Table of Contents

Advertisement

ASSEMBLY ISTRUCTIONS

SPARE PARTS MANUAL

DATE ____________ APPROVED ____________

VIMEC reserves the right to make modifications and changes to its products at any time in response to technological deve-

STAIRLIFT

V 64 - 74

MODEL

B.I. - INDEPENDENT BARS

B.R. - RETRACTILE BARS

MANUAL CODE

7 5 1 2 1 1 6

15 - 11 - 2007

lopments.

Via Parri, 7 (I) - 42045 Luzzara (RE)

Tel.0522/970666 r.a.- Fax.0522/970919

Page 03 - 14

Page 15 - 25

Page 26 - 52

Advertisement

Table of Contents

Summary of Contents for vimec V64-74 B.I.

- Page 1 Page 26 - 52 MANUAL CODE 7 5 1 2 1 1 6 DATE ____________ APPROVED ____________ 15 - 11 - 2007 VIMEC reserves the right to make modifications and changes to its products at any time in response to technological deve- lopments.

- Page 2 VIMEC DECLARATION OF CONFORMITY S.R.L. "EC" DECLARATION OF CONFORMITY The manufacturer: servoscale Via Parri N°7,42045 Luzzara (RE) ITALIA Tel.0522/970666 r.a. Fax 0522/970919 states on his own responsibility that the platformlift for the transport of person on wheelchair type: V 64/74 - B.I. - B.R.

- Page 3 7502116 USE AND MAINTENANCE CONTENTS OF THE MANUAL 1. Stairlift and manufacturer identification data Page 04 2. After-sales service Page 04 3. Description of the stairlift Page 05 4. Technical specifications Page 07 5. Intended and improper uses of the lift Page 08 6.

- Page 4 7502116 1) STAIRLIFT AND MANUFACTURER IDENTIFICATION DATA I - 42045 LUZZARA (RE) Via Parri N° 7 - Tel. 0522 / 970666 TYPE SERIAL Nr. (Nr) - - - - YEAR - - - - LOAD (Kg) - - - POWER (V / A / Hz) 230 / 5 / 50 LOAD...

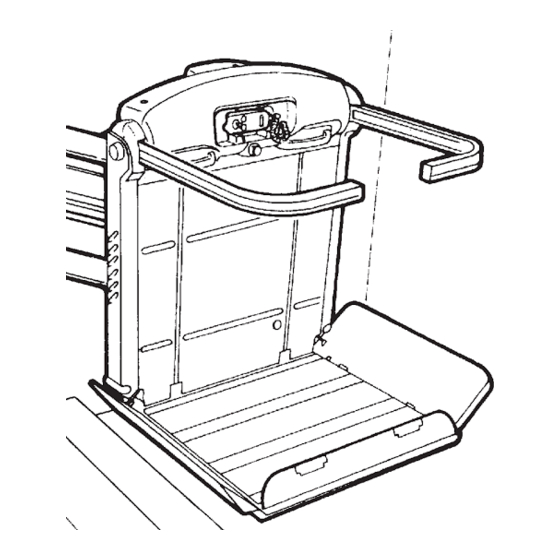

- Page 5 7502116 3) DESCRIPTION OF THE STAIRLIFT FIG.2 3.1) Description Lift unit - Fig. 1 Comprises: - carriage. - load-bearing structure. - safety bars - Fig. 1/a. - load platform - Fig. 1/c. - bodywork - Fig. 1/b. - control board - Fig. 1/d. Contains: - motor - Fig.

- Page 6 - Carriage - Fig. 6 Fig. 7/b. - Lift structure. - Platform - Fig. 7/c. - Bodywork - Fig. 7/d. - Handwheel for manual operation - Fig. 7/e. The system must be installed by specialist operators authorised by VIMEC. FIG.7...

- Page 7 7502116 3.6) Reference technical norms EN 60204-1 Safety of machinery The stairlift complies with the following norms: Electrical equipment of machinery Part. 1: General rules 98/37 EEC 98/79 EEC EN 50081-1 Electromagnetic compatibility General standard on emission. Machinery Directive and subsequent amendments Residential, commercial and light industrial environ- ments.

- Page 8 7502116 5) INTENDED AND IMPROPER USES OF THE STAIRLIFT 5.1) Intended use The Mod. V64/74 stairlift is a system for transporting persons SEATED ON A WHEELCHAIR OR ON A SPECIAL SEAT (optional) with STRAIGHT rail at CONSTANT gradient which can be installed on stairs having the following characteristics: - Ambient: Indoor and outdoor...

- Page 9 7502116 1) For stairlifts with motor-operated platform (optional) 6.2) Electrical connection - insert the key and turn it to ON using the control board The power supply lead is of 4x1 mm2 type (number of on the lift or at the floor (optional) - Fig. 9/a). wires x gauge).

- Page 10 7502116 FIG.11 stops; if the up button is kept pressed, the bars and the guard facing in the up direction automatically move to the drive-off position. The guard facing in the down direction is locked in the safety position, to ensure the wheelchair can leave and return to the lift in safety.

- Page 11 7502116 FIG.13 CAUTION: In the B.R. - B.I. Version, the platform can only be operated with the down side bar in the working position. N.B.: If the platform fold button is accidentally pressed when someone is on the lift, a motor overload cut-out is tripped, stopping the electromechanical actuator.

- Page 12 CAUTION: In case of a system failure or trip- ping of the safety gear, call in an authorised VIMEC technician. In case of any kind of malfunction, put the lift out of use by turning the master switch to OFF.

