Graco A Series Instructions-Parts List Manual

4-ball lowers

Hide thumbs

Also See for A Series:

- Instructions - parts manual (52 pages) ,

- Instructions-parts list manual (48 pages) ,

- Manual (36 pages)

Advertisement

Quick Links

Instructions - Parts List

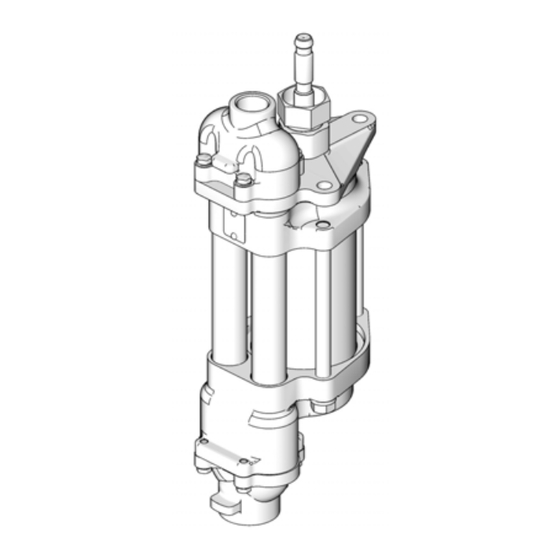

4-Ball Lowers

1500cc and 2000cc Models

Designed for low pressure oil transfer.

Do not use for flushing or purging lines with caustics, acids, abrasive line strippers, and

other similar fluids. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this

manual and in your separate pump manual

before using the equipment. Save these

instructions.

Models:

24J088 - 1500cc, Series A

24J089 - 2000cc, Series A

Maximum Working Pressure, 460 psi (3.2 MPa, 32 bar)

24J090 - 2000cc, Series A

Maximum Working Pressure, 400 psi (2.8 MPa, 28 bar)

US Patent Pending

3A2023C

Models 24J088 and

24J089

Model 24J090

EN

Advertisement

Summary of Contents for Graco A Series

- Page 1 Instructions - Parts List 4-Ball Lowers 3A2023C 1500cc and 2000cc Models Designed for low pressure oil transfer. Do not use for flushing or purging lines with caustics, acids, abrasive line strippers, and other similar fluids. For professional use only. Important Safety Instructions Models 24J088 and Read all warnings and instructions in this 24J089...

-

Page 2: Fire And Explosion Hazard

Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama- tion point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this manual where applicable. -

Page 3: Personal Protective Equipment

Warnings WARNING WARNING WARNING WARNING EQUIPMENT MISUSE HAZARD Misuse can cause death or serious injury. • Do not operate the unit when fatigued or under the influence of drugs or alcohol. • Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. -

Page 4: Pressure Relief Procedure

Repair - Models 24J088 and 24J089 Only Repair - Models 24J088 and 24J089 Only The following instructions are for models 24J088 and 4. Unscrews the coupling nut (a) from the motor shaft. 24J089 only. Instructions for model 24J090 begin on Lift the motor shaft and remove the coupling nut (a) page 9. - Page 5 Repair - Models 24J088 and 24J089 Only 6. Lubricate the throat packings and glands. Install one NOTE: The fluid tubes (3), cylinder (1), and piston male gland (19†) then seven v-packings with the lips assembly (17, 10, 11, 44, 12) may come loose with the facing down: one UHMWPE (20†), one leather outlet housing, or may remain in place on the inlet hous- (25†), UHMWPE, leather, UHMWPE, leather, UHM-...

- Page 6 Repair - Models 24J088 and 24J089 Only NOTE: If the pressure relief valve in the seat (6) is clogged or filled with material, soak the seat in a com- patible solvent. Make sure all material residue is cleaned from the ball and seat area. If the relief valve cannot be thoroughly cleaned so that the ball and spring are free to move, replace the seat (6).

- Page 7 Repair - Models 24J088 and 24J089 Only 35 † 19† 20† 25† 20† 26† 20† 25† 20† 25† 20† 19† Tighten uniformly until cylinder (4) is Apply lubricant to all packings and Apply thread lubricant. seated. Torque to 25-30 ft-lb (34-40 seals.

- Page 8 Repair - Models 24J088 and 24J089 Only OUTLET †35 †19 7*, 24 †20 †25 †20 †26 †20 †25 †20 †25 †20 †19 INLET . 5: Cutaway View 3A2023C...

- Page 9 Repair - Models 24J088 and 24J089 Only Lower Reassembly 1. See F . 4. Place the halves of the piston (10) tioning of the seat, ensuring that the vent is not around the packing (11) and snap them together. blocked by part of the housing. See F .

- Page 10 Repair - Model 24J090 NOTE: It may be necessary to use a rubber mallet to set 13. Fill the cavity in the bottom of the motor shaft with the fluid tubes (3) and cylinder (4) in place. grease. Reconnect the lower to the motor as described in your separate pump manual.

