Hioki MR6000 Quick Start Manual

Memory hicorder

Hide thumbs

Also See for MR6000:

- Instruction manual (392 pages) ,

- Quick start manual (142 pages) ,

- Instruction manual (291 pages)

Table of Contents

Advertisement

Quick Links

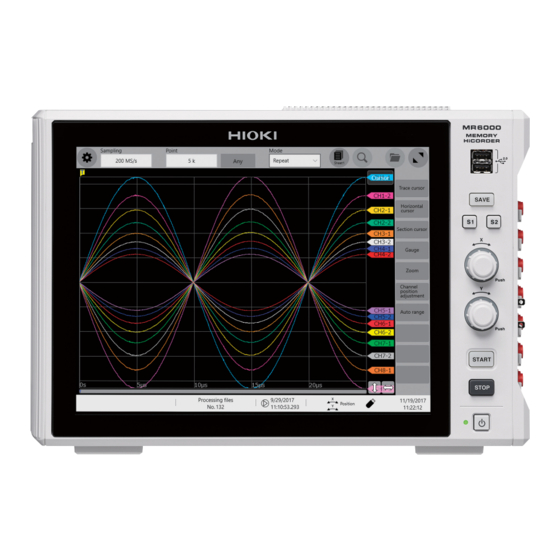

MR6000

MR6000-01

MEMORY HiCORDER

Be sure to read this manual before using the instrument.

When using the instrument for the first

time

Name and Function of Each Part

Basic Operation

Preparing for Measurement

Feb. 2019 Revised edition 1

MR6000A965-01 19-02H

Visit us at www.TestEquipmentDepot.com

Troubleshooting

p. 20

Maintenance and Service

p. 27

Troubleshooting

p. 37

Message

Quick Start Manual

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

p. 6

p. 135

p. 137

p. 140

EN

Advertisement

Table of Contents

Summary of Contents for Hioki MR6000

- Page 1 Quick Start Manual MR6000 99 Washington Street MR6000-01 Melrose, MA 02176 Phone 781-665-1400 Toll Free 1-800-517-8431 Visit us at www.TestEquipmentDepot.com MEMORY HiCORDER Be sure to read this manual before using the instrument. p. 6 When using the instrument for the first...

- Page 2 To set the measurement range automatically Refer to “3.7 Measuring Signals With the Auto-range Setting” (p. 81). To change the measurement range Refer to “Analog channel” (p. 73). To add a comment to the data Refer to “Touch keyboard” (p. 34) and “Analog channel” (p. 73). To minimize influence of noise (Low-pass filter, LPF) Refer to “Analog channel”...

- Page 3 Measurement Procedure The basic measurement procedure is as follows. For advanced use, refer to Instruction Manual (PDF) in the accompanying CD. Preparing for measurement (p. 37) Inspecting the instrument before measurement (p. 69) Configuring the basic settings for measurement (p. 70) Choose a sampling rate.

-

Page 4: Table Of Contents

(For precisely measuring voltage) ....51 Computer (Wave Viewer) ....87 Connection cable ......52 (for measuring high voltage) Specifications Supplying Power to Current Sensors ..........53 Specifications of Model MR6000 ..89 External Sampling (EXT.SMPL) ..54 .......89 General specifications Connecting the External Control Trigger ............93 Terminals ..........55 Waveform screen ........95... - Page 5 Contents Index Others ............103 Specifications of the Options ....105 ....105 Model Z5021 Probe Power Unit Model U8332 SSD Unit ......105 Warranty Model U8333 HD Unit ......106 ......106 Model 8966 Analog Unit ......108 Model 8967 Temp Unit ....110 Model 8968 High Resolution Unit Model U8969 Strain Unit ......112 Model 8970 Freq Unit...

-

Page 6: Introduction

Thank you for choosing the Hioki MR6000, MR6000-01 Memory HiCorder. Preserve this manual carefully and keep it handy to make full use of this instrument for a long time. Model MR6000-01 Memory HiCorder is an upper model of Model MR6000, which is equipped with the following calculation functions (options): •... -

Page 7: Notations

Notations Notations Safety notations In this document, the risk seriousness and the hazard levels are classified as follows. Indicates an imminently hazardous situation that will result in death or serious DANGER injury to the operator. Indicates a potentially hazardous situation that may result in death or serious WARNING injury to the operator. - Page 8 Notations Others Additional information is presented below. Indicates the initial setting values of the items. Initializing the instrument restores settings to each of these values. (p. ) Indicates the location of reference information. START Names and keys on the screen are indicated in boldface. (Bold-faced) Menus, dialog boxes, buttons in a dialog box, and other names on the screen are indicated in brackets.

-

Page 9: Confirming Package Contents

Carefully check the accessories, panel keys and switches, and connectors. If the instrument seems to have been damaged or does not work as specified, contact your authorized Hioki distributor or reseller. Check that the package contents are correct. -

Page 10: Options (Sold Separately)

Confirming Package Contents Options (sold separately) Options available only at the time of purchase For voltage measurement order issuance for the instrument Model L9197 Connection Cord Model L9198 Connection Cord Model U8332 SSD Unit Model L9790 Connection Cord Model U8333 HD Unit Model L9217 Connection Cord... -

Page 11: Safety Information

Safety Information Safety Information This instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly tested for safety prior to shipment. However, using the instrument in a way not described in this manual may negate the provided safety features. Read the following safety notes carefully before using the instrument. - Page 12 Safety Information Measurement categories To ensure safe operation of measuring instruments, IEC 61010 establishes safety standards for various electrical environments, categorized as CAT II to CAT IV, and called measurement categories. DANGER • Using a measuring instrument in an environment designated with a higher- numbered category than that for which the instrument is rated could result in a severe accident, and must be carefully avoided.

-

Page 13: Operation Precautions

• Check if there is any damage to the instrument occurred during storage or shipping and verify that it operates normally before using the instrument. If you find any damage, contact your authorized Hioki distributor or reseller. - Page 14 Operation Precautions Installing the instrument and modules WARNING Installing the instrument in inappropriate locations could cause a malfunction of the instrument an accident, or fire. Avoid the locations that are: • Exposed to direct sunlight or high temperatures • Exposed to corrosive or combustible gases •...

