Summary of Contents for tams elektronik Multi-Timer

- Page 1 Manual Multi-Timer Item no. 51-01055 | 51-01056 | 51-01057 Time switch for analogue and digital model railway layouts tams elektronik n n n...

-

Page 2: Table Of Contents

6.1. Preparation...............20 6.2. PCB layout................23 6.3. Parts list................24 6.4. Assembly................25 6.5. Performing a visual check..........26 7. Connecting the Multi-Timer............27 7.1. Functional test..............27 7.2. Voltage supply..............28 7.3. Connections with operation modes 1, 2 and 3.....29 7.4. Connection with operation mode 4........31 8. -

Page 3: Getting Started

Any other use is inappropriate and invalidates any guarantees. The Multi-Timer should not be assembled or mounted by children under the age of 14. Reading, understanding and following the instructions in this manual are mandatory for the user. - Page 4 English Multi-Timer Caution: The Multi-Timer contains integrated circuits. These are very sensitive to static electricity. Do not touch components without first discharging yourself. Touching a radiator or other grounded metal part will discharge you. Checking the package contents Please make sure that your package contains: ...

-

Page 5: Safety Instructions

Multi-Timer English For the connection to the switching inputs you need: for use as a time switch or a pulse delay (operation mode 1 or 2): four push buttons, e.g. item no. 84-5212x, x=1..5 (or circuits to release a switching pulse);... - Page 6 English Multi-Timer Never perform wiring on a powered module. Assembling and mounting the kit should only be done in closed, clean, dry rooms. Beware of humidity. Only use low power for this module as described in this manual and only use certified transformers.

- Page 7 Multi-Timer English Dangerous environments A working area that is too small or cramped is unsuitable and can cause accidents, fires and injury. Prevent this by working in a clean, dry room with enough freedom of movement. Other dangers Children can cause any of the accidents mentioned above because they are inattentive and not responsible enough.

-

Page 8: Safe And Correct Soldering

English Multi-Timer 3. Safe and correct soldering Caution: Incorrect soldering can cause dangers through fires and heat. Avoid these dangers by reading and following the directions given in the chapter Safety instructions. Use a small soldering iron with max. 30 Watt or a regulated soldering iron. - Page 9 Multi-Timer English Cut the wires after soldering directly above the soldering joint with a side cutter. After placing the parts, please double check for correct polarity. Check the PCB tracks for solder bridges and short circuits created by accident.

-

Page 10: Operation Overview

Setting the mode of operation The mode of operation has to be set by means of jumpers. The operation modes 1 and 2 are set to the 4 outputs of the Multi-Timer individually. Thus using one Multi-Timer as a combined time switch and pulse delay is possible. -

Page 11: Operation Mode 1 "Time Switch

In order to release a switching pulse push-buttons or comparable external circuits can be used. In this operation mode the Multi-Timer can be set either to allow it to be retriggered or not. -

Page 12: Operation Mode 2 "Pulse Delay

(and the train brought to a stopp), as soon as the train has passed a reed contact. In case the train would stop immediately after passing the reed contact, it would be impossible to switch on the rail section again. With the Multi-Timer it is possible to Page 12... -

Page 13: Operation Mode 3 "Random Switch

4.3. Operation mode 3 "Random Switch" Use in analogue or digital layouts The 4 outputs of the Multi-Timer are switched separately for a time at random. The time interval after which the random generator decides whether to release a switching operation or not, can be set for each output individually via a trimpot, the maximum interval is 4,5 minutes. -

Page 14: Operation Mode 4 "Start-Brake-Stopover Switch

English Multi-Timer 4.4. Operation mode 4 "Start-Brake-Stopover Switch" Use in analogue layouts only The Multitimer controls braking, stopping and starting of analogue locomotives (e.g. in a station or at a signal stop). optionally: the signal position (stop or clear) ... - Page 15 Multi-Timer English Sequence Via a switch connected to switching input 1, the signal is set to "stop" (switching input closed) or to "clear" (switching input open). Semaphore signals are to be switched directly, light signals can be switched via bistable relays as well. It is also possible to do without connecting signals, the outputs 1 and 2 stay then open.

