Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Festo CMSX Series

- Page 1 CMSX-...-C-U-F1-... Positioner Description 8107909 8107909 2019-09d [8107911]...

- Page 2 Translation of the original instructions Festo — CMSX-...-C-U-F1-... — 2019-09d...

-

Page 3: Table Of Contents

Main menu level......................27 9.4.1 Parameter overview - 1 IDENT.................27 9.4.1.1 SW-Ver – Software version..................28 9.4.1.2 ActFct – Actuator function..................28 9.4.1.3 ActTyp − Actuator type....................28 9.4.1.4 SafPos - Safety position of the positioner............... 29 Festo — CMSX-...-C-U-F1-... — 2019-09d... - Page 4 LoadCf - Loading the last saved user-defined configuration........48 9.4.6.3 SafeCf - Saving the user-defined configuration............48 9.4.6.4 BLight - Configuring the backlight of the digital display.......... 48 Schematic view of the mode of action of the parameters..........49 Commissioning positioner..................... 49 Festo — CMSX-...-C-U-F1-... — 2019-09d...

- Page 5 Check sensing range of the path/angle sensor............. 49 Perform initialisation....................50 Complete commissioning..................... 50 Operation........................50 Malfunctions....................... 50 Disassembly........................ 52 12.1 Dismantling CMSX-....................... 52 Disposal........................52 Technical data......................52 Festo — CMSX-...-C-U-F1-... — 2019-09d...

-

Page 6: About This Document

Seal unused openings with blanking plugs. Return to Festo Hazardous substances can endanger the health and safety of personnel and cause damage to the environment. To prevent hazards, the product should only be returned upon explicit request by Festo. – Consult your regional Festo contact. -

Page 7: Service

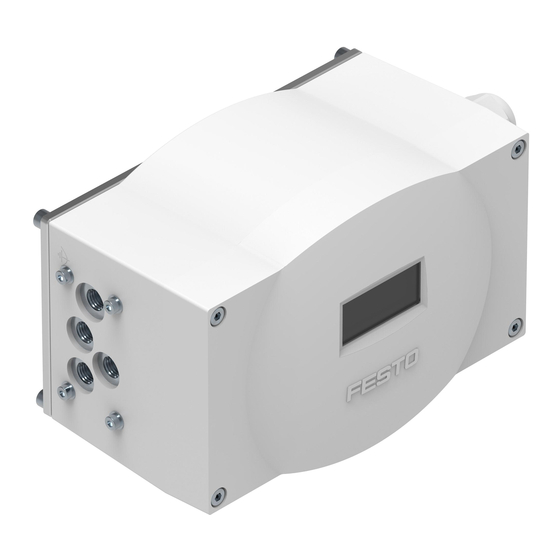

Service Service Contact your regional Festo contact person if you have technical questions è www.festo.com. Product overview Constructive design CMSX-P-S-... 1 Housing cover 7 Shaft 2 Inspection window for LCD display 8 Mechanical coupling 3 Housing screws 9 Base plate 4 Blanking plug... - Page 8 2 Connection of shield of external displace- 6 Set pushbutton ment encoder 7 Sub pushbutton 3 Terminal strip 1 (pin 1 ... 14) 8 Add pushbutton 4 Digital output LEDs 9 Earth terminal Fig. 3 Operating elements and connections Festo — CMSX-...-C-U-F1-... — 2019-09d...

-

Page 9: Function

Position feedback 4 20 mA … Function double-acting single-acting Standard nominal flow rate 50 l/min -130 130 l/min Safety function open or close in case of system failure block in case of system failure Tab. 2 Overview of variants Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 10: Safety Functions

2 and 4 needed with an emer- gency pneumatic sup- ply. CMSX-...-C: CMSX-...-C: regulating Regulating effect block- effect blocking Tab. 4 Overview of safety position (pneumatic initial position) Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 11: Cmsx-P

– Working port (2) is blocked. – Working port (4) is blocked. – Compressed air is trapped in the drive. – The regulating effect is blocking. – The current position of the actuator is blocked. Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 12: Cmsx-P

– Select the mounting position so the underside of the device is protected from spray and moisture. – Note the direction of motion of the actuator. – Use only mounting adapters DARQ-K-P-A1-F05 or DADG-AK-F6-A2 è www.festo.com/sp. Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 13: Mounting Cmsx-P-S

