Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for INGENIA Jupiter JUP-20/80

- Page 1 Installation Guide Author: INGENIA MOTION CONTROL Type: Report Space: i033-01-Jupiter Servo Drive Date: 09-Sep-2015 17:31 URL: http://doc.ingeniamc.com/display/JUP/Installation+Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 2: Table Of Contents

Dynamic applications with non constant current _____________________________________________________________________________ 29 Architecture ________________________________________________________________________________________________________________ 30 Hardware revisions __________________________________________________________________________________________________________ 32 Specifications ______________________________________________________________________________________________________________ 33 Power and current ratings _____________________________________________________________________________________________________ 38 6.7.1 Jupiter power specifications _____________________________________________________________________________________________ 39 Architecture ________________________________________________________________________________________________________________ 49 INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 3 STO connector ______________________________________________________________________________________________________ 82 7.2.21 Motor safety connector ________________________________________________________________________________________________ 83 7.2.22 USB connector ______________________________________________________________________________________________________ 84 Mating connectors ___________________________________________________________________________________________________________ 85 7.3.1 CAN interface mating connector _________________________________________________________________________________________ 85 7.3.2 Feedbacks mating connectors ___________________________________________________________________________________________ 87 INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 4 8.2.4 External Shunt resistor ________________________________________________________________________________________________ 122 8.2.5 MOTOR WIRING RECOMMENDATIONS _________________________________________________________________________________ 135 8.2.6 AC and DC Brushless motors __________________________________________________________________________________________ 138 8.2.7 DC motors and voice coil actuators ______________________________________________________________________________________ 139 INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 5 Step and direction ___________________________________________________________________________________________________ 260 8.5.6 PWM command _____________________________________________________________________________________________________ 262 8.5.7 Encoder following or Electronig gearing __________________________________________________________________________________ 267 8.5.8 Network interface ____________________________________________________________________________________________________ 269 8.5.9 Standalone _________________________________________________________________________________________________________ 270 8.5.10 Analog input _______________________________________________________________________________________________________ 270 INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 6 RS232 interface _____________________________________________________________________________________________________ 286 8.6.4 RS485 interface _____________________________________________________________________________________________________ 291 9 Dimensions ___________________________________________________________________________________________________________________ 295 JUP-20/80 ________________________________________________________________________________________________________________ 295 JUP-50/80 ________________________________________________________________________________________________________________ 299 JUP-15/130 _______________________________________________________________________________________________________________ 301 JUP-35/130 _______________________________________________________________________________________________________________ 303 EtherCAT version __________________________________________________________________________________________________________ 305 INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 7: Contents

Hardware revisions 1.3 Installation Installing the USB Driver Connectors position and pinout Mating connectors Signalling LEDs 1.4 Wiring and Connections Power supply wiring Motor output wiring Feedback connections IO connections INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 8: Dimensions

Installation Guide Command sources Communications 1.5 Dimensions INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 9: Revision History

Installation Guide 2 Revision History Revision Release Date Changes May 2015 Private preliminary draft. Not for public use. September 2015 First public manual. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 10: Preliminary Notes

3 Preliminary notes A PDF version of this manual is available in the Downloads section. Please refer to product hardware revisions page for information on previous hardware revisions and changes. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 11: Disclaimers And Limitations Of Liability

INGENIA-CAT rejects all liability for errors or omissions in the information or the product or in other documents mentioned in this document. INGENIA-CAT shall in no event be liable for any incidental, accidental, indirect or consequential damages (including but not limited to those resulting from: (1) -

Page 12: Safety Information

Some components become electrically charged during and after operation. Expect voltages > 100 V that could be lethal. The power supply connected to this controller should comply with the parameters specified in this document. INGENIA MOTION CONTROL Confidential and proprietary information. - Page 13 Do not make any connections to any internal circuitry. Only connections to designated connectors are allowed. All service and maintenance must be performed by qualified personnel. Before turning on the Jupiter Servo Drive, check that all safety precautions have been followed, as well as the installation procedures. INGENIA MOTION CONTROL Confidential and proprietary information. Page...

-

Page 14: Product Description

(LEDs, actuators, solenoids, etc.). Some of the digital and analog inputs can also be used as command / target sources. Jupiter includes many protections to ensure its safe operation and easy integration. INGENIA MOTION CONTROL Confidential and proprietary information. Page... -

Page 15: Specifications

6.1 Specifications Each Ingenia Digital Servo Drive has a separate datasheet that contains important information on the options and productspecific features available with that particular drive. The datasheet is to be used in conjunction with this manual for system design and installation. - Page 16 Sensors for commutation Digital halls (Trapezoidal) (brushless motors) Analog halls (Sinusoidal / Trapezoidal) Quad. Incremental encoder (Sinusoidal / Trapezoidal) PWM encoder (Sinusoidal / Trapezoidal) Analog potentiometer (Sinusoidal / Trapezoidal) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 17 1 x 0 V... 5 V single ended analog input (12 bits). AN_IN1. 2 x Open open drain digital outputs with a weak pull-up to 5 V. (1 A short-circuit and over-current rugged) INGENIA MOTION CONTROL Confidential and proprietary information.

- Page 18 -40 ºC to +50 ºC full current (operating) +50 ºC to +100 ºC current derating (operating) -50 ºC to -40ºC and 100ºC to +125 ºC (non-operating) Maximum humidity 5% - 85% (non-condensing) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 19: Power Ratings

Driver safety is always ensured by its protections. However, power losses and temperature limit the allowable motor current. Future versions of firmware will allow an automatic current foldback based on temperature. This means the current will be reduced before an overtemperature occurs. Stay tuned for upgrades! INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 20 Do not touch the Jupiter when operating and wait at least 5 minutes after turn off to allow a safe cool down. Following figure shows the basic power flow and losses in a servo drive system. INGENIA MOTION CONTROL Confidential and proprietary information. Page...

-

Page 21: Jupiter Power Specifications

Other less relevant parameters affect also the power loss but are not considered in the graphs: Air temperature, higher power semiconductor temperatures reduce their efficiency. Motor speed. Faster motor speeds result in higher overall power loss since the input current is greater. INGENIA MOTION CONTROL Confidential and proprietary information. Page... - Page 22 Installation Guide Graph 1: power loses versus motor current at different voltages for Jupiter 80V Graph 2: power loses versus motor current at different voltages for Jupiter 130V INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 23: Jupiter Without Cold Plate

T < 110ºC for safe operation. The thermal impedance typical value is shown above, hower its exact value will vary according to: Air flow around the driver. Position (vertical allows natural convection). INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 24 Installation Guide Graph 3: Maximum current ratings NO heatsink. Various Vbus voltages. 80V variant. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 25 Installation Guide Graph 4: Maximum current ratings NO heatsink. Various Vbus voltages. 130V variant. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 26: Jupiter With Cold Plate, Choosing Appropriate Heatsink

6.3.2 Jupiter with cold plate, choosing appropriate heatsink If power dissipation is < 17 W. No heatsink is needed. When using high efficiency heatsinks or in enclosed spaces the equation can be simplified as follows. INGENIA MOTION CONTROL Confidential and proprietary information. Page... - Page 27 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 28 TYPICALLY The jupiter without cold plate is suitable when power dissipation is < 13 W. This indicates that the maximum current it can withstand at 50 ºC is 20 A at 80 V bus voltage. INGENIA MOTION CONTROL Confidential and proprietary information.

