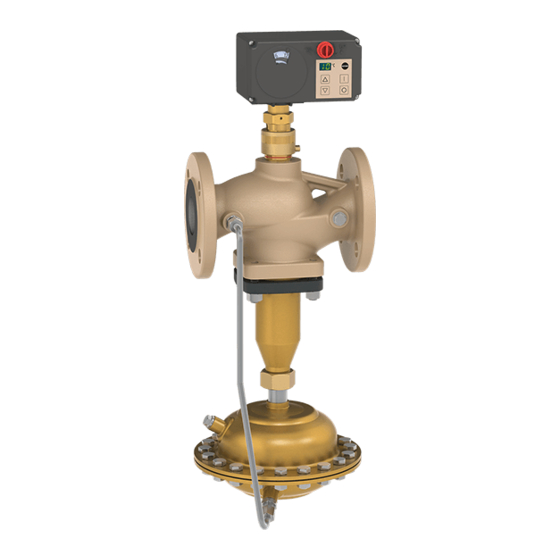

Samson 42-36 Mounting And Operating Instructions

Flow regulator self-operated regulators

Hide thumbs

Also See for 42-36:

- Mounting and operating instructions (20 pages) ,

- Mounting and operating instructions (98 pages)

Summary of Contents for Samson 42-36

- Page 1 EB 3015 EN Translation of original instructions Type 42-36 Flow Regulator Self-operated Regulators Edition June 2020...

- Page 2 Note on these mounting and operating instructions These mounting and operating instructions assist you in mounting and operating the device safely. The instructions are binding for handling SAMSON devices. The images shown in these instructions are for illustration purposes only. The actual product may vary.

-

Page 3: Table Of Contents

Contents Safety instructions and measures ..............1-1 Notes on possible severe personal injury ............1-4 Notes on possible personal injury ..............1-4 Notes on possible property damage .............1-6 Markings on the device ................2-1 Nameplates ....................2-1 Location of the nameplates ................2-2 Material numbers ..................2-2 2.3.1 Type 2423 Valve ..................2-2 2.3.2... - Page 4 Decommissioning ..................10-1 Removal ....................11-1 11.1 Removing the regulator from the pipeline ............11-1 11.2 Removing the actuator from the valve ............11-1 Repairs ....................12-1 12.1 Returning devices to SAMSON ..............12-1 Disposal ....................13-1 Certificates ....................14-1 Annex......................15-1 15.1 Tightening torques ..................15-1 15.2 Lubricant ....................15-1 15.3...

-

Page 5: Safety Instructions And Measures

In case operators intend to use the regulators in other applications or conditions than specified, contact SAMSON. SAMSON does not assume any liability for damage resulting from the failure to use the de- vice for its intended purpose or for damage caused by external forces or any other external factors. - Page 6 Hazards resulting from the special working conditions at the installation site of the regulator must be identified in a risk assessment and prevented through the corresponding safety in- structions drawn up by the operator. We also recommend checking the hazards posed by the process medium being used (e.g. u GESTIS (CLP) hazardous substances database). Î Observe safety measures for handling the device as well as fire prevention and explosion protection measures. Safety features The Type 42-36 Regulator does not have any special safety features. When relieved of pressure, the regulator is opened by the force of the set point springs. EB 3015 EN...

- Page 7 Safety instructions and measures Responsibilities of the operator The operator is responsible for proper operation and compliance with the safety regulations. Operators are obliged to provide these mounting and operating instructions as well as the referenced documents to the operating personnel and to instruct them in proper operation. Furthermore, the operator must ensure that operating personnel or third persons are not ex- posed to any danger.

-

Page 8: Notes On Possible Severe Personal Injury

Safety instructions and measures 1.1 Notes on possible severe personal injury DANGER Risk of bursting in pressure equipment. Regulators and pipelines are pressure equipment. Impermissible pressure or improper opening can lead to regulator components bursting. Î Observe the maximum permissible pressure for regulator and plant. Î... - Page 9 Î Wear protective clothing and safety gloves. Damage to health relating to the REACH regulation. If a SAMSON device contains a substance which is listed as being a substance of very high concern on the candidate list of the REACH regulation, this circumstance is indi- cated on the SAMSON delivery note.

