Subscribe to Our Youtube Channel

Summary of Contents for Newport PM500 Series

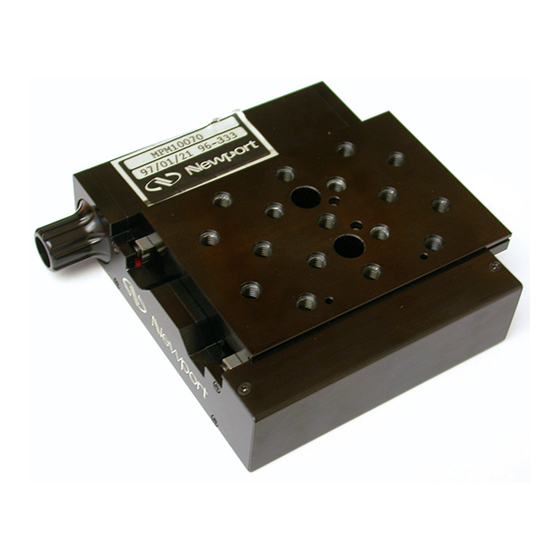

- Page 1 (217) 352-9330 | Click HERE Find the Newport PM500-C at our website:...

- Page 2 PM500 SERIES Operation and Command Reference Manual Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 3 Windows is a registered trademark of Microsoft Corporation. LabVIEW and LabWindows are trademarks of National Instruments Corporation. Copyright 2001 by Newport Corporation, Irvine, CA. All rights reserved. No part of this manual may be reproduced or copied without the prior written approval of Newport Corporation.

- Page 4 Preservation of Secrecy and Confidentiality and Restrictions to Access: Customer shall protect the Newport Programs and Related Materials as trade secrets of Newport, and shall devote its best efforts to ensure that all its personnel protect the Newport Programs as trade secrets of Newport Corporation.

-

Page 5: Technical Support Contacts

Telephone: (800) 222-6440 Newport Corporation RMA Procedures Each defective part must have an RMA number assigned by a Newport representative. The serial number of the damaged component must be provided to the Newport representative. Please refer to Appendix G of this manual for complete RMA procedure. -

Page 6: Table Of Contents

Preface Table of Contents Warranty....................ii Technical Support Contacts ..............iv Table of Contents ................... v List of Figures ..................xi Introduction Scope of the Manual..............13 Manual Conventions..............14 1.2.1 Keys, Buttons and Icons ..........14 1.2.2 Key Operation ..............14 1.2.3 User Input ................14 1.2.4 The Display ..............14 Safety Precautions... - Page 7 Preface 5.5.2 Cable routing ..............32 Remote Motor Shutdown Connector.......... 33 Cooling ..................33 Attaching Loads to Positioners Outline of Section 6..............35 Effect of Vibrations ..............36 Constructing fixtures ..............36 6.3.1 Rigidity ................36 6.3.2 Weight ................37 6.3.3 Locating the load .............37 Attaching Cables and Feeds ............

- Page 8 Preface 9.3.1 RS-232 Handshaking Modes...........55 9.3.2 Synchronous RS-232 Interfacing ........56 9.3.3 RS-232 default configuration interfacing......57 9.3.4 Disabling RS-232 responses..........58 10 RS-232 Quick Start 10.1 Outline of Section 10..............59 10.2 PM500-C6 configuration for RS-232 (Quick Start)....59 10.2.1 What you’ll need .............59 10.2.2 Verifying communication..........61 11 GRIP (IEEE-488) Computer Interface 11.1 Outline of Section 11..............

- Page 9 viii Preface 12.6.2 Parallel Program Execution (Serial Poll) ......80 12.7 Serial Polling ................80 13 Programming the PM500-C6 13.1 Outline of Section 13..............81 13.2 System Software of PM500 Controllers........82 13.3 Checking Your System Software Version........82 13.4 The Difference Between the Modes ........... 83 13.5 Status and Error Report Flowchart for the PM500.....

- Page 10 Preface 18.9 Controller- Maintenance............282 18.10 Maintenance Schedule.............. 283 19 Service 19.1 Outline of Section 19..............285 19.2 Removing and Installing Axis Boards........286 19.2.1 Axis card removal............287 19.2.2 Axis card installation.............288 19.3 Removing and Installing the Controller Board ......289 19.3.1 Controller board installation..........291 19.4 Upgrading System Firmware............

- Page 11 Preface 25 Appendix F 25.1 Outline of Appendix F.............. 317 25.2 Packaging your PM500 System..........317 25.3 Packaging your PM500-C6 Controllers ........318 26 Appendix G 26.1 Warranty and Service Policy ............ 319 27 Appendix H 27.1 Service Form ................321 28 Appendix I 28.1 System Settings ................

-

Page 12: List Of Figures

Preface List of Figures Figure 1: General Warning or Caution Symbol ......... 15 Figure 2: Grounding Symbol ..............15 Figure 3: Electrical Shock Symbol ............15 Figure 4: P500 Stage .................. 20 Figure 5: PM500 Stage Shipping Tab............20 Figure 6: PM500 Stage Shipping Tab............ - Page 13 Preface Figure 43: PM500 Controller functional elements........269 Figure 44: Motherboard................270 Figure 45: Power supply/Motherboard functional elements...... 270 Figure 46: Controller board................ 271 Figure 47: High Resolution Axis Board............ 273 Figure 48: Figure 16.8: Axis board schematic........... 273 Figure 49: Schematic of axis board velocity loop........

-

Page 14: Introduction

Introduction Scope of the Manual Welcome to the PM500 Series Operations and Command Reference Manual. This manual provides descriptions, operating procedures, and service requirements for the PM500 Linear and Rotary Stages. Safety considerations, conventions and definitions are provided in Section 2, Safety Considerations. -

Page 15: Manual Conventions

Introduction Manual Conventions The following conventions and standards will be used in this manual. 1.2.1 Keys, Buttons and Icons Computer keyboard keys and onscreen buttons and icons are used in the text to describe many user operations. The key-top symbol as it appears on the keyboard, the button or icon name is represented in boldface type. -

Page 16: Safety Precautions

Electrical Shock Symbol The Electrical Shock Symbol in the figure above appears on labels affixed to the PM500 Series Products, and this symbol indicates a hazard arising from dangerous voltage. Any mishandling could result in irreparable damage to the equipment, and personal injury or death. -

Page 17: Terminology

Safety Precautions Terminology The following is a brief description of the terms specific to PM500 Series Controller and Stages. Axis – a logical name for a stage/positioner/ motion device Encoder – a displacement measuring device, term usually used for both linear and rotary models. -

Page 18: Safety Considerations

• Do not make modifications or parts substitutions. • Return equipment to Newport Corporation for service and repair. • Do not touch, directly or with other objects, live circuits inside the unit. • Keep air vents free of dirt and dust. - Page 19 Safety Precautions WARNING This product operates with voltages that can be lethal. Pushing objects of any kind into cabinet slots or holes, or spilling any liquid on the product, may touch hazardous voltage points or short out parts. WARNING When opening or removing covers observe the following precautions: •...

