Table of Contents

Advertisement

Quick Links

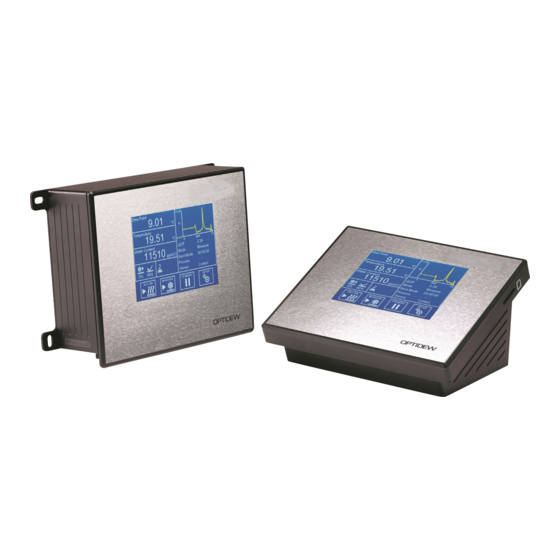

Optidew

Chilled Mirror Hygrometer

User's Manual

Kahn Instruments, Inc. October 2019

This document is the property of Kahn Instruments and may not, either in part or whole, be copied or

otherwise reproduced, communicated in any way to third parties nor stored in any data processing

system, without the written authority of Kahn Instruments, Inc.

Advertisement

Table of Contents

Summary of Contents for Kahn Optidew Series

- Page 1 User's Manual Kahn Instruments, Inc. October 2019 This document is the property of Kahn Instruments and may not, either in part or whole, be copied or otherwise reproduced, communicated in any way to third parties nor stored in any data processing...

- Page 2 Optidew For Kahn Instruments' contact information please go to www.kahn.com...

-

Page 3: Table Of Contents

Electrical Safety........................vii Pressure Safety ........................vii Calibration (Factory Validation) ................... viii Repair and Maintenance ....................viii Abbreviations ........................ix INTRODUCTION ....................1 Optidew Series ....................1 Optidew Sensor ....................2 INSTALLATION ....................3 Mounting ......................3 Instrument Connections ..................5 2.2.1 Optidew Wall Mount ..................5 2.2.2... - Page 4 Optidew User’s Manual 3.3.1 Optics Calibration ..................... 29 OPERATION ....................30 Operating Cycle ....................30 Operating Guide ....................31 4.2.1 Description ....................31 4.2.2 Operating Practice ..................31 Good Measurement Practice ................32 4.3.1 Sampling Hints.................... 32 4.3.2 First Time Operation ..................35 Operational Functions ..................

- Page 5 Mirror contamination warning symbol ............33 Figure 27 Material permeability comparison ...............34 Figure 28 Formation of condensation ................35 Figure 29 2-Stage minimum measurable dewpoint .............40 Figure 30 System alarm ...................41 Figure 31 Mirror contamination warning ..............42 Figure 32 Sensor cleaning ..................43 Kahn Instruments...

- Page 6 Optidew User’s Manual Appendices Appendix A Technical Specifications ................44 Appendix B Modbus Register Map ................47 Appendix C Dimensional Drawings................56 October 2019...

-

Page 7: Safety

For this product to operate satisfactorily, pressurized gas must be connected to it. Observe all the information contained within this manual and all local operation & installation requirements at the intended location of use. Refer to Section 2 (Installation) of this manual for further details. Kahn Instruments... -

Page 8: Calibration (Factory Validation)

Kahn Instruments can provide a fully traceable factory calibration service for the instrument and it is recommended that this is considered at intervals of every year of the analyzer's life. Please contact Kahn Instruments for further details (www.kahn.com). -

Page 9: Abbreviations

(gauge) relative humidity RS485/232 standards defining the electrical characteristics of drivers & receivers real time clock Remote Terminal Unit storage device card UART universal asynchronous receiver/transmitter Universal Serial Bus Volts " Inch Δ delta percentage Ω ohms Kahn Instruments... -

Page 10: Introduction

The Optidew chilled mirror hygrometer is based on the proven, fundamental condensation temperature dewpoint principle, giving unmatched long-term drift-free performance. Kahn offers three highly durable sensor options, which are suitable for measuring in a wide variety of different samples. Optidew Series... -