-

Page 10: Notes On Possible Property Damage

The lubricants to be used depend on the regulator material. Unsuitable lubricants may corrode and damage the surface. Î Only use lubricants approved by SAMSON. When in doubt, consult SAMSON. Risk of leakage and regulator damage due to excessively high or low tightening torques. - Page 11 Î Keep the regulator and the tools used free from solvents and grease. Î Make sure that only suitable lubricants are used. Note SAMSON's After-sales Service can support you concerning lubricant, tightening torques and tools approved by SAMSON. EB 3015 EN...

- Page 12 Safety instructions and measures EB 3015 EN...

-

Page 13: Markings On The Device

Markings on the device 2 Markings on the device Several nameplates are affixed to the device. The nameplates are used to identify the sepa- rate regulator components (see section 2.1). 2.1 Nameplates Nameplates of Type 2423 Valve DIN version ANSI version ANSI version · DIN version Valve type Set point range or spring 10 Perm. temperature Model number with index range 11 Body material Material number Valve size Order number or date Pressure rating... -

Page 14: Location Of The Nameplates

Markings on the device 2.2 Location of the nameplates 2.3 Material numbers 2.3.1 Type 2423 Valve See the nameplate (11 for DIN/ANSI ver- sion, body material). For more details on the Location of the nameplate, see section 2.1. nameplate on the regulator components 2.3.2 Type 2426 Actuator Specifying the material number, you can contact us to find out which material is used. -

Page 15: Design And Principle Of Operation

Valves balanced by a dia- Î See Fig. 3-1 and Fig. 3-2 phragm have a balancing diaphragm (5.1) instead of the balancing bellows (5). The Type 42-36 · The flow regulator is used to downstream pressure p acts on the bottom limit the flow rate in the pipeline. The set of the diaphragm and the upstream pressure point is adjusted at the restriction. - Page 16 Design and principle of operation Type 2423 Valve balanced by a bellows Type 2426 Actuator Fig. 3-1: Functional diagram for regulators, DN 15 to 250 with balancing bellows EB 3015 EN...

- Page 17 Design and principle of operation Type 2423 Valve balanced by a diaphragm Type 2426 Actuator Fig. 3-2: Functional diagram for regulators, DN 65 to 250 with balancing diaphragm Legend for Fig. 3-1 and Fig. 3-2 5 Balancing bellows 14 Differential pressure springs 1 Valve body 1.1 Set point adjuster for flow rate 5.1 Balancing diaphragm 15 Screws 6 Diaphragm stem 16 Diaphragm plate 1.2 Lock nut 7 Plug stem 17 Nut...

-

Page 18: Additional Fittings

The minimum required plant differential pressure Δp = Δp ∆p across the valve is calculated as follows: restriction ∆p Minimum differential pressure across the valve in bar ∆p Differential pressure created at the restriction for restriction measuring the flow rate in the regulator · Adjusted flow rate in m³/h Valve flow coefficient in m³/h Fig. 3-3: Installation example: Type 42-36 installed in the flow and return flow pipe EB 3015 EN... -

Page 19: Technical Data

1) − Set points from 0.05 to 520 m³/h Note − Valve size DN 15 to 250 The Type 42-36 Regulator is not a safety − Pressure ratings from PN 16 to 40 valve. If necessary, a suitable overpressure The regulator is open when relieved of protection must be installed on site in the pressure. - Page 20 Design and principle of operation Temperature range Noise emissions Depending on how the regulator is config- SAMSON is unable to make general state- ured, it can be used up to temperatures of ments about noise emissions. The noise emis- 220 °C (see Table 3-1). The minimum tem- sions depend on the regulator version, plant...

- Page 21 Design and principle of operation Table 3-2: K coefficients, x values, flow rate set point ranges for water and max. permissible differential pressures Δp Type 2423 Valve balanced by a bellows Valve size DN Valve travel 10 mm 16 mm 22 mm coefficient value 0.65 0.55 0.45 0.35 Flow rate set point ranges for water in m³/h 0.05 to 0.15 to 0.25 to 0.4 to 0.6 to...