4. Fasten the mounting adapter to the positioner: – 4 housing screws M4 – Tightening torque 1.5 Nm ± 20% 5. Fasten the mechanical coupling to the shaft of the positioner: – 2 threaded pins – Tightening torque 0.5 Nm ± 10% Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 14: Sensing Range Of The Positioner

The angle position of the quarter turn actuator is detected by the shaft of the positioner. The shaft of the positioner can be freely rotated and does not have a mechanical stop. The permissible sensing range is 100° è 14 Technical data. Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 15: Mounting Cmsx-P-Se

– 4 retaining screws M5 – Tightening torque 2.7 Nm ± 10% 5. Secure the positioner with mounting adapter to the housing (flange type socket): – 4 retaining screws M6 – Tightening torque 3 Nm ± 20% Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 16: Installation

For the electric power supply, use only PELV or SELV circuits that guarantee a reliable electric dis- connection from the mains network. • Observe IEC 60204-1/EN 60204-1. • Connect all circuits for operating and load voltage supplies. Festo — CMSX-...-C-U-F1-... — 2019-09d... - Page 17 7. Tighten the union nut on the cable connector. – Tightening torque: 1.5 Nm 8. Place the housing cover in position and tighten the 4 housing screws. – Note the correct position of the seal. – Tightening torque: 1.5 Nm Festo — CMSX-...-C-U-F1-... — 2019-09d...

- Page 18 D-OUT2 Digital output Out 2 +24 V DC Load voltage outputs Supply to digital outputs 0 V DC Terminal strip 2 (pin 15, 16) D-IN+ Digital input + Digital input D-IN– Digital input – Tab. 5 Pin allocation of terminal strips Festo — CMSX-...-C-U-F1-... — 2019-09d...

- Page 19 Switch is located between 24 V DC and digital input. Fig. 11 PNP connection Connection as NPN input: – The NPN input is negative reading. – Switch is located between digital input and 0 V DC. Fig. 12 NPN connection Festo — CMSX-...-C-U-F1-... — 2019-09d...

- Page 20 Connect negative load pole to pin 14. Fig. 13 PNP output Connection of ALARM, D-OUT1, D-OUT-2 as NPN outputs: – The NPN outputs are negative switching. – Connect positive load pole to pin 13. Fig. 14 NPN output Festo — CMSX-...-C-U-F1-... — 2019-09d...

-

Page 21: Commissioning

Commissioning Commissioning Menu structure 1 Base menu 2 Main menu Fig. 15 Menu structure Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 22: Operation And Display

Calling the sensor test (sensor in INIT submenu) – Resetting the parameters to factory settings (FReset in DEVICE submenu) – Save the user-defined configuration (SaveCf in DEVICE submenu) – Loading the last saved user-defined configuration (LoadCf in DEVICE submenu) Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 23: Input Of Numerical Values For Parameters

To make large value changes, hold down the corresponding key (Add or Sub). The values of the control parameters (P, I, D) are entered digit by digit è Fig.17. Fig. 17 Input of numerical values Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 24: Adoption Of Changes

Base menu After the operating voltage supply is switched on, the positioner is at the basic menu level. The basic menu level consists of the following submenus: – Default view – Selection of mode of operation Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 25: Representation Of Operating Modes In The Digital Display

Representation of operating modes in the digital display Default view Mode of operation Description of mode of Digital display operation Automatic mode (pre- The control mode is 1st line: preset setpoint set) executed. position at analogue input (TP = Target posi- tion) Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 26: Display Of System Messages In The Digital Display

2) only if positioner is initialized Tab. 7 9.3.2 Display of system messages in the digital display System messages are displayed as follows in the standard views: Display text Meaning Example ERROR System faults NO INIT Positioner not initialised Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 27: Main Menu Level

Description Reference value range SW-Ver Software version 9.4.1.1 – Software è version – XX.YY.ZZ Identification of the software version ActFct Drive function 9.4.1.2 – Actuator è function – single single-acting drives – double double-acting drives Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 28: Sw-Ver - Software Version

ActTyp − Actuator type This parameter can be used to set the actuator type for double-acting drives. If a single-acting drive is connected, the parameter setting is ignored. Every parameter option is assigned a control type. Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 29: Safpos - Safety Position Of The Positioner

è setpoint – linear linear characteristic curve characteristic curve (factory setting) – 1:25 equal-percentage characteristic curve – 1:33 – 1:50 – 25:1 inverse equal-percentage characteristic curve – 33:1 – 50:1 – userdef user-defined characteristic curve Festo — CMSX-...-C-U-F1-... — 2019-09d... - Page 30 – 55.0 100.0% Factory setting: 98.0% … value SL-Mod Stroke-limitation mode 9.4.2.6 − Stroke- è limitation mode – inactiv Stroke-limitation mode deactivated (factory setting) – bothact Stroke-limitation mode for lower and upper stroke-limitation value active Festo — CMSX-...-C-U-F1-... — 2019-09d...