- Page 15 Model U8979 Charge Unit 40 V DC 60 V DC Model MR8990 Digital Voltmeter Unit 500 V DC 300 V AC/DC (CAT II) High Maximum input voltage Model MR6000 Modules Maximum rated voltage to earth Maximum rated voltage to earth...

- Page 16 Operation Precautions Ratings of connection cords Connection cord Maximum input voltage Maximum rated voltage to earth 600 V AC/DC (CAT III) Model L9197 Connection Cord 600 V AC/DC 300 V AC/DC (CAT IV) Model L9198 Connection Cord 600 V AC/DC (CAT II) 300 V AC/DC 300 V AC/DC (CAT III) Model L9217...

- Page 17 • To prevent the instrument damage or an electric shock, use only the screws that are originally installed for securing the module in place. If you have lost any screws or find that any screws are damaged, please contact your authorized Hioki distributor or reseller. • Setting the measurement mode to [Preamp] allows Model U8979 Charge Unit to constantly provide power (3.5 mA, 22 V) to sensors.

- Page 18 • Keep discs inside a protective case and do not expose to direct sunlight, high temperature, or high humidity. • Hioki is not liable for any issues your computer system experiences in the course of using this disc. Handling storage devices CAUTION •...

- Page 19 Operation Precautions • Media that can be used to save data is as follows. Use the product available as Hioki’s option only. (p. 5) Model Z4006 USB Drive Model Z4001 SD Memory Card (2 GB) Model Z4003 SD Memory Card (8 GB)

- Page 20 The following connection procedure is recommended to avoid this problem: • Connect the accompanying power Measurement cord to the instrument and supply Model MR6000 target power from a single outlet as the Logic probe measurement target.

- Page 21 Before connecting the instrument to external equipment DANGER To avoid electrical hazards and damage to the instrument, do not apply voltage exceeding the rated maximum to the external control terminals. Model MR6000 I/O terminals Maximum input voltage I/O terminals Maximum input voltage 10 V DC EXT.SMPL...

-

Page 22: How To Refer To This Document

How to Refer to This Document How to Refer to This Document How to open a screen Indicates the order of tapping the screens. The button represents the setting key. Procedure numbers Numbered same as a corresponding step-by-step instruction. Options and explanations Describes options available when an item is tapped. - Page 23 How to Refer to This Document...

-

Page 24: Overview

Overview 1.1 Product Overview and Features This recorder allows you to observe a wide range of waveforms from low-speed signals to high- speed waveforms. You can mainly use this instrument for analyzing test and evaluation results of various products and troubleshooting those products. -

Page 25: Name And Function Of Each Part

Name and Function of Each Part 1.2 Name and Function of Each Part Right side (p. 23) Operation keys (p. 22) Name Function Reference Holds the SSD or HD unit. One port is available for Media box USB3.0 connector (dedicated to USB flash drives). Always p. - Page 26 Serial number indicate the month of manufacture. Required for product – control. Do not remove this label. Inform your authorized Hioki distributor or reseller of this number if required. GND terminal Connects this terminal to a grounded conductor. (Functional earth p.

- Page 27 Name and Function of Each Part Operation keys Name Function Reference Opens the manual-save dialog box. Lights up SAVE p. 78 in blue while accessing the storage device. Frequently-used settings can be registered Shortcut keys on the keys. Allows you to choose a sampling rate and Rotary knob X moves the cursors.

- Page 28 Name and Function of Each Part Right side Name Function Reference USB 2.0 connector Connect a USB flash drive, USB mouse, or USB key- p. 59 board. USB 3.0 connector SD memory card slot Insert an SD memory card. p. 59 p.

-

Page 29: Screen

This screen is used to configure the settings of the numerical, waveform , FFT, real-time waveform (Model MR6000-01 only) calculations. Refer to “7 Numerical Calculation Function” of Instruction Manual, and “2 Real-time Waveform Calculation” of MR6000-01 Dedicated Functions. System This screen is used to configure the system environment, communications, and external control terminal settings, and to initialize the instrument. -

Page 30: Explanation Of Each Screen

Screen Explanation of each screen Waveform screen Item Description Reference Switches between the setting and waveform screens. p. 70, p. 83 Allows you to choose a sampling rate, recording length (the Measurement number of points and user-defined length), and recording p. - Page 31 Screen “ ” *1: Refer to 1.4 Configuring the Sheet Settings of Instruction Manual. “ ” *2: Refer to 6 Search Function of Instruction Manual. “ ” *3: Refer to 4 Saving/Loading Data and Managing Files of Instruction Manual. “ ”...

-

Page 32: Basic Operation

Basic Operation 1.4 Basic Operation Touch panel The touch panel allows the following operations. Touch operation Description “Tap” means to touch the display with a finger and then to lift the finger quickly. “Drag” means to choose something shown on the display with a fin- Drag ger by touching it and to slide the finger while toughing the display. -

Page 33: Rotary Knob

Basic Operation Rotary knob Push the rotary knob to choose an action and turn the knob to perform the action. Operation of the rotary knob Each time you push the rotary knob X, the following actions are Rotate chosen one after another. Push M a g n i f i c a t i o n / Changes the magnification/demagnification ratio... - Page 34 Basic Operation Tap a channel marker. Choose a channel.

-

Page 35: Changing Screens And Settings

Basic Operation Changing screens and settings Switching between the waveform and setting screens Tap the button to switch between the waveform and setting screens. Waveform screen Setting screen Switching the setting screens Tap a tab to switch the setting screens. - Page 36 Basic Operation Choosing an option from a list Example: Choosing a sampling rate Example: Choosing a measurement range of Model 8966 Entering numerical values Example: Entering a user-defined recording length Example: Entering a scaling ratio...

-

Page 37: Quick-Access Menu

Basic Operation Quick-access menu The quick-access menu allows various operation that includes undoing the action and switching over to the entire waveform display. Item Description See entire waveform Displays the recording length of the waveforms so that they fit the single screen width. -

Page 38: Key Lock

Basic Operation Key lock The key lock function disables touch panel operation and key operation to prevent an operation er- ror during measurement. Even if the key lock is engaged, the external control terminal and remote operation are enabled. To disable touch panel and key operations: Set the switch in “ALL.”... -

Page 39: Mouse Operation

Basic Operation Mouse operation Using a commercially available USB mouse enables you to operate the instrument as with the touch panel. Basic mouse operation for the instrument is as follows: Touch panel oper- Mouse operation Description ation S a m e a c t i o n a s Allows you to choose a menu or execute an ac- Click tapping the screen... - Page 40 Basic Operation Icon Description You can drag and move the keyboard. The icon appears to the left of this icon. Each tap switches between the icon and the icon You cannot drag the keyboard. Each tap switches between the icon and the icon Closes the keyboard.