-

Page 20: Getting Started

Getting Started Outline of Section 1 The following topics are covered in this section: • Unpacking and inspection of the system • Handling of motion devices For additional setup and operation information for optional features, refer to the appropriate sections: OPTION SECTION Vertical stages... -

Page 21: Unpacking And Handling

Getting Started Unpacking and Handling CAUTION All PM500 stages must be handled with care during shipping. Unpack your system carefully. PM500 stages are double-boxed and wrapped in plastic. Always handle stages by the base. Do not handle the stages by the motor or by the carriage. -

Page 22: Inspection And Damage

(if any). CAUTION Please request an empty box and/or stage locking tabs from Newport if you do not have them. Do not ship the stage without the locking tabs installed or without the proper shipping materials. -

Page 23: Linear Stage Shipping Tab Removal (Except Pm500-1A, 1L, 1V)

If you have any concerns about the safe operation of this equipment contact Newport Corporation. Linear Stage Shipping Tab Removal (Except PM500-1A, 1L, 1V) To prevent damage during shipping, a temporary steel restraining plate has been installed between the stage carriage and body. -

Page 24: Mounting Positioners And Actuators

Mounting Positioners and Actuators Outline of Section 4 The following topics are covered in this section: • Considerations for mounting motion devices • Proper mounting of motion devices Great care must be taken when attaching stages to work surfaces. PM500 stages are manufactured to better than micron-level flatness, whereas most optical benches and other common work surfaces are flat within only a few thousandths of an inch. -

Page 25: Preparing The Mounting Surface

Mounting Positioners and Actuators Preparing the Mounting Surface Before mounting the stage to a surface, remove all dirt, dust, or particulate matter which may affect the flatness of the surface. For metal surfaces we recommend hand-lapping the surface with an Indian Oil Stone to remove any high spots, rough areas or burrs. -

Page 26: Mounting Pm500-1A Actuators

Mounting Positioners and Actuators Mounting PM500-1A Actuators PM500-1A actuators are designed to replace 3/8-inch diameter micrometers and can operate a broad range of positioning components. Follow these guidelines for best performance: • Install in positioning components that employ clamp or ring-nut mounting (ring-nut mounting is preferred avoid set screws) which impose a high point load on the actuator mounting barrel. -

Page 27: Mounting Pm500 Linear Stages (Except Pm500-1L)

Mounting Positioners and Actuators Figure 10: Mounting PM500-1 Linear Stage The base plate will protect the stage from damage if it is affixed to an uneven mounting base. Motion Devices may be bolted together directly without the base plate. Mounting PM500 Linear Stages (Except PM500-1L) •... -

Page 28: Figure 11: Exploded View Of Linear Stage

If these screws are not available to you, contact Newport. PM500 rotary stages should be mounted with 1/4-20 x 1 1/2" screws via the four mounting thru-holes provided. Caution should be exercised that mounting hardware will not obstruct motion. -

Page 29: Mounting Pm500 Rotary Stages

Mounting Positioners and Actuators Mounting PM500 Rotary Stages PM500 rotary stages can be mounted vertically but are not designed to handle high-torque loads. In extreme cases, such as when the load mass isn’t placed about the center of rotation, the stage will stall, oscillate or continuously servo to position. -

Page 30: Device Controller Interconnection

Device damage or improper operation may result if motion devices and axis cards are mixed. Newport strongly cautions against attempted use of PM500 motion devices with other controllers. CAUTION Linear motion devices (stages and actuators) are supplied with PM500-L16 cables. -

Page 31: Matching Devices And Axis Cards

Rack Mounting The PM500 can be rack-mounted using either rack slides or rack ears. Rack ears (PM500-R) are available from Newport. The unit also has provisions for rack slides, accessible by removing the side plates via the button-head screws. The PM500 feet can be removed for rack mounting. -

Page 32: Back Panel Connectors

Device Controller Interconnection Back Panel Connectors Locate the following connectors on the controller’s rear panel (refer to Figure 15). • Voltage selector (slide switch) • Remote motor shutdown (BNC connector) • Circuit breaker • Power cord receptacle • Remote console operator interface (9-pin D-style connector) WARNING Dangerous Voltages Present. -

Page 33: Connecting Cables

Device Controller Interconnection Connecting Cables CAUTION Controller power should be off before connecting cables. Cable connections should be made with the power OFF to prevent possible damage. Cables should be securely fastened with both screws on the D-style connector. Loose screws/connections can result in erratic or uncontrolled motion. -

Page 34: Remote Motor Shutdown Connector

Device Controller Interconnection Remote Motor Shutdown Connector An emergency motor stop BNC connector is provided on the back panel below the cooling fan. It is an emergency motor shutdown for the entire PM500 system. When tied to ground, either remotely or via the permanently attached BNC shorting cap provided, motor power is enabled. - Page 35 Device Controller Interconnection This page is intentionally left blank Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 36: Attaching Loads To Positioners

Attaching Loads to Positioners Outline of Section 6 This section covers: • Effects of vibration • Constructing fixtures for stages • Attaching cables and feeds The placement, attachment, and location of loads is a critical factor in sub- micron motion control. Loads can include: •... -

Page 37: Effect Of Vibrations

Attaching Loads to Positioners Figure 16: Placeing loads. Effect of Vibrations The PM500 servo system senses stage vibration if the amplitude of the vibration is greater than the system resolution. Such vibration may cause oscillations as the servo tries to compensate. This usually occurs after a movement (but not necessarily a movement of the oscillating stage). -

Page 38: Weight

Attaching Loads to Positioners 6.3.2 Weight The combined load of the fixture and your sample (and the top stage in multistage configurations) should not exceed the load capacity of the stage that supports it (see Figure 17). When cantilevered, even lighter loads can exceed the stage capacity. -

Page 39: Attaching Cables And Feeds

Attaching Loads to Positioners Attaching Cables and Feeds Never allow stage motion to drag cables or feeds. Always secure, but do not restrict cables. Support cable from above if possible (see Figure 17). The dragging of cables can cause micron-level disturbances in the motion system. This can cause the motion system to attempt to compensate for the disturbance. -

Page 40: Vertical Stages

• Ultra-precision Z-bracket We recommend that the pneumatic load-compensation piston be used in all vertical applications. Should you decide to build your own Z-bracket, contact Newport for design guidelines. CAUTION Proper preparation of the mounting surface for Z-bracket installation is essential. Z-bracket surfaces are machined to... -

Page 41: Figure 21: Mounting To Another Stage

Attaching Loads to Positioners 6.5.1.1 Z-bracket mounting Mounting the Z-bracket requires care to avoid twisting or distorting of the bracket which can compromise motion performance. 6.5.1.2 Mounting directly to the work surface The bracket should be securely fastened to a super flat or lapped surface and attached using four bolts. -

Page 42: Pneumatic Load Compensation Piston

Attaching Loads to Positioners Pneumatic Load Compensation Piston The pneumatic load-compensation piston uses air pressure to counterbalance the load on the stage. The air regulator must be precisely adjusted to counter the stage load. The regulator setting is usually made at the factory using the weight of the load given by the user. -

Page 43: Routing Of Air Supply Line

Attaching Loads to Positioners 12. Adjust air pressure. Increase if motor current is higher moving up then down, decrease if motor current is higher moving down then up. 13. Repeat steps 7 through 12 until motor current is within 8 to 10 DAC counts when traveling in both directions. -

Page 44: Operation

Operation Outline of Section 7 The following topics are covered in this section: • Choosing an interface—RS-232/GPIB Choosing an Interface In general, the PM500-K Remote Control Console is useful only for manual control of very simple positioning tasks. To take full advantage of the advanced features and capabilities of the PM500 system, we recommend operation using the RS-232 or GPIB (IEEE-488) communication interfaces. -

Page 45: Gpib

Operation Disadvantages • Low to moderate speed (up to 19k baud or 2k cps) • Supports only one instrument per port • No synchronization or coordination facilities • Cabling, pin-outs, handshaking and protocols not standardized 7.2.2 GPIB Advantages • Moderate to high speed (up to 10 characters per second) •... -