-

Page 31: Curtyp − Type Of Setpoint Characteristic Curve

This parameter can be used to set the characteristic of the transfer characteristic curve between set- point value and setpoint position. The transfer characteristic curve is used to correct the operating characteristic curve. Value range Description inactiv linear characteristic curve (factory setting) 1:25 equal-percentage characteristic curve 1:33 1:50 Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 32: Curdef - Interpolation Points

The distance between the individual interpolation points is 5%. A setpoint position (setting range 0 to 100%) can be assigned to every interpolation point. The setpoint values of the interpola- tion points can only be selected in ascending order. Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 33: Tc-Mod − Tight-Closing Mode

TC-Mod − Tight-closing mode Tight-closing mode can be activated with this parameter. If the tight-closing mode is active, the valve is moved to the end position with the maximum actuating force of the actuator. The tight-closing mode Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 34: Tc-Low - Lower Tight-Closing Limit Value

Tab. 17 Stroke limitation and tight closing cannot be active simultaneously in one end position. If it is not pos- sible to change the mode, a message appears on the display. Fig. 23 Tight-closing mode Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 35: Tc-Up - Upper Tight-Closing Limit Value

Stroke limitation mode for lower stroke limitation value active Tab. 20 Stroke limitation and tight closing cannot be active simultaneously in one end position. If it is not pos- sible to change the mode, a message appears on the display. Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 36: Low - Lower Stroke Limitation Value

A deadband that is too small results in oscillations around the setpoint position up to permanent oscillations (instability). The process valve, actuator and solenoid valves of the positioner are sub- jected to unnecessary loads. – A deadband that is too large results in low positioning accuracy Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 37: P-Gain - P-Proportion Of The Pid Controller

The higher the value the higher the setpoint specification change in the case of a deviation. – A P-proportion that is too high results in overshoots. – A P-proportion that is too low slows the closed-loop control. Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 38: I-Gain - I-Proportion Of The Pid Controller

A D-proportion that is too high makes the closed-loop control more sluggish. – A D-proportion that is too low makes the closed-loop control more dynamic. Value range Description 0 25000 D-proportion of the PID controller … Tab. 26 Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 39: Parameter Overview - 3 In/Out

DirOut Position feedback direction 9.4.3.6 – Position è feedback direction – rising The position feedback is incremented with increasing actual position (factory setting) – falling The position feedback is incremented with falling actual position Festo — CMSX-...-C-U-F1-... — 2019-09d... - Page 40 Digital output 2 function deactivated (factory setting) – lowlmt Feedback of reaching the lower position limit value (2%). – uplmt Feedback of reaching the lower position limit value (98%). – bothlmt Feedback of reaching the upper (2%) or lower (98%) position limit value. Festo — CMSX-...-C-U-F1-... — 2019-09d...

-

Page 41: Ai-Typ - Type Of Analogue Input

Description inactiv Split range mode deactivated (factory setting) bothact Split-range mode for lower and upper limit active up_act Split range mode for upper limit active low_act Split range mode for lower limit active Tab. 29 Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 42: Sr-Low - Value Of Lower Limit Split Range

Dir-In – Setpoint value direction This parameter can be used to set the operating direction between setpoint value and setpoint posi- tion. The setting is independent of the setpoint characteristic curve (linear, equal percentage, user- defined). Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 43: Dirout - Position Feedback Direction

The setpoint position is incremented with falling setpoint value. Tab. 32 Fig. 27 Setpoint value direction 9.4.3.6 DirOut – Position feedback direction This parameter can be used to set the operating direction between actual value and actual position (position feedback). Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 44: Di-Fct - Digital Input Function

Digital input function deactivated (factory set- ting) stop Pneumatic outputs 2 and 4 are closed. exhaust Exhausting pneumatic output 2 and pressurising pneumatic input 4 pressur Pressurising pneumatic output 2 and exhausting pneumatic input 4 Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 45: Di-Log - Digital Input Logic

