Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Pentair Myers D35 Series

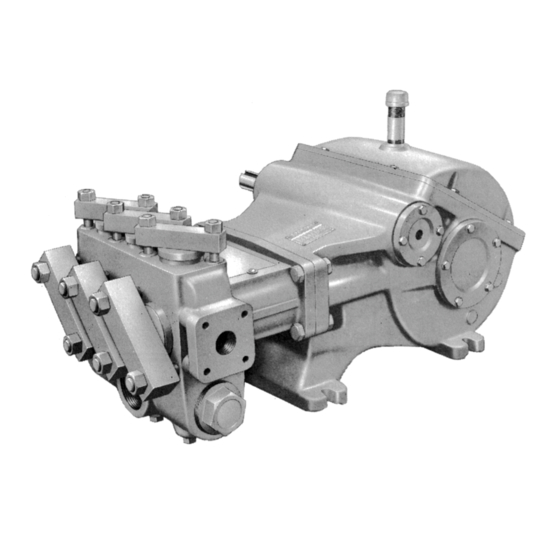

- Page 1 D35, D50 AND D60 SerieS INDUSTRIAL PUMPS NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Part # 23833A034 | © 2014 Pentair Ltd. | 06/04/14...

- Page 2 GENERAL INSTRUCTIONS Nozzle capacity or demand should not exceed 90% of pump capacity for satisfactory regulating valve Reciprocating pumps of both the plunger and cup operation. Nozzling in excess of this capacity may type are positive displacement in principle. Due to cause unstable pressure regulator operation.

- Page 3 REmOvING PLUNGERS: BELL ShAPED suction to water supply. Open valve if present in suction line. If pumping from a pit, make sure that CUPS suction line is completely submerged. Make sure all valves, including spray gun or nozzles, are open Place plunger at front end of cylinder and remove in discharge line.

- Page 4 V-rings should be lubricated with Molykote for ease in Reasonable care and judgment should be used assembly. Do not use a graphite type grease. when installing the new tapered cylinder shell. Clean out any accumulation of loose rust or corrosion in tapered cylinder slots.

- Page 5 REPLACING SEATS: CAGED vALvES REPLACING PINION ShAFT AND ShImmING BEARINGS Remove spring retaining bar, spring and flat valve. When removing upper valve seat, pass head of puller After installing the link-crosshead assemblies and through hole in valve seat before the slide wedge is moving them toward the fluid end as far as possible, inserted alongside puller bolt.

- Page 6 RECOmmENDED TORQUE vALUES Check for adequate side clearance of links on crankshaft. Some shims must be moved from one (foot-pounds) end to the other until sideways movement of all links FASTENER LOCATION can be seen. Check the torque of cap screws on all bearing caps.

- Page 7 D35-8PP-2h & D45-12PP INDUSTRIAL PUmPS PARTS LIST 40 38 36 34 24 25 21 22 27 29 30 17 15 13 14 Cap Screw 18832A000 (3 req) Cap Screw 18832A000 (3 req) Retainer 18833A001 (3 req) Retainer 18833A000 (3 req) Spring 11829A000 (3 req) Spring 18462A000 (3 req) Valve 18834A001...

- Page 8 D35-8PP-2h & D45-12PP INDUSTRIAL PUmPS PARTS LIST Catalog Number of Industrial Pump (Helical Gears) D35-8PP-2H D45-12PP Catalog Number of Industrial Pump (Helical Gears) D35-8PP-2H D45-12PP Item Description Qty. Eng. No. Eng. No. Item Description Qty. Eng. No. Eng. No. GEAR CASE 04663E000 04663E000 SPRING, FOR RETAINER FOR OIL SEAL WIPER...

- Page 9 D35-12D-2h INDUSTRIAL PUmP PARTS LIST 40 38 36 34 24 25 21 22 27 29 30 17 15 13 14 Locknut 11904A001 (3 req) Locknut 11904A001 (3 req) Valve Clamp 11818A000 (3 req) Valve Clamp 11828A000 (3 req) Retainer Retainer 11817A000 (3 req) 11827A000 (3 req) Valve Spring...

- Page 10 D35-12D-2h INDUSTRIAL PUmP PARTS LIST Catalog Number of Industrial Pump (Helical Gears) D35-12D-2H Catalog Number of Industrial Pump (Helical Gears) D35-12D-2H Item Description Qty. Eng. No. Item Description Qty. Eng. No. GEAR CASE 04663E000 GASKET, VELLUMOID, FOR OIL SEAL ASSEMBLY 05059A058 GASKET, FOR GEAR CASE LID 06222C000...

