Rockwell Automation Allen-Bradley MP Series Installation Instructions Manual

Heavy duty electric cylinders

Hide thumbs

Also See for Allen-Bradley MP Series:

- Installation instructions manual (24 pages) ,

- Installation instructions manual (26 pages) ,

- User manual (136 pages)

Advertisement

Quick Links

Installation Instructions

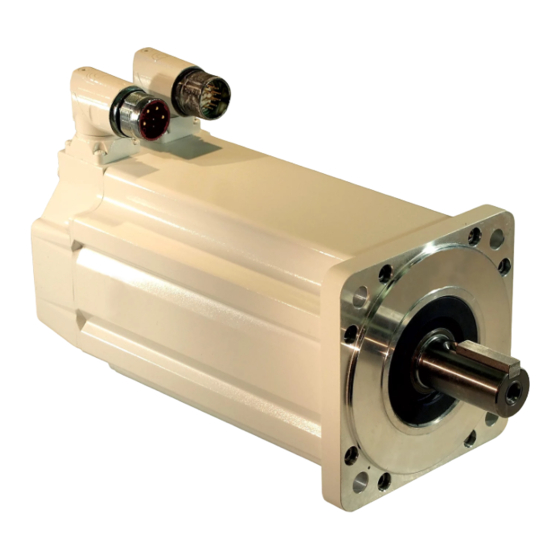

MP-Series Heavy Duty Electric Cylinders

Catalog Numbers MPAI-A2xxxC, MPAI-B2xxxC, MPAI-A3xxxC, MPAI-B3xxxC,

MPAI-A3xxxE, MPAI-B3xxxE, MPAI-A3xxxR, MPAI-B3xxxR, MPAI-A3xxxS, MPAI-B3xxxS,

MPAI-A4xxxC, MPAI-B4xxxC, MPAI-A4xxxE, MPAI-B4xxxE, MPAI-A4xxxR, MPAI-B4xxxR,

MPAI-A4xxxS, MPAI-B4xxxS MPAI-A5xxxC, MPAI-B5xxxC, MPAI-A5xxxE, MPAI-B5xxxE

Topic

Dimensions

Connector Data

Commissioning

Lubrication

Troubleshooting

Accessories

Specifications

Additional Resources

Page

2

3

5

6

9

13

16

17

29

30

46

51

53

64

66

Advertisement

Summary of Contents for Rockwell Automation Allen-Bradley MP Series

-

Page 1: Table Of Contents

Installation Instructions MP-Series Heavy Duty Electric Cylinders Catalog Numbers MPAI-A2xxxC, MPAI-B2xxxC, MPAI-A3xxxC, MPAI-B3xxxC, MPAI-A3xxxE, MPAI-B3xxxE, MPAI-A3xxxR, MPAI-B3xxxR, MPAI-A3xxxS, MPAI-B3xxxS, MPAI-A4xxxC, MPAI-B4xxxC, MPAI-A4xxxE, MPAI-B4xxxE, MPAI-A4xxxR, MPAI-B4xxxR, MPAI-A4xxxS, MPAI-B4xxxS MPAI-A5xxxC, MPAI-B5xxxC, MPAI-A5xxxE, MPAI-B5xxxE Topic Page Important User Information Catalog Number Explanation About the MP-Series Heavy Duty Electric Cylinders Before You Begin Install the Electric Cylinder Mount the Electric Cylinder... -

Page 2: Important User Information

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment. -

Page 3: Catalog Number Explanation

(1) The Special Feature field is for customer specific coding. (2) Not available in the 64 mm (2.25 in.) frame. (3) 76 mm (3.0 in.) stroke length, is only available in the 64 mm (2.5 in.) and 83 mm (3.27 in.) frames. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012... - Page 4 NE = Rod-end accessory NR = Replacement kit accessory Actuator Type AI = Actuator rod Actuator Series MP-Series (1) The Stroke Length field is used only for the anti-rotation guide, catalog number MPAI-NEx02xx. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

-

Page 5: About The Mp-Series Heavy Duty Electric Cylinders

Wrench flats for counteracting torque on thrust rod when installing rod-end accessories Grease fitting (not included on catalog number MPAI-x2xxxC) Thrust rod (1) Trunnion mount electric cylinders, not shown, have threaded mounting holes only on the rear surface. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012... -

