Dresser D Series Installation Supplement Manual

Hide thumbs

Also See for D Series:

- Installation, operation and maintenance manual (49 pages) ,

- Testing manual (12 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Dresser D Series

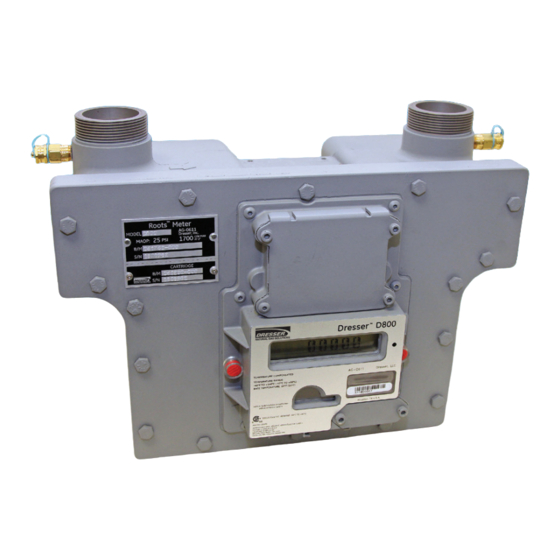

- Page 1 Dresser Series D Meter ™ Models D800 and D1000 Installation Supplement © 2019 Natural Gas Solutions North America, LLC – All Rights Reserved.

-

Page 2: Table Of Contents

Dresser Series D Installation Supplement Contents 1 Introduction ........................3 2 Receiving, Handling, and Storage ..................3 At Time of Delivery ........................3 Storage............................3 3 Parts Identification ......................4 Meter Display ..........................4 RPM Wheel ..........................5 4 Problems with Installation or Operation ................5 5 Meter Installation...................... -

Page 3: Introduction

This manual provides information to install and start using the Dresser D800/D1000 Series D meters. Please read the entire manual and refer to the Dresser Series D Installation, Operation, and Maintenance Manual for information about how to properly and safely install, use, and maintain these meters and some of their accessories. -

Page 4: Parts Identification

Dresser Series D Installation Supplement Parts Identification 3.1 Meter Display View the meter information on its LCD (liquid-crystal display) screen. 3.1.1 Scrolling Through the Screens To scroll through the different screens, swipe a magnet across the black dot to the right of the LCD screen on the meter’s label, as shown in Figure 1 and Figure 2. -

Page 5: Rpm Wheel

Dresser Series D Installation Supplement Note: Use the Dresser MeterWare software to configure parameters on the screens by selecting or clearing the checkbox for the parameter to be displayed (refer to the Dresser MeterWare Software Manual). 3.2 RPM Wheel... -

Page 6: Meter Installation

Dresser meters are designed for continuously measuring and indicating accurate measurement of clean, dry natural gas and other non-corrosive gases at constant or varying flow rates. The Dresser Series D meters have excellent rangeability and are capable of accurately measuring small pilot loads. Contact your Dresser meter supplier for a list of approved gases or additional performance details. - Page 7 If over-speed conditions can occur, a restricting flow orifice plate should be installed two to four (2–4) pipe diameters downstream of the meter outlet. Contact Dresser Meters and Instruments for sizing, pricing, and availability. The warranty does not cover over-speed conditions.

-

Page 8: Placing Meter In Line

Dresser Series D Installation Supplement 5.1.4 Safety Considerations WARNING To reduce the risk of severe injury or death, follow your company guidelines and industry accepted practices. Other safety considerations are provided below: This equipment is designed to operate at temperatures between -40°F and 140°F (-40°C to 60°C). - Page 9 Figure 6. Ensure gas flow is in the same direction as configured on the meter index. For the volume accumulation method, refer to the Meter Operation section in the Dresser™ Series D Meter Installation, Operation, and Maintenance Manual. Hand tighten the nut to the meter ferrule.

- Page 10 Dresser Series D Installation Supplement Verify the meter index is parallel to the ground with both meter ferrules (spuds) pointing upward. Refer to Figure 8. Figure 8: Meter placed in line Verify the meter is installed without piping strain to prevent binding.

