Table of Contents

Advertisement

M

ODEL

Hydrocarbon Smart Transmitter

Hydrocarbon Sulphide

Smart Transmitter

Hydrocarbon Sulphide

Smart Transmitter

Hydrocarbon Sulphide

Smart Transmitter

Hydrocarbon Sulphide

Smart Transmitter

Hydrocarbon Sulphide

Smart Transmitter

Hydrocarbon Sulphide

Smart Transmitter

Hydrocarbon Sulphide

Smart Transmitter

Hydrocarbon Sulphide

Smart Transmitter

Hydrocarbon Sulphide

Smart Transmitter

Hydrocarbon Sulphide

S4100C

The information and technical data disclosed in this

document may be used and disseminated only for

the purposes and to the extent specifically

authorized in General Monitors in writing. Such

information and technical data are proprietary to

General Monitors and may not be used or

disseminated except as provided in the foregoing

sentence.

Instruction Manual

General Monitors reserves the right to change published

specifications and designs without prior notice.

Part No.

Revision

01/18

MANS4100C-EU

Q/01-18

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for MSA General Monitors S4100C

- Page 1 S4100C ODEL Hydrocarbon Smart Transmitter Hydrocarbon Sulphide Smart Transmitter Hydrocarbon Sulphide Smart Transmitter Hydrocarbon Sulphide Smart Transmitter Hydrocarbon Sulphide Smart Transmitter The information and technical data disclosed in this document may be used and disseminated only for Hydrocarbon Sulphide the purposes and to the extent specifically Smart Transmitter authorized in General Monitors in writing.

- Page 3 Model S4100C Warranty Statement General Monitors warrants the Model S4100C to be free from defects in workmanship or material under normal use and service within two (2) years from the date of shipment. General Monitors will repair or replace without charge any equipment found to be defective during the warranty period.

-

Page 4: Table Of Contents

Model S4100C Table of Contents Page Warranty Statement Warnings Table of Contents Introduction 1.1General Description ..................1 Specifications 2 2.1Approvals ......................2 2.2Functional ......................2 2.3Mechanical ......................3 2.4Environmental ....................3 2.5Electrical ......................3 2.6Factory default settings ..................4 2.7Sensor Material and Specifications when connected to S4100C ..... 4 2.8Outline Drawing.................... - Page 5 Model S4100C 5.1Maintenance ....................23 5.2Storage ......................23 Trouble Shooting ....................24 6.1Fault codes and Remedies ................24 6.2Alarms ......................25 6.3Modbus RTU Serial Interface problems ............25 Ancillary Equipment ..................26 7.1Dust Guard Assembly (P/N 10110)..............26 7.2Sintered Stainless Steel Dust Guard (P/N 1800822-1) ........26 7.3Splash Guard (P/N 10395-1) ................

-

Page 6: Introduction

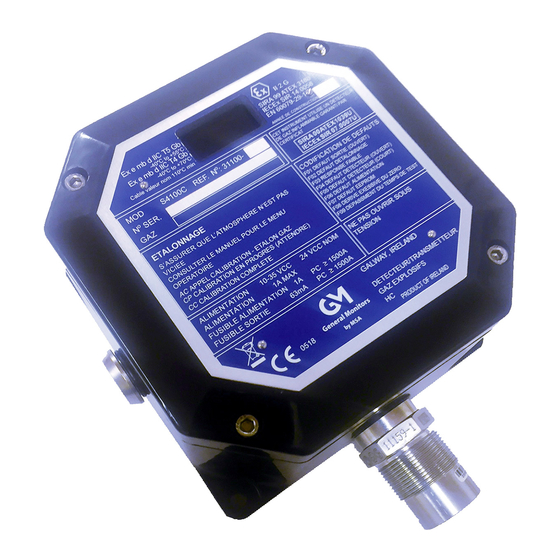

Model S4100C Introduction General Description The General Monitors Model S4100C Smart Transmitter is a highly reliable, self contained, microprocessor controlled, Hydrocarbon gas monitor with integral 3-digit readout. The Transmitter is connected to the user’s indicating and shut-down equipment by means of a screened and armoured cable. The S4100C is designed to measure and display concentrations of combustible gases in the range of: 0-100% Lower Explosive Level (LEL), but will continue to display concentrations up to 120% LEL. -

