Table of Contents

Summary of Contents for Pentair MYERS D65-16 Series

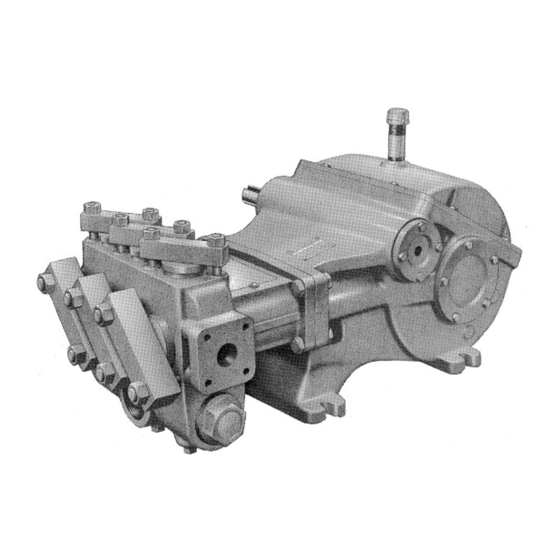

- Page 1 D65-16 AND D65-20 SERIES RECIPROCATING PUMPS NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Part # 26850A002 | © 2014 Pentair Ltd. | 06/04/14...

-

Page 2: General Instructions

GENERAL INSTRUCTIONS SUGGESTED MAINTENANCE SCHEDULE CAUTION: Positive Displacement Pumps must have a Check oil level – Daily proper size and operable type of pressure regulating valve or pressure relief valve piped into the discharge Drain & change oil – 300 hr. line. - Page 3 PULLER DISC PLATE SCREW Inspect cylinders for linear grooving. If any is detected, Reasonable care and judgment should be used when replace cylinders. New packing will rapidly cut or wear installing the new cylinder. Clean out any accumulation of loose rust or corrosion in cylinder body. Install a new out in grooved cylinders.

- Page 4 REMOVING AND REPLACING SEATS: REMOVING CRANKSHAFT AND CENTER POST VALVES - D65-20 SERIES PINION SHAFT Remove valve and cylinder caps which provide Remove packing assemblies and remove connecting link access to both suction and discharge valves. Remove caps. Move the link-crosshead assembly as far forward the stainless steel shoulder screw which serves as a as possible.

- Page 5 REPLACING PINION SHAFT AND SHIMMING RECONDITIONED CRANKSHAFTS BEARINGS ON HYDRAULIC DRIVEN PUMPS When the crank throws are slightly damaged, they can sometimes be reconditioned for further use. This can Press bearing cones onto both ends of the pinion shaft, be done by sandpapering and polishing until all ridges being sure bearing seats completely against stop on are completely removed.

- Page 6 D65-16 SERIES 26850A002 06/04/14...

- Page 7 D65-16 SERIES PARTS LIST Item Description Qty. Eng. No Item Description Qty. Eng. No CASE, GEAR 04625E001 PLUG, PIPE, 1-1/4" 05022A047 PLUG, PIPE, 3" 03210A000 GASKET, LID 06201C000 LINER, CYLINDER 316 SST FOR AVAB-CP PUMP 20851A002 SCREW, CAP, 5/16"-18 UNC x 7/8", STEEL 19100A005 O-RING, CYLINDER (INCL.

- Page 8 D65-16AVD-AF/AFL SERIES 26850A002 06/04/14...

-

Page 9: Parts List

PARTS LIST D65-16AVD-AF (20160F027) Right Hand Drive D65-16AVD-AFL (20160F028) Left Hand Drive Item Description Qty. Eng. No Item Description Qty. Eng. No CASE, GEAR 04625E100 SPRING M01643A000 GASKET 05059A058 GASKET, LID 06201C000 PLUG, PIPE, MAGNETIC 17481A002 SCREW, CAP, 5/16"-18 UNC x 7/8", STEEL 19100A005 SCREW, CAP, 3/4"-10 UNC x 3"... - Page 10 D65-20 SERIES Cap Screw 18832A000 Retainer 18833A001 (3 req) Discharge Spring 11829A000 (3 req) Suction Spring 11463A000 Valve 18834A001 (3 req) Valve Seat 18835A002 (3 req) COMPLETE DISCHARGE VALVE AND SEAT 18925A004 COMPLETE SUCTION VALVE AND SEAT 18925A003 26850A002 06/04/14...

- Page 11 D65-20 SERIES PARTS LIST Item Eng. No Description Qty. Item Eng. No Description Qty. 04625E001K CASE, GEAR 19105A008 SCREW, CAP, 5/8"-11 UNC x 2", STEEL 06201C000 GASKET, LID 16654A006 SCREW, CAP, .551"-14 METRIC x 2-3/4" 19100A005 SCREW, CAP, 5/16"-18 UNC x 7/8", STEEL 18923A002 FOLLOWER 04561B000...

- Page 12 D65-20 HYDRAULIC DRIVE COMPONENTS Item Description Qty. Eng. No CASE, GEAR 04625E100 SHAFT, PINION 20164B040 SHIM, GREEN, .003" THICK 05863A024 SHIM, PINK, .015" THICK 05863A023 CONE, BEARING 05674A020 CUP, BEARING 05675A019 CAP, BEARING & SEAL PLATE 04741B010 SEAL, OIL 05710A046 SCREW, CAP, SOCKET HEAD GRADE 8;...

- Page 13 THE PUMP MUST BE INSTALLED WITH A PRESSURE RELIEF VALVE IN DISCHARGE LINE TROUBLESHOOTING Pump fails to build pressure with discharge closed Failure to hold pressure with discharge open Pump is noisy Pump gets hot Pressure gauge shows abnormal fluctuation POSSIBLE CAUSE OF PROBLEM 1.

- Page 14 5. If the pressure regulator internal bypass valve is 11. Worn connecting link bearings are caused by worn, it will allow too much of the pump capacity to unusual or adverse operating conditions and are be bypassed and recirculated back to the tank. By seriously affected by corrosion if water is present in examining the flow from this valve with the discharge the crankcase.

- Page 15 D SERIES CROSSHEAD SEALS 24648A000 KIT Hand Grind Here Field installation of these kits will require removal of the fluid end to replace the existing retainer and seals. On some fluid ends it may be necessary to hand grind I.D. of fluid end to fit new kit. The same spring and gasket is used to hold and seal the retainer.

- Page 16 (f) if unit is used for purposes other than for what it is designed and manufactured; (g) to any unit that has been repaired or altered by anyone other than Pentair Myers or an authorized Pentair Myers service provider;...

Need help?

Do you have a question about the MYERS D65-16 Series and is the answer not in the manual?

Questions and answers