- Page 16 English Multi-Timer 2. The locomotive stops in front of the signal until the hold time has expired (and switching input 1 has been switched to "open" automatically) or until switching input 1 has been opened (e.g. by means of an external switch).

- Page 17 Multi-Timer English Example 2: Signal set to "Clear" (switching input 1 open) Passing the sensor at the beginning of the braking track has no effect, the braking process is not started. The state of switching input 3 has no effects, too.

- Page 18 English Multi-Timer Effects of the swtich position switching input open switching input closed Switching Switching Switching Effects input 1 input 2 input 3 → Signal → release → prolong stop/clear braking hold time Passage with the set velocity. The state of switching inputs 2 and 3 has no effects.

-

Page 19: Technical Specifications

Multi-Timer English 5. Technical specifications Caution: Do not use the same transformer for the power supply of the Multi- Timer as used for the power supply of downstream circuits or the rails. Supply voltage 12-18 Volt d.c. or a.c. voltage Current consumption (approx.) -

Page 20: Assembling The Kit

English Multi-Timer 6. Assembling the kit You can skip this part if you have purchased a ready-built module or device. 6.1. Preparation Put the sorted components in front of you on your workbench. The separate electronic components have the following special features... - Page 21 Multi-Timer English Ceramic capacitors Among other things ceramic capacitors are used for filtering interference voltages or as frequency determining parts. Ceramic capacitors are not polarized. Normally they are marked with a three-digit number which indicates the value coded. The number 104 corresponds to the value 100 nF.

- Page 22 English Multi-Timer Transistors Transistors are current amplifiers which convert low signals into stronger ones. There are several types in different package forms available. The type designation is printed on the component. Transistors for a high power rating (e.g. BD types, BT types) have a flat package (TO-package), which is in use in different versions and sizes.

-

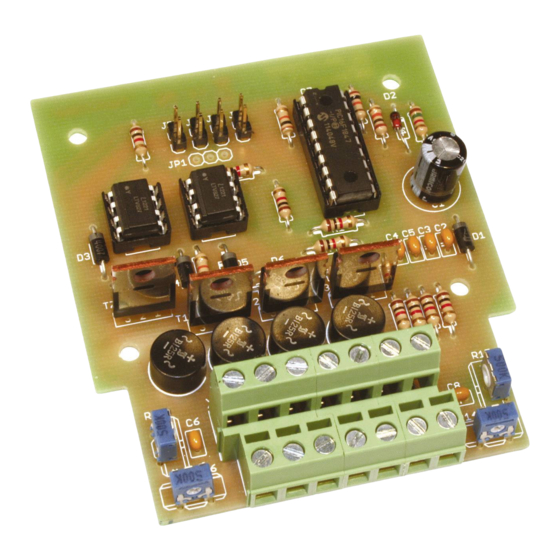

Page 23: Pcb Layout

Multi-Timer English Terminal strips Terminal strips are solder-in screw-type terminals. They provide a solder-free and safe connection of the cables to the circuit, which can still be separated any time. 6.2. PCB layout Page 23... -

Page 24: Parts List

English Multi-Timer 6.3. Parts list Carbon film resistors R1, R2, R3, R4, R12, R18, 1 k R19, R20, R21 1,5 k R5, R6, R7, R8, R9, R10, 10 k Trim pots R14, R15, R16, R17 500 k Ceramic capacitors C2, C3, C4, C5, C6, C7, C8... -

Page 25: Assembly

Multi-Timer English 6.4. Assembly Proceed according to the order given in the list below. First solder the components on the solder side of the PCB and then cut the excess wires with the side cutter. Follow the instructions on soldering in section 3. -

Page 26: Performing A Visual Check

English Multi-Timer Electrolytic Observe the polarity! capacitors One of the two leads (the shorter one) is marked with a minus sign. Transistors Observe the polarity! With transistors for a high power rating in TO packages (e.g. MOSFETs) the labelled front side is marked by a beveled line in the PCB layout. -

