Graco A Series Instructions - Parts Manual

Automatic plural component, impingement mix spray gun for use with non-flammable foam and polyurea, not for use in explosive atmospheres

Hide thumbs

Also See for A Series:

- Instructions - parts manual (52 pages) ,

- Instructions-parts list manual (48 pages) ,

- Manual (36 pages)

Table of Contents

Advertisement

Quick Links

Instructions - Parts

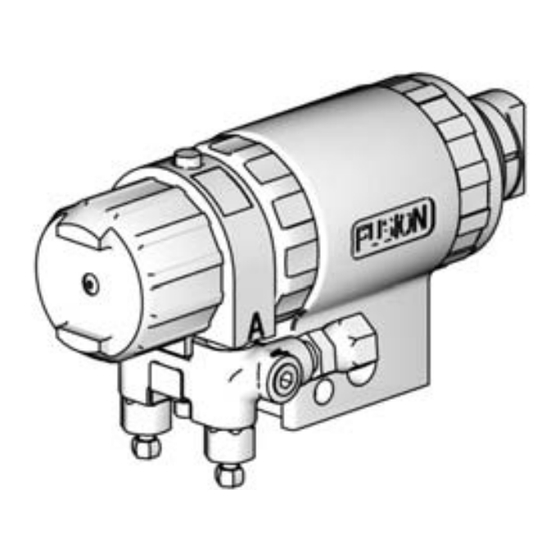

Automatic Plural Component, Impingement

Mix Spray Gun

For use with non-flammable foam and polyurea.

Not for use in explosive atmospheres.

3500 psi (24.2 MPa, 242 bar) Maximum Fluid Working Pressure

80-130 psi (0.55-0.9 MPa, 5.5-9.1 bar) Air Inlet Pressure Range

200°F (94°C) Maximum Fluid Temperature

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Air Purge Gun

For model information and related manuals, see page 3.

Mechanical Purge Gun

For model information and related manuals, see page 4.

US Patent No. D479,305

Korean Patent No. 338185

Australian Patent No. 152610

ROC Patent No. I288661

Chinese Patent No. ZL200380101833

Japanese Patent No. 4331721

310649C

EN

TI4524b

TI4525b

Advertisement

Table of Contents

Need help?

Do you have a question about the A Series and is the answer not in the manual?

Questions and answers