Page 6: Before You Begin

ATTENTION: The electric cylinder is not intended to be used in applications where side-loading occurs. Loads must be guided and supported. Aligned load with the line-of-motion of the thrust rod. Side loading will reduce the lifetime of the electric cylinder. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012... - Page 7 Refer to page 59 for catalog information on thrust rod seals. • Inspect the seals for damage or wear on a regular basis. If damage or excessive wear is observed, replace the item. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 8 If necessary, use additional electrical noise reduction techniques to reduce EMI in noisy environments. Refer to System Design for Control of Electrical Noise Reference Manual, publication GMC-RM001, for additional information on reducing the effects of EMI. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

-

Page 9: Install The Electric Cylinder

2. Make sure the mounting surface supports the electric cylinder evenly so that it is free of mechanical stress and distortion. • Evenness of the mounting surface must be within 0.127 mm (0.005 in.). • The thrust rod must be parallel to the guide within 0.0254 mm (0.010 in.). Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012... - Page 10 M20 x 1.5 38.08 mm (1.489 in.) 76.3 N•m (56.3 lb•ft) Flats M27 x 2.0 53.98 mm (2.125 in.) 135.6 N•m (100.0 lb•ft) (1) Unless otherwise noted, torque specifications have a ±20% tolerance. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 11 To reduce wear on the horizontal guides of the Anti-rotation kit, adjust the guides at the work load and the electric cylinder so that they are exactly parallel, as described in Mount the Electric Cylinder on page Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 12 5. Carefully position the rear clevis mount and seal on the mounting surface. The seal is included in the rear clevis mounting kit. 6. Using an alternating torque pattern, evenly torque each of the four mounting bolts to value shown on page Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

-

Page 13: Mount The Electric Cylinder

The risk area must be protected by a safety system that stops the equipment if anyone enters the risk area. Personnel who enter the risk area must be authorized, trained, and qualified for any task performed inside the risk area. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012... - Page 14 Continuous flex cables with a SpeedTec DIN connector have an M7 designation. 2. Fully seat the feedback connector and the power/brake connector. • Hand tighten the collar of a threaded (M4) connector five or six turns. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 15 3. Form a drip loop in the cable to keep liquids away from the connectors. 4. Verify the continuity and functionality of the thermal switch signals, TS+ and TS-. These signals are transmitted through the feedback cable that connects the motor to its controlling drive. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