Page 7: Specifications

Model S4100C Specifications Approvals Hazardous Area Standards EN 60079-0, EN 60079-7, EN 60079-18, EN 60079-29-1 Code of Protection Ex emd IIC T5 Gb (Tamb -40C +55C) Ex emd IIC T4 Gb (Tamb -40C +70C) Cable insulation rated to at least 110C Application: Combustible Gas Monitor Functional... -

Page 8: Mechanical

Model S4100C Mechanical Height excl. Sensor: 150mm (6”) Height incl. Sensor: 200mm (8”) Width: 150mm (6”) Depth: 95mm (3.75”) Weight including Sensor: 2.5kg (5.5lbs) Mounting Holes: 4 x 7 mm (0.28”) dia holes Termination: Ex e rated Terminal Block Environmental Operating temperature range (continuous) min/max - 40C to + 70C Storage temperature range min/max... -

Page 9: Factory Default Settings

Model S4100C Analogue output termination resistance min/max: (including total cable resistance) 0 – 750 ohms Analogue output open-circuit detection current range min/max: 1.0mA – 22.0mA Analogue output fuse rating: 63mA Char “F” PC 1500A Remote calibration input Isink max 2.7mA Remote calibration input Vin max: 24VDC... -

Page 10: Outline Drawing

Model S4100C Outline Drawing... -

Page 11: Installation

Model S4100C Installation WARNING - Installation and Maintenance must be carried out by suitably skilled and competent personnel only. On Receipt of your Equipment All instruments shipped by General Monitors are pre-packed in stout containers and enclosed in a shock absorbing filling which affords a considerable degree of protection against physical damage. -

Page 12: Sensor Poisons

Model S4100C • Observe the ambient temperature limitations quoted in the specification. If a sampling preconditioning system is employed, take steps to ensure that vapours will not condense in the associated pipework. • The mounting should be as free from shock and vibration as possible. Avoid mounting Smart Transmitters directly on structures or process equipment prone to high levels of vibration or shock. -

Page 13: Interconnecting Cable Guidelines

Model S4100C Interconnecting cable Guidelines • The Smart Transmitter requires an interconnecting cable with an overall screen (shield) and armour. Cables to BS5308 Part 2, Type 2 or equivalent are suitable. • Interconnecting cables should be segregated from power and other “noisy” cables. -

Page 14: Installation Instructions

Model S4100C Installation Instructions 3.6.1 Smart Transmitter Cable Termination • The Smart Transmitter should be installed in accordance with the certification documents and the relevant regulations of the country concerned. • Ensure that the gas sensor, if used, points downwards so as to protect it from rain and the accumulation of deposits. -

Page 15: 3Cable Termination Drawing

Model S4100C 3.6.3 Cable Termination Drawing... - Page 16 Model S4100C The electrical rating for all open collector outputs is 100mA @ 35VDC. The diagram below illustrates some typical open collector external circuits.

-

Page 17: Interconnection Details

Model S4100C Interconnection Details Signal 12-Way Module Name Terminal Function If not used Fly lead colour + 24VDC Power Supply brown Analogue output connect to OV yellow Power Supply Return blue Remote calibration input (Note) leave unconnected* grey Alarm 2 open collector output leave unconnected* orange Alarm 1 open collector output... - Page 18 Model S4100C Do not over tighten such that the O’Ring is damaged Screw Continuity Hex Nut (P/N 928-814) on the inside of the S4100x Housing to the Earth/Stopping Plug (P/N 311001-1). Tighten to insure it is secure and making good contact with internal continuity plate. ...

- Page 19 Model S4100C...