-

Page 11: Meter Startup

Dresser Series D Installation Supplement Meter Startup After proper installation and leveling of the meter, as described in Section 5, perform the following steps to start up the meter: Slowly open the meter inlet valve just enough to allow gas into the meter. -

Page 12: Downstream Leak Tests

For more information about the RPM Wheel, refer to Section 3.2. 7.2 Electronic Method – Magnetic Interface If the LEAKTEST screen is not available, use the Dresser MeterWare software to enable this test feature on the meter. For information about enabling this feature, refer to the Dresser MeterWare Software Manual. -

Page 13: Electronic Method - Meterware Interface

IR dongle connected to the USB extension cable. For more information, refer to the Dresser™ Series D Meter Installation, Operation, and Maintenance Manual. With the Dresser MeterWare software, you can adjust the test parameters and run the leak test (refer to Figure 15). -

Page 14: Amr Installation

Figure 14: Advanced screen in Dresser MeterWare Figure 15: Leak Test Parameters screen in Dresser MeterWare Figure 16: Leak test pass/fail indications in Dresser MeterWare AMR Installation Perform the following steps to install an AMR (automatic meter reading) device, if applicable. - Page 15 Dresser Series D Installation Supplement 8.1.1 Preparing the AMR Bracket and Cable After you remove the brackets, the pulse output cable is visible as shown in Figure 18. Figure 18: Pulse output cable on backside of meter Loosen the cable gland and pull the cable until at least 7.5–8 inches of cable extend from the...

- Page 16 Dresser Series D Installation Supplement 8.1.2 Preparing the AMR Bracket and Connecting the Cable After you remove the brackets, the pulse output cable connector is visible as shown in Figure 22. Figure 22: Pulse output cable connection on backside of meter Plug the pulse output cable into the cable connection as shown in Figure 23.

- Page 17 Dresser Series D Installation Supplement 8.1.3 Installing an Itron ERT Module To install an Itron ERT® (encoder receiver transmitter) module on the meter, perform the following steps: Splice the meter pulse output wires to the ERT. • If using Pulse Output 1, the green meter wire connects to the red AMR wire and the brown meter wire connects to the white AMR wire.

- Page 18 Dresser Series D Installation Supplement Carefully dress wires into the housing, and install the backplate on the Endpoint using the supplied T15 Torx screws as shown in Figure 29. Figure 29: Attach ERT to backplate with Torx screws Source locally one (1) #8-32 x 1/2 inch screw, two (2) each #8-32 x 3/4 inch screws, and three (3) #8-32 Kep®...

-

Page 19: Pulse Output Connections

Dresser MeterWare software. Each Dresser Series D meter comes standard with two (2) flow frequency pulse outputs (Pulse Outputs 1 and 2) that represent volumetric information for remote data collection. Pulse Outputs 1 and 2 can be configured for faults and alarm signals. -

Page 20: Pulse Output Allocation Settings And Testing

In the Dresser MeterWare software, the Corrector pulse output allocation is configured on the Volume Configuration screen (refer to Figure 35). For more information about the settings on this screen, refer to the Dresser MeterWare Software Manual. Note: Some customers have their meter configured by the Factory. Verify your company policy before making any configuration changes. -

Page 21: Wiring Instructions For Hazardous Locations

For hazardous areas, use a recommended barrier such as Turck Brand IM1-12EX-T Single Channel or IM1-22 EX-R Dual Channel Barrier or an equivalent. For wiring products in hazardous locations, refer to the Dresser™ Series D Meter Installation, Operation, and Maintenance Manual. - Page 22 Dresser Series D Installation Supplement WARNING Products certified as intrinsically safe installations shall be: Installed, put into service, used, and maintained in compliance with national and local regulations • and in accordance with the recommendations contained in the relevant standards concerning potentially explosive atmospheres.

- Page 23 Dresser Series D Installation Supplement Meter serial number: ______________________________ Digital index serial number: ______________________________ Meter badge number: ______________________________ Notes © 2019 Natural Gas Solutions North America, LLC Page 23 of 24...

- Page 24 Contact your Dresser Natural Gas Solutions representative for the most current information. The Dresser Logo and all Trademarks containing the term “Dresser” are the property of Dresser, LLC, a subsidiary of Baker Hughes, a GE Company.

Need help?

Do you have a question about the D Series and is the answer not in the manual?

Questions and answers