- Page 41 Basic Operation...

-

Page 42: Preparing For Measurement

Preparing for Measurement Carefully read “Operation Precautions” (p. 8) before starting preparation. Keyboard, mouse Modules Connection cords External sampling (p. 34) (p. 38) (p. 40) (p. 54) External control Computer Storage devices Power cord terminals (p. 55) (p. 59) (p. 63) (p. -

Page 43: Installing And Removing Modules

Phillips-head screwdriver. Pinch the two knobs and pull out the module. When not installing any module after removal Install a blank panel. To order additional blank panels, contact your authorized Hioki distributor or reseller. Blank panel Place a blank panel. -

Page 44: Allocation Of Modules And Channels

Installing and Removing Modules Allocation of modules and channels Module numbers Channel numbers Modules are The channels are numbered numbered beginning beginning from the top left. at the top. UNIT 1 CH1, CH2 UNIT 2 CH1, CH2 UNIT 3 CH1, CH2 UNIT 4 LA, LB, LC, LD * UNIT 5... -

Page 45: Attaching Connection Cords

Attaching Connection Cords 2.2 Attaching Connection Cords Refer to the instruction manual of each module and each connection cord if provided. Measurement Applicable module Cord to be connected Reference target Model 8966 Analog Unit Model L9197 Connection Cord Model 8968 High Resolution Unit Model L9198 Connection Cord... -

Page 46: Connection Cords (For Measuring Voltage, Frequency, Or Rotation Speed, And Obtaining Accumulations)

Attaching Connection Cords Connection cords (For measuring voltage, frequency, or rotation speed, and obtaining accumulations) Insert connection cords to modules. Choose an appropriate connection cord based on the maximum input voltage and tips of cords. The maximum input voltage of the instrument or connection cord, whichever is lower, is applicable. Refer to “Before connecting cords”... - Page 47 Attaching Connection Cords How to connect a cord Example: Model 8966 Analog Unit Align the slots in the BNC connector of a connection cord with the locking studs of a BNC connector on the module, and insert the connector. Turn the BNC connector of the connection cord BNC connector slots clockwise until it locks.

-

Page 48: Thermocouple (Temperature)

Attaching Connection Cords Thermocouple (Temperature) Connect thermocouples to Model 8967 Temp Unit. Required items: Thermocouple and flat-blade screwdriver (2.6-mm-width blade) 25 mm Recommended cable Outer Compatible wire: Thermocouple element wires with a diameter 10 mm insulation Inner insulation of 0.4 mm to 1.2 mm Standard insulation stripping length: About 10 mm Strip the insulation of the thermocouple wires as shown on the Thermocouple... -

Page 49: Strain Gauge Transducer

Connect a strain gauge transducer* to Model U8969 Strain Unit via Model L9769 Conversion Cable* *1: Hioki does not offer any strain gauge transducers. *2: Model L9769 Conversion Cable is an accessory of Model U8969 Strain Unit. CAUTION To prevent damage due to snapped wires, do not excessively bend, pull, or twist the cables and joints between the cables and connectors. - Page 50 Attaching Connection Cords Connector pin-out Model L9769 Conversion Cable Model U8969 Strain Unit (Strain gauge converter) Applied voltage: A bridge voltage of 2 V The metal shell is connected to the GND terminal of The metal shell is connected to the GND terminal of the instrument.

-

Page 51: Current Sensor

Attaching Connection Cords Current sensor Familiarize yourself with “Operation Precautions” (p. 8) before connecting a current sensor. Refer to the instruction manual that comes with each current sensor for details on specifications and directions for use. CAUTION Do not connect and remove a current sensor while the instrument is left turned on. Doing so will cause damage to the current sensor. - Page 52 Attaching Connection Cords Connecting a current sensor with Model U8977 3CH Current Unit You can directly connect a current sensor with the sub model-number “-05,” which has a metal connector (ME15W). Point the widest key upward. Align the guides of the cable connector with those of the module connector.

- Page 53 Attaching Connection Cords By using Model CT9920 Conversion Cable (optional), you can connect a current sensor of Model CT7000 series with Model U8977 3CH Current Unit. The instrument cannot recognize any sensor with Model CT9920 connected. Select a mode in the setting screen. Applicable models: CT7631, CT7636, CT7642, CT7731, CT7736, CT7742, CT7044, CT7045, CT7046 Model CT9920 Conversion Cable...

-

Page 54: Acceleration Sensor

Attaching Connection Cords Acceleration sensor Connect a acceleration sensor to Model 8971 Current Unit. Familiarize yourself with “Operation Precautions” (p. 8) before connecting a current sensor. Acceleration sensor connectable with Model U8979 CAUTION Use an acceleration sensor with a built-in pre-amplifier that conforms to the specification of Model U8979 Charge Unit. - Page 55 Attaching Connection Cords Connecting a charge-output acceleration sensor Model U8979 Charge Unit Align the screw of the miniature connector, and turn the connector clockwise to tighten it. Attach the charge-output acceleration sensor to a measurement target. How to disconnect the current sensor Turn the miniature connector counterclockwise, and then pull out the connector.