- Page 22 Design and principle of operation Table 3-3: Materials · Material numbers according to DIN EN Type 2423 Valve · Balanced by a bellows Pressure rating PN 16 PN 25 PN 16, 25 and 40 Spheroidal graphite Forged stainless Cast iron EN- Cast steel Cast stainless Valve body iron steel 1.4571 GJL-250 1.0619 steel 1.4408 EN-GJS-400-18-LT Seat 1.4104, 1.4006...

- Page 23 Design and principle of operation Table 3-4: Dimensions in mm and weights · Type 2423 Valve balanced by a bellows Valve size Length L Height H1 1.4571 – – – Height H2 Other materials Height H (ØD = 285 mm, Actuator (ØD = 225 mm, A = 160 cm²) 2) A = 320 cm²) 3) Weight for PN 16 in kg 12.5 13.5 20.5...

- Page 24 Design and principle of operation Dimensional drawings Type 2423 Valve balanced by a bellows Type 2423 Valve balanced by a diaphragm Ø D V-ring packing For the version with a V-ring packing (e.g. for steam) in DN 15 to 100, add 60 mm to the specified dimension for H2. Fig. 3-4: Dimensions 3-10 EB 3015 EN...

-

Page 25: Shipment And On-Site Transport

2. Check the shipment for transportation They prevent foreign particles from enter- damage. Report any damage to ing the valve. SAMSON and the forwarding agent Î Dispose and recycle the packaging in ac- (refer to delivery note). cordance with the local regulations. 3. Determine the weight and dimensions of... -

Page 26: Transporting And Lifting The Regulator

Shipment and on-site transport 4.3 Transporting and lifting the WARNING regulator Risk of personal injury due to the regulator tipping. Î Observe the regulator's center of gravity. DANGER Î Secure the regulator against tipping over Risk due to suspended loads falling. or turning. -

Page 27: Lifting The Regulator

Shipment and on-site transport 4.3.2 Lifting the regulator 2. Carefully lift the regulator. Check wheth- er the lifting equipment and accessories To install a large regulator into the pipeline, can bear the weight. use lifting equipment (e.g. crane or forklift) 3. -

Page 28: Storing The Regulator

Î To keep elastomers in shape and to pre- Î Avoid long storage times. vent cracking, do not bend them or hang Î Contact SAMSON in case of different them up. storage conditions or long storage peri- Î Store elastomers away from lubricants, ods. -

Page 29: Installation And Assembly

Con- the body. tact SAMSON if the lengths are significantly shorter than the recommended lengths. Î Contact SAMSON if the mounting posi- tion is not as specified above. To ensure that the regulator functions proper- ly, proceed as follows: NOTICE Î... - Page 30 If the regulator tends to hunt, we recommend pipeline must be supported or suspended. installing a needle valve in the control line in addition to the standard SAMSON screw NOTICE joint with restriction. Do not attach supports directly to the valve or actuator.

-

Page 31: Preparation For Installation

Installation and assembly 5.2 Preparation for installation Î For steam applications, dry the pipelines. Moisture will damage the inside of the The valve and actuator of regulators that regulator. have not yet been assembled or have been Î Check any mounted pressure gauges to tested beforehand can be assembled before make sure they function properly. - Page 32 Type 42-36 installed in the return flow pipe Type 42-36 installed in the flow pipe (T >150 °C): (T <150 °C): Type 42-36 installed in the return Type 42-36 installed in the flow flow pipe (T <150 °C) pipe (T >150 °C) Shut-off valve Pressure gauge Needle valve (return flow pipe) Strainer 18 Compensation chamber (optional) Shut-off valve Pressure gauge (flow pipe) Motorized valve Flow regulator Fig. 5-2: Installation example: Type 42-36 installed in the flow and return flow pipe EB 3015 EN...