Page 46: Pm500-K6 Remote Control Console

PM500-K6 Remote Control Console Outline of Section 8 The following topics are covered in this section: • Connecting the console • Operating modes • Controlling the PM500-K6 • Menu key functions Features The PM500-K6 Remote Control Console provides manual control over most motion operations and continuous position display for three selected axes. -

Page 47: Connection

PM500-K6 Remote Control Console Connection WARNING Do not attempt to connect anything other than the PM500-K or K6 Remote Control Console to the operator interface port. Voltages are present at this interface which can cause personal injury. Uncontrolled motion or damage to system may also result. -

Page 48: Execute Mode Operation

PM500-K6 Remote Control Console 8.3.1 Execute mode operation Briefly pressing a keypad key causes a jog motion; if you hold the keypad key down, after a moment continuous slewing will occur. The displays will show the position of selected axes. The size of the jog and slew speed depend on the speed range selected. -

Page 49: Menu Key Functions

PM500-K6 Remote Control Console Menu Key Functions The menu/Set functions are as follows: Pressing the UP or DOWN key enters the menu system. Each subsequent UP or DOWN keystroke sequences through the menu options. The PROGM key executes and stores the current selection. The CLEAR key exits the menu system (without saving if menu instructions do not request it) and the PM500-K6 returns to Execute mode. -

Page 50: Setup Menu

PM500-K6 Remote Control Console 8.4.2 Setup Menu The Setup Menu lets you modify certain key functions and facilitates the selection and storing of menu parameters. To access the Setup Menu, cycle through the main menu until the display reads “Press PROGM to enter Setup Menu.”... -

Page 51: Controlling The Pm500-K6 Via Rs-232/Gpib

PM500-K6 Remote Control Console Press PROGM to execute clear position command. The PM500-K6 will clear the position register of the PM500 and return to execute mode. Example: Clear Axes Position Press the UP key in the Menu/Set keypad, and sequence through the Main menu until the display selection reads “Press PROGM to clear position of all axes.”... -

Page 52: Computer Interface

RS-232 Computer Interface Outline of Section 9 The following topics are covered in this section: • Setup • Operation Setup and Operation The RS-232 port allows the PM500 to communicate with computers having a RS-232 port. High-level language programs can be written to customize control of the PM500. -

Page 53: Setting The Rs-232 Parameters

RS-232 Computer Interface 9.2.2 Setting the RS-232 parameters Back Panel Figure 23: DIP switch location in PM500-C6 9.2.3 Configuring for RS-232 communications The PM500 is shipped configured for GPIB communication. You’ll need to reconfigure the controller for RS-232. This is done by the mode switches located on the SBC board inside the controller. -

Page 54: Rs-232 Interface Specifications

RS-232 Computer Interface 9.2.4 RS-232 interface specifications The RS-232 port on the back panel of the PM500 controller is a 25-pin female connector. Figure 25: Back panel of the PM500 controller. 9.2.5 Description of the PM500 RS-232 port The PM500 RS-232 port is a db25-pin female connector. Pin # Description Protective ground. -

Page 55: Rs-232 Cable Length Restrictions

RS-232 Computer Interface Voltage specifications for the RS-232 interface Open-Circuit Voltage +25 volts Permissible +15 volts Logical“0” “ON” Condition +5 volts or “Space Noise margin +3 volts Transition Region 0 volts Noise Margin -3 volts Logical “1” “OFF” Condition -5 volts or “MARK”... -

Page 56: Rs-232 Operation

RS-232 Computer Interface Example 2: Three-wire hookup with XON / XOFF PM500 pins Host device (DTC or DTE) Description Protective ground Signal ground 3 or 2 Data to PM500 2 or 3 Data from PM500 Enable transmitter on PM500 Enable transmitter on DCE/DTE Example 3: Full hardware handshake PM500 pins Host device (DTC or DTE) -

Page 57: Synchronous Rs-232 Interfacing

RS-232 Computer Interface 9.3.1.1 Considerations for configuring the RS-232 handshaking mode When using the system in RS-232 mode, overall system goals must be considered. If the host computer interface is a simple, one-action/one- reaction type of system, then sending commands and acknowledging them via the STAT command is the easiest method of interfacing. -

Page 58: Rs-232 Default Configuration Interfacing

RS-232 Computer Interface 9.3.2.1 Asynchronous RS-232 interfacing This method involves sending commands, acknowledging them, and waiting for the status of an axis response. This is the most efficient method of interfacing. The required configuration command is: SCUM1 SENAINT $876 (See SENAINT command—Section 16 - Command Reference.) •... -

Page 59: Disabling Rs-232 Responses

RS-232 Computer Interface • no immediate limit reporting • transfer all axes on limit The interface process is: User Sends User Reads Response Means Echo XG 1000 XG 1000 Command accepted Echo YG 1000 YG 1000 Command accepted X axis done Y axis done NOTE An important point about echoes: If a command entry is in process, each... -

Page 60: Quick Start

RS-232 Quick Start 10.1 Outline of Section 10 The following topics are covered in this section: • PM500-C6 configuration 10.2 PM500-C6 configuration for RS-232 (Quick Start) 10.2.1 What you’ll need RS-232 cable (A 25-pin female connector is required for the PM500 back panel;... -

Page 61: Figure 27: The Rs-232 Parameters Are Changed Via S1 And S2 Switch

RS-232 Quick Start Figure 27: The RS-232 parameters are changed via S1 and S2 switch . After replacing the cover and restarting the PM500-C6, launch the Hyper Terminal Program, type the PM500 command COMOPT3, and then press Enter or Return. This command enables completion of signaling and echoing. Figure 28: Command to complete signaling and echoing. -

Page 62: Verifying Communication

RS-232 Quick Start 10.2.2 Verifying communication To test successful configuration of the Terminal Program and the PM500 motion controller, type SCUM0 and press Enter or Return. The PM500 should respond with the firmware version as shown in Figure 29. Figure 29: PM500 response to firmware version query. Refer to Section 16 - Command Reference for a complete list of RS-232 commands. - Page 63 RS-232 Quick Start This page is intentionally left blank Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 64: Grip (Ieee-488) Computer Interface

The IEEE- 488 port allows the PM500 to communicate with computers and other devices that have a GPIB port. Free instrument drivers for the PM500 and other GPIB-compatible Newport instruments are available for LabVIEW, in Windows. Commands are sent to the PM500 controller through the GPIB port via a standard IEEE-488 cable. -

Page 65: Setting The Gpib Address

GRIP (IEEE-488) Computer Interface 11.2.2 Setting the GPIB address Back Panel Figure 30: DIP switch location in PM500-C6 The default GPIB address for the PM500 as shipped from the factory is 1. Should the default address be in conflict with another GPIB device address, you may change the PM500 controller address to any other valid GPIB address by setting the mode switches located on the controller board inside the controller. -

Page 66: Gpib Quick Start With Interactive Control Software

GRIP (IEEE-488) Computer Interface 11.3 GPIB Quick Start with Interactive Control Software In order to begin communicating with your PM500 quickly, try the following example using Interactive Control Software by National Instruments (starting from version 1.6), a terminal emulation program included with National Instruments’... -

Page 67: Ieee-488 Operation

GRIP (IEEE-488) Computer Interface 11.4 4.2.1.2 IEEE-488 Operation The following capabilities are supported in the PM500’s IEEE-488 interface: Complete source handshake Complete acceptor Basic talker, serial poll-unaddressed if MLA Basic listener, serial poll-unaddressed if MTA Complete service request capabilities Remote local, no local lockout Parallel poll, remotely configurable Device clear, complete capability Device trigger, complete capability... - Page 68 GRIP (IEEE-488) Computer Interface The most powerful interface method is the IEEE-488 service request function. This method reduces your computer overhead and also reduces the bus activity considerably. This method can be enhanced by using parallel poll in conjunction with serial poll. The following sequence shows an application: User sends User reads Response means...