-

Page 29: Dynamic Applications With Non Constant Current

The Jupiter has a big thermal inertia that allows storing heat during short current pulses (exceeding nominal current) without causing an over temperature. This allows achieving high peak current ratings without need of additional heatsink. INGENIA MOTION CONTROL Confidential and proprietary information. -

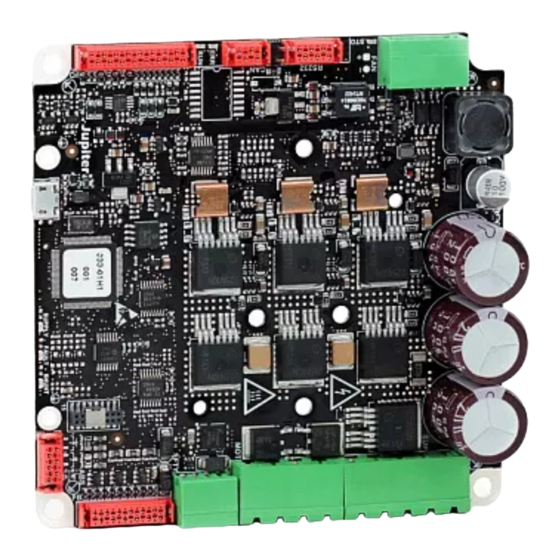

Page 30: Architecture

Instead of considering thermal resistances you should consider the thermal impedance. The Jupiter model can be simplified as a 2nd order. << Back to top 6.4 Architecture Following figure shows a simplified hardware architecture of the Jupiter. Links provide direct access to relevant pages. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 31 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 32: Hardware Revisions

Installation Guide << Back to top 6.5 Hardware revisions Hardware Description and changes revision* 1.0.1B First product demo. May 2015 INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 33: Specifications

6.6 Specifications Each Ingenia Digital Servo Drive has a separate datasheet that contains important information on the options and productspecific features available with that particular drive. The datasheet is to be used in conjunction with this manual for system design and installation. - Page 34 Rotary or linear brushless (trapezoidal and sinusoidal) DC brush Voice coil 2 phases bipolar stepper 3 phases stepper Power stage PWM frequency 20 kHz (default) 40 kHz (high PWM frequency, configurable INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 35 (Sinusoidal / Trapezoidal) Analog potentiometer (Sinusoidal / Trapezoidal) Sensors supported for servo DC tachometer loops Digital halls Analog halls Quad. Incremental encode PWM encoder Analog potentiometer Sin-Cos encoder Absolute encoder INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 36 1 x 0 V... 5 V single ended analog input (12 bits). AN_IN1. 2 x Open open drain digital outputs with a weak pull-up to 5 V. (1 A short-circuit and over-current rugged) INGENIA MOTION CONTROL Confidential and proprietary information.

- Page 37 -40 ºC to +50 ºC full current (operating) +50 ºC to +100 ºC current derating (operating) -50 ºC to -40ºC and 100ºC to +125 ºC (non-operating) Maximum humidity 5% - 85% (non-condensing) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 38: Power And Current Ratings

Some parts of the Jupiter exceed 110ºC when operating, especially at high load levels. Do not touch the Jupiter when operating and wait at least 5 minutes after turn off to allow a safe cool down. INGENIA MOTION CONTROL Confidential and proprietary information. Page... -

Page 39: Jupiter Power Specifications

/ no heatsink 16.7 W Thermal resistance from power stage to heatsink (cold plate version) 3.6 K/W Thermal time constant 3000 s?? Temperature stabilization is found after ~ 3 τ INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 40 Air temperature, higher power semiconductor temperatures reduce their efficiency. Motor speed. Faster motor speeds result in higher overall power loss since the input current is greater. Graph 1: power loses versus motor current at different voltages for Jupiter 80V INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 41 Installation Guide Graph 2: power loses versus motor current at different voltages for Jupiter 130V INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 42 T < 110ºC for safe operation. The thermal impedance typical value is shown above, hower its exact value will vary according to: Air flow around the driver. Position (vertical allows natural convection). INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 43 Installation Guide Graph 3: Maximum current ratings NO heatsink. Various Vbus voltages. 80V variant. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 44 Installation Guide Graph 4: Maximum current ratings NO heatsink. Various Vbus voltages. 130V variant. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 45 Jupiter with cold plate, choosing appropriate heatsink If power dissipation is < 17 W. No heatsink is needed. When using high efficiency heatsinks or in enclosed spaces the equation can be simplified as follows. INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 46 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 47 TYPICALLY The jupiter without cold plate is suitable when power dissipation is < 13 W. This indicates that the maximum current it can withstand at 50 ºC is 20 A at 80 V bus voltage. INGENIA MOTION CONTROL Confidential and proprietary information.

- Page 48 The Jupiter has a big thermal inertia that allows storing heat during short current pulses (exceeding nominal current) without causing an over temperature. This allows achieving high peak current ratings without need of additional heatsink. INGENIA MOTION CONTROL Confidential and proprietary information.

-

Page 49: Architecture

Instead of considering thermal resistances you should consider the thermal impedance. The Jupiter model can be simplified as a 2nd order. 6.8 Architecture Following figure shows a simplified hardware architecture of the Jupiter. Links provide direct access to relevant pages. INGENIA MOTION CONTROL Confidential and proprietary information. Page... - Page 50 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 51: Hardware Revisions

Installation Guide 6.9 Hardware revisions Hardware Description and changes revision* 1.0.1B First product demo. May 2015 INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 52 JUP-74 Manufacturing improvements [ JUP-23 JUP-28 JUP-52 JUP-67 JUP-68 JUP-69 JUP-22 JUP-25 JUP-27 JUP-30 JUP-45 JUP- 47 JUP-54 JUP-84 Add new INGENIA Logo [ JUP-85 *Hardware revision is screen printed on the board. INGENIA MOTION CONTROL Confidential and proprietary information.

