Summary of Contents for Schmidt D-2005 Series

- Page 1 S C H M I D T c o n t r o l i n s t r u m e n t s Edition D-2005 01.E D-2005 Series Instruction Manual Valid as of: 01.11.2020 • Please keep the manual for future reference!

-

Page 2: Table Of Contents

Contents 1 Warranty and Liability ....................3 1.1 Notices within the Operating Instructions ............... 3 1.2 Responsibilities of the Operating Company ............3 1.3 Responsibilities of the Personnel ................3 1.4 Informal Safety Measures ..................4 1.5 Training of the Personnel ..................4 1.6 Intended Use ...................... -

Page 3: Warranty And Liability

Warranty and Liability In principle, the supply of the device is subject to our “General Conditions of Sale and Delivery.” These have been provided to the operating company on conclusion of the contract, at the latest. Warranty: - Thickness gauges are warranted for 12 months. Parts subject to wear, electronic components and measuring springs are not covered by the warranty. -

Page 4: Informal Safety Measures

Any other use or any use ex- ceeding this intention will be regarded as misuse. Under no circumstances shall HANS SCHMIDT & Co GmbH be held liable for damage resulting from misuse. The intended use also includes: - Complying with all notices included in the Operating Instructions and observing all inspection and maintenance works. -

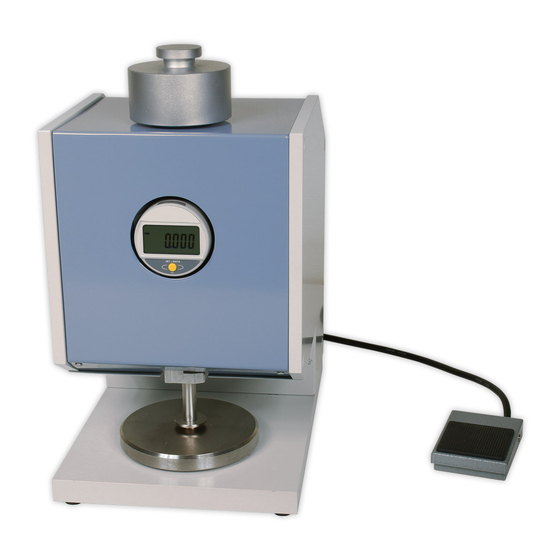

Page 5: Available Models

Available Models These Operating Instructions refer to Model D-2005-T of the D-2005 Series; they are also applicable to the following models. The individual models of the D-2005 Series are also available with the following feelers and weights: Model Standard Application feeler cm²... -

Page 6: Delivery Includes

2.2 Delivery Includes 1 Thickness Gauge 1 Operating manual and certificate 1 Sub-D9/USB adapter cable 1 USB AC adapter 1 AC adapter 1 pedal switch 1 or 2 additional weights, if applicable (depending on model, see chapter 2) 1 Operating manual for dial gauge Load table 2.3 Unpacking Unpack the thickness gauge and inspect it for any shipping damage. -

Page 7: Measuring

Measuring Notices Before Starting Measurement Have you read and understood the Operating Instructions, in particular Chapter 1 “Basic Safety Notices” ? You are not permitted to operate the device before doing so. Before working with the device you must put on your personal protective clothing, if necessary. -

Page 8: Preparations Before Measuring

Preparations Before Measuring 3.4.1 Setting the Measurement Parameters Set the parameters as described in the operating manual for the DIAL GAUGE. 3.4.2 Checking and Setting the Zero Point Requirement: - Clean the MEASURING TABLE and the bottom of the FEELER. Zero adjustment: - Press the SET key on the DIAL GAUGE. -

Page 9: Adjusting The Thickness Gauge To Different Materials

Adjusting the Thickness Gauge to Different Materials Using different combinations of test weight and feeler shape, you can adjust the thickness gauge to check a wide variety of materials. 3.6.1 Changing the Feeler The feeler is screwed to the PRESSURE DIE. 1. -

Page 10: User Interface

3.8.3 User Interface Maximum value of measuring series Average value of Batch or Minimum value of Standard deviation measuring series part number measuring series of measuring series Number of the current measurement Current actual value of measuring series Display area for readings Display of data source... -

Page 11: Basic Settings

3.8.4 Basic Settings Click the “Configuration” button (see chapter 3.8.3) to open the Configuration dialog box. - Choose the data source Must be set to “Sylvac-Mode” and “Simplex” - Choose a data storage option: No data storage, or data storage as Excel or CSV file. -

Page 12: Service And Maintenance

Please indicate in your order whether you require an Calibration certificate done by an DAkkS (DKD) approved laboratory. Service address: HANS SCHMIDT & Co GmbH Schichtstr. 16 84478 Waldkraiburg Germany Seit 70 Jahren in aller Welt Hans Schmidt &...

Need help?

Do you have a question about the D-2005 Series and is the answer not in the manual?

Questions and answers