- Page 69 GRIP (IEEE-488) Computer Interface This page is intentionally left blank Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 70: Motion Programming

Motion Programming 12.1 Outline of Section 12 The following topics are covered in this section: • Command Types and their Responses • Command Syntax • Status Characters • GPIB basics • SRQ Assertion (GPIB) • Serial Polling (GPIB) 12.2 Command Types and Their Responses There are two types of commands as defined by IEEE-488.2 standard. -

Page 71: Command Types

Motion Programming Command Types 12.2.3 12.2.3.1 System Control Command System Control commands allow global recovery/modification of the system’s configuration/operation. 12.2.3.2 RS-232 In RS-232 mode, system commands do not allow acknowledge reporting upon receipt of a command. When the command is complete or an error has occurred, the system will return a status message. -

Page 72: Read/Status Commands

Motion Programming 12.2.4.2 IEEE-488 In IEEE-488 mode the response from these commands may be determined by issuing a “READ/STATUS”, i.e. <axis>R?, <axis>STAT?, command or by performing an interface serial poll function. The serial poll will generate a response that has the following bit definitions: Bits Decimal Description... -

Page 73: Read Response Formats

Motion Programming 12.2.5.1 RS-232 In RS-232, the “acknowledge” reporting is suppressed upon receipt of a Read/Status command. The system returns a response that includes the system status as well as any additionally requested data. The output is buffered to allow operation of interrupt driven systems with independent input/output data paths. -

Page 74: Parametric Data Commands

Motion Programming Low-speed loop velocity and acceleration units are: Velocities: µm (arc-sec) per second µm (arc-sec) per second 2 Accelerations: The default units for velocities and accelerations when specified in hexadecimal are: Velocities: Counts per millisecond * 65536 Counts per millisecond 2 * 65536 Accelerations: This hexadecimal representation allows fractional entry of counts per millisecond by observing the following format:... -

Page 75: Command Syntax

Motion Programming 12.3 Command Syntax Commands for the PM500 have the following syntax construction: For system or motion commands 12.3.1 <ID> <COMMAND>[1 space][parameter]\terminator No space is allowed between the <ID> and <COMMAND> else a command error will result and the command will be ignored. A [space] is allowed between the <COMMAND>... - Page 76 Motion Programming 5-axis controllers 6-axis controllers Description Description X axis X axis Y axis Y axis Z axis ZZ axis A axis A A axis B axis B axis System C axis System * 5 axis controller under SCUM1 mode references the command issued, see Command COMMAND Reference section.

-

Page 77: Numeric Formats

Motion Programming 12.3.5 Numeric Formats 12.3.5.1 Decimal Number Entry Decimal number entry is supported by the following IEEE-728 formats: NR1, NR2, and NR3 Exponent notation is accepted by the controller. Twelve digits are allowed (excluding the decimal point) before the exponent. The exponent is optional and is invoked by an “E”... -

Page 78: Command Status Characters

Motion Programming 12.4 Command Status Characters PM500 returns can be customized to include a single ASCII status character with each return. The status character field is a fixed length of 1. The format of returns will be: <axis or system ID> <status character> <response value-numeric> The first return field will be 1 character;... -

Page 79: Gpib Basics

Motion Programming Enabling Status Characters The Status and acknowledge characters are enabled via the COMOPT (1–7) or ENAINT Command. The COMOPT command offers a pre-selected menu of various communications protocols. The ENAINT command allows custom control of each of the command parameters. See the Command Reference section for more information on the appropriate command. -

Page 80: Table 1: A Graphical Representation Of The Pm500 Srq Register

Motion Programming that bus speed is not loaded down by the addition of instruments on the bus. The PM500 supports the IEEE-488 GPIB (SRQ) Request for Service function. The user can define what events, if any, occurring within the PM500 will trigger a (SRQ) Service Request. This is done via the PM500’s SRQ register. -

Page 81: Srq Assertion/Serial Polling Methods

Motion Programming In addition to the Serial Poll register, the PM500 has a hierarchical register system for establishing detailed information on status and errors. These are the STAT, ESTAT, and EESTAT registers: • STAT—single character status • ESTAT—device level error register value When a FAULT condition occurs the user can refer to the STAT, ESTAT, and EESTAT registers respectively to derive the specific nature of an error or status condition. -

Page 82: Programming The Pm500-C6

Programming the PM500-C6 13.1 Outline of Section 13 System Software of PM500 Controllers Checking your PM500-C6 System Software The Difference Between the Modes Status and Error Reporting System of the PM500 Error Handling Program Flow charts: • System Initialization • General Communication and Handshaking •... -

Page 83: System Software Of Pm500 Controllers

This usually encompasses a simple firmware (EPROM) change. However, some earlier PM500 systems, pre 1990 may also require a hardware upgrade. Contact Newport with your systems serial number for more information about upgrading your system firmware. Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 84: The Difference Between The Modes

Programming the PM500-C6 13.4 The Difference Between the Modes There are 3 significant differences between the system level communications mode and the earlier PM500 communications mode: 1. A new serial poll register format is available - via the SENAINT command to provide event reporting for up to 6 axes. Old 5 axis serial Poll register FAULT SRQ DONE... -

Page 85: Status And Error Report Flowchart For The Pm500

Programming the PM500-C6 13.5 Status and Error Report Flowchart for the PM500 ESTAT? Bitmap Response: EESTAT? Bitmap Response: <axis>EESTAT? Bit 0: Data not present Bit 0: Edge range error Bit 1: Extra data present Bit 1: Edge width error Bit 2: Invalid data entry Bit 2: Edge overflow error Bit 3: Data overrun Bit 3: EC slope error... -

Page 86: Error Handling

ENAINT command i.e. Bit 0 of the ENAINT register controls whether the system will halt all axes on an single axis limit or only the effected axis. Lab View examples can be downloaded from Newport Website-www.newport.com Initializing the PM500 (SCUM1 13.6.1... -

Page 87: General Communication And 'Handshaking' With Pm500

Programming the PM500-C6 This configures the SCUM1 PM500 controller under SCUM1 and clears out the system. Send: SSRQCTL$EF NOTE: This procedure is for 6- and 12-axis PM500 controllers. Send: SENAINT$6207 Perform: Bit 16 = 0 No Serial Poll (Serial Polling will clear any "stacked"... -

Page 88: Simultaneous Preset Motions

Programming the PM500-C6 Settings for this mode: Send Command SCUM1 SSRQCTL$EF SENAINT$6207 (You may "Wait for SRQ" hardware Serial Poll Wait for SRQ line to assert or you can Serial Poll Bit 6 (SRQ) until Bit = 6 (SRQ) to be set.) SRQ asserted Serial Poll Bit 4 = On... -

Page 89: Figure 35: Pm500'S Simultaneous Preset Motion

Programming the PM500-C6 Figure 35: PM500’s simultaneous preset motion. NOTE Specific acceleration, deceleration, and velocity can be specified for the preset move. The move definition and trigger command used depends upon the move type to be initiated. There are two sets of preset move definition commands and trigger commands which depend upon the type of move (relative or absolute) to be initiated. -

Page 90: The Motion Profile And Related Motion Commands

Programming the PM500-C6 13.7 The Motion Profile And Related Motion Commands The PM500 has a unique self-adjusting motion profiling and servo system. The command set is intuitive and easily related to the classical “trapezoidal move profile.” Take time to read through this section, as it will provide valuable insight into the significance and relationships of the PM500 motion command set. -