-

Page 53: Installation

Before you connect your Jupiter Servo Drive to a computer running Microsoft Windows, you should install its drivers: Download the USB driver Win XP, VISTA, W7 and W8. Open the .ZIP archive and extract the files in a folder. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 54 "Update Driver Software". After installing the drivers, if you go to your computer’s Device Manager and expand the “Ports (COM & LPT)” list, you should see the Ingenia USB driver installed: INGENIA MOTION CONTROL Confidential and proprietary information.

-

Page 55: Windows 8 Installation

“A digitally signed driver is required” and “The driver installation failed” are a few of the error prompts you may have come across when attempting to install the drivers on Windows 8. Follow these steps to install the USB driver. Bring up the Charms Bar , and click Settings INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 56 , and scroll to the bottom of the page, click the Restart Now button under the Advanced Startup section. The computer will reboot: Go to Troubleshoot > Advanced Options > Startup Settings and click Restart INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 57: Connectors Position And Pinout

CAN interface connector Feedbacks connector Absolute encoder connector I/O connector RS232 interface connector Supply and shunt connector Supply, shunt and motor connector Motor connector STO connector Motor safety connector INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 58 Installation Guide USB connector Next figures show Jupiter Servo Drive connectors. Connector functionalities and pinouts are described in detail in the next subchapters. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 59 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 60: Can Interface Connector

. Polarization hole on PCB indicates pin 1 and ensures correct mating connector position. Pin numbers and pinout are shown below. Name Description CAN_GND CAN ground (connected to circuit ground) CANL CAN bus line dominant low INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 61: Feedbacks Connector

Description +5V_OUT 5 V @ 250mA supply for feedbacks Ground connection ENC_A+ / SIN+ Single ended digital encoder: A input Differential digital encoder: A+ input Sin-Cos encoder: Sin+ input INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 62 Analog Halls: B input Digital Halls: B input HALL_3 Analog Halls: C input Digital Halls: C input The connector pinout is identical as in Pluto Servo drive. See: Cable Kit Manual INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 63: Absolute Encoder Connector

. Polarization hole on PCB indicates pin 1 and ensures correct cable position. Pin numbers and connector pinout are shown below: Name Description +5V_OUT +5 V @ 250 mA supply Ground connection CLK+ Absolute encoder CLK positive signal input INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 64: I/O Connector

Pin numbers and connector's pinout are shown below. Name Description HS_GPI2+ / DIR+ High speed digital differential input 2+ Command source: Direction+ input HS_GPI2- / DIR- High speed digital differential input 2- Command source: Direction- input INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 65 Low speed digital single ended input 2 (Could be safe torque off input on request, please contact us) LS_GPI1 Low speed digital single ended input 1 +5V_EXT +5V 200mA max output (shared with feedback connector) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 66: Rs232 Interface Connector

. Polarization hole on PCB indicates pin 1 and ensures correct cable position. Pin numbers and connector pinout are shown below: Name Description RETURN_TX Daisy chain TX return line, connected to pin 6 INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 67: Supply And Shunt Connector

691313710005 . See Power supply wiring for power wiring information. Pin numbers and connectors pinout are shown below. Name Description SHUNT_OUT Shunt output POW_SUP Power supply input Ground connection INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 68: Supply, Shunt And Motor Connector

Motor phase A connection (+ in DC motors) PH_B Motor phase B connection (- in DC motors) PH_C Motor phase C connection (not connected in DC motors) SHUNT_OUT Shunt output POW_SUP Power supply input INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 69: Motor Connector

Motor phase A connection (+ in DC motors) PH_B Motor phase B connection (- in DC motors) PH_C Motor phase C connection (not connected in DC motors) Protective Earth connection INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 70: Sto Connector

Pin numbers and pinout are shown below. Name Description STO1+ STO1 positive input STO1- STO1 negative input STO2+ STO2 positive input STO2- STO2 negative input STO_SUP Positive supply for STO Negative supply for STO INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 71: Motor Safety Connector

Pin numbers and pinout are shown below. Name Description EXT_TEMP External temperature sensor input Ground connection BRAKE- Brake negative output BRAKE+ Brake positive output << Back to top 7.2.11 USB connector INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 72 Ground SHIELD Not Connected (Connector metallic shield) USB drivers Please install the USB drivers before connecting the Neptune, see Installing USB driver on Windows 8/8.1 << Back to top INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 73: Can Interface Connector

Pin numbers and pinout are shown below. Name Description CAN_GND CAN ground (connected to circuit ground) CANL CAN bus line dominant low CANH CAN bus line dominant high CAN_GND CAN ground (connected to circuit ground) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 74: Feedbacks Connector

ENC_A+ / SIN+ Single ended digital encoder: A input Differential digital encoder: A+ input Sin-Cos encoder: Sin+ input ENC_A- / SIN- Differential Encoder: A- input Sin-Cos encoder: Sin- input INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 75 The connector pinout is identical as in Pluto Servo drive. See: Cable Kit Manual Feedback connector pinout is shared with Pluto Neptune servo drives, which allows using the IO starter kit with Jupiter. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 76: Absolute Encoder Connector

Ground connection CLK+ Absolute encoder CLK positive signal input CLK- Absolute encoder CLK negative signal input DATA+ Absolute encoder DATA positive signal input DATA- Absolute encoder DATA negative signal input INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 77: Io Connector

High speed digital differential input 2+ Command source: Direction+ input HS_GPI2- / DIR- High speed digital differential input 2- Command source: Direction- input Ground GPO2 Digital output 2 GPO1 Digital output 1 Ground INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 78 Low speed digital single ended input 1 +5V_EXT +5V 200mA max output (shared with feedback connector) The connector pinout is identical as in Pluto Servo drive. See: Cable Kit Manual INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 79: Rs232 Interface Connector

Common (internally connected to driver GND) RS232 receive data (should be connected to master TX) RS232 transmit data (should be connected to master RX) Common (internally connected to driver GND) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 80: Supply And Shunt Connector

Pin numbers and connectors pinout are shown below. Name Description SHUNT_OUT Shunt output POW_SUP Power supply input Ground connection LOGIC_SUP Logic supply input Protective Earth INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 81: High Current Connector

Motor phase B connection (- in DC motors) PH_C Motor phase C connection (not connected in DC motors) SHUNT_OUT Shunt output POW_SUP Power supply input Ground connection LOGIC_SUP Logic supply input Protective Earth INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 82: Motor Connector

The Safe Torque Off (STO) connector is a 6 pin Phoenix connector. Part number 1881480 . A notch in the connector indicates pin 1 and ensures correct mating connector position. Pin numbers and pinout are shown below. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 83: Motor Safety Connector