-

Page 20: Operating Instructions

Model S4100C Operating Instructions WARNING – Installation and Maintenance must be carried out by suitably skilled and competent personnel only. Menu Operation and Display Codes Note: See Table 1 and Table 2 for Display Codes Menu operation starts at Level 1. To enter the menu, the magnet is applied to the General Monitors Logo on the Nameplate and held in place. - Page 21 Model S4100C Menu Selection Availability: Latched Level 1 menu selections Menu entry Faults? Alarms? Alarms? LEL<10% available delay ACA, CCA, ASU, CSU & ncl 5 sec ACA, ASU, CSU & ncl 5 sec ACA, & CCA 90 sec ACA & ncl 90 sec ACA &...

-

Page 22: Tables

Model S4100C Tables TABLE 1 – MENU DISPLAY CODES Level 1 Level 2 Level 3 Level 4 Activate calibration, Activate calibration Apply calibration gas mode Calibration in progress Calibration completed, Remove calibration gas Check calibration mode Activate calibration mode Open collector output Activate setup mode A1 alarm setup normally energized... - Page 23 Model S4100C TABLE 1 – MENU DISPLAY CODES Level 1 Level 2 Level 3 Level 4 A1 open collector output Check setup mode norm. (de)-energized A1 open collector output (non)-latching A1 alarm triplevel % LEL A2 open collector output norm. (de)-energized A2 open collector output (non)-latching A2 alarm triplevel % LEL...

-

Page 24: Calibration

Model S4100C Calibration Calibration may be carried out as follows: • Ensure that the instrument has stabilised for at least 1 hour and that there is no combustible gas present at the sensor. If the background levels of gas are suspected, their presence may be confirmed by capping the sensor and observing a fault in indicated gas concentration as the sensor oxidises the entrapped gas. -

Page 25: New Sensor Calibration

Model S4100C New Sensor Calibration New sensor calibration may be carried out as follows: • Ensure that the instrument has stabilised for at least 1 hour and that there is no combustible gas present at the sensor. If the background levels of gas are suspected, their presence may be confirmed by capping the sensor and observing a fault in indicated gas concentration as the sensor oxidises the entrapped gas. -

Page 26: Calibration Check

Model S4100C Calibration Check • Place the magnet on the General Monitors Logo on the Nameplate. The instrument will display “ - - -“ for 5 seconds and then enter the menu routine. Remove the magnet. Select “CCA” by briefly reapplying the magnet when the display scrolls around. -

Page 27: Special Power Up Routine

Model S4100C Special Power up Routine If the instrument is powered up with the magnet present it will display “EEPROM write activity” for 1 second, followed by “Power up in progress” as above. The magnet present will cause the Modbus Parameters to be reset to factory default. The magnet may be removed immediately. -

Page 28: Maintenance

Model S4100C Maintenance WARNING - Installation and Maintenance must be carried out by suitably skilled and competent personnel only. Maintenance Once correctly installed, systems require very little maintenance other than Routine Re-calibration (see section 4) and periodic inspection. Sensors exposed to the elements may require a little grease on the accessory mounting threads. -

Page 29: Trouble Shooting

Model S4100C Trouble Shooting Fault codes and Remedies Faults are stacked according to priority, i.e.: if more than one Fault exists at a particular time, the display will show the Fault with the highest priority (lowest number in priority column). As the Faults are being cleared, the Fault with the next highest priority will be displayed, until all Faults have been cleared. -

Page 30: Alarms

Model S4100C Alarms Alarms are stacked below Faults according to priority i.e.: if a Fault and (latched) Alarm(s) exist at a particular time, the display will show the Fault. As the Fault is cleared, the Alarm with the next highest priority will be displayed. Latched Alarms may be cleared by briefly applying the magnet to the General Monitors Logo on the Nameplate if the Alarm condition no longer exists. -

Page 31: Ancillary Equipment

Model S4100C Ancillary Equipment Dust Guard Assembly (P/N 10110) The dust guard is a simple, threaded (1 3/16-18 UNEF 2B) stainless steel cylinder with a wire screen at one end. It is easily unscrewed for cleaning and/or replacement of the disposable screen. The screen material is stainless steel with a nominal 40 micron mesh. -

Page 32: Duct Mounting Plate (P/N 10041 Dash-1 Or -2)