Page 91: Motion Device Dependent Commands & Pm500 Devices

Programming the PM500-C6 motion dependent on the size of the motion. This allows the user to execute motions of various sizes without specifying velocity and accelerations. The function of these three speed ranges is analogous to driving a car. To travel a few meters one would not attempt to cover that distance at maximum acceleration, but rather at a lower speed to provide better accuracy with no overshoot. -

Page 92: Rotary Motion Device Commands

Programming the PM500-C6 Figure 38: Linear motion device commands forPM500 Linear Stages. All motions are centered about the stage fiducial point (center of travel). You must specify motions in (+) positive or (–) negative for motions relative to this point. The default direction of motion (+direction) is towards the motor Units Position: Position commands should be in microns. -

Page 93: Figure 39: Pm500-360/A Rotary Stages

Programming the PM500-C6 –1 — 45° 315° 0° 90° 270° 225° 135° 180° Figure 39: PM500-360/A Rotary stages. Units Position: Position commands should be in arc-seconds. All returns from position queries are in arc-seconds. Velocity: In K arc-sec/sec In K arc-sec/sec 2 Acceleration: Fiducials: The PM500-Rotary stages have 8 fiducial points located... -

Page 94: Vertical Motion Device Commands

Programming the PM500-C6 13.9.3 Vertical motion device commands The following illustration demonstrates various commands that relate to mechanical properties of PM500-1V Vertical linear stage. The default direction of motion (+ direction) is up. Figure 40: PM500-V1 Vertical stages. Units Position: Position commands should be in microns. -

Page 95: Essential Motion Commands

Programming the PM500-C6 13.10 Essential Motion Commands The following is a list of the most often used commands of the PM500 command set: Initialization Commands Page ENAINT Communications Configure SCUM System Communications Mode Enable SRQCTL Service Request Assertion Masking Motion Commands Page Go Absolute... -

Page 96: Command Index (By Type)

Command Index (by Type) System/control commands Page Auto zeros analog control loops CONFIG Reports axis firmware version SDEFEE Default EEPROMs (follow w/RSTART) Emergency Shutdown protocol Motor off command NULL Sets null window size SRSTART Restarts the entire system SAVEAX Saves axis configuration SETUP Used in service. - Page 97 Command Index (by Type) Goes to home position (position = 0) Offsets clear command OFFSET Defines position offset Transfers position command (motor “ON”) Relative motion commands Page Defines relative position Goes to specified relative position Goes to relative preset position Same as GR - low speed loop Moves relative command Offset clear command...

- Page 98 Command Index (by Type) Low and ultra-low speed loops HSLOPE Sets holding slope parameter LACCEL Sets low speed loop acceleration LDECEL Sets low speed loop deceleration LSIZE Defines the threshold between high and low speed loop Sets low speed loop max. velocity Ultra-low-speed scan Ultra-low-speed velocity Read/Status commands...

- Page 99 Command Index (by Type) SOMRAE Sets up PM500-K remote control status SOMSA Controls PM500-K setup menuing SOMSCAN Sets scan rate for PM500-K control SOMSPD Selects PM500-K speed control keys SOMSPDA Controls PM500-K speed keys SSAVEOM Saves PM500-K settings to memory Essential motion commands Page ACCEL...

-

Page 100: Command Index (Alphabetical)

Command Index (Alphabetical) In a PDF format you may click on a line to be automatically taken to the corresponding page. ACCEL - Define Acceleration for High-Speed Loop ACCEL? - Acceleration for High-Speed Loop Query AZ - Auto Zero Self Calibration C - Clear Position S/COMOPT –... - Page 101 14BCommand Index (Alphabetical) ESTAT - Read Error Register F - Fiducial Seek FNUM - Define Fiducial Default Number FV - Fiducial Velocity G - Go to Position Absolute G? - Position Absolute Query GP - Go to Preset Absolute Position GR - Go Relative Move GRP - Go to Preset Relative Position H - Home...

- Page 102 Command Index (Alphabetical) NULL - Define Null Window Size NULL? - Null Window Size Query OC - Offset Clear OFFSET - Define Position Offset OFFSET? - Position Offset Query S/OMA - Power On/Off PM500-K6 S/OMA? - Power On/Off PM500-K6 Query N/OMAA - Enable PM500-K6 Axis N/OMAA? - PM500-K6 Active Axis Enabled Query S/OMDA - Enable PM500-K6 Display...

- Page 103 14BCommand Index (Alphabetical) S/OMSPD - Define PM500-K6 Speed Level S/OMSPD? - PM500-K6 Speed Level Query S/OMSPDA - Enable PM500-K6 Speed Select Keys S/OMSPDA? - PM500-K6 Speed Select Keys Enable Query N/OMSTEP - Define PM500-K6 Speed Key Step Size N/OMSTEP? - PM500-K6 Speed Key Step Size Query PM - Preventive Maintenance PMACC - Define Preventive Maintenance Acceleration PMACC? - Preventive Maintenance Acceleration Query...

- Page 104 Command Index (Alphabetical) SCUM - System Communications Mode SETUP - Service Command - Servo Adjustment SIGN - Define Default Direction for Motion Coordinate System SMP - System Move to Preset Absolute Positionc (For use in SCUM1 mode only) SMPL - System Move Preset Logic (For use in SCUM1 mode only) SMRP - System Move to Relative Preset (For use in SCUM1 mode only) SRQCTL - Define SRQ Serial Poll Mask S/RSTART - Restart Entaire System...

- Page 105 14BCommand Index (Alphabetical) This page is intentionally left blank Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 106: Command Reference

Command Reference ACCEL - Define Acceleration for High-Speed Loop Syntax: [n]ACCEL <acceleration> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose High speed Loop acceleration is to be set. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted. - Page 107 15BCommand Reference User set values can be stored in non-volatile memory using the [n]SAVEAX command. User set SAVEAX values are restored after system power-up. See SAVEAX command for details. Recommendations: The factory default setting of this value will provide excellent performance under a broad range of loads and velocities.

- Page 108 Command Reference ACCEL? - Acceleration for High-Speed Loop Query Syntax: [n]ACCEL? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose High speed Loop acceleration is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 109 15BCommand Reference - Auto Zero Self Calibration Syntax: [n]AZ Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis is to be self calibrated. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 110 Command Reference User set SAVEAX values are restored after system power-up. See SAVEAX command for details. Recommendations: The AutoZero command should be issued shortly after system warm-up prior to use. The SAVEAX command should be issued to save the AutoZero parameters. Related commands: AZVAL? Artisan Technology Group - Quality Instrumentation ...

- Page 111 15BCommand Reference - Clear Position Syntax: [n]C Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose position is to be cleared. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted. A space is allowable between the command and the parameter but is not required.

- Page 112 Command Reference S/COMOPT – Communication Setup Syntax: (S)*COMOPT <option> Parameters: <option> must be an interger within the range as defined by the options listed. The <option> will be rounded to the nearest interger or ignored if out of range. A space is allowable between the command and the parameter but is not required.

- Page 113 15BCommand Reference Examples: Send: COMOPT 1 The above example sets communication for RS232, echo disabled, sign on message disabled, acknowledge reporting enabled, command completion/termination disabled, CR LF termination on. User set values can be stored in non-volatile memory using the [n]SAVEAX command. User set SAVEAX values are restored after system power-up.

