH www.gizatech.eu/ comercial@milexia.es ANTRIMON MOTION Switzerland www.antrimon.com motion@antrimon.com Turkey FEMSAN www.femsan.com melike@femsan.com United MOTION CONTROL Kingdom PRODUCTS www.motioncontrolproducts.com info@motioncontrolproducts.com United States NAMPRO www.namproinc.com sales@namproinc.com United States GROUP SIX www.grp6.com ingenia@grp6.com INGENIA-CAT S.L. 8-14 MARIE CURIE, ADVANCED INDUSTRY PARK 08042 BARCELONA...

Need help?

Do you have a question about the Triton Go and is the answer not in the manual?

Questions and answers