- Page 13 8.3) Other safety devices CAUTION: In all cases, call in only staff au- a) Electrical and mechanical limit stops thorised by VIMEC for servicing and repairs; use The electrical limit switches (Fig. 18/a) fitted to the lift only original spare parts.

- Page 14 No power supply Check the power supply; see point 7.5 (operating by hand). A safety device has been tripped Call in an authorised VIMEC technician The stairlift moves downward Safety gear tripped Call in an authorised VIMEC technician more quickly then cuts out...

- Page 15 7602116 ASSEMBLY INSTRUCTIONS CONTENTS OF THE MANUAL 1. System supply condition Page 16 2. Positioning the rail Page 17 3. Assembling the carriage Page 19 4. Complete actuator assembly Page 19 5. Assembling the bodywork Page 19 6. Assembling the platform with motorized access frontal Page 21 7.

- Page 16 7602116 FIG.1 1) SYSTEM SUPPLY CONDITION The stairlift is supplied subdivided into the following components: Lift structure (Fig. 1/a) Complete with gear motor, safety bars, drive compo- nents and electrical system. Carrier platform (Fig. 1/b) Complete with guard boards and sensor base with safety microswitches.

- Page 17 7602116 FIG.5 2) INSTALLING THE RAIL ONLY FOR STOCK GUIDE: - Following the dimensions shown on the assem- bly drawing (see example in Fig. 5) specific to each installation, place the rail in position of the guide connections using the screws M8 x 25 (Fig. 5/a) (driving torque: 1,6 ÷...

- Page 18 7602116 ONLY FOR STOCK GUIDE: - Holding to the specific dimensions (Fig. 9) for each equipment, proceed to the drilling of the chain holder profile (aluminium bonnet - Fig. 10). - Assemble the terminal mesh (Fig. 11/a) to the cable carriage chain (Fig. 11/b) and fix it to the support. The cable (Fig.

- Page 19 7602116 FIG.12 ONLY FOR STOCK GUIDE: - Pass the power supply cable inside the spiral tube and fix with the proper fairlead to the lid by the top side of the guide (after having removed the feather of the down side of the lid) (Fig.9/e). - Drill with Ø...

- Page 20 7602116 - Fix the down limit stop plate (SQ16 or SQ12) (Fig. 12/g). FIG.17 - Fix the up limit stop plate (SQ16 or SQ12) and the up overlimits microswitch (SQ4) (Fig. 12/h). - Connect the safety gear microswitch connector (SQ2) -Fig.

- Page 21 7602116 FIG.21 6) ASSEMBLING THE PLATFORM WITH MOTORI- ZED ACCESS FRONTAL (B.I. - B.R.) On customer request it is possible to have a footboard with overturning front side (Fig. 20/a). Such a footboard permits, on the lower floor only, to access/go down perpendicularly to the machine.

- Page 22 7602116 f) Connect the lateral guard board operating cables (Fig. B.R.: fix the cable (Fig. 24/f) already present on the 24/f) and frontal (Fig. 24/e) to the fork (Fig. 24/b). side bar chute with special screws. - Tighten with nut and screw. - Fix the cable eye (Fig.

- Page 23 7602116 i) Tighten with a driving torque of 4 daN ± 0,1the dowel, the 7) ASSEMBLING THE PLATFORM nut and the locknut (Fig. 29/d,e,f). a) Remove the top plate from the platform by undoing the relative screws. l) Plug in the connectors J1A, J1B, J1C, J1D (Fig. 29 bis). FIG.27 b) Make sure that the two platform supports, fixed by a wedge and a plastic clamp, are in the assembly position...

- Page 24 7602116 FIG.30 8) CONNECTING THE ELECTRICAL SYSTEM Two wires lead out from the top end of the extruded aluminium raceway on the rail (Fig. 31/a) - blue wire 4x1, power supply Connect these wires as follows: - Connect the 4x1 blue wire (Fig. 31/a) to the power supply mains using the circuit breaker installed previou- sly by the customer (fairlead + sheath).

- Page 25 7602116 FIG.33 11) FINAL TESTING Supply power to the system and perform the fol- SN CARRIAGE CONFIGURATION lowing functional checks: FRONT VIEW - Load test: - Load the lift with 1.1 times the rated load stated on the nameplate. - Send the lift up and down several times, checking its stability on the rail.

- Page 26 7201116 CATALOGO RICAMBI - PARTS CATALOGUE ERSATZTEILKATALOG - CATÁLOGO DE REPUESTOS CATALOGUE DES PIECES DE RECHANGE INDICE DEL CATALOGO CATALOGUE INDEX - INHALTSVERZEICHNIS ÍNDICE DEL CATÁLOGO - INDEX 6. Protezioni Pag. 43 N° 7801230 1. Carrello Pag. 27 N° 7801225 Carriage Guards Schutzeinrichtungen...

- Page 30 TELAIO 7801226...

- Page 43 SOLO PER MOD. V64 SOLO PER MOD. V74 PROTEZIONI 7801230...

- Page 47 PANNELLO ELETTRICO B.I. 7801232...

- Page 49 ABBINAMENTI: CONNETTORI 7801246...

- Page 51 BARRE RETRATTILI BARRE INDIPENDENTI CAVI AZIONAMENTO PEDANA/BANDELLA 7804457...

Need help?

Do you have a question about the V64-74 B.I. and is the answer not in the manual?

Questions and answers