The Motor safety connector is a 4 pin Phoenix connector. Part number 1881464 . A notch in the connector indicates pin 1 and ensures correct mating connector position. Pin numbers and pinout are shown below. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 84: Usb Connector

Neptune includes a 5 pin micro-USB connector for USB interface. This allows easy access to the driver configuration using MotionLab or downloading firmware upgrades . Please see USB interface page for further information. Pin numbers and standard pinout are shown below: Name Description INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 85: Mating Connectors

The easiest and lowest cost option is using a flat ribbon cable with 1.27 mm pitch. Manufacturer Manufacturer ID Farnell Digikey Mouser Connector TE Connectivity 215083-4 2399655 A107032TR-ND 571-215083-4 INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 86 The Jupiter CAN pinout allows an easy connection to the standard DB9 connector using a 4 way 1.27 pitch flat ribbon cable. Use a DB9 to ribbon connector like: H7MXH-0906M-ND or AMPHENOL L117DEFRA09S-ND. Corresponding pinouts: Jupiter Micro-Match DB9 standard to ribbon cable 1 (GND) 6 (GND) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 87: Feedbacks Mating Connectors

The easiest and lowest cost option is using a flat ribbon cable with 1.27 mm pitch. Please see Pluto feedbacks cable Manufacturer Manufacturer ID Farnell Digikey Mouser Connector TE Connectivity 8-215083-2 149093 A99460CT-ND 571-8-215083-2 Suggested cable 3302/16 300SF 1369751 MC16M-300-ND 517-C3302/16SF INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 88: Absolute Encoder Mating Connectors

7.3.3 Absolute encoder mating connectors For flat ribbon cable The easiest and lowest cost option is using a flat ribbon cable with 1.27 mm pitch. Manufacturer Manufacturer ID Farnell Digikey Mouser INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 89: I/O Mating Connectors

The easiest and lowest cost option is using a 16 way flat ribbon cable with 1.27 mm pitch. Please see Pluto feedbacks cable Manufacturer Manufacturer ID Farnell Digikey Mouser Connector TE Connectivity 8-215083-6 149147 A99458CT-ND 571-8-215083-6 Suggested cable 3302/16 300SF 1369751 MC16M-300-ND 517-C3302/16SF INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 90 TE Connectivity 1-338095-6 A99495-ND 571-1-338095-6 Crimp terminals TE Connectivity 1-338097-1 1291807 A99491CT-ND 571-1-338097-1 Suggested cable Use 0.2 ~ 0.5 mm² (20 ~24 AWG) flexible wires. << Back to top INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 91: Rs232 Mating Connectors

Mouser Connector TE Connectivity 338095-6 A99416-ND 571-338095-6 Crimp terminals TE Connectivity 1-338097-1 1291807 A99491CT-ND 571-1-338097-1 Suggested cable Use 0.2 ~ 0.5 mm² (20 ~24 AWG). << Back to top INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 92: Supply And Shunt Mating Connector

Wire gauges Dimension the wiring according to the application current ratings. Higher section is preferred to minimize resistance and wire self-heating. Recommended wire section is 1.5 mm² ~ 4 mm². INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 93: Motor Mating Connector

Wire gauges Dimension the wiring according to the application current ratings. Higher section is preferred to minimize resistance and wire self-heating. Recommended wire section is 1.5 mm² ~ 4 mm². INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 94: Sto Mating Connector

Wire gauges Dimension the wiring according to the application current ratings. Higher section is preferred to minimize resistance and wire self-heating. Recommended wire section is 0.14 mm² ~ 0.5 mm². INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 95: Motor Safety Mating Connector

Wire gauges Dimension the wiring according to the application current ratings. Higher section is preferred to minimize resistance and wire self-heating. Recommended wire section is 0.14 mm² ~ 0.5 mm². INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 96: Usb Mating Connector

Mouser Micro USB 2.0 cable assembly Molex 68784-0002 1617586 WM17146-ND 538-68784-0002 7.4 Signalling LEDs Jupiter Servo Drive has 4 signalling LEDs near the CAN interface connector and USB connector. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 97 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 98: Power And Motor Signalling Leds

The CANopen ERROR LED indicates the status of the CAN physical layer and errors due to missing CAN messages (sync, guard or heartbeat). Next table shows the CANopen ERROR LED truth table: INGENIA MOTION CONTROL Confidential and proprietary information. Page... - Page 99 The device is in state STOPPED Operational The device is in state OPERATIONAL See the description of the states next: State Description The LED is always on The LED is always off INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 100 Sequence of 3 short flashes (~200 ms), separated by an off phase (~200 ms). The sequence is finished by a long off phase (~1000 ms) Blinking On and off with a frequency of ~2.5 Hz: ON for ~200 ms followed by off for ~200 ms. << Back to top INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 101: Wiring And Connections

The Jupiter can be powered from USB for configuration purposes without the need of an external power supply. An internal switch automatically chooses the power source prioritizing the external supply. Please note that several functionalities will not be available when powered from USB. 8.1.1 Contents Recommended power supply connection Simplified battery supply connection INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 102: Recommended Power Supply Connection

The following picture shows the Jupiter versions JUP-20/80 and JUP-50/80 power supply connection diagram. These versions can be supplied using only the POW_SUP input or using separated power supplies for POW_SUP and SHUNT_OUT. It could be interesting to use this method to avoid loosing communication with the Jupiter in case of POW_SUP failure. INGENIA MOTION CONTROL Confidential and proprietary information. Page... - Page 103 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 104 The following picture shows the Jupiter versions JUP-15/130 and JUP-35/130 power supply connection diagram. For safety reasons, the power supply must always provide full galvanic isolation. << Back to top INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 105: Simplified Battery Supply Connection

Next figure shows a simplified wiring diagram for the Jupiter Standard version and High Current version power supply from a battery. Next figure shows a simplified wiring diagram for the Jupiter High Voltage version and High Current High Voltage version power supply from a battery. INGENIA MOTION CONTROL Confidential and proprietary information. -

Page 106: Connection Of Multiple Drivers

8.1.4 Connection of multiple drivers Always use "star" connections when different servo drivers are connected to the same power supply. Connect each drive to the common supply using separate wires for positive and return. INGENIA MOTION CONTROL Confidential and proprietary information. Page... -