Page 11: Optidew Sensor

Optidew User’s Manual INTRODUCTION Optidew Sensor The new Optidew sensor is available with either a single or dual stage thermoelectric cooler and with a choice of sensor head materials making it suitable for use in air/inert gases or in corrosive environments. The following tables show the capabilities of each sensor type: Harsh Single Stage... -

Page 12: Installation

Figure 2 Optidew Wall Mount mounting points Optidew Bench Top The Optidew Bench Top is designed to be placed on a bench or table to operate. Alternatively it can be used directly from within the optional Transport Case. Kahn Instruments... - Page 13 Optidew User’s Manual INSTALLATION This page is intentially left blank October 2019...

-

Page 14: Figure 3 Optidew Wall Mount Display Front Panel

Optidew User’s Manual INSTALLATION Instrument Connections 2.2.1 Optidew Wall Mount Front Panel (Display version) Figure 3 Optidew Wall Mount display front panel Number Description Display Shows measured and calculated parameters, controls all instrument settings and functionality. Kahn Instruments... -

Page 15: Figure 4 Optidew Wall Mount Non-Display Front Panel

Optidew User’s Manual INSTALLATION Front Panel (Non-display version) Figure 4 Optidew Wall Mount non-display front panel Number Description DCC Control/ Status indicator Optidew Wall Mount bottom panel Figure 5 Bottom Panel Number Description Power Connector Sensor Cable connector Temperature probe cable connector Pressure transmitter cable connector Alarm contacts connector RS485 and analog output connector... -

Page 16: Figure 6 Optidew Bench Top Top Panel

Optidew User’s Manual INSTALLATION 2.2.2 Optidew Bench Top Top Panel Optidew Bench Top top panel Figure 6 Number Description Display Figure 7 Optidew Bench Top left side panel Left Side Panel Number Description Power Connector Power Switch Kahn Instruments... -

Page 17: Figure 8 Optidew Bench Top Right Side Panel

Optidew User’s Manual INSTALLATION Figure 8 Optidew Bench Top right side panel Right Side Panel Number Description SD Card slot Figure 9 Optidew Bench Top rear panel Rear Panel Number Description Sensor Cable connector Temperature probe cable connector Pressure transmitter cable connector Alarm contacts connector RS485 and analog output connector USB port... -

Page 18: Electrical Connections

DCC cycle. Refer to Section 4.4.1. Replacement power cables are available - contact Kahn Instruments. Optidew Bench Top The Optidew Bench Top is supplied with a 6 foot IEC cable. The IEC socket on the side of the instrument features an integrated ON/OFF switch. -

Page 19: Analog And Digital Communications

The fuse is rated at 5 x 20mm medium acting: Power 230 V AC 2.5 A A replacement fuse can be obtained by contacting Kahn Instruments Service Department. Equipment Ratings This product is designed to be safe at least under the following conditions: between a temperature range of -40°F/C to +140°F/+60°C, in maximum 80% relative humidity... -

Page 20: 2.3.2.2 Current Outputs

This alarm can also be used to give an early indication that the optics require cleaning. System Alarm (Relay 2) This relay changes state to indicate a fault has occurred which requires operator intervention. See section 4.6 for detailed information on faults. Relay contact connector Figure 12 Kahn Instruments... - Page 21 Optidew User’s Manual INSTALLATION Pin Label (from left to right as Description shown) Relay 1 Normally Closed Relay 1 Common Relay 1 Normally Open Relay 2 Normally Closed Relay 2 Common Relay 2 Normally Open October 2019...

-

Page 22: Sensor Installation

A bonded seal is provided to fill the connection between the sensor and the block. Insure that all connections to and from the sensor block are made with appropriate materials and fittings for moisture measurement. For guidance on suitable apparatus, see section 4.3. Kahn Instruments... -

Page 23: Integral Sensor Mounting

Optidew control unit via the 4-pin M12 connector. Kahn can supply a pressure transmitter with the Optidew, which is installed via a 1/8” NPT male thread. For ease of use, the dewpoint sensor and pressure transmitter should be installed so they are operating at the same pressure;... -