- Page 11 Repair - Model 24J090 4. Unscrews the coupling nut (a) from the motor shaft. lips facing up: UHMWPE, leather, UHMWPE. Install Lift the motor shaft and remove the coupling nut (a) the other male gland (30†). Also see page 23 for and collars (b) (F .

- Page 12 Repair - Model 24J090 5. Use a 13 mm socket wrench to loosen and remove 7. Remove the throat cartridge (45). Remove the the twelve caps crews (9) and lockwashers (8) on o-ring (40), glands (29, 30), and packings (27, 28). the outlet manifold (1).

- Page 13 Repair - Model 24J090 the valve's ball to see if the ball and spring are free to move. See F . 11. ball spring pressure relief valve . 11. Inlet Seat with Pressure Relief Valve NOTE: If the pressure relief valve in the inlet seat (14) is clogged or filled with material, soak the seat in a com- patible solvent.

- Page 14 Repair - Model 24J090 30 † 44† † 28 † 29 † 27 † 28 † 30 † ® Apply lubricant to all packings and Torque to 18-20 ft-lb (24-27 N•m). Apply high strength (red) Loctite seals. or 2760 to entire length of threads. Tighten uniformly until cylinder is Sealant must be allowed to cure for a ®...

- Page 15 Repair - Model 24J090 †44 †30 †27 †29 28† †27 28† †30 †40 . 13: Cutaway View of Lower 3A2023C...

- Page 16 Repair - Model 24J090 Lower Reassembly 3. Install o-ring retainer (20). Lubricate o-ring (22*) and slide it on over the threads of piston rod (19). Apply ® 1. Lubricate the new piston seal (25*) and install it on high strength (red) Loctite 263 or 2760 to entire the piston.

- Page 17 Repair - Model 24J090 7. Clean the remaining pump parts in a compatible sol- vent. Apply lubricant to all packings and seals. . 17 TI0221 1 Do not damage edges of seal. . 16. Install Piston in Cylinder COMPONENT RUPTURE HAZARD The relief valve seat (14) must be installed at the fluid 8.

- Page 18 Repair - Model 24J090 valves. Then tighten all twelve screws oppositely and evenly to 24-27 N•m (18-20 ft-lb). See F . 19. 01410 Torque oppositely and evenly to 81-88 N•m (60-65 ft-lb). . 18. Inlet Seat with Pressure Relief Valve ®...

- Page 19 Repair - Model 24J090 (1) on the outlet valve housing (2) and install the lips facing up: UHMWPE, leather, UHMWPE. Install twelve screws (9) and lockwashers (8) loosely. the other male gland (30†). 19. Tighten the inside four screws (9) oppositely and 21.

- Page 20 Parts - 24J088 and 24J089 Parts - 24J088 and 24J089 23** 24** *7[**] 19† 35† 20† 25† 20† 26† 20† 25† 20† 25† 20† 19† Tighten uniformly until cylinder (4) is Apply lubricant to all packings and Apply thread lubricant. seated.

- Page 21 Parts - 24J088 and 24J089 Part No. 24J088 Series A Ref. Part No. Description Ref. Part No. Description 16A462 ROD, piston; sst 183048 CYLINDER, pump; sst/chrome 192260 MANIFOLD, inlet; tri-clamp; sst PACKING, o-ring; PTFE 19† GLAND, male; sst 183085 TUBE, fluid; sst 20†...

- Page 22 Kits Kits For Part Nos. 24J088 1500 cc 4-Ball For Part Nos. 24J089 2000 cc 4-Ball Pump Repair Kit 24F662 Pump Repair Kit 24F663 Ref. Description Ref. Description PACKING, o-ring; 1.25 in. (31 mm) OD; PTFE PACKING, o-ring; 1.25 in. (31 mm) OD; PTFE SEAL, gasket, cylinder SEAL, gasket, cylinder GASKET, seat, valve...

- Page 23 Parts - 24J090 Parts - 24J090 30 † 27 † 28 † 29 † 27 † 28 † 30 † †40 ® Apply lubricant to all packings and Torque to 18-20 ft-lb (24-27 N•m). Apply high strength (red) Loctite seals. or 2760 to entire length of threads.

- Page 24 Parts - 24J090 Part No. 24J090 Series A Ref. Part No. Description Ref. Part No. Description 196356 RETAINER, o-ring, piston 180520 MANIFOLD; cst 196243 NUT, piston 16E085 HOUSING, outlet; cst O-RING; PTFE encapsulated fluoro- GASKET, cylinder; UHMWPE elastomer 180499 CYLINDER, pump; sst/chrome O-RING;...

-

Page 25: Technical Data

Technical Data Pump Repair Kit 24F664 Ref. Ref. Description Description 27† V-PACKING; UHMWPE SEAL, gasket, cylinder 28† V-PACKING; leather SEAL; UHMWPE 29† GLAND, female GASKET, seat, valve 30† GLAND, male SEAL; UHMWPE 40† O-RING; PTFE; 1.75 in. (44 mm) OD O-RING;... -

Page 26: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the A Series and is the answer not in the manual?

Questions and answers