Page 107: Power Supply Wiring Recommendations

Insulator size should not exceed 5 mm (connector pitch). Following table indicates recommended section: Connection Minimum wire size Maximum wire size INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 108 The distance between the Jupiter Servo Drive and the power supply should be minimized when possible. Short power cables are preferred. For best immunity use twisted cables for the DC power supply. INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 109 It is recommended to use wire ferrules to prevent cable damage or wrong contacts. Ensure crimped ferrule diameter does not exceed 2.5 mm and the insulator is < 5 mm. Following are some suggested ferrules: Manufacturer Part number Image Description INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 110: Recommended Power Supply Connection

The following picture shows the Jupiter versions JUP-20/80 and JUP-50/80 power supply connection diagram. These versions can be supplied using only the POW_SUP input or using separated power supplies for POW_SUP and SHUNT_OUT. It could be interesting to use this method to avoid loosing communication with the Jupiter in case of POW_SUP failure. INGENIA MOTION CONTROL Confidential and proprietary information. Page... - Page 111 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 112: Simplified Battery Supply Connection

For safety reasons, the power supply must always provide full galvanic isolation. 8.1.7 Simplified battery supply connection Next figure shows a simplified wiring diagram for the Jupiter Standard version and High Current version power supply from a battery. INGENIA MOTION CONTROL Confidential and proprietary information. Page... - Page 113 Installation Guide Next figure shows a simplified wiring diagram for the Jupiter High Voltage version and High Current High Voltage version power supply from a battery. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 114: Connection Of Multiple Drivers

8.1.8 Connection of multiple drivers Always use "star" connections when different servo drivers are connected to the same power supply. Connect each drive to the common supply using separate wires for positive and return. INGENIA MOTION CONTROL Confidential and proprietary information. Page... -

Page 115: Power Supply Wiring Recommendations

Insulator size should not exceed 5 mm (connector pitch). Following table indicates recommended section: Connection Minimum wire size Maximum wire size Stranded wire (preferred) 1.5 mm 4 mm (12 AWG) Solid wire 1.5 mm 4 mm (12 AWG) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 116 The distance between the Jupiter Servo Drive and the power supply should be minimized when possible. Short power cables are preferred. For best immunity use twisted cables for the DC power supply. INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 117 It is recommended to use wire ferrules to prevent cable damage or wrong contacts. Ensure crimped ferrule diameter does not exceed 2.5 mm and the insulator is < 5 mm. Following are some suggested ferrules: Manufacturer Part number Image Description INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 118: Motor Output Wiring

Typically the necessary values are around 100 μH. 8.2 Motor output wiring CONTENTS AC and DC Brushless motors DC motors and voice coil actuators Stepper motors External Shunt resistor Brake wiring External temperature sensor wiring INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 119: Ac And Dc Brushless Motors

Brushless motors should be connected to phases A, B and C pins. Note that some manufacturers may use different phase name conventions (see Table below). A motor choke with the three phases winded together is recommended to minimize potential noise issues. INGENIA MOTION CONTROL Confidential and proprietary information. -

Page 120: Dc Motors And Voice Coil Actuators

<< Back to top 8.2.2 DC motors and voice coil actuators DC motors and voice coil actuators are connected to phase A and phase B connections. Phase C output is left unconnected. INGENIA MOTION CONTROL Confidential and proprietary information. Page... -

Page 121: Stepper Motors

2 using this configuration since phase C shares the current of two phases. The connection of 3 phase bipolar stepper motors is identical to the one of the brushless motors INGENIA MOTION CONTROL Confidential and proprietary information. Page... -

Page 122: External Shunt Resistor

The external shunt resistor should be connected between SHUNT_OUT and POW_SUP pins of the Jupiter Supply and shunt connector It´s strongly recommended to use an external fuse to limit the maximum power dissipation according to the chosen shunt resistor. INGENIA MOTION CONTROL Confidential and proprietary information. Page... - Page 123 A shunt circuit prevents the bus voltage from rising too high and therefore protects the Drive and the power supply. It is based on a resistor (sometimes referred as braking resistor) that is connected between the DC bus and GND through a power transistor. INGENIA MOTION CONTROL Confidential and proprietary information.

- Page 124 User configured shunt PWM Duty Cycle Phase current during deceleration [A Motor phase resistance line to line [Ω] Mechanical parameters ω Motor angular velocity before deceleration [rad/s = rpm · 0.1047] INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 125 (E ) (eqn. 3) of the system before deceleration. If some parameters regarding system loses are not known, some terms may be cancelled in the formula, this may oversize the shunt resistor but is a safe approach. INGENIA MOTION CONTROL Confidential and proprietary information.

- Page 126 If a shunt resistor is necessary, the deceleration peak power P should be calculated using eqn. 5. D(PK) In systems with cyclic decelerations, the average deceleration power P should be determined using eqn. 6. D(PK) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 127 STO function will not be used. Next figure shows how to connect the STO input in two different ways: the self supplied option and the external supplied option. INGENIA MOTION CONTROL Confidential and proprietary information.

- Page 128 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 129 Installation Guide << Back to top Motor safety systems connection INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 130 (e.g. falling suspended loads). Jupiter Digital Servo Drive includes a brake output (1 A full temperature range) to that end. Next figure show how to connect a brake. Brake connection using the on board supply INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 131 GPO5 PWM duty cycle. Although effective brake voltage will be reduced by the PWM, ensure the brake withstands the peak voltage. Brake connection using an external power supply INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 132 User should verify that the application will be within the brake output specifications shown in next table. Specification Value Type of output N-Channel MOSFET ESD protection 1000 V (Human Body Model) 300 V (Machine Model) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 133 The real time required for mechanical braking will strongly depend on the brake model and its dynamic behavior. External temperature sensor wiring An external temperature sensor (PTC thermistor) can be connected to the Jupiter to measure the motor temperature. The following picture shows the recommended connection. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 134 Details The external temperature sensor input has the following electrical specifications. Specification Value Type of input Single ended ESD protection 1000 V (Human Body Model) 300 V (Machine Model) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 135: Motor Wiring Recommendations

It is recommended to use wire ferrules to prevent cable damage or wrong contacts. Ensure crimped ferrule diameter does not exceed 2.5 mm and the insulator is < 5 mm. Following are some suggested ferrules: INGENIA MOTION CONTROL Confidential and proprietary information. - Page 136 If this happens, the choke temperature would increase rapidly. Next table shows a choke that fits the Jupiter Servo Drive specifications. Type Manufacturer Reference Output Choke Emikon CH-1 INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 137 The distance between the Jupiter Servo Drive and the motor should be minimized when possible . Short cables are preferred since they reduce power losses as well as electromagnetic emissions and immunity. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 138: Ac And Dc Brushless Motors

Brushless motors should be connected to phases A, B and C pins. Note that some manufacturers may use different phase name conventions (see Table below). A motor choke with the three phases winded together is recommended to minimize potential noise issues. INGENIA MOTION CONTROL Confidential and proprietary information. -