High level is output when digital output 1 is activ- ated. Tab. 37 9.4.3.11 DO2Fct – Digital output 2 function This parameter can be used to set the action for which digital output 2 is activated. Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 46: Do1Log - Digital Output 2 Logic

Switching logic active low highact Switching logic active high (factory setting) Tab. 40 9.4.3.14 DO-Mod – Switching mode of digital outputs The switching mode of the digital outputs (D-OUT-1, D-OUT-2, ALARM) can be set with this parameter. Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 47: Parameter Overview - 4 Diag

Tab. 43 INIT menu: commissioning 9.4.5.1 A-Init – Start automatic initialisation The automatic initialisation can be started with this parameter. The following values are determined automatically during the initialisation routine: – maximum possible mechanical stroke range Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 48: Sensor - Check Sensing Range Of The Path/Angle Sensor

Backlight of the digital display switched on in case of system error – always Backlight of the digital display always switched on 1) Recommendation: after successful commissioning, save the user-defined configuration as individual default settings. Tab. 44 Menu DEVICE: device configuration Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 49: Schematic View Of The Mode Of Action Of The Parameters

Ensure there is a stable compressed air supply, particularly during the commissioning phase. 1. Check operating conditions and critical limits è 14 Technical data. 2. Check that the connection points are tight. 3. Switch on the operating voltage supply. 4. Switch on the setpoint specification. Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 50: Check Sensing Range Of The Path/Angle Sensor

Observe the operating conditions. • Observe limit values. After the supply voltage is switched on, the positioner is in the same operating status and the same operating mode that was valid before the supply voltage was switched off. Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 51: Malfunctions

è IN/OUT Manual setpoint position mode Activate automatic mode (ManVent or ManTPos) is active 9.3 Base menu è Setpoint input defective Check setpoint value. Replace device. Device not initialised Perform initialisation 9.8 Perform initialisation. è Festo — CMSX-...-C-U-F1-... — 2019-09d... -

Page 52: Disassembly

7. Unscrew 4 retaining screws (è Fig.7, 3 or è Fig.9, 4) and remove the positioner with the mounting adapter. Disposal ENVIRONMENT! Send the packaging and product for environmentally sound recycling in accordance with the current regulations è www.festo.com/sp. Technical data Type CMSX-...-C-U-F1 General Constructive design digital, electro-pneumatic positioner Mode of operation Festo — CMSX-...-C-U-F1-... — 2019-09d... - Page 53 Standard nominal flow rate CMSX-...-50 [l/min] CMSX-...-130 [l/min] Pneumatic connection Electrics Nominal operating voltage Operating voltage range DC 21.6 26.4 … max. current consumption [mA] Reverse polarity protection for operating voltage connection Connection resistance < 80 Ω Festo — CMSX-...-C-U-F1-... — 2019-09d...

- Page 54 NPN (negative switching) Reverse polarity protection Electrical isolation yes, optocoupler Digital output Supply voltage Switching output 3 x PNP or 3 x NPN switchable max. output current [mA] Reverse polarity protection Short circuit current rating Overload protection Festo — CMSX-...-C-U-F1-... — 2019-09d...

- Page 55 Storage temperature [°C] –20 +60 … Relative humidity 5 95, non-condensing … Degree of protection IP65 Shock resistance in accordance with EN 60068 part 2-29 Vibration resistance in accordance with EN 60068 part 2-6 Pollution degree Festo — CMSX-...-C-U-F1-... — 2019-09d...

- Page 56 PC reinforced Inspection window material Base plate Aluminium Shaft High-alloy stainless steel Coupling High-alloy stainless steel Screws High-alloy stainless steel Seals Cable connector Blanking plug PWIS criterion PWIS-free Information on materials RoHS-compatible Tab. 46 Technical data Festo — CMSX-...-C-U-F1-... — 2019-09d...

- Page 58 Copyright: Festo SE & Co. KG Ruiter Straße 82 73734 Esslingen Germany Reproduction, distribution or sale of this document or communic- Phone: ation of its contents to others without express authorization is +49 711 347-0 prohibited. Offenders will be liable for damages. All rights...

Need help?

Do you have a question about the CMSX Series and is the answer not in the manual?

Questions and answers