- Page 114 The above example queries the X axis configuration. The return is an axis configuration code. Recommendations: This command is useful when axis configuration is unknown. Contact Newport for the type of interface option (if present) that the code represents. Related commands: VN? SVN?

- Page 115 15BCommand Reference CSCUR - Define Motor Current Limit Syntax: [n]CSUR <-limit> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose current limit value is to be modified. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 116 Command Reference Range: -511 to 0 Each bit equals 0.02 amperes of motor current. Defaults: Linear and rotary translators: -150 (3 amps) PM500-1 Mini-Stage: PM500-1A Actuators: -50 (1 amps) Returns: NONE Examples: Send: XCSUR -100 The above example sets the X axis motor current to 2 amps.

- Page 117 15BCommand Reference CSCUR? - Define Motor Current Limit Query Syntax: [n]CSUR? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose current limit value is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 118 Command Reference Recommendations: It is not recommended that this parameter be adjusted. The factory default setting of this value will provide excellent performance under a broad range of loads and velocities. Any modification to this command should be in conjunction with changes to the related commands listed below.

- Page 119 15BCommand Reference CSMOVE - Define Motor Current Limit Sense Move Value Syntax: [n]CSMOVE <distance> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose motor limit move value is to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 120 Command Reference Recommendations: It is not recommended that this parameter be adjusted. The factory default setting of this value will provide excellent performance under a broad range of loads and velocities. Any modification to this command should be in conjunction with changes to the related commands listed below.

- Page 121 15BCommand Reference CSTIME - Define Motor Current Limit Sense Time Value Syntax: [n]CSTIME <time> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Motor Current Limit Sense time is to be modified. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 122 Command Reference User set values can be stored in non-volatile memory using the [n]SAVECS command. User set SAVECS values are restored after system power-up. See SAVECS command for details. Recommendations: It is not recommended that this parameter be adjusted. The factory default setting of this value will provide excellent performance under a broad range of loads and velocities.

- Page 123 15BCommand Reference CSTIME? - Motor Current Limit Sense Time Query Syntax: [n]CSTIME? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Motor Current Limit Sense time is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 124 Command Reference DECEL - Define Deceleration Value for Large Moves Syntax: [n]DECEL <value> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose deceleration is to be modified. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 125 15BCommand Reference DECEL? - Deceleration Value for Large Moves Query Syntax: [n]DECEL? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose deceleration is to be modified. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 126 Command Reference DEFCS - Default Current Sense Parameters Syntax: [n]DEFCS <option> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose current sense parameters are to be defaulted. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 127 15BCommand Reference SDEFEE - System Reset to Factory Defaults Syntax: (S)*DEFEE Parameters: This is a system level command. This command under SCUM1 operation will require the system ID specifier. No axis identifier or parameter is allowed with this command else the command will not be executed and a command error will be posted.

- Page 128 Command Reference DEFLM - Default Axis Soft Limits Syntax: [n]DEFLM <option> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis soft limits is to be defaulted. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 129 15BCommand Reference SDEFOM - Default PM500-K6 Settings Syntax: (S)*DEFOM <option> Parameters: This is a system level command. This command under SCUM1 operation will require the system ID specifier. No axis identifier or parameter is allowed with this command otherwise the command will not be executed and a command error will be posted.

- Page 130 Command Reference - Define Preset Position Syntax: [n]DP <position> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose position is to be predefined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 131 15BCommand Reference - Preset Position Query Syntax: [n]DP? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose predefined position is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 132 Command Reference - Define Relative Preset Position Syntax: [n]DRP <position> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose position is to be predefined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 133 15BCommand Reference DRP? - Relative Preset Position Query Syntax: [n]DRP? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose position is to be predefined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 134 Command Reference EESTAT - Read Execution Error Register Syntax: [n]EESTAT Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Execution Error Register is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 135 15BCommand Reference Refer to Section 19.7 - Troubleshooting Tables for correction procedures of system errors. Returns: Bit mapped value in hexadecimal format Examples: Send: Receive: AE+000456.0 an “E” error, check ESTAT Send: ESTAT Receive: AE$400000 The error returned is Hex 400000 which equalsdecimal 4194304, which is bit 22, thus the error is an Execute Error.

- Page 136 Command Reference ENAINT - Control Internal Configuration Syntax: (S)*ENAINT <$><Hexadecimal bitmap value> Parameters: This is a system level command. No axis identifier is allowed else the command will not be executed and a command error will be posted. The parameter must be in a hexadecimal format and thus requires the value to be pre-pended with a dollar sign ($).

- Page 137 15BCommand Reference Description Options Comments Limit Halt 0: All axes halt when any axis encounter limit GPIB & RS-232 1: Only affected axis will halt Limit out 0: System will respond with <axis>L when commanded RS-232 only message out of limit condition. 1: No message issued when axis move out of limit Query Echo 0: System will respond to queries by echoing the...

- Page 138 Command Reference Description Options Comments Hexadecimal 0: Numbers will be specified in decimal format unless GPIB\RS-232 Format one format or the other is required by the command. When specifying Hexadecimal numbers, you must prepend the number with a dollar sign ($) 1: All numbers will be specified in Hexadecimal format.

- Page 139 15BCommand Reference Value Description ENAINT $606 Global axes halt on fault/limit No Limit out message Query Echo Acknowledge disabled Sign-on disabled No Carriage Return CR\LF\EOI CR LF with CR terminator Example: Send: ENAINT $30F Receive: NONE The above example sets ENAINT bits 0,1,2,4,7 and 9 ON.

- Page 140 Command Reference - Emergency Shutdown Protocol Syntax: [n]ESP <n> Parameters: [n] defines the axis n = X, Y, Z, A, B, C whose emergency shutdown protocol is to be defined. If no axis identifier is specified the command will be ignored and an error will be posted.

- Page 141 15BCommand Reference ESTAT - Read Error Register Syntax: [n]ESTAT Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose error register is to be read. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 142 Command Reference Returns: Bit mapped value in hexadecimal format. Examples: Send: AR Receive: AE+000456.0 an “E” error, check ESTAT Receive: AE$400000 The error returned is Hex 400000 which equals decimal 4194304, which is bit 22, thus the error is an Execute Error. Refer to EESTAT. Send: EESTAT Receive: AE$000100...

- Page 143 15BCommand Reference - Fiducial Seek Syntax: [n]F <option> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C which will be commanded to conduct the fiducial search. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 144 Command Reference Examples: Send:XF-1. In the above example the X axis would move to the extreme of travel in the direction away from the motor then Seek fiducial at center of travel. Recommendations: The fiducial should be used a reference point in your experimental setup.

- Page 145 15BCommand Reference FNUM - Define Fiducial Default Number (Rotary Stages Only) Syntax: [n]FNUM <parameter> Parameters: [n] defines the axis n = X, Y, Z, A, B, C whose fiducial number is to be defined. If no axis identifier is specified the command will be ignored and an error will be posted.

- Page 146 Command Reference - Fiducial Velocity Syntax: [n]FV <option> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose fiducial search velocity will be modified. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 147 15BCommand Reference - Fiducial Velocity Query Syntax: [n]FV? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose fiducial search velocity will be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 148 Command Reference - Go to Position Absolute Syntax: [n]G <position> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose absolute position is to be commanded. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 149 15BCommand Reference - Position Absolute Query Syntax: [n]G? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose absolute position is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 150 Command Reference - Go to Preset Absolute Position Syntax: [n]GP <position> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose preset position is to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 151 15BCommand Reference - Go Relative Move Syntax: [n]GR <distance> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis is to be moved. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 152 Command Reference Recommendations: Due to the unique way the PM500 handles relative motion commands, absolute commands G and the relative command GR can be used interchangeably without the concern of accumulating errors which are normally associated with relative move commands. Related commands: LGR, G Artisan Technology Group - Quality Instrumentation ...