Page 139: Dc Motors And Voice Coil Actuators

DC motors and voice coil actuators are connected to phase A and phase B connections. Phase C output is left unconnected. Use a motor choke with 2 turns of the phase wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page... -

Page 140: Stepper Motors

The connection of 3 phase bipolar stepper motors is identical to the one of the brushless motors Current ratings are divided by 2 when working with 2 phase bipolar stepper motors. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 141: External Shunt Resistor

It´s strongly recommended to use an external fuse to limit the maximum power dissipation according to the chosen shunt resistor. Shunt resistor connections should also be as short as possible to reduce parasitic inductances. Shunt resistor may have hot surfaces during operation. Shunt resistor overview and sizing INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 142 Turn on voltage for shunt circuit, user configured maximum Bus voltage [V] Hysteresis point of Bus voltage during deceleration cycles [V] Bus capacitance [F] >600 µF (Jupiter Internal) User configured shunt PWM Duty Cycle Phase current during deceleration [A INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 143 Net deceleration energy [J] Deceleration peak power [W] D(PK) Average deceleration power on a cyclic system [W] D(AV) Calculated shunt resistor [Ω] 5 to 200 Shunt resistor rated power [W] INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 144 If a shunt resistor is necessary, the deceleration peak power P should be calculated using eqn. 5. D(PK) In systems with cyclic decelerations, the average deceleration power P should be determined using eqn. 6. D(PK) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 145: Safe Torque Off Connection

STO function will not be used. Next figure shows how to connect the STO input in two different ways: the self supplied option and the external supplied option. INGENIA MOTION CONTROL Confidential and proprietary information. - Page 146 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 147: Motor Safety Systems Connection

(e.g. falling suspended loads). Jupiter Digital Servo Drive includes a brake output (1 A full temperature range) to that end. Next figure show how to connect a brake. INGENIA MOTION CONTROL Confidential and proprietary information. - Page 148 The brake nominal voltage is lower than the power supply voltage. In this case, the brake output voltage can be easily configured via the GPO5 PWM duty cycle. Although effective brake voltage will be reduced by the PWM, ensure the brake withstands the peak voltage. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 149 The Jupiter brake output can also be used as a general purpose high current digital output (GPO5). This can be easily configured using Motion Lab Brake details INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 150 Typical electrical Turn-On/Turn-Off time 80 µs / 500 µs Max. (resistive load) 5 ms / 10 ms (inductive load) Protection Overload and short circuit (maximum 10 s) Overvoltage Overtemperature INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 151 An external temperature sensor (PTC thermistor) can be connected to the Jupiter to measure the motor temperature. The following picture shows the recommended connection. The suggested PTC thermistor value is a 1 KΩ nominal resistance (@ 25 ªC) as Vishay PTC ( TFPTL10L1001FL2B INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 152: Motor Wiring Recommendations

. Short cables are preferred since they reduce power losses as well as electromagnetic emissions and immunity. Avoid running motor wires in parallel with other wires for long distances, especially feedback and signal wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page... - Page 153 It is recommended to use wire ferrules to prevent cable damage or wrong contacts. Ensure crimped ferrule diameter does not exceed 2.5 mm and the insulator is < 5 mm. Following are some suggested ferrules: Manufacturer Part number Image Description WAGO 216-206 2.5 mm (14 AWG) WAGO 216-224 1.5 mm (16 AWG) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 154 It is recommended to use wire ferrules to prevent cable damage or wrong contacts. Ensure crimped ferrule diameter does not exceed 2.5 mm and the insulator is < 5 mm. Following are some suggested ferrules: Manufacturer Part number Image Description INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 155: Feedback Connections

5 V @ 200 mA output for feedbacks supply. This output is overload and short circuit protected. Additional feedback connections can be found on I/O connector for PWM and Analog input feedback. Position feedback interfaces Velocity feedback interfaces Feedback wiring recommendations INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 156: Position Feedback Interfaces

Channel A and channel B signals should have a phase shift of 90 degrees. Based on the speed and the order of the pulse, the drive can calculate the motor velocity and position. Index signal (Z) is used to detect absolute rotor position. Example of single ended digital encoder inputs Example of digital differential encoder signals INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 157 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 158 IEC 61000-4-2 (ESD) ± 15 kV (air), ± 8 kV (contact) IEC 61000-4-4 (EFT) 40 A (5/50 ns) Nominal voltage range 0 ~ 5 V Maximum voltage range -0.5 ~ 5.5 V Maximum working frequency 10 MHz INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 159 Next figures illustrate how to connect a differential and a single ended encoder to the Jupiter Servo Drive. Refer to Feedback wiring recommendations for more information about connections and wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 160 Installation Guide Next figure shows the circuit model of the digital encoder inputs. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 161 Encoder broken wire detection For differential digital encoders only a broken wire detection circuit is included. The circuit is based on 3 EX-OR gates only works for differential encoders INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 162 Depending on the both signals amplitude, rotor position can be calculated. The signals may be generated by optical or magnetic means. For noise immunity the signals are typically transmitted differentially from the encoder to the sensor interface electronics. The signals are shown next: INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 163 An automatic calibration based on Lissajous curves is included in Motion lab , this allows adjusting the feedback easily. Next table summarizes analog encoder inputs main features. Specification Value INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 164 1 kΩ to GND Resolution 10 bits Next Figure shows how to connect a Sin-Cos encoder to Jupiter Servo Drive. Refer to Feedback wiring recommendations for more information about connections and wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 165 Installation Guide Circuit model for each differential channel (A, B, REF) is shown in the next figure. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 166 If power is lost, its output will be correct whenever power is restored. It is not necessary to move to a reference position as with incremental type encoders. Next table shows the absolute encoder inputs electrical specifications. Specification Value INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 167 2 (CLK and DATA) Nominal voltage range 0 ~ 5 V Maximum voltage range -13 ~ 16.5 V Next figures show the circuit model for the absolute encoder receiver. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 168 Installation Guide << Back to top INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 169 60º or 120º apart. Using these 3 signals, the drive is capable to detect the position, direction and velocity of the rotor. Next figures show examples of digital halls signals. Digital halls signals example (60º option) Digital halls signals example (120º option) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 170 Type of sensors Open collector Logic output Push-pull output Pull-up resistor value 1 kΩ (The pull-up is activated only when the driver is configured to use digital hall sensors) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 171 Next figure shows the circuit model of the digital Halls inputs. Next figure illustrates how to connect the digital halls to the Jupiter Servo Drive. Refer to Feedback wiring recommendations for more information about connections and wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 172 2.5 V offset and a phase shift of 120 degrees. These sensors can be used for a fine positioning of the rotor. Jupiter analog halls inputs main features are shown in next table: INGENIA MOTION CONTROL Confidential and proprietary information.

