Subscribe to Our Youtube Channel

Summary of Contents for RINGFEDER TNM GBT Series

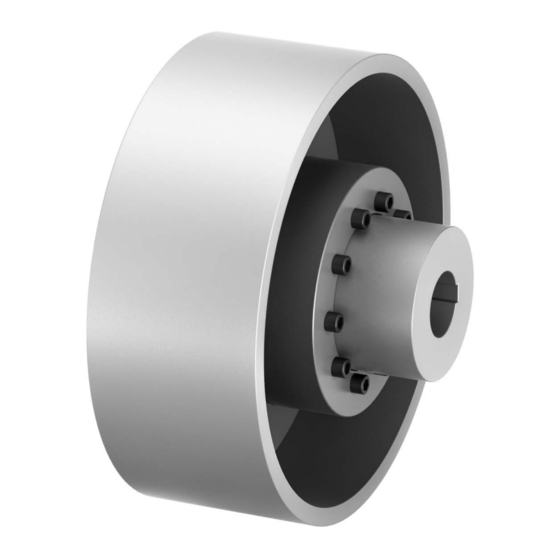

- Page 1 08.2019 Elastomer Jaw Couplings RINGFEDER TNM GBT, TNM GTW ® Installation and Operation Manual TNM GBT TNM GTW Partner for Performance www.ringfeder.com...

-

Page 2: Table Of Contents

In the case of transport, mounting, dismounting and maintenance, attention is to be paid to the relevant regulations for industrial safety and for environmental care. The coupling may only be operated, mounted, serviced and maintained by authorised and trained personnel. - 2 - ® BAWN 006-GBR-1 RINGFEDER TNM GBT, TNM GTW... -

Page 3: Function

In the interest of further development, we reserve the right to make changes which serve technological progress. By the use of accessories and spare parts, which were not originally manufactured by RINGFEDER POWER TRANSMISSION, we are not responsible for any resulting damage or liability or guarantee. 2 Function... -

Page 4: Marking Of The Coupling

The coupling parts can be stored in their delivered standard-state for 6 months in a dry, roofed place at normal room temperature. For a longer storage duration a long-term preser- vation is necessary (consult RINGFEDER POWER TRANSMISSION). The elastic intermediate ring must not be subjected to ozone containing mediums, direct solar influence or strong light sources with ultraviolet-light. -

Page 5: Construction

6 Coupling flange FE/FG part 102…0X4 8. Twiflex-brake disk part 506 9. Locking washer (caging-washer) 10. Hexagon head screw DIN 933 Fig. 1 Construction RINGFEDER TNM GBT, TNM GTW ® Details: Claw ring (Pos. 3) and flange hub (Pos. 4), coupling hub (Pos. 6) and brake drum/disk (Pos. -

Page 6: Technical Data

6 Technical data Fig. 2 RINGFEDER ® TNM GBT, TNM GTW Table 1 Technical Data: size Cnom Cpeak Cnom Cpeak Pb72 Pb72 Pb82 Pb82 [Nm] [Nm] [Nm] [Nm] 1350 1300 1800 1050 2000 1650 2400 1500 3100 2400 4200 2400... - Page 7 RINGFEDER TNM GTW: ® Table 3 z x M x Ls undrilled [mm] [Nm] [Nm] [min [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] DIN 933 8.8 [Nm] 250-12,7 4580 55,8 6 x M8 x 16 64,5 3,5±1,0...

-

Page 8: Assembly

· The maximum permissible borehole diameter must not be exceeded. · Check whether the shaft hub connections can safely transmit the occurring operating torques. · The standard RINGFEDER ® TNM tolerance for the finished boreholes is fit H7. · Standard parallel key slot is according to DIN 6885 page 1. -

Page 9: Finished Borehole

H7/m6 is carried out. · Provide a setscrew for axial securing on the hub back above the parallel key slot. In the case of other shaft hub connections consultation with RINGFEDER POWER TRANSMISSION is necessary. -

Page 10: Installing Coupling

(Figure 4). Pay attention to possible differing agreements! · Secure possible available setscrews by tightening with an adhesive e.g. Loctite 222 against automatic loosen- ing and flying out. Fig. 4 - 10 - ® BAWN 006-GBR-1 RINGFEDER TNM GBT, TNM GTW... -