Page 24: User Interface

Display model, or a button with multicolor LED indicator on the transmitter version. All functionality through the local user interface is available when running the Kahn Application Software. The Optidew offers three interfaces to connect to a PC or network: •... -

Page 25: Main Screen

Optidew User’s Manual OPERATION 3.1.1 Main Screen Main screen layout Figure 14 Name Description Display measured and calculated parameters. See Customizable Readouts section 3.1.2 for additional information Displays both thermo-electric cooler (TEC) drive and optical signal condition. Also indicates Sensor Status Display whether TEC is 1 or 2 stage. -

Page 26: 3.1.2.1 Locking The Analyzer

After five minutes, this function will lock the analyzer (you will need to return to the main screen). To unlock the screen you must enter 5491. It is possible to deactivate the function before it is triggered or after activation by simply pressing the solid padlock item in the Settings Menu. Kahn Instruments... -

Page 27: Menu Structure

Optidew User’s Manual OPERATION 3.1.3 Menu Structure Setup Logging Output Alarm Type Interval Output Select Type Display Clock Inputs Comms Setpoint Filename Output Type Parameter Resolution Date Source Pressure Unit Modbus Address Mode Status Stability Time Compensation Setpoint Parameter Setpoint A Setup Interval Minimum... -

Page 28: Operational Status Display

Alarm is active Process Alarm is inactive For further information on alarm configuration see sections 3.2 and 4.6. Indicates whether the sensor has established a condensate Sensor formation, or if the system is in a transient condition: Heating, Cooling, Control. Kahn Instruments... -

Page 29: Sensor Status Display

Optidew User’s Manual OPERATION 3.1.5 Sensor Status Display Indicates the whether the sensor is heating or cooling the mirror: TEC Drive Also indicates the power level applied as a percentage to total possible. Indicates the reflectivity of the mirror, and whether this is clean or has a condensate formation. -

Page 30: Setup Menus

Limits: 00:04 to 00:59 Turns frost assurance on or off. See section 4.4.3 for further FAST information Available input: On, Off Passing this mirror temperature will trigger the frost assurance FAST SetP function without a DCC Available input: -28 to -2°C Kahn Instruments... -

Page 31: Figure 16 Logging Screen

Optidew User’s Manual OPERATION Logging Logging screen Figure 16 Changes the interval at which data is recorded Interval Input format: mm:ss – Limits: 00:05 to 10:00 Indicates status of inserted SD card: No SD Card inserted Ready to log Initializing card SD status indicator: Error occurred... -

Page 32: Figure 17 Outputs Screen

Namur alarm level (20.6mA). Available input: None, System, Process, Both The minimum output range for the selected parameter Minimum Available input: Dependant on parameter The maximum output range for the selected parameter Maximum Available input: Dependant on parameter Kahn Instruments... -

Page 33: Figure 18 Alarm Screen

Optidew User’s Manual OPERATION Alarm Alarm screen Figure 18 Sets the trip criteria for the process alarm Type Available input: Over, Under, In. Band, Out. Band, Off Sets the parameter associated with the process alarm Parameter Available input: DP, Temperature, Pressure, %RH, wvp, g/m g/kg, ppm , ppmW, Wet Bulb Sets the trip point for Over or Under alarm types... -

Page 34: Figure 19 Display Screen

When enabled, values on display are also held during Data Hold Display Hold Available input: Off, On Sets User Interface language Language Available input: English, Deutsch, Español, Français, Italiano, Português, USA, Russian, Chinese, Japanese Display backlight control Brightness Available input: 0 to 100% Kahn Instruments... -

Page 35: Figure 20 Clock Screen

Optidew User’s Manual OPERATION Clock Clock screen Figure 20 Date Current date Time Current time October 2019... -

Page 36: Figure 21 Inputs Screen

Select ‘To Atmos’ if dewpoint sensor is at entered fixed pressure or pressure measured by transducer. Source Changes between temperature input from external PT100 or a (Temperature fixed value. Input) Available input: Fixed, External Value (If ‘Fixed’ Sets temperature used for internal calculations selected) Kahn Instruments... -

Page 37: Figure 22 Comms Screen

Optidew User’s Manual OPERATION Comms Screen Comms screen Figure 22 Modbus Address Sets the Modbus slave address for this Optidew Setup Access the TCP/IP Network Settings page Network Settings Figure 23 Network settings screen IP Address The IP address of the instrument (default 10.0.50.100) Subnet Mask Determines network subnet address (default 255.255.255.0) Default Gateway... -