- Page 173 Digital Halls interface , to avoid any signal distortion, when analog halls interface is selected, the 1 kΩ pull-up is disconnected automatically. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 174 Installation Guide Next figure shows how to connect the linear Halls to the Jupiter Servo Drive. Refer to Feedback wiring recommendations for more information about connections and wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 175 Hall sensors wiring must be electrically isolated from motor, AC power and any other power wiring. << Back to top Analog input interface The included page could not be found. << Back to top INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 176 For this feedback interface the high speed digital input 1 is used (HS_GPI1). Next table summarizes main features of this input: Specification Value for 5 V input Number of inputs Type of input ESD protected. Differential ESD capability IEC 61000-4-2 (ESD) ± 12 kV (air), ± 6 kV (contact) INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 177 -24 V to 24 V Recommended frequency range 500 - 20000 Hz Minimum detectable pulse width 200 ns Next figure shows the circuit model for the PWM encoder input: INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 178 Installation Guide Next figure illustrates how to connect a PWM encoder to the Jupiter Servo Drive: INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 179 Installation Guide Single ended PWM encoders can also be connected to Jupiter Servo Drive. Next figure shows how to do it: INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 180 Jupiter can use single ended or differential encoder inputs for velocity and/or position control, as well as commutation sensor. The encoder provides incremental position feedback that can be extrapolated into precise velocity or position information. Using high resolution encoders allows Jupiter Servo Drive to use sinusoidal commutation. INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 181 Channel A and channel B signals should have a phase shift of 90 degrees. Based on the speed and the order of the pulse, the drive can calculate the motor velocity and position. Index signal (Z) is used to detect absolute rotor position. Example of single ended digital encoder inputs Example of digital differential encoder signals INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 182 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 183 IEC 61000-4-2 (ESD) ± 15 kV (air), ± 8 kV (contact) IEC 61000-4-4 (EFT) 40 A (5/50 ns) Nominal voltage range 0 ~ 5 V Maximum voltage range -0.5 ~ 5.5 V Maximum working frequency 10 MHz INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 184 Next figures illustrate how to connect a differential and a single ended encoder to the Jupiter Servo Drive. Refer to Feedback wiring recommendations for more information about connections and wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 185 Installation Guide Next figure shows the circuit model of the digital encoder inputs. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 186 Encoder broken wire detection For differential digital encoders only a broken wire detection circuit is included. The circuit is based on 3 EX-OR gates only works for differential encoders INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 187 For noise immunity the signals are typically transmitted differentially from the encoder to the sensor interface electronics. The signals are shown next: Typical signal Signal description INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 188 An automatic calibration based on Lissajous curves is included in Motion lab , this allows adjusting the feedback easily. Next table summarizes analog encoder inputs main features. Specification Value INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 189 1 kΩ to GND Resolution 10 bits Next Figure shows how to connect a Sin-Cos encoder to Jupiter Servo Drive. Refer to Feedback wiring recommendations for more information about connections and wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 190 Installation Guide Circuit model for each differential channel (A, B, REF) is shown in the next figure. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 191 If power is lost, its output will be correct whenever power is restored. It is not necessary to move to a reference position as with incremental type encoders. Next table shows the absolute encoder inputs electrical specifications. Specification Value INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 192 2 (CLK and DATA) Nominal voltage range 0 ~ 5 V Maximum voltage range -13 ~ 16.5 V Next figures show the circuit model for the absolute encoder receiver. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 193 The Hall sensors are Hall effect devices that are built into the motor to detect the position of the rotor magnetic field. Usually, motors include 3 hall sensors, spaced 60º or 120º apart. Using these 3 signals, the drive is capable to detect the position, direction and velocity of the rotor. Next figures show examples of digital halls signals. INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 194 This interface accepts 0-5 V level input signals. Inputs are pulled up to 5 V, so industry standard open collector and logic output hall effect sensors can be connected. Next table summarizes digital halls inputs main features: Specification Value INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 195 The 1 kΩ pull-up resistors are disconnected when Analog-halls input is selected to prevent the analog data corruption. Next figure shows the circuit model of the digital Halls inputs. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 196 Installation Guide Next figure illustrates how to connect the digital halls to the Jupiter Servo Drive. Refer to Feedback wiring recommendations for more information about connections and wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 197 2.5 V offset and a phase shift of 120 degrees. These sensors can be used for a fine positioning of the rotor. Jupiter analog halls inputs main features are shown in next table: Specification Value INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 198 Digital Halls interface , to avoid any signal distortion, when analog halls interface is selected, the 1 kΩ pull-up is disconnected automatically. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 199 Installation Guide Next figure shows how to connect the linear Halls to the Jupiter Servo Drive. Refer to Feedback wiring recommendations for more information about connections and wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 200 There are 2 analog inputs with different input voltage range. Both can be used as position or velocity feedback input (selected via software). Next table summarizes main features of these analog inputs: Specification Value Number of inputs INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 201 Next table shows the Jupiter Servo Drive analog inputs voltage range. Input Max. differential voltage (Analog In+) – (Analog In-) Analog input 1 0 V to + 5 V Analog input 2 -10 V to + 10 V INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 202 Installation Guide Next figure shows the circuit model for the analog input 2: Next figure shows the circuit model for the analog input 1: INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 203 Next figures illustrate how to connect an analog source to the Jupiter Servo Drive analog input 2 (for differential and single ended sources). Refer to Feedback wiring recommendations for more information about connections and wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 204 Next figure illustrates how to connect an analog single ended source to the Jupiter Servo Drive analog input 1. Refer to Feedback wiring recommendations for more information about connections and wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 205 Installation Guide The following picture shows how to connect a potentiometer as a position sensor using analog input 1: INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 206 PWM encoder interface A PWM encoder provides a Pulse Width Modulated signal with a duty cycle proportional to the angle (position) of the rotor. Next figure illustrates PWM feedback input for different rotor positions: INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 207 > 10 kΩ High level input voltage (HS_GPI1+ - HS_GPI1-) > 150 mV Low level input voltage (HS_GPI1+ - HS_GPI1-) < -600 mV Typical voltage range 0 to 5 V INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 208 Minimum detectable pulse width 200 ns Next figure shows the circuit model for the PWM encoder input: Next figure illustrates how to connect a PWM encoder to the Jupiter Servo Drive: INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 209 Installation Guide Single ended PWM encoders can also be connected to Jupiter Servo Drive. Next figure shows how to do it: INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 210: Velocity Feedback Interfaces

DC Tachometer The Jupiter Servo Drive can use a DC tachometer signal as velocity feedback element. Tachometer provides an analog signal whose voltage level is proportional to the rotor speed. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 211 Next figure illustrates how to connect source tachometer to the Jupiter Servo Drive for differential sources. DC tachometer feedback wiring should be physically isolated from motor, AC power and all other power wiring. INGENIA MOTION CONTROL Confidential and proprietary information.