Model S4100C Duct Mounting Plate (P/N 10041 Dash-1 or –2) The Duct Mounting Plate is a rectangular plate measuring 73 x 116mm (2.88” x 4.56”) containing four captive mounting screws (6-32 UNC), and fitted with a Neoprene O- ring seal. The sensor is mounted in a 1 3/16-18 UNEF threaded hole in the centre of the plate. - Page 33 Model S4100C Available from stock Portable Purge Calibrator Replacement Cylinder Methane Gas 50% LEL 1400150-M Hydrogen 50% LEL 140155-H Portable Purge Calibrator Replacement Cylinder Hydrogen Gas 50% LEL 1400150-H Butadine Gas 50% LEL 140155-BD Portable Purge Calibrator Replacement Cylinder Butadine Gas 50% LEL 1400150-BD Butane Gas 50% LEL 140155-B...

-

Page 34: Remote Test Gas Applicator - Tga-1

Model S4100C Remote Test Gas Applicator – TGA-1 The Remote Test Gas Applicator, (TGA-1) is designed to be permanently installed on a combustible gas sensor. The TGA-1 provides protection from outside elements, such as splashing water, and it allows the user to apply test gas from a remote source. -

Page 35: Volatile Liquids And Solvents

Model S4100C Volatile Liquids and Solvents Volatile liquids and solvents are not supplied by General Monitors. This page provides a listing of some volatile liquids and solvents and the respective volumes required (in microlitres) to produce a 50% LEL vapor concentration in the 3 Litre Portable Calibration Chamber (P/No. -

Page 36: Modbus Rtu Serial Interface

Model S4100C Modbus RTU Serial Interface General The Modbus communications interface is based on the RS485 standard. It is implemented as a 2 wire, half-duplex, balanced differential interface which conforms to the EIA-485 specification. Each slave device must have its unique address so that more than one device can be connected to an independently addressed on the same RS485-link. -

Page 37: Modbus Read/Write - Commands

Model S4100C Modbus Read/Write - Commands Function Code Description Access Type Read coil status Read Read input status Read Read holding registers Read Read input registers Read Force single coil Write Preset single register Write Force multiple coils Write Preset multiple registers Write Any of commands with Function Code 1, 2, 3, 4 allow data to be read from the instrument. -

Page 38: Modbus Register Configuration

Model S4100C Modbus Register Configuration Registers 1, 2, 4, 5, 6, 8 & 11 contain the value of the single parameter specified, the remaining registers contain composite parameters. Attempts to write a data value out of range for these parameters will result in the Illegal Data Value response (Exception Code 3). -

Page 39: Register 7

Model S4100C 8.5.2 Register 7 Description Bit position Dec. value Function 15-6 Analogue output at 0.0mA calibration 1.5mA 2.0mA A2 alarm open collector De-energised output normally Energised energised/de-energised A1 alarm open collector De-energised output normally Energised energised/de-energised A2 alarm open collector Non-latching output normally Latching... -

Page 40: Maximum Sensor Cable Length

Model S4100C Appendix A Maximum Sensor Cable Length Note: Cables to be screened and armoured to BS5308 Part 2 or equivalent. References to Sq. mm and AWG are not to be taken as direct equivalents. Maximum Sensor Cable length for various conductor sizes: Conductor Size Maximum Cable Length Sq. - Page 41 Model S4100C Conductor Size Maximum Cable Length Power Supply Rating Cable Drop sq mm metres feet mA max total VDC 1300 (2250) 5150 (8850) 0.75 (675) 1190 (1825) 30.0 (550) 15.0 (900) 1850 (2850) (1350) 2350 (3650) 1150 (1800) 3730 (5775) 1435 (2250)

-

Page 42: Customer Satisfaction Questionnaire

Model S4100C Customer Satisfaction Questionnaire Attention Field Operations: We would appreciate your help in assessing and thus improving the quality of our Equipment and Service and would therefore be grateful if you would complete the Questionnaire below and return it to: General Monitors Ireland Ltd, Ballybrit Business Park, Galway,...

Need help?

Do you have a question about the General Monitors S4100C and is the answer not in the manual?

Questions and answers