Summary of Contents for Eaton 70122

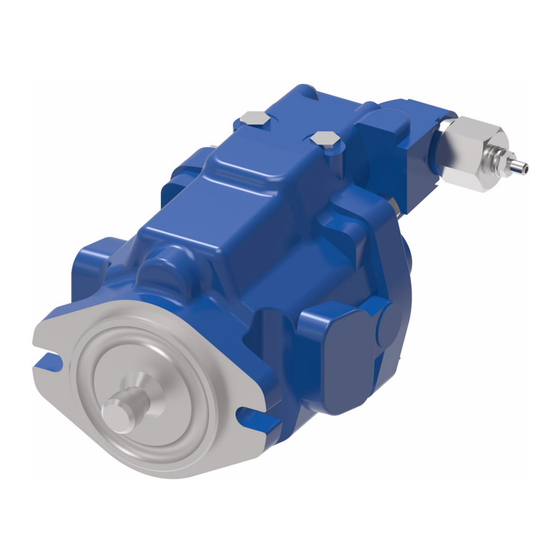

- Page 1 Eaton ® January 1998 Medium Duty Piston Pump Parts and Repair Information Model 70122, 0 -19 cm /r [0-1.16 in /r] Displacement Pressure or Pressure-Flow Compensated Piston Pumps...

-

Page 2: Table Of Contents

Fault-Logic Troubleshooting ................17 - 19 Introduction This manual provides service information for the Eaton Models 70122 Pressure or Pressure - Flow Compensated Piston Pumps. Step by step instructions for the complete disassembly, inspection, and reassembly of the pump are given. The following recommendations should be followed to insure successful repairs. -

Page 3: Identification

Pressure or Pressure-Flow Compensated Piston Pump Stamped on each units mounting flange. Single Pump - Product Number: A - Product Number Description 70122 = Single Piston Pump 7 0 1 2 2 - R A A B - Rotation L - Lefthand (CCW) -

Page 4: Parts Drawing

Model 70122 Parts Drawing Pump drawn below is typical of a righthand rotation pump. 22 23 Serial code and assembly number location Cover only) All left (CCW) or right (CW) directions given are viewed from the input shaft end of the pump. -

Page 5: Parts List

Model 70122 Parts List Item Part No. Qty. Description ♦ Drive Shaft (Identification drawing on page #6) ♦ Backplate Assembly (Identification drawing on page #7) 70102-301 Housing Assembly, .5625-18 - SAE Straight Thread O-ring Port - Right side of housing... -

Page 6: Item 1 - Drive Shaft Id

Model 70122 Item 1 - Drive Shaft Identification Item 1 Drive Shaft Identification Part Number Input Drive 70122-203, 22.2 [.875] Dia. keyed 70102-200, 13 Tooth 70122-200, 19.05 [.75] Dia. keyed 70102-201, 13 Tooth w/ Retaining Ring Groove... -

Page 7: Item 2 - Backplate Assembly

Model 70122 Item 2 - Backplate Assembly 2-2-1 (Loctited) 2(a) 2(b) Item 2 - Parts List Lefthand Righthand Rotation Rotation Item Part No. Part No. Qty. Description 2(a) 70120-311 70120-309 Rear Porting Backplate Assembly 2(b) 70120-314 70120-318 Opposite Side Porting Backplate Assembly... -

Page 8: Item 4 - Compensator Assembly And Parts List

Model 70122 Item 4 - Compensator Assembly Pressure-Flow Compensator Pressure Compensator *4-11 *4-11 *4-11 Cover Cover Cover non-set non-set non-set 4(a) 4(b) 4(c) 70422-HU 70422-HY 70422-HR Lefthand (CCW) Pump Rotation Righthand (CW) Pump Rotation Fits Both Pump Rotations (Righthand (CW) rotation shown) *4-11, Cover not included with non-set compensator assy. - Page 9 Model 70122 Item 4 - Compensator Parts List Item 4 - Parts List (Refer to drawings) Item Part No. Qty. Description 4(a) 70422-HU Non-Set Pressure-Flow Compensator Assembly, Lefthand Rotation 4(b) 70422-HY Non-Set Pressure-Flow Compensator Assembly, Righthand Rotation 4(c) 70422-HR Non-Set Pressure Compensator Assembly...