-

Page 16: Change Connector Orientation

ATTENTION: Only apply force to the connectors; do not apply force to the cable. Do not use tools (for example, pliers and vise-grips) to assist with the rotation of the connector. Failure to observe these safety precautions could result in personal injury or damage to equipment. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012... - Page 17 MP-Series Heavy Duty Electric Cylinders 17 Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 18 718.4 681.1 MPAI-A/B3450xM32A (28.29) (26.81) (1) For MPAI-A/B3xxxxMx4A actuators, add 47.7 mm (1.88 in.) to dimensions G2, L7, and ZJ. (2) The tolerance for this dimension is +0.0, -0.038 mm (+0.0, -0.0015 in.). Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 19 858.2 807.4 MPAI-A/B5450xM32A (33.79) (31.79) (1) For MPAI-A/B5xxxxMx4A actuators, add 51.5 mm (1.88 in.) to dimensions G2, L7, and ZJ. (2) The tolerance for this dimension is +0.0, -0.038 mm (+0.0, -0.0015 in.). Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 20 20 MP-Series Heavy Duty Electric Cylinders Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 21 M8 x 1.25 x 8 1.8 (0.07 69.0 (2.72) 36.0 (1.42) 17.6 (0.69) (0.05 x 0.31) MPAI-A/B3300xM32E-W 529.0 (20.83) MPAI-A/B3450xM32E-W 681.4 (26.83) (1) For MPAI-A/B3xxxxMx4E-W actuators, add 47.7 mm (1.88 in.) to dimensions G2, L7, and ZJ. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 22 M12x 1.75 x 12 MPAI-A/B5300xM32E-W 1.7 (0.07) 110.0 (4.33) 65.0 (2.56) 24.4 (0.96) 654.2 (25.76) (0.07 x 0.47) MPAI-A/B5450xM32E-W 806.6 (31.76) (1) For MPAI-A/B5xxxxMx4E-W actuators, add 51.6 mm (2.03 in.) to dimensions G2, L7, and ZJ. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 23 23 MP-Series Heavy Duty Electric Cylinders Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 24 (0.68) (20.81) 681.1 MPAI-A/B3450xM32B (26.81) (1) For MPAI-A/B3xxxxM34B actuator, add 47.7 mm (1.88 in.) to dimensions G2, L7, and ZJ. (2) The tolerance for this dimension is +0.0, -0.038 mm (+0.0, -0.0015 in.). Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 25 (0.95) (25.79) 807.4 MPAI-A/B5450xM32B (31.79) (1) For MPAI-A/B5xxxxM34B actuator, add 51.5 mm (2.03 in.) to dimensions G2, L7, and ZJ. (2) The tolerance for this dimension is +0.0, -0.038 mm (+0.0, -0.0015 in.). Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 26 26 MP-Series Heavy Duty Electric Cylinders Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 27 32.3 (1.27) 64.3 (2.53) 83.6 (3.29) 17.3 (0.68) MPAI-A/B3300xM32C-W 566.0 (22.29) 528.7 (20.81) MPAI-A/B3450xM32C-W 718.4 (28.29) 681.1 (26.81) (1) For MPAI-A/B3xxxxMx4C-W actuator, add 47.7 mm (1.88 in.) to dimensions G2, L7, and ZJ. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 28 MPAI-A/B5300xM32C-W 1.4 (0.06) 705.0 (27.76) 143.6 (5.66) 24.1 (0.95) 654.2 (25.76) (2.375) (4.500) MPAI-A/B5450xM32C-W 857.4 (33.76) 806.6 (31.76) (1) For MPAI-A/B5xxxxM34C-W actuator, add 51.6 mm (1.82 in.) to dimensions G2, L7, and ZJ. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 29 Excessive and uneven lateral force at the cable connector may result in damage to the housing and contacts as the cable flexes. Failure to observe these safety precautions could result in damage to the motor and its components. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 30 Firmware revision 1.30 or later • Ultra3000 drives with Ultraware software – Firmware revision 1.52 or later – Motion Database (.mdb) file, dated May 2011 or later • Motion Analyzer software, version 4.8 or later Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 31 Initiating a motion command on an electric cylinder with an incorrect Position mode setting may result in damage to the electric cylinder, and the machine in which it is installed. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 32 20,000 drive cnts/1.0 mm 508,000 drive cnts/1.0 in. for MPAI-x3xxxEM1xx MPAI-x3xxxEM3xx MPAI-x3xxxSM1xx MPAI-x3xxxSM3xx MPAI-x4xxxEM3xx MPAI-x4xxxSM3xx MPAI-x5xxxEM3xx Conversion Constant 40,000 drive cnts/1.0 mm 1,016,000 drive cnts/1.0 in. for MPAI-x2xxxCM1xx MPAI-x2xxxCM3xx MPAI-x3xxxCM1xx MPAI-x3xxxCM3xx MPAI-x3xxxRM1xx MPAI-x3xxxRM3xx MPAI-x4xxxCM3xx MPAI-x4xxxRM3xx MPAI-x5xxxCM3xx Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 33 MPAI-x3450SM3xx 13.9 MPAI-x4150CM3xx 11.0 MPAI-x4150EM3xx 22.0 MPAI-x4150RM3xx 11.0 MPAI-x4150SM3xx 22.0 MPAI-x4300CM3xx 11.0 MPAI-x4300EM3xx 22.0 MPAI-x4300RM3xx 11.0 MPAI-x4300SM3xx 22.0 MPAI-x4450CM3xx MPAI-x4450EM3xx 19.3 MPAI-x4450RM3xx MPAI-x4450SM3xx 13.3 MPAI-x5150CM3xx MPAI-x5150EM3xx 15.7 MPAI-x5300CM3xx MPAI-x5300EM3xx 15.7 MPAI-x5450CM3xx MPAI-x5450EM3xx 15.7 Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 34 Maximum Positive Enter a value that is within the thrust rod mechanical travel. Maximum Negative Enter a value that is within the thrust rod mechanical travel. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 35 A positive-direction move command denotes a rod extend operation: a IMPORTANT negative-direction move command denotes a retract operation. This is when Drive Polarity is positive, which is the default setting in RSLogix 5000 software. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 36 4. Reduce the default Stopping Time Limit from 10 seconds to 0.5 seconds. To prevent the rod from moving or falling when installed in a vertical orientation, IMPORTANT the Stopping Time Limit must be set to 0.99 seconds or less. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 37 Only check Torque Offset, as shown below, if the electric cylinder is installed in a IMPORTANT non-horizontal mount position. 