Page 27: Connecting The Multi-Timer

7. Connecting the Multi-Timer 7.1. Functional test Especially, when you have mounted the Multi-Timer from a kit, you should perform a functional test before mounting it in your layout. Connect an electric bulb with a separate power supply to output 1 (connections 1 and 2) and a push-button to switching input 1 (connection 9) as described in section 7.3 for operation mode 1. -

Page 28: Voltage Supply

Multi-Timer. Caution: If you use a d.c. transformer for the power supply of the Multi-Timer, you generally have to respect the polarity when connecting it. If using an a.c. transformer the polarity is of no importance first. -

Page 29: Connections With Operation Modes 1, 2 And 3

Multi-Timer English 7.3. Connections with operation modes 1, 2 and 3 1 | 2 Output 1 3 | 4 Output 2 5 | 6 Output 3 7 | 8 Output 4 Switching input 1 Operation mode 3: Operation mode switch... - Page 30 Multi-Timer Connection to the outputs (operation modes 1, 2 and 3) The Multi-Timer works like a switch. It does not provide current for the operation of downstream circuits at it´s outputs. That is why these need an external voltage supply (d.c. or a.c.).

-

Page 31: Connection With Operation Mode 4

English 7.4. Connection with operation mode 4 For use as a start-brake-stopover switch you have to isolate the rail section to be controlled by the Multi-Timer from the remaining layout. These can be e.g.: rail sections with a signal stop (e.g. block sections) ... - Page 32 2 are closed at at switching pulse. Switching Not in use input 4 Voltage supply for Multi-Timer, signal and bistable relay for security section (not driving transformer!). 13 = Return conductor for switching inputs Page 32...

-

Page 33: Setting The Multi-Timer

The Multi-Timer reads in the currently set operation mode immediately after having been switched on. If altering the order of the jumpers after the switching on, this has no effect until the Multi-Timer has been switched off and on again. - Page 34 English Multi-Timer Jumper Operation mode JP2 JP3 JP4 JP5 Output 1 Output 2 Output 3 Output 4 1 (r) 1 (r) 1 (r) 1 (r) 1 (r) 1 (r) 1 (r) 1 (r) 1 (r) 1 (r) 1 (nr) 1 (nr)

- Page 35 Please notice that with operation mode 3 "random switch" not the maximum toggling time is set, but the time interval, which elapses before the Multi-Timer decides at random if to toggle the output or not. Operation...

-

Page 36: Check List For Troubleshooting

English Multi-Timer 9. Check list for troubleshooting Parts are getting too hot and/or start to smoke. Disconnect the system from the mains immediately! Possible cause: one or more components are soldered incorrectly. à In case you have mounted the module from a kit, perform a visual check (à... - Page 37 Multi-Timer English Hotline If problems with your module occur, our hotline is pleased to help you (mail address on the last page). Repairs You can send in a defective module for repair (address on the last page). In case of guarantee the repair is free of charge for you. With...

-

Page 38: Guarantee Bond

English Multi-Timer 10. Guarantee bond For this product we issue voluntarily a guarantee of 2 years from the date of purchase by the first customer, but in maximum 3 years after the end of series production. The first customer is the consumer first... -

Page 39: Eu Declaration Of Conformity

Multi-Timer English 11. EU declaration of conformity This product conforms with the EC-directives mentioned below and is therefore CE certified. 2004/108/EG on electromagnetic. Underlying standards: EN 55014-1 and EN 61000-6-3. To guarantee the electromagnetic tolerance in operation you must take the following precautions: ... - Page 40 Information and tips: http://www.tams-online.de Warranty and service: Tams Elektronik GmbH Fuhrberger Straße 4 DE-30625 Hannover fon: +49 (0)511 / 55 60 60 fax: +49 (0)511 / 55 61 61 e-mail: modellbahn@tams-online.de...

Need help?

Do you have a question about the Multi-Timer and is the answer not in the manual?

Questions and answers