Page 38: Transmitter Version

After power is applied the LED indicator on the front of the instrument will turn white for the first 5 seconds. Pressing the button during this phase will initiate an optics calibration. The indicator will flash indicating the button-press has been registered. Kahn Instruments... -

Page 39: Operation

Optidew User’s Manual OPERATION OPERATION Operating Cycle Figure 24 Typical operating cycle At initial switch-on, the instrument enters a DCC cycle for 2 minutes. During this time the mirror is heated above the prevailing dewpoint to ensure that all condensate is driven off the surface of the mirror. -

Page 40: Operating Guide

Dew point is beyond depression capability at sample temperature The basic considerations for each measurement type are as follows: In-Situ Dewpoint Sensor position – will the sensor see an area of the environment that is representative of what you want to measure? For Kahn Instruments... -

Page 41: Figure 25 Room Measurement Example

If this is the case, then a guard equipped over the sensor can mitigate the effects of excessive gas speed by dissipating the sample throughout it’s surface area. An appropriate guard can be purchased from Kahn Instruments, or your local representative. -

Page 42: Figure 26 Mirror Contamination Warning Symbol

If replacing an old Optidew installation then be aware that using the old sensor block will result in poor response speed at low dew-points, as it does not allow enough flow across the mirror. Kahn Instruments... -

Page 43: Good Measurement Practice

Optidew User’s Manual OPERATION Good Measurement Practice 4.3.1 Sampling Hints Measurement of moisture content is a complex subject, but does not need to be difficult. This section aims to explain the common mistakes made in measurement situations, the causes of the problem, and how to avoid them. Mistakes and bad practices can cause the measurement to vary from the expectation;... -

Page 44: Figure 28 Formation Of Condensation

It provides protection from liquid droplets, and can even stop flow to the analyzer completely when a large slug of liquid is encountered. Condensation and Leaks Dewpoint > T Dewpoint < T Formation of condensation Figure 28 Kahn Instruments... - Page 45 Optidew User’s Manual OPERATION Maintaining the temperature of the sample system tubing above the dewpoint of the sample is vital to prevent condensation. Any condensation invalidates the sampling process as it changes the water vapor content of the gas being measured. Condensed liquid can alter the humidity elsewhere by dripping or running to other locations where it may re-evaporate.

-

Page 46: First Time Operation

DCC Plus is a feature designed to further control the build-up of contaminants on the mirror surface without physical intervention from the operator. The function operates immediately prior to either a scheduled automatic DCC or a manual DCC, by cooling the mirror for a few seconds before heating it. Kahn Instruments... -

Page 47: Maxcool Function

Optidew User’s Manual OPERATION This cooling causes additional condensation on the mirror, which dissolves water-soluble matter, and dislodges non water-soluble matter. When the surface is then heated and the water evaporated, the contamination will cluster together leaving areas of clean mirror between, which has less overall impact on the optics. -

Page 48: Standby Mode

The minimum dewpoint that can be measured is determined by the sensor temperature, and whether the sensor can be maintained at that temperature. The following chart assumes operation in a climatic chamber, where the air speed is sufficient to remove any excess heat generated by the sensor. Kahn Instruments... -

Page 49: Warnings And Faults

Optidew User’s Manual MAINTENANCE Sensor Temperature °C 2-Stage minimum measurable dewpoint Figure 29 Warnings and Faults The Optidew contains a comprehensive self-diagnosis system to alert the user whenever there is an issue which could affect the measurement. These alerts are divided into two categories: Warnings –... -

Page 50: Maintenance

External temperature probe above upper limit Pressure Tx. Fault (Open) Pressure transmitter signal < 0.2mA (open circuit) Pressure transmitter signal 3.6-3.8mA OR 20.5- Pressure Tx. Fault (Alarm) 21mA Pressure Tx. Fault (Fail) Pressure transmitter signal > 21mA, or < 3.6mA Kahn Instruments... -