- Page 212 Next figure illustrates how to connect source tachometer to the Jupiter Servo Drive for differential sources. DC tachometer feedback wiring should be physically isolated from motor, AC power and all other power wiring. INGENIA MOTION CONTROL Confidential and proprietary information.

-

Page 213: Feedback Wiring Recommendations

2 positive input (2+); 2nd wire connects the signal minus to the drive analog 2 negative input (2-) and 3rd wire connects the source ground to the drive GND. INGENIA MOTION CONTROL Confidential and proprietary information. -

Page 214: Io Connections

1 x 0 – 5 V differential 12 bits analog input. 8.4.1 Contents Low-speed (LS) single ended digital inputs interface High-speed (HS) digital inputs interface Analog inputs interface Digital outputs interface INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. -

Page 215: Low-Speed (Ls) Single Ended Digital Inputs Interface

Low level input voltage 0 < Vin < 1 V Input impedance 30 kΩ Max delay 2 μs Max frequency ~ 200 kHz Inputs electrical equivalent circuit is the following: INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 216 Jupiter Inputs and outputs are not isolated. The ground of the Jupiter Servo Drive and the ground of the devices connected to I/Os must be the same. Otherwise inputs or outputs may be damaged. INGENIA MOTION CONTROL Confidential and proprietary information.

- Page 217 Installation Guide Three-wire sensors can also be connected to Jupiter Servo Drive LS inputs. Next figures illustrate how to do it for PNP and NPN 3 wire sensors (LS_GPI1 can also be used). INGENIA MOTION CONTROL Confidential and proprietary information. Page...

-

Page 218: High-Speed (Hs) Digital Inputs Interface

8.4.3 High-speed (HS) digital inputs interface The high-speed (HS) non-isolated digital inputs are ready for 5 V levels and tolerant to 24 V. Next table show their electrical specifications. Specification Value INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 219 If lower impedance is desired to improve noise immunity, a termination resistor can be placed between HS_GPI+ and HS_GPI-. Next figure shows an example on how to connect differential sources to these inputs: INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 220 Otherwise inputs or outputs may be damaged. For a high speed signal connection (such as Step and Direction ) to these inputs, refer to next figure (HS_GPI2 can also be used): INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 221 Installation Guide If a single ended input is used follow the next recommendation: INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 222 Installation Guide For three wire sensor connection to these inputs, refer to next figures (HS_GPI2 can also be used). INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 223 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 224: Analog Inputs Interface

8.4.4 Analog inputs interface Jupiter Servo Drive has two 12-bit analog inputs with different input voltage ranges. Next table shows their main features: Specification Value Number of inputs Type of inputs INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 225 Maximum working frequency 10 kHz Maximum voltage on any input pin for analog inputs (referred to GND) +24 V Input impedance see schematic Next figures illustrate analog inputs circuit models: INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 226 Next figure shows how to interface voltage sources to the differential analog input 2. The differential analog input is typically used as a command source. Refer to Feedback wiring recommendations for more information about connections and wires. INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 227 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 228 Installation Guide To interface to a single ended (non-differential) voltage source, use analog input 1: INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 229: Digital Outputs Interface

Jupiter Servo Drive has two digital non-isolated outputs. Refer to IO Connector for connector's position and pinout. Next table shows their main features: Specification Value Number of outputs Type of output INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 230 15μs @ 30 V and R = 100 kΩ load 50 μs @ 5 V and R = 100 kΩ load Max working frequency 3.5 kHz Next figure shows digital outputs circuit model. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 231 Load should be connected in a different way depending on desired voltage levels. 5 V outputs Next figure illustrates how to connect a load to 5 V digital outputs (GPO1 can also be used). INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 232 If 24 V outputs are needed, an external power supply should be used. For this option, outputs may be connected as voltage or current outputs. Next figures illustrate how to do it (GPO1 can also be used). INGENIA MOTION CONTROL Confidential and proprietary information.

- Page 233 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 234 Actually, there are other options to avoid inductive kicking. Instead of a diode, a varistor or a RC snubber in parallel with the brake can also be used. This will improve transistor turn off time. Next figure show how to connect an inductive load to Jupiter outputs (GPO1 can also be used). INGENIA MOTION CONTROL Confidential and proprietary information. Page...

-

Page 235: Low-Speed (Ls) Single Ended Digital Inputs Interface

8.4.6 Low-Speed (LS) single ended digital inputs interface The low-speed (LS) non-isolated digital inputs are ready for 5 V levels and are 24 V tolerant. Next table show their electrical specifications. Specification Value INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 236 0 < Vin < 1 V Input impedance 30 kΩ Max delay 2 μs Max frequency ~ 200 kHz Inputs electrical equivalent circuit is the following: Next figure shows proper inputs connection. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 237 Otherwise inputs or outputs may be damaged. Three-wire sensors can also be connected to Jupiter Servo Drive LS inputs. Next figures illustrate how to do it for PNP and NPN 3 wire sensors (LS_GPI1 can also be used). INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 238 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 239: High-Speed (Hs) Digital Inputs Interface

The high-speed (HS) non-isolated digital inputs are ready for 5 V levels and tolerant to 24 V. Next table show their electrical specifications. Specification Value Number of inputs 2 (HS_GPI1, HS_GPI2) Type of input ESD protected. INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited. - Page 240 If lower impedance is desired to improve noise immunity, a termination resistor can be placed between HS_GPI+ and HS_GPI-. Next figure shows an example on how to connect differential sources to these inputs: INGENIA MOTION CONTROL Confidential and proprietary information. Page...

- Page 241 Otherwise inputs or outputs may be damaged. For a high speed signal connection (such as Step and Direction ) to these inputs, refer to next figure (HS_GPI2 can also be used): INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 242 Installation Guide If a single ended input is used follow the next recommendation: INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 243 Installation Guide For three wire sensor connection to these inputs, refer to next figures (HS_GPI2 can also be used). INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

- Page 244 Installation Guide INGENIA MOTION CONTROL Confidential and proprietary information. Page Unauthorized Copies Prohibited.

-

Page 245: Analog Inputs Interface