Table of Contents

Advertisement

Quick Links

801 GLASGOW AVE.

FORT WAYNE, IN 46803

ELECTRIC SHOCK HAZARD

HIGH VOLTAGES ARE PRESENT IN THIS EQUIP-

MENT. FOLLOW THESE RULES TO AVOID ELEC-

TRIC SHOCK.

L Use only a properly grounded circuit. A ground

fault interrupter is recommended.

L Do not spray water directly on burner.

L Turn off power before servicing.

L Read the owner's manual before using.

SPECIFICATIONS

FUELS

Use No. 1 or No. 2 heating oil (ASTM D-396) only.

* NEVER attempt to use gasoline as a fuel for your burner, as it is more combustible and could result in a

serious explosion.

* NEVER burn garbage or refuse in the heating unit.

* NEVER try to ignite oil by tossing burning paper or other material into the heating unit

* NEVER burn waste or crankcase oil in the heating unit.

FIRING CAPACITIES -

MODEL EHA and EHASR

0.75 TO 3.00 GALLONS PER HOUR

105,000 TO 420,000 BTU/HR INPUT

FIRING CAPACITIES - MODEL EH

3.00 TO 6.00 GALLONS PER HOUR

420,000 TO 840,000 BTU/HR INPUT

FUEL PUMPS

Suntec or Danfoss - Single Stage Standard

ELECTRICAL

Power Supply .............................115V / 60HZ / 1 PH

Motor ..........................................3450 RPM, N.E.M.A. Flange, Manual Reset Overload Protection

Ignition........................................10,000V / 23MA secondary, Continuous Duty-Shielded Interrupted

INSTALLATION OF THE BURNER MUST BE DONE BY A QUALIFIED INSTALLER IN ACCORDANCE WITH REGULATIONS OF THE NATION-

AL FIRE PROTECTION STANDARD FOR OIL-BURNING EQUIPMENT, NFPA NO. 31, AND IN COMPLETE ACCORDANCE WITH ALL LOCAL

CODES AND AUTHORITIES HAVING JURISDICTION.

A QUALIFIED INSTALLER IS THE PERSON WHO IS RESPONSIBLE FOR THE INSTALLATION AND ADJUSTMENT OF THE EQUIPMENT

AND WHO IS LICENSED TO INSTALL OIL-BURNING EQUIPMENT IN ACCORDANCE WITH ALL CODES AND ORDINANCES.

THESE INSTRUCTIONS SHOULD BE AFFIXED TO THE BURNER

MODEL

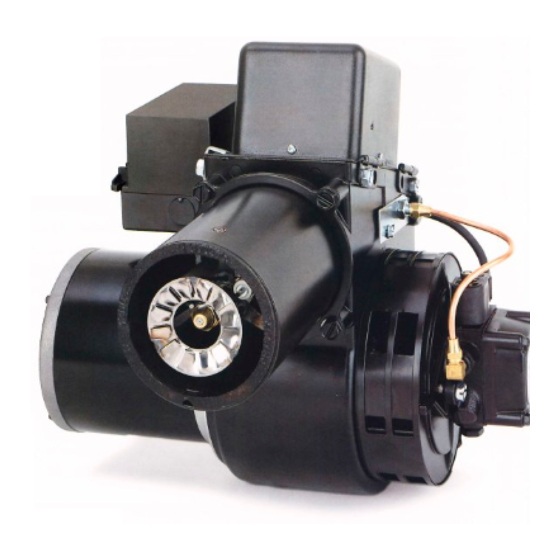

EHA/EH & EHASR

OIL BURNERS

Publication Date 8/14/2000

Manual 21530

INSTALLATION OF BURNER

OR ADJACENT TO THE HEATING APPLIANCE.

Revision 06

U.S. Patent No. 4,388,064

OVERHEATING HAZARD

SHOULD OVERHEATING OCCUR:

L Shut off the manual oil valve to the appliance.