-

Page 33: Installation

Risk of regulator damage due to the use of of flow. unsuitable tools. 4. Make sure that the correct flange gaskets Î Only use tools approved by SAMSON are used. (see 'Tools' in Annex). 5. Bolt the pipe to the valve free of stress. Î Additional activities required for indi-... -

Page 34: Cleaning The Pipeline

Installation and assembly 5.4 Checking the regulator 7. Mount the control line. − Mount the control line onto the valve and actuator. Observe the specified tighten- DANGER ing torques (see 'Tightening torques' in Risk of bursting due to incorrect opening of Annex). pressurized equipment or components. −... -

Page 35: Leak Test

Î Wear protective clothing and safety tion. gloves. SAMSON regulators are delivered ready for SAMSON's After-sales Service can support use. To test the regulator functioning before you to plan and perform a leak test for your start-up or putting back the regulator into plant. -

Page 36: Pressure Test

Note filling the plant and carefully rinsing it. The The plant operator is responsible for regulator must not yet be insulated at this performing the pressure test. SAMSON's stage. After-sales Service can support you to plan 1. Start up the plant and adjust the set point and perform a pressure test for your plant. -

Page 37: Start-Up

Start-up 6 Start-up DANGER The work described in this section is only to Risk of personal injury due to process be performed by personnel qualified for the medium escaping under pressure. assignment accordingly. Î First start up the regulator after mounting all parts. WARNING Before start-up or putting the valve back into Risk of burn injuries due to hot or cold com- service, make sure the following conditions ponents and pipeline. -

Page 38: Starting Up The Plant

Start-up Before starting up the plant, make sure the Î For liquid medium temperatures above following conditions are met: 150 °C, first fill the compensation cham- ber with the process medium. Proceed as − The control line is open (needle valve) follows: and correctly connected. 1. Unscrew filler plug from the compensa- 6.2 Starting up the plant tion chamber. 2. -

Page 39: Operation

Operation 7 Operation 7.1 Adjusting the set point Immediately after completing start-up or Î The control and shut-off valves as well as placing the regulator back into service (see all consumers or a bypass valve (if in- the 'Start-up' section), the regulator is ready stalled) must be open to ensure that the for use. -

Page 40: Adjusting The Flow Rate

Operation 7.2 Adjusting the flow rate 5. Check the flow rate at the heat meter and correct it, if necessary. 1. Unscrew the cap (1.3). 6. Lock the restriction screw in place with 2. Undo lock nut (1.2). Turn restriction the nut (1.2) and screw the cap (1.3) screw clockwise as far as it will go. back on after the required flow rate is 3. - Page 41 Operation V ˚ V ˚ /h ] /h ] ³ ³ DN50 DN25 DN20 DN40 DN25 DN50 DN15 DN40 DN20 DN32 DN15 DN32 Turns of the set point adjuster (restriction) = 0.5 bar · ____ ∆p – – – – ∆p = 0.2 bar restriction restriction V ˚...

- Page 42 Operation V ˚ V ˚ /h ] ³ /h ] ³ DN125 DN100 12 14 16 18 Turns of the set point adjuster (restriction) = 0.5 bar · ____ ∆p – – – – ∆p = 0.2 bar restriction restriction V ˚ /h ] V ˚ ³...

- Page 43 Operation V ˚ ˚ V [ m³/h ] [ m³/h ] DN 150 DN 250 DN 200 DN 125 0 2 4 6 8 10 12 14 16 18 0 2 4 6 8 10 12 14 16 18 20 Turns of the set point adjuster (restriction) DN 125, DN 150 · A = 320 cm² · ∆p = 0.2 bar,...

- Page 44 Operation EB 3015 EN...

-

Page 45: Malfunctions

Î Remove foreign particles. Foreign particles blocking the plug Î Replace damaged parts. Î Contact SAMSON's After-sales Service. Î Replace the damaged seat and plug. Flow rate exceeds Seat and plug are worn or leak. adjusted set point. - Page 46 Î Contact SAMSON's After-sales Service. Î Check the sizing. Loud noises High flow velocity, cavitation Î Install larger regulator, if necessary. Leakage at the Defective operating diaphragm Î Replace damaged diaphragm. actuator Note Contact SAMSON's After-sales Service for malfunctions not listed in the table. EB 3015 EN...

-

Page 47: Emergency Action

3. Rectify those malfunctions that can be remedied based on the instructions SAMSON's After-sales Service can support provided here. Contact SAMSON's you in drawing up an inspection and test After-sales Service in all other cases. - Page 48 EB 3015 EN...