-

Page 56: Logic Probe (Measuring Logic Signals)

Attaching Connection Cords Logic probe (Measuring logic signals) Connect logic probes to Model 8973 Logic Unit. Refer to “Before connecting a logic probe to a measurement target” (p. 15). Refer to an instruction manual of each logic probe. Required item: Logic Probe (Model 9320-01, Model MR9321-01, or Model 9327) How to connect the Logic Probe Example: Connecting Model 9327 Logic Probe Model 8973 Logic Unit... -

Page 57: Connection Cable (For Measuring High Voltage)

Attaching Connection Cords Connection cable (for measuring high voltage) Connect Model L4940 Connection Cable Set to Model U8974 High Voltage Unit. Choose appropriate connection cord tips based on the maximum input voltage and terminal type. Required item: Model L4940 Connection Cable Set Model L4934* Small CAT III 300 V Alligator Clip Set... -

Page 58: Supplying Power To Current Sensors

For resolving this problem, a conversion cable is available on a special order basis. Contact your authorized Hioki distributor or reseller. Example: Model CT6700 Current Probe... -

Page 59: External Sampling (Ext.smpl)

Externally inputting the signal can control the sampling rate. Refer to “Before connecting the instrument to external equipment” (p. 16). Input sampling signal. SMB cable MR6000 External device How to connect the external device Connect the external sampling terminal of the instrument and the external device (sampling signal source) with each other using an SMB cable. -

Page 60: Connecting The External Control Terminals

The term “external control terminals” is used to refer to all of these terminals collectively. Refer to “Before connecting the instrument to external equipment” (p. 16). MR6000 External device Wires to be connected... - Page 61 Connecting the External Control Terminals Terminal block Pin name Operation – Starts/stops measurement, saves data files, aborts measurement, enters events – OUT1 Outputs signals indicating judgments and status (error, busy, waiting for a trigger) OUT2 – The instrument is triggered when an external signal is EXT.TRIG inputted as a trigger source.

-

Page 62: Connecting The Instrument With Computers

Connecting one instrument to multiple computes Connecting multiple instruments to a computer LAN cable* LAN cable* LAN cable* LAN cable* MR6000 Computer Computer MR6000 *: Use one of the following cables: • 1000BASE-T straight-through cable (maximum length: 100 m, commercially available) - Page 63 Connecting the instrument with your computer via a LAN cable allows the computer to control and monitor the instrument. LAN cable* Computer MR6000 *: Use one of the following cables: • 1000BASE-TX compatible crossover cable (maximum length: 100 m) • 1000BASE-T straight-through cable and crossover connector (maximum length: 100 m) •...

-

Page 64: Preparing Storage Devices (Recording Media)

Preparing Storage Devices (Recording Media) 2.7 Preparing Storage Devices (Recording Media) You can use the following recording media on the instrument: SD memory cards, USB flash drives, and a built-in drive. Refer to “Handling storage devices” (p. 13). SD memory card You have to configure the SD memory card setting on the instrument to use SD memory cards. -

Page 65: Built-In Drive

Preparing Storage Devices (Recording Media) Built-in drive The built-in drive is factory-formatted. Model U8332 SSD Unit (capacity: 256 GB*, option available only at the time of purchase order issuance for the instrument) Model U8333 HD Unit (capacity: 320 GB*, option available only at the time of purchase order issuance for the instrument) *: Once the drive has been formatted, the actual capacity available decreases. -

Page 66: Formatting Storage Devices

Preparing Storage Devices (Recording Media) Formatting storage devices The instrument can format SD cards, USB flash drives, and the built-in drive. Once they are formatted, the “HIOKI_MR6000” folder is created. IMPORTANT Note that formatting a storage device deletes all the information stored on the storage device, and deleted information cannot be recovered. -

Page 67: How To Open The Media Box

How to Open the Media Box 2.8 How to Open the Media Box The USB3.0 port in the media box is dedicated to USB flash drives. Be sure to use the instrument with the cover closed. Before handling a USB flash drive, eliminate any static on your body. -

Page 68: Supplying Power To The Instrument

Supplying Power to the Instrument 2.9 Supplying Power to the Instrument Refer to “Before turning on the instrument” (p. 15). Turning on the instrument Connect the power cord to the power inlet on the instrument. Connect the plug to a grounded type outlet. Connect the GND terminal (functional earth terminal) to the earth. -

Page 69: Setting The Clock

Setting the Clock 2.10 Setting the Clock Specify the date, time, and time zone. The instrument has the automatic calendar with leap year correction and 24-hour clock. > [System] > [Env.] [Date and time]. [Date and time] dialog box will appear. [Change date and time]. -

Page 70: Executing Zero-Adjustment

Executing Zero-Adjustment 2.11 Executing Zero-Adjustment Executing zero-adjustment regulates the zero positions of all channels in each module on the reference potential of the instrument. Zero-adjustment involves all ranges of all channels. Before executing zero-adjustment • Warm up the instrument for about 30 minutes after the power-on to stabilize the internal temperature of the modules, and then execute zero-adjustment. - Page 71 Executing Zero-Adjustment Re-execute zero-adjustment in the following cases: • After replacing any modules • After cycling the instrument • After initializing the instrument • After switching between DC mode and RMS mode on Model 8971 Current Unit, Model 8972 DC/ RMS Unit, or Model U8974 High Voltage Unit.

-

Page 72: Executing Calibration

Executing Calibration (For the Instrument With Model MR8990 Installed) 2.12 Executing Calibration (For the Instrument With Model MR8990 Installed) Executing calibration regulates the zero position of each channel in Model MR8990 Digital Voltmeter Unit on the reference potential of the instrument. Calibration involves all ranges of all channels. - Page 73 Executing Calibration (For the Instrument With Model MR8990 Installed)

-

Page 74: Measurement Method

Send them for repair. Are the instrument and modules damaged? When turning on the instrument The power cord may have a Does the screen display the logo “HIOKI”? brake or the internal circuit of the instrument may have failed. Send The screen the instrument for repair. -

Page 75: Setting Measurement Conditions

Setting Measurement Conditions 3.2 Setting Measurement Conditions Set conditions required for measurement, such as the sampling rate and recording length. > [Status] > [Condition] Tap the [Sampling] box, and then choose a sampling rate from the list. Refer to “Sampling rate setting guideline” (p. 71). 200 MS/s ... -

Page 76: Sampling Rate Setting Guideline

Setting Measurement Conditions Sampling rate setting guideline Choose a sampling rate using the following table as a guideline. Maximum display Maximum display Sampling rate Sampling rate frequency frequency 8 MHz 200 MS/s 400 Hz 10 kS/s 4 MHz 100 MS/s 200 Hz 5 kS/s 2 MHz... -

Page 77: Configuring The Input Channel Settings

Configuring the Input Channel settings 3.3 Configuring the Input Channel settings Configure the analog channel settings. How to configure the channel settings This section describes how to configure the analog channel (CH1-1 through CH8-4) settings. For details of analog channels such as a setting of each module, refer to “1.3 Configuring the Input of Instruction Manual. -

Page 78: Analog Channel

Configuring the Input Channel settings Analog channel > [Channel] > each module (UNIT) Tap the [Use] button to set it to [On] or [Off]. Measures a waveform through this module. Does not measure any waveform through this module. Since no data is acquired, the instrument displays or saves nothing. Enter a comment in the [Comment] box. - Page 79 Configuring the Input Channel settings Specify the cutoff frequency of the low-pass filter and the probe ratio in [L.P.F] [Probe ratio], respectively. Tapping the area that includes [L.P.F] [Probe ratio] allows the setting dialog box to appear. (1) Tap the [L.P.F] box, and then choose a cutoff frequency of the low-pass filter from the list.