Page 51: Mirror Cleaning

Optidew User’s Manual APPENDIX A MAINTENANCE Mirror Cleaning Throughout the life of the instrument, periodic cleaning of the mirror surface and optics window may be required. The frequency of this depends upon operating conditions and the potential in the application for contaminants to be deposited on the mirror. The Optidew will notify the user on the state of mirror contamination. -

Page 52: Exchanging Sensors

Enter the 12 character configuration code found on the calibration certificate for the sensor you are connecting. Connect the new sensor, then navigate to the 'Alarms' screen, and press the 'Calibrate Optics' button. A DCC will follow, which cannot be canceled. Do not disconnect the sensor during this time. Kahn Instruments... - Page 53 Optidew User’s Manual APPENDIX A Appendix A Technical Specifications October 2019...

- Page 54 Cable length 0.3, 3, 5, 10 & 20m lengths available Temperature PT100 1/10 DIN Class A Measurement Remote Pressure Sensor (Optional) Pressure Measurement ±0.25% FS Accuracy Pressure Measurement 0-160KPa OR 0-2500KPa Range Process Connection 1/8” NPT-M Output 4-20 mA Kahn Instruments...

- Page 55 Optidew User’s Manual APPENDIX B Control Unit Resolution 1 or 2 decimal places selectable °Fdp or °Cdp Relative humidity - % Absolute humidity - g/m , ppm Mixing Ratio - g/kg Measurement Units Wet Bulb Temperature (Twb) - °F, °C Water Vapor Pressure (wvp) - Pa Ambient Temperature - °F, °C pressure converted DP - °F, °C...

- Page 56 Optidew User’s Manual APPENDIX B Appendix B Modbus Register Map Kahn Instruments...

- Page 57 Communications In order to communicate with the instrument over a USB connection, first install the Kahn application software which contains a USB->UART bridge driver. The Optidew will then appear in Device Manager as a virtual serial port. Serial Port Settings (USB/RS485)

- Page 58 Modbus protocol. Full descriptions of the function codes (FC03/FC06/FC16) can be found in the sidebar. https://www.scadacore.com/tools/programming-calculators/ online-hex-converter/ is an excellent resource for determining register types/byte order issues in raw received Modbus data. Kahn Instruments...

- Page 59 Optidew User’s Manual APPENDIX B Register Address Access Data Type Description Comment Instrument Information 0000 uint16 Instrument Modbus Address 0002 uint32 Instrument Serial MS 0003 Instrument Serial LS 0004 uint16 Instrument Firmware Version 0005 uint16 Register Map Version Measured and Calculated Values Units = Temperature 0006 float...

- Page 60 Fault Status 2 0=OK 1=Ambient Pt100 Open 2=Ambient Pt100 Low 4=Ambient Pt100 High 8=Mirror Pt100 Open 16=Mirror Pt100 Low 32=Mirror Pt100 High 64=Loop Open (Pressure Tx) 128=Loop Alarm (Pressure Tx) 256=Loop Fail (Pressure Tx) 512=Contaminated 0028 uint16 Alarms Status Kahn Instruments...

- Page 61 Optidew User’s Manual APPENDIX B 0=No Alarm 1=System 2=Process 0029 uint16 Logging Status 0=Not Equipped 1=No Card 2=Ready 3=Logging 4=Writing 5=Mount Error 6=Write Error 7=Mounting 8=Write Protected 9=Unknown 002A boolean Data Hold Active 002B boolean Display Hold Active 0032 int16 Peltier Drive % 0033 uint16...

- Page 62 Manual Temperature LS Instrument Configuration 007F uint16 DCC Setpoint Mode 0=Absolute 1=Relative 0080 int16 DCC Temperature Setpoint (Degrees * 100) 0081 uint16 DCC Interval Mode 0=Auto (Recommended) 1=Manual 0082 uint16 DCC Interval Mins 0083 uint16 DCC Duration Mins Kahn Instruments...

- Page 63 Optidew User’s Manual APPENDIX B 0085 boolean FAST Enable 0086 float FAST Setpoint MS 0087 FAST Setpoint LS 0088 uint16 Peltier Stages 1=1 Stage 2=2 stage (Degrees * 1000) .. 0089 uint16 Stability Band Threshold to end Data Hold (Degrees * 1000) .. 008C uint16 Stability Band...