-

Page 49: Servicing

Risk of regulator damage due to the use of become very hot or cold. Risk of burn inju- unsuitable tools. ries. Î Only use tools approved by SAMSON Î Allow components and pipelines to cool (see 'Tools' in Annex). down or heat up. - Page 50 Servicing Note The regulator was checked by SAMSON before it left the factory. − Certain test results certified by SAMSON lose their validity when the regulator is opened. Such testing includes seat leakage and leak tests. − The product warranty becomes void if...

- Page 51 Servicing Type 2423 Valve balanced by a bellows Type 2426 Actuator Fig. 9-1: Functional diagram for regulators, DN 15 to 250 with balancing bellows EB 3015 EN...

- Page 52 Servicing Type 2423 Valve balanced by a diaphragm Type 2426 Actuator Fig. 9-2: Functional diagram for regulators, DN 65 to 250 with balancing diaphragm EB 3015 EN...

-

Page 53: Preparing The Valve For Service Work

Servicing 9.1 Preparing the valve for 9.2 Installing the regulator service work after service work 1. Lay out the necessary material and tools Î Put the regulator back into operation (see to have them ready for the service work. the 'Start-up' section). Make sure the re- quirements and conditions for start-up or 2. -

Page 54: Service Work

Servicing 9.3 Service work 9.3.1 Replacing the actuator Î Before performing any service work, Î See Fig. 9-2 and Fig. 9-1 preparations must be made to the regu- Removing the actuator lator (see section 9.1). 1. Put the regulator out of operation (see Î After all service work is completed, check the 'Decommissioning' section). the regulator before start-up (see the 2. -

Page 55: Replacing The Seat And Plug

Do not exchange the operating diaphragm Further information is available in Annex in an FDA-compliant regulator version. ('After-sales service'). SAMSON's After-sales Service can support you to perform such service work. The associated order number is written on the actual operating diaphragm. -

Page 56: Ordering Spare Parts And Operating Supplies

1. Place a new operating diaphragm (12) onto the diaphragm plate (16) (ensuring Contact your nearest SAMSON subsidiary the pressurized side is facing in the cor- or SAMSON's After-sales Service for infor- rect direction) and tighten the diaphragm mation on spare parts, lubricants and tools. plate nut (17). Observe the specified tightening torques (see 'Tightening Spare parts torques' in Annex). -

Page 57: Decommissioning

Decommissioning 10 Decommissioning WARNING The work described in this section is only to Risk of personal injury due to pressurized be performed by personnel qualified for the components and process medium escaping assignment accordingly. under pressure. Î Do not loosen the control line while the valve is pressurized. DANGER Risk of bursting due to incorrect opening of pressurized equipment or components. - Page 58 Decommissioning To decommission the regulator for service WARNING WARNING work or disassembly, proceed as follows: Risk of personal injury due to residual 1. Close the shut-off valve (1) on the up- process medium in the regulator. stream side of the regulator. While working on the regulator, residual 2.

-

Page 59: Removal

Removal 11 Removal 11.1 Removing the regulator from the pipeline The work described in this section is only to be performed by personnel qualified for the 1. Support the regulator to hold it in place assignment accordingly. when separated from the pipeline (see the 'Shipment and on-site transport' WARNING section). - Page 60 11-2 EB 3015 EN...

-

Page 61: Repairs

Î Do not perform any repair work on your send you a return merchandise authori- own. zation (RMA). Î Contact SAMSON's After-sales Service 6. Attach the RMA (together with the for repair work. Declaration on Decontamination) to the outside of your shipment so that the 12.1 Returning devices to... - Page 62 12-2 EB 3015 EN...

-

Page 63: Disposal

Disposal 13 Disposal Î Observe local, national and internation- al refuse regulations. Î Do not dispose of components, lubricants and hazardous substances together with your household waste. EB 3015 EN 13-1... - Page 64 13-2 EB 3015 EN...

