Graco F Series Instructions-Parts List Manual

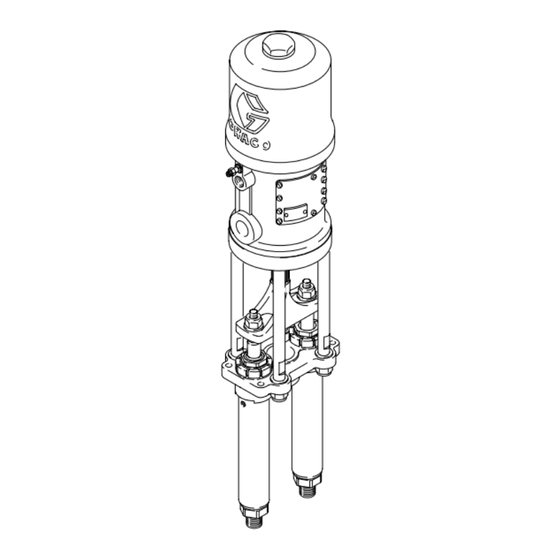

1:1 mix ratio president plural component proportioning pump

Hide thumbs

Also See for F Series:

- Instructions-parts list manual (12 pages) ,

- Instructions manual (12 pages) ,

- Instructions (2 pages)

Table of Contents

Advertisement

Quick Links

Instructions - Parts List

Parts

1:1 MIX RATIO PRESIDENT

Plural Component

Proportioning Pump

For use in Hydra-Cat

1440 psi (9.2 MPa, 92 bar) Maximum Working Pressure

Part No. 208851, Series F

12:1 Pressure Ratio

Model 208851 meets

Part No. 239389, Series A

12:1 Pressure Ratio

1:1 mix ration by volume. See page 10 for other possible mix ratios.

Read warnings and instructions.

Table of Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 1968, Graco Inc. is registered to I.S. EN ISO 9001

R

and Foam-Cat

certification.

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

R

Sprayers

2

4

6

8

9

10

12

13

13

13

16

16

306989L

06915

Advertisement

Table of Contents

Summary of Contents for Graco F Series

-

Page 1: Table Of Contents

......GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441 Copyright 1968, Graco Inc. is registered to I.S. EN ISO 9001... -

Page 2: Warnings

D This equipment is for professional use only. D Read all instruction manuals, tags, and labels before operating the equipment. D Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco distributor. D Do not alter or modify this equipment. Use only genuine Graco parts and accessories. - Page 3 WARNING INJECTION HAZARD Spray from the gun, hose leaks, or ruptured components can inject fluid into your body and cause extremely serious injury, including the need for amputation. Splashing fluid in the eyes or on the skin can also cause serious injury. D Fluid injected into the skin might look like just a cut, but it is a serious injury.

-

Page 4: Installation

D Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and solvent manufacturer. D Graco does not manufacture or supply any of the reactive chemical components that may be used in this equipment and is not responsible for their effects. Graco assumes no responsibility for loss, damage, expense or claims for personal injury or property damage, direct or consequential, arising from the use of such chemical components. - Page 5 Installation Grounding 5. Fluid supply container: follow your local code. 6. Object being sprayed: follow your local code. WARNING 7. Solvent pails used when flushing: follow your local FIRE AND EXPLOSION HAZARD code. Use only metal pails, which are conductive, Before operating the pump, ground the placed on a grounded surface.

-

Page 6: Operation

Operation Pressure Relief Procedure 4. Close the fluid valves to your gun/valve, if so equipped. WARNING 5. Unlock the gun/valve trigger safety. INJECTION HAZARD 6. Hold a metal part of the gun/valve firmly to the side The system pressure must be manually of a grounded metal pail, and trigger it to relieve relieved to prevent the system from pressure. - Page 7 If you have purchased a foam sprayer, refer to the separate system instruction manual for your sprayer (307106 or 307542) for complete startup and priming procedures. If this pump is not used in a Graco Hydra-Cat or Foam-Cat sprayer, follow these operating instructions 06915 Fig. 2 for the proportioning pump.

-

Page 8: Maintenance

Operation Using the Proportioning Pump System If a supply container is dry, stop the pump immediately, and relieve the pressure. Refill the container, and When the system is primed and operating, check the prime the system. Be sure to eliminate all of the air fluid outlet pressure gauges. -

Page 9: Troubleshooting Chart

Troubleshooting NOTE: Check all possible problems and solutions WARNING before disassembling the pump. INJECTION HAZARD To reduce the risk of serious injury, follow the Pressure Relief Procedure on page 6 before checking or servicing any part of the system. Problem Cause Solution Not enough air pressure or volume... -

Page 10: Service

Service Mix Ratio – Pump Combination Chart WARNING For ratios other than 1:1, use three displacement pumps in the following combinations. INJECTION HAZARD To reduce the risk of serious injury, follow the Pressure Relief Procedure Displacement Pump Part No. on page 6 before checking or servicing Ratio Ratio any part of the system and whenever you are... - Page 11 Service Pump Reassembly (See Fig. 3) NOTE: If you are using three displacement pumps, install the center one first. 1. Install the displacement rod and the piston assem- bly in the cylinder. Leave the throat packing nut (E) and the piston stud loose. Refer to displacement pump manual 307944.

-

Page 12: Parts List And Drawing

Parts Part No. 208851, Series F Includes items 1–23 Part No. 239389, Series A Includes items 1–23 Ref. Part No. Description Qty. 207352 AIR MOTOR, See manual 306982 for parts 168418 PLATE, adapter 100018 LOCKWASHER, spring; 1/2” screw size 100017 SCREW, hex hd cap;... -

Page 13: Dimensions

Dimensions Mounting Hole Layout 0.438” (11 mm) dia. 4 holes 14.75” (375 mm) 1/2 npt(f) air inlet 36.5” (972 mm) 6.275” 20.75” (162 mm) (539 mm) 3/8 npt(f) 4.75” (111 mm) dia. 5.5” (140 mm) dia. fluid outlet square cutout bolt circle 3/4 npt(m) fluid inlet... - Page 14 Accessories Bleed-type Master Air Valve Grounding Clamp and Wire 222011 300 psi (2.1 MPa, 21 bar) Maximum Working Pressure 25 ft. (7.7 m) long., 12 gauge (1.5 mm Relieves air trapped in the air line between the pump air inlet and this valve when it is closed. 107141 3/4 npt(m x f) inlet and outlet 107142...

- Page 15 Notes 306989...

-

Page 16: Warranty

Graco distributor to the original purchaser for use. Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defec- tive.

Need help?

Do you have a question about the F Series and is the answer not in the manual?

Questions and answers