Rockwell Automation Allen-Bradley MP Series Installation Instructions Manual

Food-grade servo motor with 100 mm to 165 mm frame size

Hide thumbs

Also See for Allen-Bradley MP Series:

- Installation instructions manual (24 pages) ,

- Installation instructions manual (68 pages) ,

- User manual (136 pages)

Table of Contents

Advertisement

Quick Links

Installation Instructions

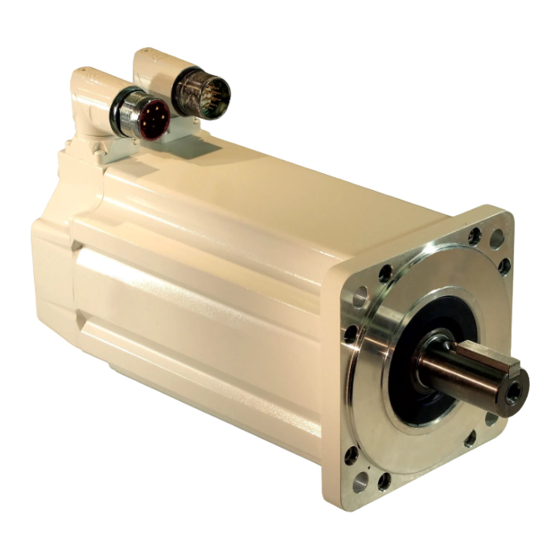

MP-Series Food-grade Servo Motor with

100 mm to 165 mm Frame Size

Catalog Numbers MPF-A310, MPF-A320, MPF-A330, MPF-A430, MPF-A4530, MPF-A4540,

MPF-A540, MPF-B310, MPF-B320, MPF-B330, MPF-B430, MPF-B4530, MPF-B4540, MPF-B540

Topic

Page

2

3

4

4

10

14

16

18

20

21

23

24

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Rockwell Automation Allen-Bradley MP Series

-

Page 1: Table Of Contents

Installation Instructions MP-Series Food-grade Servo Motor with 100 mm to 165 mm Frame Size Catalog Numbers MPF-A310, MPF-A320, MPF-A330, MPF-A430, MPF-A4530, MPF-A4540, MPF-A540, MPF-B310, MPF-B320, MPF-B330, MPF-B430, MPF-B4530, MPF-B4540, MPF-B540 Topic Page Important User Information Catalog Number Explanation About the MP-Series Food-grade Motors Before You Begin Install the Motor Product Dimensions... -

Page 2: Important User Information

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment. -

Page 3: Catalog Number Explanation

Frame Size (IEC 72-1 flange number) = 100 mm = 115 mm = 130 mm = 165 mm Voltage Class = 200V = 400V Series Type = Food grade Series = Premium permanent magnet rotary servo motor Rockwell Automation Publication MP-IN004F-EN-P - January 2015... -

Page 4: About The Mp-Series Food-Grade Motors

Change Connector Orientation on page Only an authorized Allen-Bradley repair center can service this item. Refer to Rockwell Automation Support for assistance to locate the nearest repair center. Store or operate your motor in a clean and dry location within the environmental conditions... - Page 5 The brake option on this servo motor is a spring-set holding brake that releases when voltage is applied to the brake coil. A separate power source is required to disengage the brake. This power source can be applied by a servo motor controller or manual operator control. Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

- Page 6 • Refer to Kinetix® Motion Accessories Specifications, publication GMC-TD004, to find environmentally sealed connectors and cables compatible with the MP-Series motors. Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

- Page 7 EMI in noisy environments. Refer to System Design for Control of Electrical Noise Reference Manual, publication GMC-RM001, for additional information on reducing the effects of EMI by improving the system level electromagnetic compatibility (EMC). Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

- Page 8 Grounding of Signal Wire Shields in a Power Cable on page 9. Then clamp all of the shields together in the power cable (chassis) ground connection on the drive. Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

- Page 9 The signal wire pairs within a power cable often carry a 24V DC brake signal, but can also carry logic signals. Grounding the shield that surrounds the signal wires dissipates an induced voltage and reduces the effects of EMI. Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

-

Page 10: Install The Motor

ATTENTION: Apply force to only the motor connector and cable plug. Do not apply force to the cable extending from the cable plug. Do not use tools (for example, pliers and vise-grips) to rotate the connector. 3. Repeat these steps for the other connector. Rockwell Automation Publication MP-IN004F-EN-P - January 2015... -