-

Page 10: Factory Pre-Set Compensator Assemblies

Model 70122 Factory Pre-set Compensator Assemblies Pre-set Pressure-Flow Compensator Assemblies Non-Set Pre-set Assembly Assembly Pump Rotation Pressure Setting Flow Setting 70422-HU 70422-AY-03 Lefthand (CCW) 210±3.5 bar [3050±50 lbf/in 13.8±0.7 bar [200±10 lbf/in 70422-HU 70422-BH-03 Lefthand (CCW) 191±2.1 bar [2770±30 lbf/in 15.2±0.7 bar [220±10 lbf/in... -

Page 11: Item 5 - Rotating Kit

Model 70122 Item 5 - Rotating Kit Assembly Item 5 Rotating Kit Assembly Item Part No. Qty. Description 70111-695 Rotating Kit Assembly Piston Assembly Spider Spider Pivot Retainer Piston Block Pins Washer Spring Retaining Ring NSS - Not Sold Separately... -

Page 12: Product Number

Model 70122 Product Number This list of product numbers is to aid in Item identification. If your product number is not listed contact your Eaton representitive. Model 70122, Lefthand Rotation (CCW) Description of Part Number Product Drive Shaft Backplate Assy. -

Page 13: Repair Information

Model 70122 Repair Information Cleanliness is extremely important when repairing should not be removed without compressing the these pumps. Work in a clean area. Before spring. disconnecting the lines clean port area of pump. The following parts will be needed to disassemble the... -

Page 14: Inspection

Model 70122 Repair Information may be disassembled for cleaning and inspection. end of the piston. The flat surface of the shoes should be flat, and smooth. Do not lap piston shoes. ATTENTION: Removal of the adjusting screw covers from cap may void the warranty on this assembly. - Page 15 Model 70122 Repair Information 14 Place new o-ring (4-19-1) on plug (4-19). Install and the chamfered l.D. of the race should face plug assembly, flow compensator spool (4-12), inward. spring pivot (4-13), spring (4-14), flow spring 4 Install new 0-ring (26) around O.D. of camplate follower (4-16) with new o-ring (4-15), and flow pivot bearing (25).

-

Page 16: Start-Up Procedure

Model 70122 Start-up Procedure When initially starting a rebuilt load sensing system, 5 Replace the coil wire or return the fuel flow to the it is extremely important that the start-up procedure injectors and start the engine. Run at low idle speed be followed. -

Page 17: Fault-Logic Troubleshooting

Model 70122 Fault - Logic Troubleshooting This fault - logic troubleshooting guide is a Explanatory diagnostic aid in locating pump problems. Diagram Symptom: Match the pump systems with the problem Action statements and follow the action steps shown in the Step box diagrams. - Page 18 Model 70122 Fault - Logic Troubleshooting Symptom: System will not Develop Proper Pressure or Flow Check Check Inspect Inspect Oil Level in Hyd. Fluid Inlet Screen Compensator Reservoir Specs or Strainer Signal Below Level Improper Clogged Fill to Install Clean...

- Page 19 Model 70122 Fault - Logic Troubleshooting Symptom: Pump Noisy or Overheating Check Check Inspect Replace Oil Level in Hyd. Fluid Inlet Screen Pump Reservoir Specs or Strainer Below Level Improper Clogged Fill to Install Clean Proper Proper Level Fluid Replace Diagram Action Step Comments 1.

- Page 20 Model 70122 Each order must include the following information. 1. Product and/or Part Number 2. Serial Number Code 3. Part Name 4. Quantity...

- Page 21 Shanghai 200021 Tel: +41 (0) 21 811 4600 China Tel: 952-937-9800 Tel: 86-21-6387-9988 Fax: 952-294-7722 Fax: +41 (0) 21 811 4601 Fax: 86-21-6335-3912 www.eaton.com/hydraulics © 2008 Eaton Corporation All Rights Reserved Printed in USA Document No. E-PUPI-TP006-E Supersedes 06-615 December 2008...

Need help?

Do you have a question about the 70122 and is the answer not in the manual?

Questions and answers