6. Click Start Tuning to access the Initiate Motion dialog box. ATTENTION: Motion occurs immediately after clicking Yes in the Motion Initiation dialog box. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 38 45.14153 Hz, and a Load Inertia Ratio of 6.8707952. 1. Calculate the Corrected Position Bandwidth. Corrected Position Loop Bandwidth = (Initial Position Loop Bandwidth Result/(Initial Load Inertia Ratio Result +1) For example, 5.73532 = 45.14153/7.8707952 Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 39 3. Click OK. 4. Answer the remaining dialog boxes to apply the values. The proper Position Bandwidth results in a stable starting point, from which you can adjust the gains to fit your application requirements. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 40 5. Verify the data in the Model Field is correct for your electric cylinder. 6. From the Displayed Units pull-down menu, choose User. This programs Ultraware software to make distance moves in User Units (mm or in.). Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 41 (0.19685) (2663383.04) (2663383.04) (2663383.04) MPAI-x4xxxS 10.0 1024 104857.60 104857.60 104857.60 (2663383.04) (2663383.04) (2663383.04) (0.3937) MPAI-x5xxxC 1024 209715.20 209715.20 209715.20 (0.19685) (2663383.04) (2663383.04) (2663383.04) MPAI-x5xxxE 10.0 1024 104857.60 104857.60 104857.60 (0.3937) (2663383.04) (2663383.04) (2663383.04) Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 42 7. Set User Units by entering values for your model from this table. Cat. No. Lead mm/rev (in./rev) Rev/unit MPAI-xxxxCxxx, MPAS-xxxxRMxx 5.0 (0.197) MPAI-xxxxEMxx, MPAS-xxxxSMxx 10.0 (0.394) 8. Home the axis. See Kinetix 300 Single-axis Servo Drives User Manual, publication 2097-UM001, if you need guidance. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 43 Motion Analyzer software to calculate the minimum deceleration distance at the maximum speed of your application. A positive-direction move command denotes a rod extend operation, a IMPORTANT negative-direction move command denotes a retract operation. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 44 4. From the Drive Organizer, select Dynamics. 5. Click Autotune. The Autotune dialog box opens with the default set to Velocity Tuning. 6. Check Velocity Tuning or Position Tuning or both. 7. Follow the instructions in the dialog box. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 45 3. Clean the electric cylinder with a soft cloth and, if needed, non-abrasive cleaning solution. 4. Lightly dampen a soft cloth with isopropyl alcohol and wipe the thrust rod and seal. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 46 5.0 g of Mobilith SHC220 for frame size 110 • 6.0 g of Mobilith SHC220 for frame size 144 Use Mobilith SHC220 to lubricate the ball screw. Set your browser to http://www.mobil.com view the Mobilith SHC220 product information. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 47 ) to the application maximum commanded force (F Xpeak IMPORTANT Load Correction (K) must not be greater than one (<1). Frame Size 83, 5 mm Roller Screw Load Correction = 0.24 (F )-0.15 MPAI-x3xxxSM3xx Xpeak Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 48 The maximum lubricant fill capacity for a roller screw drive is the following: IMPORTANT • 3.0 g of factory recommended lubricant for frame size 83 • 5.0 g of factory recommended lubricant for frame size 110 Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 49 MPAI-x3xxxRM3xx EXAMPLE 1.66 in/s 1700 lbf xpeak 400 lbf = 4500 x (1.66 in/s)-1.57 = 2030 hr -0.15 = 0.24 (1700 lbf/400 lbf) = 0.87 MPAI-x3xxxRM3xx = 2030 x (0.87) = 1766 hr Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 50 After 6 months of storage, cycle the equipment two complete strokes to redistribute the internal lubricants. • After storage for a period longer than 2 years without use, lubricant replacement is recommended through Rockwell Automation Technical Support. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 51 Improper/failed wiring. Check the wiring. Electric cylinder is enabled but not Feedback cable may be damaged. Test the feedback cable. operating or is operating erratically. Feedback wiring may be incorrect. Verify correct feedback wiring. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 52 Verify load forces and electric cylinder rating. rating. Actuator operated outside of Adjust operation to be within continuous continuous rating. operation rating. Amplifier is poorly tuned, requiring Verify gain settings. excessive current be applied to the motor. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 53 4170 (147.1) Rear clevis MPAI-NA203 310 (10.9) Front flange mount MPAI-NA221 500 (17.6) mount (stainless steel) MPAI-NA303 700 (24.7) MPAI-NA321 1090 (38.4) MPAI-NA403 1430 (12.3) MPAI-NA421 1770 (62.4) MPAI-NA503 3010 (106.2) MPAI-NA521 4250 (149.9) Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 54 In most applications, such as those where the load is coupled to linear bearings, or some other support device, the load cannot rotate, and thus provides anti-rotation for the extending rod of the actuator. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 55 MP-Series Heavy Duty Electric Cylinders 55 For applications in which the load is free to rotate, Rockwell Automation offers the anti-rotation systems shown below. ATTENTION: The anti-rotation option is not a guide or support mechanism. It is intended only as an anti-rotation device.