-

Page 80: Configuring The Level Trigger Settings

Configuring the Level Trigger Settings 3.4 Configuring the Level Trigger Settings The trigger function allows you to start and stop measurement using specific signals. When recording is started or stopped by specific signals, it is called “The instrument is triggered.” The trigger function is useful to find trends in unexpected events. - Page 81 Configuring the Level Trigger Settings Configuring the trigger source settings > [Trigger] > [Source] Tap a trigger source to be set. The setting dialog box will appear. You can set up to four triggers per module. Tap the [Channel] box, and then choose a channel to be used for the level trigger from the list.

-

Page 82: Starting/Stopping A Measurement

Starting/Stopping a Measurement 3.5 Starting/Stopping a Measurement Starting a measurement Pressing the START key starts a measurement. Waveforms shown on the screen are cleared once the measurement starts. Stopping the measurement STOP Pressing the key once stops the measurement after the instrument has acquired the specified recording length of the waveforms. -

Page 83: Saving Data Consisting Of Items Selected

Saving Data Consisting of Items Selected 3.6 Saving Data Consisting of Items Selected Save types and setting procedure There are mainly three types of save operation. To automatically save data To save data manually by pressing the SAVE during measurement To save data after choosing To save data immediately items... -

Page 84: Selective Save

Saving Data Consisting of Items Selected Selective save Pressing the SAVE key allows you to choose any of the following items and save them: • Waveform data • Screenshot • Numerical calculation result • Setting Refer to “4 Saving/Loading Data and Managing Files” of Instruction Manual. Press the SAVE key. - Page 85 Saving Data Consisting of Items Selected Tap the [Type] box, and then choose a save format of waveform data or save target from the list. Waveform Saves waveform data in binary format. Choose this option to reload the waveforms into (Binary) ...

-

Page 86: Measuring Signals With The Auto-Range Setting

Measuring Signals With the Auto-range Setting 3.7 Measuring Signals With the Auto-range Setting The auto-range function is available only for signals inputted to analog measuring modules. You cannot use the auto-range function concurrently with the envelope function. Input signals to an analog measuring module. [Auto range] on the waveform screen. - Page 87 Measuring Signals With the Auto-range Setting • Be careful when performing auto-range measurement while using the TRIG OUT signals. Starting a measurement with the auto-range setting outputs a trigger signal from the TRIG.OUT terminal. • Input signals (waveforms) before starting a measurement with the auto-range setting. The auto- range function changes the setting depending on a signal inputted on the start of execution.

-

Page 88: Analysis Method

Analysis Method 4.1 Reading Measured Values (Trace Cursors) You can read measured values (scaled values when the scaling is used) using trace cursors on the waveform screen. The instrument can simultaneously display up to eight trace cursors. You can read differences in times and measured values at any two cursors you choose from among all cursors. - Page 89 Reading Measured Values (Trace Cursors) [Cursor Value]. Value You can switch between on and off for the cursor value display every time you tap [Cursor [Change page]. When the instrument displays multiple channels, you can switch the pages to check cursor values of each channel.

- Page 90 Reading Measured Values (Trace Cursors) [Select cursor]. Every time you tap it when the instrument displays multiple trace cursors, a cursor is activated one by one in sequence. In addition, you can activate any one of the cursors displayed on the screen by tapping it. While you are operating the cursors on the waveform screen, the instrument may not displays [Cursor] [Select cursor]...

-

Page 91: Handling Waveforms

Handling Waveforms 4.2 Handling Waveforms Scrolling through waveforms You can use the scroll bar to check the position of waveforms presently displayed on the waveform screen. Drag the scroll bar to scroll through the waveforms. Scroll bar Zooming in and out waveforms Horizontally pinching in or pin out the waveform screen enlarges or compresses waveforms horizontally. -

Page 92: Loading Data On Your Computer (Wave Viewer)

Loading Data on Your Computer (Wave Viewer) 4.3 Loading Data on Your Computer (Wave Viewer) You can load waveform data saved in CSV format into spreadsheets. This section explains how to install, uninstall, start, and exit the Wave Viewer. Supported computer: Computers running on Windows 7, or Windows 8, or Windows 10 Installing Wave viewer (for computers running on Windows 7) Insert the accompanying application disc into the CD-ROM drive. - Page 93 [System] > [Apps and Features]. Right-click [HIOKI Wave Viewer (Wv)] to display the shortcut menu, and then click [Uninstall]. Wave viewer is uninstalled. When updating Wave viewer to the latest version, uninstall the earlier version before installing the latest version.

-

Page 94: Specifications

Analog Unit is installed in every slot) Logic: Up to 128 channels (when Model 8973 Logic Unit* is installed in every slot*) *: The logic probe input connectors have the same-potential ground as Model MR6000. Maximum sampling 200 MS/s (when Model U8976 High Speed Analog Unit is used), Samples values acquired rate across all channels simultaneously. - Page 95 Specifications of Model MR6000 2. Specifications for accuracy Conditions of Guaranteed accuracy period: 1 year guaranteed accuracy Temperature and humidity for guaranteed accuracy: 23°C ±5°C (73°F ±9°F), 80% RH or less Time axis accuracy ±0.0005% Clock accuracy ±8 ppm 3. Display Display type 12.1-inch XGA TFT color LCD (1024 ×...

- Page 96 Specifications of Model MR6000 5. Auxiliary I/O (1) External sampling terminals Connector Maximum input 10 V DC voltage Input voltage High level: 2.5 V to 10 V, low level: 0 V to 0.8 V Acceptable pulse High-level period: 50 ms or more; Low-level period: 50 ms or more...