L Do not shut off the control switch to the pump or blower.

THIS BURNER, AS IT IS MORE COMBUSTIBLE

AND COULD RESULT IN A SERIOUS EXPLOSION.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

DIMENSIONS (STANDARD)

HEIGHT ..........................................................13 3/8"

WIDTH ..........................................................16 9/16"

DEPTH..............................................................8 1/4"

CENTER LINE

OF TUBE TO FLOOR

MOUNTING

Rigid Flange, Adjustable Flange, or Base Mount

NEVER ATTEMPT TO USE

GASOLINE AS A FUEL FOR

8 1/16"

Advertisement

Table of Contents

Summary of Contents for Wayne EHA

- Page 1 * NEVER try to ignite oil by tossing burning paper or other material into the heating unit * NEVER burn waste or crankcase oil in the heating unit. FIRING CAPACITIES - DIMENSIONS (STANDARD) HEIGHT ............13 3/8” MODEL EHA and EHASR WIDTH ............16 9/16” 0.75 TO 3.00 GALLONS PER HOUR DEPTH..............8 1/4” 105,000 TO 420,000 BTU/HR INPUT...

- Page 2 FUEL PUMPS AND OIL LINES Model EHA, EH and EHASR oil burners are provided with single stage 3450 RPM fuel pumps with the by-pass plug removed for a single pipe installation. This is satisfactory where the fuel supply is on the same level, or above burn- er, permitting gravity flow of oil.

-

Page 3: Air Supply For Combustion

NOZZLE AND AIR CONE SELECTION The EHA, EH and EHASR oil burners typically fire well with a solid or semi-solid nozzle with a spray angle of 80, 70 or 60 degrees. In most upgrading or conversion installations, the use of an 80 degree solid nozzle is the best way to start with. -

Page 4: Starting Procedure

(A) Selecting firing rate desired. (B) Install proper nozzle for appliance (see paragraph under “Nozzle and Air Cone Selection” page 3). (C) For model EHA and EH burners make gun adjustments per firing rate (see Figure 5, page 6). Note: the EHASR guns are permanently set and not adjusted with changing rates (see Figure 6, Page 6). (D) Fire burn- er, adjust interlocking air bands for yellow tips above combustion chamber. - Page 5 EFFICIENCY CHART FOR NO. 2 FUEL OIL NET STACK TEMPERATURE (DEGREES F˚) 300˚ 350˚ 400˚ 450˚ 500˚ 550˚ 600˚ 650˚ 700˚ 750˚ 800˚ 850˚ 900˚ ⁄ ⁄ ⁄ ⁄ ⁄ ⁄ ⁄ ⁄ ⁄ ⁄ ⁄ ⁄ ⁄ ⁄ ⁄ ⁄...

- Page 6 GUN SETTING INSTRUCTIONS (For EHA and EH Burners only) (For EHASR Only) Suggested start-up setting: EHA Flamelock™ flush with cast iron cone face. EH Flamelock™ 1/8” ahead of cast iron cone face for 3.00 to 4.50 GPH or 1/4” ahead for 5.00 to 6.00 GPH.

- Page 7 BURNER COMPONENTS - MODELS EHA, EH AND EHASR (115 Volt 60 Hz Standard - Parts not necessarily as shown) NOTE: STATE SPECIFICATION NUMBER, BURNER MODEL, PART DESCRIPTION AND PART NUMBER WHEN ORDERING PARTS No. Description EHASR Description EHASR Motor-1/5HP 20554 20554 Cad Cell - Up to 12”...

- Page 8 Notes...

- Page 9 Notes...

- Page 10 2. Burners and/or component(s) determined to be covered under this LIMITED WARRANTY by WAYNE shall be repaired or replaced at WAYNE’s sole option. 3. WAYNE is not responsible for any labor cost for the removal and replacement of said burner or burner components and equipment associated therewith.

Need help?

Do you have a question about the EHA and is the answer not in the manual?

Questions and answers