- Page 153 15BCommand Reference - Go to Preset Relative Position Syntax: [n]GRP <position> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose preset position is to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 154 Command Reference - Home Syntax: [n]H Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B,… whose axis is to be commanded. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 155 15BCommand Reference HSLOPE - Define Holding Slope Syntax: [n]HSLOPE <value> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Holding SLOPE is to be modified. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 156 Command Reference • Take the value of HSLOPE noted in Steps 2 or 3 and increase it by approximately 15% and enter it. Check to see if the stage oscillates by tapping on the stage lightly. If oscillations persist, repeat Steps 2 and 4 using an oscilloscope to look for oscillations.

- Page 157 15BCommand Reference INITCS - Initialize Axis Current Sense Parameters Syntax: [n]INITCS Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose current sense parameters is to be initialized. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 158 Command Reference INITLM - Restore Axis Soft Limits Syntax: [n]INITLM Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis soft limits are to be restored. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 159 15BCommand Reference INITOM - Initialize PM500-K6 to User Saved Settings Syntax: INITOM Parameters: No axis identifier is required for this command. No parameters are allowed with this command otherwise a command error will occur. Function: This command initializes the PM500-K6 to power-up values as stored by the SAVEOM command.

- Page 160 Command Reference LACCEL - Define Low Speed Loop Acceleration Syntax: [n]LACCEL <accel> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Low Speed Loop acceleration is to be modified. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 161 15BCommand Reference LACCEL? - Define Low Speed Loop Acceleration Query Syntax: [n]LACCEL? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Low Speed Acceleration is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 162 Command Reference LDECEL - Define Low Speed Loop Deceleration Syntax: [n]LDECEL <decel> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Low Speed Loop Deceleration is to be modified. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 163 15BCommand Reference LDECEL? - Low Speed Loop Deceleration Query Syntax: [n]LDECEL? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Low Speed Loop Deceleration is to be modified. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 164 Command Reference - Relative Move in Low Speed Loop Syntax: [n]LGR <rel move> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis is to be commanded to move. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 165 15BCommand Reference LSIZE - Define Low Speed Loop Threshold Syntax: [n]LSIZE <threshold> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Low Speed Loop threshold is to be defined. A space is allowable between the command and the parameter but is not required.

- Page 166 Command Reference User set values can be stored in non-volatile memory using the [n]SAVEAX command. User set SAVEAX values are restored after system power-up. See SAVEAX command for details. Recommendations: The factory default setting of this value will provide excellent performance under a broad range of loads and velocities.

- Page 167 15BCommand Reference LSIZE? - Low Speed Loop Threshold Query Syntax: [n]LSIZE? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Low Speed Loop threshold is to be queried. A space is allowable between the command and the parameter but is not required.

- Page 168 Command Reference LV - Define Low Speed Loop Velocity Syntax: [n]LSIZE <velocity> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Low Speed Loop velocity is to be defined. A space is allowable between the command and the parameter but is not required.

- Page 169 15BCommand Reference LV? - Low Speed Loop Velocity Query Syntax: [n]LV? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Low Speed Loop velocity is to be queried. A space is allowable between the command and the parameter but is not required.

- Page 170 Command Reference Motor Off Syntax: [n]M Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose motor is to be turned off. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted. No space is allowed between the axis identifier [n] and the command.

- Page 171 15BCommand Reference M? - Motor Status Query Syntax: [n]M? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose motor status is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 172 Command Reference MPACC - Define Acceleration for Preset Motion Syntax: [n]MPACC <acceleration> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose preset motion acceleration is to be set. If the axis identifier is omitted the command will not be executed and a command error will be posted.

- Page 173 15BCommand Reference Recommendations: The factory default setting of this value will provide excellent performance under a broad range of loads and velocities. For large or heavy loads the MPACC should be decreased to avoid long settling times or vibration caused by sudden acceleration. See the System Settings section in this manual for factory settings.

- Page 174 Command Reference MPDEC - Define Deceleration for Preset Motion Syntax: [n]MPDEC <acceleration> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose preset motion deceleration is to be set. If the axis identifier is omitted the command will not be executed and a command error will be posted.

- Page 175 15BCommand Reference excellent performance under a broad range of loads and velocities. For large or heavy loads the MPACC should be decreased to avoid long settling times or vibration caused by sudden acceleration. See the System Settings section in this manual for factory settings. Related Commands: MPACC, MPVEL, SMPL, SMRP, SMP Artisan Technology Group - Quality Instrumentation ...

- Page 176 Command Reference MPVEL - Define Velocity for Preset Motion Syntax: [n]MPVEL <velocity> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose preset motion velocity is to be set. If the axis identifier is omitted the command will not be executed and a command error will be posted.

- Page 177 15BCommand Reference Recommendations: The factory default setting of this value will provide excellent performance under a broad range of loads and velocities. For large or heavy loads the MPACC should be decreased to avoid long settling times or vibration caused by sudden acceleration. See the System Settings section in this manual for factory settings.

- Page 178 Command Reference - Move Relative Syntax: [n]MR <r move> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose motion is to be commanded. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 179 15BCommand Reference - Move Relative Query Syntax: [n]MR? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose last MR command value is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 180 Command Reference NSLIM - Define Negative Soft Limit Syntax: [n]NSLIM <limit val> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Soft Limit is to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 181 15BCommand Reference NSLIM? - Negative Soft Limit Query Syntax: [n]NSLIM? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Soft Limit is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 182 Command Reference NULL - Define Null Window Size Syntax: [n]NULL <value> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose null window is to be modified. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 183 15BCommand Reference NULL? - Null Window Size Query Syntax: [n]NULL? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose null window size is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 184 Command Reference OC - Offset Clear Syntax: [n]OC Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Offset is to be cleared. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 185 15BCommand Reference OFFSET - Define Position Offset Syntax: [n]OFFSET <O-distance> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose offset is to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 186 Command Reference OFFSET? - Position Offset Query Syntax: [n]OFFSET? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose offset is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 187 15BCommand Reference S/OMA - Power On/Off PM500-K6 Syntax: (S)*OMA <option> Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: his command allows the PM500-K6 Keypad to be turned Off or On, depending upon the option specified.

- Page 188 Command Reference S/OMA? - Power On/Off PM500-K6 Query Syntax: (S)*OMA? Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command queries the status, Off or On of the PM500-K6 Keypad.

- Page 189 15BCommand Reference N/OMAA - Enable PM500-K6 Axis Syntax: [n]*OMAA<option> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 190 Command Reference N/OMAA? - PM500-K6 Active Axis Enabled Query Syntax: [n]*OMAA? Parameters: No axis identifier is allowed with this command. Function: This command queries the status enabled or disabled of the PM500-K6 depending upon the option returned. Returns: 0 = Axis key Disabled 1 = Axis key Enabled Examples: Send:...

- Page 191 15BCommand Reference S/OMDA - Enable PM500-K6 Display Syntax: (S)*OMDA <option> Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command enables or disables the PM500-K6 Keypad display, depending upon the option specified.

- Page 192 Command Reference S/OMDA? - PM500-K6 Display Status Query Syntax: (S)*OMDA? Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command queries the status, Off or On of the PM500-K6 Keypad display.