- Page 97 Specifications of Model MR6000 Trigger output Output format Open-drain output (equipped with a 5-volt voltage output, active-low) Output voltage High level: 4.0 V to 5.0 V, low level: 0 V to 0.5 V Maximum input 50 V DC, 50 mA, 200 mW...

-

Page 98: Trigger

Specifications of Model MR6000 Trigger When the real-time save is set to [On], the trigger function is not available. Trigger method Digital comparison method Trigger conditions Logical AND or OR operation among each trigger source and the interval trigger Trigger source... - Page 99 Specifications of Model MR6000 Logic trigger Pattern trigger defined by 1, 0, or disregard (×) Forcible trigger Available (A forcible trigger can trigger the instrument in priority to any trigger sources.) Interval trigger Data can be recorded at a user-defined measuring interval (in hours, minutes, and seconds).

-

Page 100: Waveform Screen

Specifications of Model MR6000 Waveform screen Display format Time-domain 1, 2, 4, 8, 16 screens waveform (Up to 64 channels can be displayed on each sheet.) representation: (Every channel can be set to be displayed on multiple sheets.) FFT representation: 1, 2, 4 screens, combination of time-domain waveform and FFT... -

Page 101: Setting Screen

Specifications of Model MR6000 Setting screen Sampling rate Normal 200 M, 100 M, 50 M, 20 M, 10 M, 5 M, 2 M, 1 M 500 k, 200 k, 100 k, 50 k, 20 k, 10 k, 5 k, 2 k, 1 k... - Page 102 Specifications of Model MR6000 Maximum recording Normal For the fixed recording length setting: length 20 M (32 ch.), 50 M (16 ch.), 100 M (8 ch.), 200 M (4 ch.),500 M (2 ch.), 1 G (1 ch.) (unit: points) For freely-specified recording length: 33554400 (32 ch.), 67108800 (16 ch.), 134217700 (8 ch.),268435400...

- Page 103 Specifications of Model MR6000 Digital filter Maximum number of 32 expressions (Model MR6000-01 expressions: only) Calculation target: Measurement channel of the following modules: Models 8966, 8967, 8968, U8969, 8970, 8971, 8972, U8974, U8975, U8976, U8977, U8978, and U8979 (Measurement channels of Model 8973 Logic Unit and Model MR8990 Digital Voltmeter Unit are not supported.)

-

Page 104: File

Specifications of Model MR6000 File 1. Data saving Destination to save SD memory card: Model Z4001 SD Memory Card (2 GB), Model Z4003 SD Memory Card (8 GB) USB flash drive Model Z4006 USB Drive (16 GB) SSD: Model U8332 SSD Unit (256 GB) -

Page 105: Calculation

Specifications of Model MR6000 File designation New file or existing file (Enabled when the saving format is set to the numerical calculation result) (Before starting a measurement, choose whether a new file is created or data is appended to the existing file) - Page 106 3. Real-time waveform calculation (Model MR6000-01 only) This function is optional function available only at the time of purchase order issuance for the instrument. Maximum number of...

- Page 107 Specifications of Model MR6000 4. FFT calculation The FFT calculation is disabled when the envelope is used. The FFT calculation cannot be used in combination with the real-time save. Maximum number of 8 expressions calculations Frequency range 500 mHz to 100 MHz ([sampling rate] × 0.5), external sampling...

-

Page 108: Memory Division

Specifications of Model MR6000 Memory division Maximum division 1,024 blocks number Block search The instrument can search through data stored divided memory blocks. Batch save The instrument saves previously measured data that has been recorded in all blocks in one operation. - Page 109 Specifications of Model MR6000 Key lock Three permission levels are available: • ALL (Touch panel operation and key operation are disabled.) • TOUCH PANEL (Only touch panel operation is disabled.) • OFF (The key lock is disengaged.) Beep sound Three conditions are available: •...

-

Page 110: Specifications Of The Options

Specifications of the Options 5.2 Specifications of the Options Model Z5021 Probe Power Unit Conditions of guaranteed accuracy Specified, unless otherwise designated, at 23°C ±5°C (73°F ±9°F) and 80% RH or less. Supported probe Model CT6700 Current Probe Model CT6701 Current Probe Model 3273-50 Clamp on Probe Model 3274 Clamp on Probe Model 3275 Clamp on Probe... -

Page 111: Model U8333 Hd Unit

Specifications of the Options Model U8333 HD Unit Recording capacity 320 GB Supported interface Serial ATA Revision 2.0 compatible (2.5-inch) standard Operating Consistent with the specifications of Memory HiCorder in which Model U8333 is installed. temperature and humidity Storage temperature Consistent with the specifications of Memory HiCorder in which Model U8333 is installed. - Page 112 Specifications of the Options Maximum rated 300 V AC, DC (between each input channel and the enclosure, between any two of input voltage to earth channels) Measurement category II, anticipated transient overvoltage: 2500 V Operating Consistent with the specifications of the Memory HiCorder in which Model 8966 is temperature and installed.

-

Page 113: Model 8967 Temp Unit

Specifications of the Options Model 8967 Temp Unit Conditions of guaranteed accuracy Specified under the following conditions: installed in a Memory HiCorder and operated at 23°C ±5°C (73°F ±9°F) in the range of 20% to 80% RH after a half-hour (at least) warm-up and execution of zero-adjustment. Product warranty 3 years period... - Page 114 Specifications of the Options Effect of conducted ±2% f.s. (max.) at 3 V radio-frequency electromagnetic field Standards Safety: EN61010 EMC: EN61326 Class A Accessories Ferrite clamp-on choke ×2 Options Model 9810 Thermocouple (K) Table: Measurable ranges, resolutions, and measurement accuracy of each thermocouple type and measurement range Measurement Measurement...

-

Page 115: Model 8968 High Resolution Unit

Specifications of the Options Model 8968 High Resolution Unit Conditions of guaranteed accuracy Specified under the following conditions: installed in a Memory HiCorder and operated at 23°C ±5°C (73°F ±9°F) in the range of 20% to 80% RH after a half-hour (at least) warm-up and execution of zero-adjustment. Product warranty 3 years period... - Page 116 Specifications of the Options Effect of radiated ±15% f.s. (max.) at 3 V/m radio-frequency electromagnetic field Effect of conducted ±20% f.s. (max.) at 3 V (with the 2 V f.s. range, with 1 V DC inputted) radio-frequency electromagnetic field Standards Safety: EN61010 EMC: EN61326 Class A...