-

Page 65: Certificates

Certificates 14 Certificates The EU declarations of conformity are in- cluded on the next pages: − EU declaration of conformity in compli- ance with Pressure Equipment Directive 2014/68/EU on page 14-2. EB 3015 EN 14-1... - Page 66 Modul H/Module H, Nr./No. / N° CE-0062-PED-H-SAM 001-16-DEU-rev-A SAMSON erklärt in alleiniger Verantwortung für folgende Produkte:/For the following products, SAMSON hereby declares under its sole responsibility: Ventile für Druck-, Differenzdruck-, Temperatur- und Volumenstromregler/Valves for pressure, temperature, flowregulators and differential pressure regulators Typ 2336, 2373, 2375, 44-1B, 44-2, 44-3, 44-4, 44-6B, 44-9, 45-1, 45-2, 45-3, 45-4, 45-6, (Erz.-Nr.

- Page 67 Modul H/Module H, Nr./No. / N° CE-0062-PED-H-SAM 001-16-DEU-rev-A SAMSON erklärt in alleiniger Verantwortung für folgende Produkte:/For the following products, SAMSON hereby declares under its sole responsibility: Ventile für Druck- Differenzdruck-, Volumenstrom- und Temperaturregler/Valves for pressure, differential pressure, volume flow and temperature regulators 2333 (Erz.-Nr./Model No.

- Page 68 14-4 EB 3015 EN...

-

Page 69: Annex

Nuts and bolts (15) – 40 to 640 cm² Control line connection (17) – 40 to 640 cm² 15.2 Lubricant SAMSON's After-sales Service can support you concerning lubricants and sealants ap- proved by SAMSON. 15.3 Tools SAMSON's After-sales Service can support you concerning tools approved by SAMSON. -

Page 70: Spare Parts

Annex 15.5 Spare parts Legend for Fig. 15-1 and Fig. 15-2 Bellows 34 Flange Restriction 35 Screw plug 12 Screw 46 Graphite seal on metal core 16 Seat 51 Stud 17 Plug 52 Hex nut 20 Body 81 Cap 21 Guide cap 82 Hex nut 22 Label 132 O-ring 24 Compression spring 171 Clamping ring 26 Guide tube 172 Seal... - Page 71 Annex Fig. 15-2: T ype 2423 Valve, DN 125 to 250 · Balanced by a bellows EB 3015 EN 15-3...

- Page 72 Annex Legend for Fig. 15-3 Restriction 22 Label Compression spring 27 Diaphragm case 10 Diaphragm plate 34 Ring 11 Diaphragm 46 Seal 12 Castle nut 51 Stud 13 Washer 52 Hex nut 14 Plug stem 53 Screw plug 16 Seat 81 Nut 18 Plug 82 Hex nut 19 Screw 94 Stem 20 Body...

- Page 73 Annex Legend for Fig. 15-4 Restriction 42 Clamping disk Seat 46 Seal Diaphragm case 47 Diaphragm 11 Cap 49 Screw plug 12 Body 50 Screw plug 17 Label 51 Stud 19 Plug 52 Hex nut 21 Nipple 53 Hex nut 24 Nut 54 Hex nut 38 Diaphragm plate 57 O-ring 39 Diaphragm plate...

- Page 74 Annex Legend for Fig. 15-5 15 Diaphragm Diaphragm case 17 Hex bolt Diaphragm case 19 Hex nut Screw joint with restriction 23 Hanger Diaphragm stem 26 Compression spring 27 Compression spring 13 Diaphragm plate 14 Washer Fig. 15-5: T ype 2426 Diaphragm Actuator, DN 15 to 250 15-6 EB 3015 EN...

-

Page 75: After-Sales Service

E-mail address You can reach our after-sales service at aftersalesservice@samsongroup.com. Addresses of SAMSON AG and its subsid- iaries The addresses of SAMSON, its subsidiaries, representatives and service facilities worldwide can be found on our website (u www.samsongroup.com) or in all SAMSON product catalogs. Required specifications Please submit the following details: −... - Page 76 15-8 EB 3015 EN...

- Page 80 EB 3015 EN SAMSON AKTIENGESELLSCHAFT Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany Phone: +49 69 4009-0 · Fax: +49 69 4009-1507 samson@samson.de · www.samson.de...

Need help?

Do you have a question about the 42-36 and is the answer not in the manual?

Questions and answers