- Page 56 10. Verify that the bearing block fasteners are just finger-tight allowing the bearing block to float. 11. Align the shallow counterbore of the anti-rotation clamp with the anti-rotation shaft, engage the shaft into the counterbore. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 57 Frame Size Torque 13.2 N•m (9.7 lb•ft) 39.5 N•m (29.13 lb•ft) 56.5 N•m (70.0 lb•ft) 14. Use the procedure in Configure Your Servo Drive with RSLogix 5000 Software on page 31 to re-establish home. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 58 Air Pressure Kit Installation on an M23 Feedback Connector Feedback connector attaches to a rotary or linear motion device that is not shown. O-ring Air Fitting Torx Screw M3 x 10 mm Flat Head Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 59 2012 have a front bearing block NR07 (Series A) in their construction. Check your MPAI-x3 and MPAI-x4 actuator nameplate for Series A or Series B before specifying replacement front wiper seal kits. (2) Fits a standard grease gun with 52 mm (2.0 in.) piston. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 60 Gray +5V DC Motor WHT/Gray ECOM Feedback +9V DC Orange WHT/Orange Thermostat Blue Black MBRK + Motor Brake White Brake (BC) MBRK - Connector User Supplied 2090-CFBM7DF-CDAFxx, or 24V DC 2090-CFBM7DF-CEAAxx Feedback Cable Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 61 ORANGE +9VDC Thermostat WHT/ORANGE BLUE Black White I/O (IOD) Motor Brake 2090-CFBM7DF-CDAFxx, or Connector 2090-CFBM7DF-CEAAxx Cable Shield MTR_BRAKE - Feedback Cable Clamp MTR_BRAKE + 24V DC 24V DC COM User Supplied 24V DC Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 62 Feedback WHT/Gray ECOM +9V DC Orange Thermostat WHT/Orange Blue Black Control Interface BRK - (CN1) Connector White BRK+ Motor Brake 2090-CFBM7DF-CDAFxx,Allen-Bradley , ControlLogix, CompactLogix, Kinetix, MP-Series, Rockwell Software, +24V User Supplied 24V DC Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 63 Kinetix 6200 Kinetix 6500 Clamp Expose shield secured under clamp. Clamp Screw (2) Turn clamp over to hold small cable secure. Use 2090-UXBB-DM15 connector with Ultra3000 drives. Exposed shield secured under clamp. Cable Tie Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 64 (1) Includes MPAI-x5xxxxM3xA and MPAI-x5xxxxM3xE-W (front face mount) cylinders. (2) For MPAI-x5xxxxM3xB (front trunnion mount) cylinders, add 0.5 kg (1.1 lb). (3) For MPAI-x5xxxxM3xC-W (rear clevis mount) cylinders, add 2.1 kg (4.6 lb). Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 65 2.5 g peak @ 30…2000 Hz (1) Tested for one hour per Rockwell Automation specification 10000056670. Contact your distributor for a copy of this specification. (2) The use of environmentally sealed (Bulletin 2090) cables are required to achieve this International Protection (IP) rating for the complete unit.

- Page 66 Specifications, motor/servo-drive system combinations, and accessories for Kinetix Motion Control products. You can view or download publications at http://www.rockwellautomation.com/literature. To order paper copies of technical documentation, contact your local Allen-Bradley distributor or Rockwell Automation sales representative. Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 67 MP-Series Heavy Duty Electric Cylinders 67 Notes: Rockwell Automation Publication MPAI-IN001E-EN-P - March 2012...

- Page 68 Rockwell Automation representative. New Product Satisfaction Return Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

Need help?

Do you have a question about the Allen-Bradley MP Series and is the answer not in the manual?

Questions and answers