-

Page 117: Model U8969 Strain Unit

3 years period Guaranteed accuracy 1 year period Guaranteed 1 year accuracy period after adjustment made by Hioki Accessories Model L9769 Conversion Cable ×2 (Compatible connector: NDIS connector PRC03-12A10-7M10.5) Number of input 2 channels channels Input terminals NDIS connector EPRC07-R9FNDIS... - Page 118 Specifications of the Options Effect of radiated ±10% f.s. (max.) at 3 V/m (with the filter set at 5 Hz) radio-frequency electromagnetic field Effect of conducted ±10% f.s. (max.) at 3 V (with the filter set at 5 Hz) radio-frequency electromagnetic field Low-pass filter Off, 5 ±30%, 10 ±30%, 100 ±30%, 1 k ±30% (Hz) −3 dB...

-

Page 119: Model 8970 Freq Unit

Specifications of the Options Model 8970 Freq Unit Conditions of guaranteed accuracy Specified under the following conditions: installed in a Memory HiCorder and operated at 23°C ±5°C (73°F ±9°F) in the range of 20% to 80% RH and operated after a half-hour (at least) warm-up. Product warranty 3 years period... - Page 120 Specifications of the Options Threshold value ±10 V range: Variable in the range of −10 V to +10 V (in 0.1 V increments) ±20 V range: Variable in the range of −20 V to +20 V (in 0.2 V increments) ±50 V range: Variable in the range of −50 V to +50 V (in 0.5 V increments) ±100 V range: Variable in the range of −100 V to +100 V (in 1 V increments)

-

Page 121: Model 8971 Current Unit

Models 9272-10, 9709, CT6841, CT6843, CT6844, CT6845, CT6846, CT6862, CT6863, sensors CT6865* Hioki current sensors with RM515EPA-10PC (Hirose connector) installed (Supported conversion ratio: 2 V/20 A, 2 V/50 A, 2 V/200 A, 2 V/500 A, 2 V/1000 A* 2 V/1000 A*... - Page 122 Specifications of the Options Storage temperature −10°C to 50°C (14°F to 122°F), 80% RH or less (no condensation) and humidity Dimensions Approx. 106W × 19.8H × 196.5D mm (4.17″W × 0.78″H × 7.74″D) Mass Approx. 250 g (8.8 oz.) Standards Safety: EN61010 EMC: EN61326 Class A...

-

Page 123: Model 8972 Dc/Rms Unit

Specifications of the Options Model 8972 DC/RMS Unit Conditions of guaranteed accuracy Specified under the following conditions: installed in a Memory HiCorder and operated at 23°C ±5°C (73°F ±9°F) in the range of 20% to 80% RH after a half-hour (at least) warm-up and execution of zero-adjustment. Product warranty 3 years period... - Page 124 Specifications of the Options Dimensions Approx. 106W × 19.8H × 196.5D mm (4.17″W × 0.78″H × 7.74″D) Mass Approx. 250 g (8.6 oz.) Effect of radiated ±15% f.s. (max.) at 3 V/m radio-frequency electromagnetic field Effect of conducted ±20% f.s. (max.) at 3 V (with the 2 V f.s. range, with 1 V DC inputted) radio-frequency electromagnetic field Standards...

-

Page 125: Model 8973 Logic Unit

Specifications of the Options Model 8973 Logic Unit Product warranty 3 years period Number of input 4 probes (16 channels) channels Input terminals Mini DIN Supported probes Model 9320-01 Logic Probe, Model MR9321-01 Logic Probe, Model 9327 Logic Probe Operating Consistent with the specifications of the Memory HiCorder in which Model 8973 is temperature and installed. - Page 126 Specifications of the Options Measurement Measurement range NPLC: Less than 1 NPLC: 1 or more accuracy 100 mV f.s. ±0.01% rdg. ±0.015% f.s. ±0.01% rdg. ±0.01% f.s. 1 V f.s. ±0.01% rdg. ±0.0025% f.s. 10 V f.s. 100 V f.s. ±0.025% rdg.

-

Page 127: Model U8974 High Voltage Unit

Specifications of the Options Model U8974 High Voltage Unit Conditions of guaranteed accuracy Specified under the following conditions: installed in a Memory HiCorder and operated at 23°C ±5°C (73°F ±9°F) in the range of 20% to 80% RH after a half-hour (at least) warm-up and execution of zero-adjustment. Product warranty 3 years period... - Page 128 Specifications of the Options Storage temperature −20°C to 50°C and humidity For −20°C or higher but lower than 40°C (−4°F or higher but lower than 104°F), 80% RH or less (no condensation) For 40°C or higher but lower than 45°C (104°F or higher but lower than 113°F), 60% RH or less (no condensation) For 45°C to 50°C (113°F to 122°F), 50% RH or less (no condensation) Dimensions...

-

Page 129: Model U8975 4Ch Analog Unit

A/D resolution 16 bits (± f.s. = ±32000 data points) Maximum sampling 5 MS/s rate Guaranteed accuracy 1 year period Guaranteed 1 year accuracy period after adjustment made by Hioki Measurement ±0.1% f.s. (with the filter set at 5 Hz) accuracy... - Page 130 Specifications of the Options Temperature ±0.02% f.s./°C characteristics Effect of radiated ±5% f.s. (max.) at 3 V/m (with the filter set at 5 Hz) radio-frequency electromagnetic field Effect of conducted ±5% f.s. (max.) at 3 V (in the 10 V f.s. range, with the filter set at 5 Hz, with 1 V DC radio-frequency inputted) electromagnetic field...

-

Page 131: Model U8976 High Speed Analog Unit

Input capacitance 22 pF ±5 pF (at 100 kHz) A/D resolution 12 bits (± f.s. = ±1600 pieces of data) Maximum sampling 200 MS/s rate Guaranteed accuracy 1 year period Guaranteed 1 year accuracy period after adjustment made by Hioki... - Page 132 Specifications of the Options Measurement ±0.5% f.s. (with the filter set at 5 Hz) accuracy Temperature ±0.15% f.s./°C characteristics Effect of radiated ±5% f.s. (max.) at 3 V/m (with the filter set at 5 Hz) radio-frequency electromagnetic field Effect of conducted ±5% f.s.