Page 11: Adjusting Coupling

If the coupling is mounted in a closed housing / casing so that a subsequent alignment is not possible any more, it must be guaranteed that the geometry and fit accuracy of the contact surfaces in operation aligns the shafts exactly within the mentioned tolerances. - 11 - ® BAWN 006-GBR-1 RINGFEDER TNM GBT, TNM GTW... -

Page 12: Angular Misalignment Dk

· The values of table 5 are valid for a reference rotation speed of 1500 min Fig. 7 Table 5 Maximum permissible displacement values - radial: Size [mm] r max - 12 - ® BAWN 006-GBR-1 RINGFEDER TNM GBT, TNM GTW... -

Page 13: Axial Displacement

· Keep, when aligning the gap measurement S, to the maximum permissible tolerance X according to table 6. ATTENTION! If greater axial displacements are expected in operation, consultation with RINGFEDER POWER TRANSMISSION is necessary. Fig. 8 Table 6 Recommended alignment values - axial:... -

Page 14: Operation

When using the coupling attention is to be paid to its characteristics (see „6 Technical data”). These can in no case be exceeded without having a written agreement from RINGFEDER POWER TRANSMISSION. In order to guarantee a faultless, lasting operation of the coupling, it must be laid out accord-ing to the regulations e.g. - Page 15 Alignment fault Considerable Disconnect drive wear of increase in Remove cause for alignment fault elastomer coupling tempera- Re-align coupling ture. Increased Inspect elastomer for wear reaction forces act on connected machines. - 15 - ® BAWN 006-GBR-1 RINGFEDER TNM GBT, TNM GTW...

- Page 16 Overload Coupling is Disconnect drive due to too destroyed. Verify coupling design in coopera- high torque Connected tion with RINGFEDER POWER machines can be TRANSMISSION affected, too. Replace coupling Install larger coupling, if necessary - 16 - ® BAWN 006-GBR-1...

-

Page 17: Check Of Direction Of Rotation

· Cut through a new intermediate ring at a connecting part and fit it between coupling hub and flange. · To obtain an easier mounting one can provide the new elastic intermediate ring with a slip additive before its introduction (e.g. talcum powder). - 17 - ® BAWN 006-GBR-1 RINGFEDER TNM GBT, TNM GTW... - Page 18 Fig. 10 Table 8 Tightening torques M of the claw ring threaded joint: Size DIN 912- 8.8 M10 M10 M10 DIN 912-10.9 M12 M12 M14 M14 M16 M16 M16 [Nm] - 18 - ® BAWN 006-GBR-1 RINGFEDER TNM GBT, TNM GTW...

-

Page 19: Maintenance

10 Maintenance The elastic coupling RINGFEDER ® TNM GBT, TNM GTW have in operation a low- maintenance. Reaching the wear limit of the elastic intermediate ring depends on the operating parameters and the conditions of use. In the case of routine monitoring work on the plant check: ·... -

Page 20: Wear Limit Of Elastic Buffers

(PD , Fig. 11) acc. to table 9 has been reached. Fig. 11 Buffer thickness Table 9 Minimum buffer thickness PD Size [mm] - 20 - ® BAWN 006-GBR-1 RINGFEDER TNM GBT, TNM GTW... -

Page 21: Changing The Elastic Intermediate Ring

· Tighten the claw ring threaded joint with the tightening torque M stipulated in table 8 (Figure 13). · Check the alignment of the coupling according to the specifications in „8 Cou- pling adjustment”. Fig. 13 - 21 - ® BAWN 006-GBR-1 RINGFEDER TNM GBT, TNM GTW... -

Page 22: Assembly Brake Drum/Disk

§ The covering must not touch the coupling or influence it in its functioning. When using accessories and spare parts which were not originally manufactured by RINGFEDER POWER TRANSMISSION, no liability or guarantee for any damages will be accepted. 11 Waste Disposal The waste disposal has to occur according to the specific regulations of the respective user country. - Page 23 RINGFEDER POWER TRANSMISSION INDIA PRIVATE LIMITED Plot No. 4, Door No. 220, Mount - Poonamallee Road, Kattupakkam, Chennai – 600 056, India Phone: +91 (0) 44-2679 1411 · Fax: +91 (0) 44-2679 1422 · E-mail: sales.india@ringfeder.com KUNSHAN RINGFEDER POWER TRANSMISSION COMPANY LIMITED NO.

Need help?

Do you have a question about the TNM GBT Series and is the answer not in the manual?

Questions and answers