- Page 193 15BCommand Reference N/OMDEL - Define PM500-K6 Scan Key Delay Syntax: [n] *OMDEL <delay> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 194 Command Reference N/OMDEL? - PM500-K6 Scan Key Delay Query Syntax: [n]*OMDEL? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 195 15BCommand Reference N/OMDIR - Define PM500-K6 Axis Key Direction Syntax: [n] *OMDIR <direction> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 196 Command Reference N/OMDIR? - PM500-K6 Axis Key Direction Query Syntax: [n] *OMDIR? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 197 15BCommand Reference S/OMECE - Enable PM500-K6 System Error Clearing Syntax: (S)*OMECE <option> Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command enables or disables the PM500-K6 interface from clearing system errors depending upon the...

- Page 198 Command Reference S/OMECE? - PM500-K6 System Error Clearing Status Query Syntax: (S)*OMECE? Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command queries the system error clearing ability, enabled or disabled of the PM500-K6 interface.

- Page 199 15BCommand Reference S/OMHA - PM500-K6 Active Query Syntax: (S)*OMHA Parameters: No axis identifier is allowed with this command. No parameter is allowed with this command, otherwise a command error will occur. *“S” system specifier required under SCUM1 mode. Function: This command queries whether the PM500-C recognizes the presence of the PM500-K6.

- Page 200 Command Reference S/OMMA - Enable PM500-K6 Menu System Syntax: (S)*OMMA <option> Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command enables or disables the PM500-K6 menu system depending upon the option specified.

- Page 201 15BCommand Reference S/OMMA? - PM500-K6 Menu System Enable Query Syntax: (S)*OMMA? Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command queries the menu status, enabled or disabled of the PM500-K6.

- Page 202 Command Reference /OMMULT - Define PM500-K6 Speed Key Multiplier Syntax: [n]*OMMULT <multi> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 203 15BCommand Reference N/OMMULT? - PM500-K6 Speed Key Multiplier Query Syntax: [n]*OMMULT? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 204 Command Reference S/OMNAD - Define PM500-K6 Number of Axes Displayed Syntax: (S)*OMNAD <option> Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command defines the number of axes displayed on the PM500-K6 keypad.

- Page 205 15BCommand Reference S/OMNAD? - PM500-K6 Number of Axes Displayed Query Syntax: (S)*OMNAD? Parameters: No axis identifier is allowed with this command. *“S” system specifier required under SCUM1 mode. Function: This command queries the number of axes displayed on the PM500-K6 keypad. The maximum number of axes the PM500-K6 can display is 3.

- Page 206 Command Reference S/OMPDA - Define PM500-K6 Position of Displayed Axes Syntax: (S)*OMPDA <d-location><axis> Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command defines the position of and axes displayed on the PM500-K6 keypad.

- Page 207 15BCommand Reference S/OMPDA? - Define PM500-K6 Position of Display Axes Query Syntax: (S)*OMPDA <d-location>? Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command queries the axes assigned to the display position specified on the PM500-K6 keypad.

- Page 208 Command Reference S/OMRAE - Enable PM500-K6 Axis Control during Remote Operation Syntax: (S)*OMRAE<option> Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command enables or disables the PM500-K6 from commencing motion when system motion is currently...

- Page 209 15BCommand Reference S/OMRAE - PM500-K6 Axis Control During Remote Operation Query Syntax: (S)*OMRAE? Parameters: No axis identifier is allowed with this command. *“S” system specifier required under SCUM1 mode. Function: This command queries the status enabled or disabled of the PM500-K6 depending upon the option returned. Returns: 0 = PM500-K6 Control during motion disabled 1 = PM500-K6 Control during motion enabled...

- Page 210 Command Reference S/OMSA - Enable PM500-K6 Setup Menu Syntax: (S)*OMSA <option> Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command enables or disables the PM500-K6 Setup Menu system depending upon the option specified.

- Page 211 15BCommand Reference S/OMSA? - PM500-K6 Setup Menu Enabled Query Syntax: (S)*OMSA? Parameters: No axis identifier is allowed with this command. *“S” system specifier required under SCUM1 mode. Function: This command queries the status, enabled or disabled, of the PM500-K6 Setup Menu system depending upon the option returned.

- Page 212 Command Reference S/OMSCAN - Define PM500-K6 Key Scan Rate Syntax: (S)*OMSCAN <rate><axis> Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command defines the scan rate for the PM500-K6 axis keys.

- Page 213 15BCommand Reference S/OMSCAN? - PM500-K6 Key Scan Rate Query Syntax: (S)*OMSCAN <axis>? Parameters: A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command queries the current scan rate of the PM500-K6 as set by OMSCAN, for the axis specified.

- Page 214 Command Reference S/OMSPD - Define PM500-K6 Speed Level Syntax: (S)*OMSPD<option> Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command defines the speed level for PM500-K6 depending upon the option specified.

- Page 215 15BCommand Reference S/OMSPD? - PM500-K6 Speed Level Query Syntax: (S)*OMSPD? Parameters: No axis identifier is allowed with this command. *“S” system specifier required under SCUM1 mode. Function: This command queries the currently set speed level of the PM500-K6 as set by OMSPD. Returns: 0 = Low Speed 1 = Medium Speed...

- Page 216 Command Reference S/OMSPDA - Enable PM500-K6 Speed Select Keys Syntax: (S)*OMSPDA <option> Parameters: No axis identifier is allowed with this command. A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command enables or disables the speed select keys of the PM500-K6 depending upon the option specified.

- Page 217 15BCommand Reference S/OMSPDA? - PM500-K6 Speed Select Keys Enable Query Syntax: (S)*OMSPDA? Parameters: No axis identifier is allowed with this command. *“S” system specifier required under SCUM1 mode. Function: This command queries the status, enabled or disabled, of the PM500-K6 depending upon the option returned. Returns: 0 = Speed Select Keys Disabled 1 = Speed Select Keys Enabled...

- Page 218 Command Reference N/OMSTEP - Define PM500-K6 Speed Key Step Size Syntax: [n] *OMSTEP <s-key><s-size> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 219 15BCommand Reference N/OMSTEP? - PM500-K6 Speed Key Step Size Query Syntax: (S)*OMSTEP <s-key>? Parameters: A space is allowable between the command and the parameter but is not required. *“S” system specifier required under SCUM1 mode. Function: This command queries the step size for the specified speed key on the PM500-K6 as defined via OMSTEP.

- Page 220 Command Reference PM - Preventive Maintenance Syntax: [n]PM Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose axis will commence the preventive maintenance routine. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 221 15BCommand Reference foreign object and posts a current sense error. If not, the axis restarts this procedure. Once the axis has successfully centered the cages, the electronic drive circuitry is recalibrated. Programmed values for the aforementioned parameters may be stored in non-volatile memory for recovery on system power- up using the SAVEAX command.

- Page 222 Command Reference PMACC - Define Preventive Maintenance Acceleration Syntax: [n]PMACC <accel> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Preventive Maintenance Acceleration is to be specified. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 223 15BCommand Reference PMACC? - Preventive Maintenance Acceleration Query Syntax: [n]PMACC? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Preventive Maintenance Acceleration is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 224 Command Reference PMOVE - Define Preventive Maintenance Move Size Syntax: [n]PMOVE <distance> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Preventive Maintenance move size is to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 225 15BCommand Reference PMOVE? - Preventive Maintenance Move Size Query Syntax: [n]PMOVE? Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Preventive Maintenance move size is to be queried. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.

- Page 226 Command Reference PMNULL - Define Preventive Maintenance NULL Syntax: [n]PMNULL <n-size> Parameters: [n] defines the axis identifier, n = X, Y, Z, A, B, C whose Preventive Maintenance NULL size is to be defined. If the axis identifier [n] is omitted the command will not be executed and a command error will be posted.