- Page 11 D35-12AvD-2h, D35-AvD-2hL, D35-12AvD-CP, D35-12AvAB, D35-12AvAB-CP & D35-12AvABL-CP INDUSTRIAL PUmPS PARTS LIST 29 20 21 18 15 13 14 STYLE VALVE ASSEMBLY SUCTION VALVE ASSEMBLY 11902A001K 18925A000K 18925A010K DISCHARGE VALVE ASSEMBLY 11903A001K 18925A001K 18925A014K SEAT MATERIAL 420F 420F Item Description Qty. Eng.

- Page 12 D35-12AvD-2h, D35-AvD-2hL, D35-12AvD-CP, D35-12AvAB, D35-12AvAB-CP & D35-12AvABL-CP INDUSTRIAL PUmPS PARTS LIST Item Description Qty. Eng. No. Item Description Qty. Eng. No. GEAR CASE 04663E000 STUD FOR PLUNGERS 18924A000 GASKET, FOR GEAR CASE LID 06222C000 STUD FOR PLUNGERS, 316 SST FOR AVAB-CP PUMP 18924A010 CAP SCREW, 5/16"-18 UNC x 7/8"...

- Page 13 D50-12D-3h & D50-12AB INDUSTRIAL PUmPS PARTS LIST 29 38 37 36 33 Item Description Qty. Eng. No. Item Description Qty. Eng. No. O-RING 05876A064 GASKET, SEAL HOUSING 05059A434 VALVE CAP 17390A000 KIT FOR REF. NO. 25 & 26 24648A000 VALVE CAP FOR AB PUMP 17390A002 CROSSHEAD 06211B041...

- Page 14 D50-12D-3h & D50-12AB INDUSTRIAL PUmPS PARTS LIST SUCTION VALVE AND SEAT COMPLETE NO. 11903A002K Valve Clamp 11828A000 (3 req) Locknut 11904A001 (3 req) Retainer 11827A000 (3 req) Valve Spring 18463A000 (3 req) Valve Seat 06271A000 (3 req) Valve 17553A001(3 req) DISCHARGE VALVE AND SEAT COMPLETE NO.

- Page 15 D60-10D-3h, D60-10D-3hL & D60-10AB INDUSTRIAL PUmPS PARTS LIST 29 38 37 36 33 Item Description Qty. Eng. No. Item Description Qty. Eng. No. O-RING 05876A064 GASKET, SEAL HOUSING 05059A434 VALVE CAP 17390A000 KIT FOR REF. NO. 25 & 26 24648A000 VALVE CAP FOR AB PUMP 17390A002 CROSSHEAD...

- Page 16 D60-10D-3h, D60-10LD-3h & D60-10AB INDUSTRIAL PUmPS PARTS LIST SUCTION VALVE AND SEAT COMPLETE NO. 11903A002K Valve Clamp 11828A000 (3 req) Locknut 11904A001 (3 req) Retainer 11827A000 (3 req) Valve Spring 18463A000 (3 req) Valve Seat 06271A000 (3 req) Valve 17553A001(3 req) DISCHARGE VALVE AND SEAT COMPLETE NO.

- Page 17 THE PUMP MUST BE INSTALLED WITH A PRESSURE RELIEF VALVE IN DISCHARGE LINE TROUBLEShOOTING Pump fails to build pressure with discharge closed Failure to hold pressure with discharge open Pump is noisy Pump gets hot Pressure gauge shows abnormal fluctuation Regulator chatter POSSIBLE CAUSE OF PROBLEm 1.

- Page 18 5. If the pressure regulator unloading valve is worn, it will wear out from overheating if adequate oil is not will allow too much of the pump capacity to be provided in the crankcase. It is recommended to drain, bypassed and recirculated back to the tank. By clean and refill with new oil prior to any storage period.

- Page 19 D SERIES CROSShEAD SEALS 24648A000 KIT Hand Grind Here Field installation of these kits will require removal of the fluid end to replace the existing retainer and seals. On some fluid ends it may be necessary to hand grind I.D. of fluid end to fit new kit. The same spring and gasket is used to hold and seal the retainer.

- Page 20 (f) if unit is used for purposes other than for what it is designed and manufactured; (g) to any unit that has been repaired or altered by anyone other than Pentair Myers or an authorized Pentair Myers service provider;...

Need help?

Do you have a question about the Myers D35 Series and is the answer not in the manual?

Questions and answers