Page 11: Product Dimensions

7. Rotate the shaft for electrical phasing and encoder alignment. The index pulse occurs on a single-turn encoder when the shaft key is aligned with the connectors. Refer to Product Dimensions on page 14 for a visual reference of this alignment. Rockwell Automation Publication MP-IN004F-EN-P - January 2015... - Page 12 SpeedTec-ready DIN SpeedTec DIN (M7) Cable Plug Motor Connectors • 2090-CFBM7Dx-xxAxxx standard and continuous-flex feedback cables • 2090-CPxM7DF-xxAxxx standard and continuous-flex power/brake cables 3. Form a drip loop in the cable (see page Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

- Page 13 ATTENTION: Align the keyed connectors and hand-tighten the recommended number of turns. If you cannot tighten the connectors by hand, verify that the keyed connectors are properly aligned. Do not use tools (for example, pliers and vise-grips) to tighten the connectors. Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

- Page 14 14 MP-Series Food-grade Servo Motor with 100 mm to 165 mm Frame Size Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

- Page 15 (1.91 in.) to LE; and 51.6 mm (2.03 in.) to MPF-x540 dimensions L, LB, LD, and LE. (6) Tolerance for this dimension is ±0.7 mm (±.028 in.). MP-Series food-grade motors are designed to metric dimensions. Inch dimensions are mathematical conversions. Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

-

Page 16: Motor Load Force Ratings

The following tables represent 20,000 hour L bearing fatigue life at various loads and speeds. This 20,000 hour life does not account for possible application-specific life reduction that can occur due to bearing grease contamination from external sources. Rockwell Automation Publication MP-IN004F-EN-P - January 2015... - Page 17 51 (112) 38 (84) 31 (69) — 28 (62) — MPF-A/B4540 69 (152) 51 (112) 38 (84) 31 (69) — — — MPF-A/B540 — 68 (150) 49 (108) 42 (93) — 37 (82) — Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

-

Page 18: Connector Data

(1) Power pins A, B, C, and D can also be labeled U, V, W, and GND respectively. Brake pins F and G can also be labeled as + and - (positive and negative) respectively. Reserved pins E and H can also be numbered 1 and 2. Rockwell Automation Publication MP-IN004F-EN-P - January 2015... - Page 19 M23 Feedback and M40 Power/Brake Pin Descriptions MPF-B (460V) and MPF-A5 MPF-A5 and MPF-B5 Sin+ Phase U Sin- Phase V Cos+ Phase W Cos- Ground Data+ Data- Reserved Reserved +9V DC Common Reserved M23Feedback Connector M40 Power/Brake Connector Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

-

Page 20: Remove And Install A Shaft Key

Apply a constant force evenly across the top of the key. Support Fixture Key Aligns at for Shaft End of Shaft Radius Cut at the End of the Keyway Rockwell Automation Publication MP-IN004F-EN-P - January 2015... -

Page 21: Motor Cables And Accessory Kits

Factory manufactured feedback and power cables are available in standard cable lengths. They provide the sealing needed to achieve environmental ratings and shield termination. For a complete listing of available cables, contact your nearest Rockwell Automation sales office or refer to the Kinetix Motion Accessories Specifications Technical Data, publication GMC-TD004. - Page 22 Air supplied to the motor must be clean, dry, and of instrument quality. Maximum air pressure is 0.1 bar (1.45 psi). Positive Air-pressure Kit Installation on the M23 Feedback Connector O-ring Air Fitting Torx Screw M3 x 10mm Flat Head Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

-

Page 23: Specifications

(4) IP rating descriptions are only for reference. Refer to the international standards for more complete rating descriptions. (5) International Protection Code (IP66) is roughly equivalent to a NEMA 35 (dust tight, drip tight). Rockwell Automation Publication MP-IN004F-EN-P - January 2015... -

Page 24: Additional Resources

Declarations of Conformity (DOC) for Rockwell http://www.rockwellautomation.com/products/certification/ Automation products. You can view or download publications at http://www.rockwellautomation.com/literature/. To order paper copies of technical documentation, contact your local Allen-Bradley distributor or Rockwell Automation sales representative. Rockwell Automation Publication MP-IN004F-EN-P - January 2015... - Page 25 MP-Series Food-grade Servo Motor with 100 mm to 165 mm Frame Size 25 Notes: Rockwell Automation Publication MP-IN004F-EN-P - January 2015...

- Page 26 New Product Satisfaction Return Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

Need help?

Do you have a question about the Allen-Bradley MP Series and is the answer not in the manual?

Questions and answers