- Page 64 Analog 1 Alarm Type 0=None 1=System Only 2=Process Only 3=Both 00A8 uint16 Analogue 2 Alarm Type 00AB uint16 Process Alarm Parameter 0=Dew/Frost point 1=Temperature 2=Pressure 3=Relative Humidity 4=ppm(vol) 5=ppm(wt.) 6=Mixing Ratio 7=Absolute Humidity 8=Wet bulb 9=WVP 00AC uint16 Process Alarm Type Kahn Instruments...

- Page 65 Optidew User’s Manual APPENDIX C Appendix C Dimensional Drawings October 2019...

- Page 66 Optidew User’s Manual APPENDIX C Appendix C Dimensional Drawings Optidew Bench Top Control Unit Kahn Instruments...

- Page 67 Optidew User’s Manual APPENDIX C Optidew Wall Mount Control Unit – IP54 240.0mm 9.449" 260.0mm 10.236" 220.0mm 8.661" THIS DOCUMENT IS THE PROPERTY OF MICHELL MATERIAL: See BoM INSTRUMENTS LTD. AND MUST NOT BE COPIED XXXX 25/05/17 CHANGES TO WIRING TOLERANCES &...

- Page 68 2 DEC. PLACE: ± 0.1 XXXX 04/05/17 COMPONENT CHANGES Optidew MkII HOLES Ø:± 0.1 XXXX 02/02/17 FIRST DRAFT ANGLES:± 0.5° DESCRIPTION DRAWING UNITS: mm PROJECT: ECN No. DATE CREATED APPROVED SCALE: NTS 7544 MICHELL INSTRUMENTS LTD. 20/07/2016 F0150 Kahn Instruments...

- Page 69 Optidew User’s Manual APPENDIX C Single Stage Dewpoint Sensor 101.8mm 46.0mm 1.811" M36 x 1.5 101.8mm 4.008" 44.8mm 1.764" M30 x 1 30.8mm 1.213" THIS DOCUMENT IS THE PROPERTY OF MICHELL INSTRUMENTS LTD. AND MUST NOT BE COPIED NOR DISCLOSED TO A THIRD PARTY WITHOUT THE CONSENT OF MICHELL INSTRUMENTS.

- Page 70 Optidew User’s Manual APPENDIX C Dual Stage Dewpoint Sensor Kahn Instruments...

- Page 71 Optidew User’s Manual APPENDIX C Sample Block October 2019...

- Page 72 *Weld burr may extend from 1 mm from colar to towards tip of probe. Probe and connector rated 90 °C. High Temperature Probe Maximum termperature measurement 120 °C. Connector rated 120 °C. Probe and cable rated 250 °C. Kahn Instruments...

- Page 73 Optidew User’s Manual APPENDIX C Application Software Contents Connecting a device ......................65 Main Options ........................67 Data Acquisition ......................68 Logging Setup ......................... 69 Strip Chart Controls ......................71 Configuration Screens..................... 74 Modbus Slave ........................ 75 Humidity Profiling ......................77 ...

- Page 74 Optidew User’s Manual APPENDIX C Kahn Instruments...

- Page 75 Optidew User’s Manual APPENDIX C October 2019...

- Page 76 Optidew User’s Manual APPENDIX C Kahn Instruments...

- Page 77 Optidew User’s Manual APPENDIX C October 2019...

- Page 78 Optidew User’s Manual APPENDIX C Kahn Instruments...

- Page 79 Optidew User’s Manual APPENDIX C October 2019...

- Page 80 Optidew User’s Manual APPENDIX C Kahn Instruments...

- Page 81 Optidew User’s Manual APPENDIX C October 2019...

- Page 82 Optidew User’s Manual APPENDIX C Kahn Instruments...

- Page 83 Optidew User’s Manual APPENDIX C October 2019...

- Page 84 Optidew User’s Manual APPENDIX C Kahn Instruments...

- Page 85 Optidew User’s Manual APPENDIX C October 2019...

- Page 86 Optidew User’s Manual APPENDIX C Kahn Instruments...

- Page 87 Optidew User’s Manual APPENDIX C October 2019...

- Page 88 Optidew User’s Manual APPENDIX C Kahn Instruments...

Need help?

Do you have a question about the Optidew Series and is the answer not in the manual?

Questions and answers