Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for BossWeld BRAZEN 3000

- Page 1 BRAZEN 3000 PORTABLE BRAZING AND HEATING KIT MANUAL...

-

Page 3: Table Of Contents

INDEX PAGE GENERAL SAFETY INFORMATION PHYSICAL AND SAFETY PROPERTIES OF GASES GAS SUPPLY SAFETY CYLINDER STORAGE, NOZZLE CHART PERSONAL PROTECTIVE EQUIPMENT BOX CONTENTS SETUP AND LIGHTING PROCEDURE 13-15 SHUT DOWN PROCEDURE WARNINGS & MAINTENANCE WARRANTY CONSUMABLES... - Page 4 BOSSWELD GAS WELDING EQUIPMENT Dear customer, Thank you for your purchase of our BOSSWELD BRAZEN 3000 portable brazing & heating kit. The BOSSWELD range of gas welding and cutting equipment has been rigorously tested by independent laboratories and conforms to the following Australian Standards for gas welding and cutting...

-

Page 5: General Safety Information

When using these processes, particular safety considerations apply with respect to: a) Do not leave the Brazen 3000 torch unattended when lit, or put it down b) Burns from flames, hot objects, malfunctioning hand-held equipment, molten particles, etc. -

Page 6: Physical And Safety Properties Of Gases

The oxygen cylinder once it is empty can devalued and the cylinder recycled at a scrap metal merchant. DO NOT USE BRAZEN 3000 IF THE RUBBER O-RING IS MISSING OR DAMAGED IN THE REGULATORS... -

Page 7: Gas Supply

In all cases, gas supplies may be subject to statutory or regulatory provisions. Many Australian Standards cover the subject. a) The Brazen 3000 is fueled with Oxygen and Mapp gas cylinders, Cylinders are generally obtained from gas suppliers. b) Do not tamper with the markings or colour coding of cylinders. Do not use non colour coded cylinders or those without safety and information labels. -

Page 8: Safety

Do not attempt to fix any damaged parts contact your nearest Bossweld service agent or Bossweld directly. • Always make sure the flame is fully extinguish after use before place the torch on any surface. - Page 9 SAFETY TIP REPLACEMENT Make sure you use the tool supplied and that tips are installed straight as not to wear the thread, this can result in a leak. • Ensure tip has cooled after use before replacing. • Do not over tighten •...

-

Page 10: Cylinder Storage, Nozzle Chart

CYLINDER STORAGE Storage In the case where the Brazen 3000 should not be used for a long time or when requiring transport by a motor vehicle, unscrew the cylinders from the regulators, This will ensure that the contents of the cylinder will remain contained and prevent leaks. -

Page 11: Personal Protective Equipment

PERSONAL PROTECTIVE EQUIPMENT Personal protective equipment should be used by all operators of oxy-fuel gas equipment to ensure their protection of body and clothing from: a) The heat from the work b) Burns which may result from contact with hot components or small globules of hot metal c) Radiation which may burn the skin or eyes This protection is achieved by the use of flame resistant clothing, gloves... -

Page 12: Box Contents

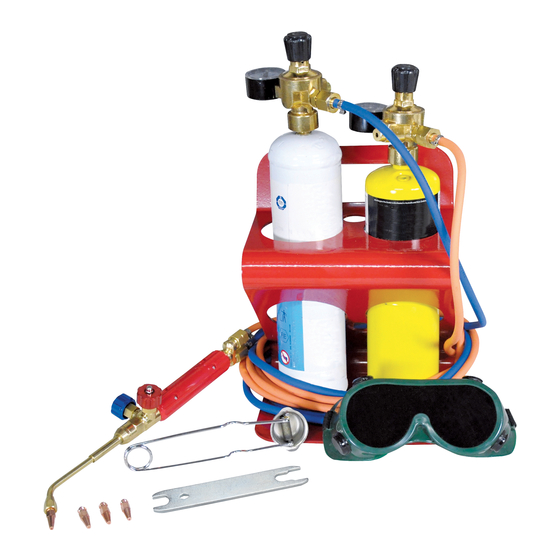

BOX CONTENTS Kit Contains Fuel gas regulator with gauge. Oxygen regulator with gauge with M12x1mm connection. Hand piece with adjustment values Blowpipe. 2.5m Oxygen / Fuel hose set. Light weight & heavy duty carry case. Flint Lighter. Combination Spanner Brazing nozzle size: 0, 1, 2, 3. 10. -

Page 13: Setup And Lighting Procedure

BRAZEN 3000 SETUP 1. Make sure you have the valve on 4. Make sure you have the valve the fuel regulator in the off position. on the Oxygen regulator in the off position. 2. Check the seal in the regulator is 5. - Page 14 BRAZEN 3000 SETUP - CONTINUED 7. Attach the blowpipe to the handle 10. Attach the hose to the fuel and using the spanner supplied, do not oxygen regulators over tighten • Orange hose connected to the fuel regulator tighten anti-clockwise using...

- Page 15 BRAZEN 3000 IGNITING PROCEDURE √ 1. Make sure the valves on the torch 4. Adjust the fuel dial on the torch handle are closed until the yellow flame flows right from the tip of the nozzle. √ 2. Turn the Oxygen regulator on until 5.

-

Page 16: Shut Down Procedure

SHUT DOWN PROCEDURE NOTE: In the case where the Brazen 3000 should not be used for a long time or when requiring transport by a motor vehicle, unscrew the cylinders from the regulators, 1. Turn The Fuel dial off from the torch handle, This will extinguish the flame. -

Page 17: Warnings & Maintenance

• Only use Bossweld approved replacement parts • Do not use this equipment if you are unshore of any procedures outline in this manuals, contact your Bossweld agent or Bossweld directly. • Do not use this equipment if part is damage, replace any damaged parts before use. -

Page 18: Warranty

BOSSWELD or other person(s) with respect to it. -

Page 19: Consumables

CODE DESCRIPTION 700015M Bossweld “GoaTig” Tig Welding Glove - Medium Bossweld Goat Skin Tig Glove White goat skin TIG glove, reinforced tipping on back of 2nd and 3rd fingers, yellow cow split cuff, Kevlar stitching, unlined, (32cm for size M). - Page 20 OTHER PRODUCTS IN OUR RANGE • ELECTRODES • MIG WIRE • TIG RODS • GAS EQUIPMENT • WELDING HELMETS • WELDING SAFETY • WELDING MACHINES • MIG TORCHES • TORCH SPARE PARTS • TIG TORCHES • WELDING ACCESSORIES • WELDING CABLE...

Need help?

Do you have a question about the BRAZEN 3000 and is the answer not in the manual?

Questions and answers