Table of Contents

Advertisement

Quick Links

Schmidt

Mess- und Regeltechnik

Operation Manual

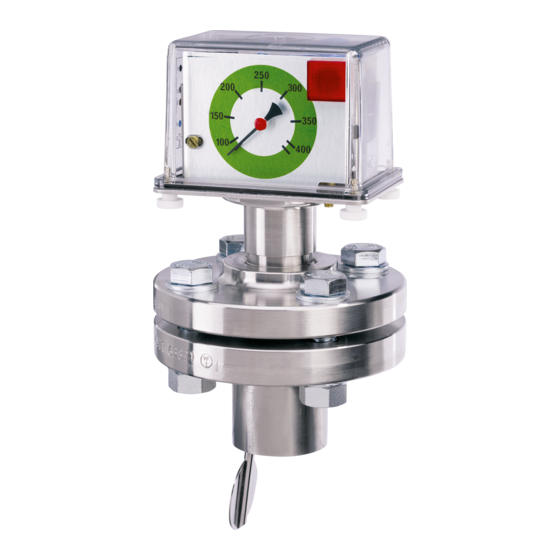

Flowmeter / Flow Control DW-U

Flow monitor after the baffle plate principle for liquids

• Easy switch point adjustment in small scale steps

• Compulsive motion transfer to a micro-switch

• Hermetic separation from the medium by means of bellows

• High power handling capacity

• Insensitive to magnetic fields

• High resistance to dirt and high operational safety

• Available for all flow directions

• Very economical monitoring of large pipes

• Output signal 0/4-20 mA for type DW-U-AN

• Without flow indication for type DW-N

©2014 Schmidt

Mess- und Regeltechnik

Fon 0 67 32 - 91 91 20

Fax 0 67 32 - 96 24 42

info@schmidt-messtechnik.de

1 1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Schmidt DW-U

- Page 1 • High resistance to dirt and high operational safety • Available for all flow directions • Very economical monitoring of large pipes • Output signal 0/4-20 mA for type DW-U-AN • Without flow indication for type DW-N ©2014 Schmidt Mess- und Regeltechnik...

- Page 2 Schmidt Mess- und Regeltechnik Operation Manual Flowmeter / Flow Control DW-U Flow monitor after the baffle plate principle for liquids Delivery and packing All instruments delivered are ready for operation. Avoid rough handling in order to prevent damage to the sensitive built-in measuring and indication mechanism. The measuring unit is not locked in position during transport.

- Page 3 Schmidt Mess- und Regeltechnik Operation Manual Flowmeter / Flow Control DW-U Flow monitor after the baffle plate principle for liquids Types of installation 3.4.1 Port with weld neck flanges The complete flange type AU-FL includes screws and sealing at delivery.

- Page 4 Schmidt Mess- und Regeltechnik Operation Manual Flowmeter / Flow Control DW-U Flow monitor after the baffle plate principle for liquids Connecting Type DW-U and DW-N Removing the device cover allows access to the four-pole terminal block. In addition to the micro-switch a control lamp is installed.

- Page 5 Maintenance The Paddle Flow Switch / Flow Meter DW-U are virtually maintenance free. In case of mal- function first of all check the pipe system for calcification or contaminations. For cleaning do not use sharp-edged tools and proceed with extreme caution. Damaged instruments should be sent in for repair, as they have to be re-calibrated by the manufacturer.

- Page 6 Flow monitor after the baffle plate principle for liquids Description of function Type device DW-U-EX is a combination of a flow switch and meter with analogue display of the current flow and a flow switch with adjustable switch-point. However, the type device DW-N-EX is a flow-switch with adjustable switch-point without an additional flow indicator of the current flow.

- Page 7 Schmidt Mess- und Regeltechnik Operation Manual Flowmeter / Flow Control DW-U Flow monitor after the baffle plate principle for liquids Installation and operation The devices have to be installed in a higher-level assembly. Depending on the degree of IP protection, the time of cleaning the device (dust deposit) has to be defined. It is important to...

- Page 8 Schmidt Mess- und Regeltechnik Operation Manual Flowmeter / Flow Control DW-U Flow monitor after the baffle plate principle for liquids Close inspection: An examination to identify such defects as e.g. loose screws which are only discernible by using access installations like a step or tools, in addition to the aspects of the visual examination.

Need help?

Do you have a question about the DW-U and is the answer not in the manual?

Questions and answers