-

Page 133: Model U8977 3Ch Current Unit (Available For The Firmware Version 2.10 Or Later)

Specifications of the Options Model U8977 3CH Current Unit (available for the firmware version 2.10 or later) Conditions of guaranteed accuracy Specified under the following conditions: installed in a Memory HiCorder and operated at 23°C ±5°C (73°F ±9°F) and 80% RH or less after a half-hour (at least) warm-up and execution of zero-adjustment. Operating Indoors, Pollution Degree 2, Operating altitude: up to 2000 m (6562 ft.) environment... - Page 134 16 bits Guaranteed accuracy 1 year period Guaranteed 1 year accuracy period after adjustment made by Hioki Measurement ±0.3% f.s. + (accuracy of current sensor) accuracy Temperature ±0.045% f.s./°C characteristics Effect of radiated ±5% f.s. (max.) at 3 V/m (with the filter set at 5 Hz)

-

Page 135: Model U8978 4Ch Analog Unit (Available For The Firmware Version 2.10 Or Later)

±1% Input capacitance 30 pF ±10 pF (at 100 kHz) A/D resolution 16 bits (± f.s. = ±32,000 data points) Maximum sampling 5 MS/s rate Guaranteed accuracy 1 year period Guaranteed 1 year accuracy period after adjustment made by Hioki... - Page 136 Specifications of the Options Measurement ±0.3% f.s. (with the filter set at 5 Hz) accuracy Temperature ±0.045% f.s./°C characteristics Effect of radiated ±5% f.s. (max.) at 3 V/m (with the filter set at 5 Hz) radio-frequency electromagnetic field Effect of conducted ±5% f.s.

-

Page 137: Model U8979 Charge Unit (Available For The Firmware Version 2.10 Or Later)

Specifications of the Options Model U8979 Charge Unit (available for the firmware version 2.10 or later) 1. General specifications Operating Indoors, Pollution Degree 2, Operating altitude: up to 2000 m (6562 ft.) environment Operating 0°C to 40°C (32°F to 104°F), 80% RH or less (no condensation) temperature and humidity Storage temperature... - Page 138 Specifications of the Options Frequency DC to 50 kHz −3 dB (DC-coupled) characteristics 1 Hz to 50 kHz −3 dB (AC-coupled, lower cutoff frequency: 1 Hz ±50%) Noise 80 μV p-p (typ.), 120 μV p-p (max.), with the highest sensitivity range and the terminals of each input connector connected with each other Ω...

- Page 139 -5. Specifications for accuracy Conditions of Guaranteed accuracy period: 1 year guaranteed accuracy Guaranteed accuracy period after adjustment made by Hioki: 1 year Temperature and humidity for guaranteed accuracy: 23°C ±5°C (73°F ±9°F), 80% RH or less Warm-up time: 30 minutes or more...

-

Page 140: Maintenance And Service

The calibration period varies depending on the state of the instrument and installation environment. We recommend that the calibration period be determined in accordance with the state of the instrument and installation environment. Please contact your authorized Hioki distributor or reseller to have your instrument periodically calibrated. - Page 141 The characteristics of some of the parts used in the instrument may deteriorate with extended use. To ensure the instrument can be used over the long term, it is recommended to replace these parts on a periodic basis. When replacing batteries, please contact your authorized Hioki distributor or reseller.

-

Page 142: Troubleshooting

Troubleshooting 6.1 Troubleshooting If damage is suspected, read the “Before having the instrument repaired” section before contacting your authorized Hioki distributor or reseller. Before sending the instrument for repair If the power or operating keys does not operate properly Problem... - Page 143 Troubleshooting If the instrument cannot save any data Condition Check item or cause Remedy Reference • Do you use Hioki’s optional SD Use Hioki’s optional SD card. p. 5 card? Initialize or replace the storage p. 59 device. • Does the storage device have...

-

Page 144: Initializing The Instrument

Initializing the Instrument 6.2 Initializing the Instrument Choose settings configured on the instrument and restore them to the factory default. > [System] > [Initialize] Choose an item to be restored. Initialize waveform Discards the waveform data saved in the internal memory. data Initialize Settings Restores the settings for measurement, channels, sheets, triggers, and calculation... -

Page 145: Message

Message 6.3 Message If any problem is found, the screen will display an error message or a warning message. It also display an information message with advice for usage. Action that should be taken after a message If a message remains Message No. -

Page 146: Error Messages

Error messages The list of error messages is as follows. Check the solution. If an error is displayed on the screen at power-on, the instrument is necessary to be repaired. Contact your authorized Hioki distributor or reseller. Message Solution Reference... -

Page 147: Warning Messages

Message Warning messages The list of warning messages is as follows. Check the solution. Message Solution Reference Insert an SD card or a USB “2.7 Preparing Storage Devices Please insert media. flash drive. (Recording Media)” (p. 59) The instrument cannot save any files because of insufficient free “2.7 Preparing Storage Devices space on the storage device. - Page 148 Message Message Solution Reference Real-time save has been canceled due to slow writing speed to the storage device. Check solutions below before measurement. Save processing was “4.2 Saving Data” of Instruction • Choose a slower sampling interrupted. Manual speed. • Reduce the number of saving channels.

- Page 149 Message Message Solution Reference The server refused to send the “12 Connecting the Instrument E-mail recipient error. email to the recipient. Check to Computers” of Instruction the recipient’s address. Manual The email size exceeds limits. “12 Connecting the Instrument The sent e-mail size exceeds Reduce the recording length or to Computers”...

- Page 150 Message Message Solution Reference Remaining clamp current that The instrument can supply up can be supplied from Z5021 to 4.8 A of current for current Current Clamp’s power supply sensors. When current sensors terminal is A [A]. connects to Model 8971 Current Unit, the instrument recognizes them automatically and displays “2.3 Supplying Power to Current...

-

Page 151: Self-Check

Self-check 6.4 Self-check Executing the self-check function checks the instrument for malfunctions. The self-check consists of the following checks: [System] [Initialize] > > (p. 146) (p. 147) (p. 147) (p. 147) (p. 148) (p. 149) “Initializing the Instrument” (p. 139) Memory check This function checks the storage memory, backup memory (SRAM memory), and calculation memory (DSP memory). -

Page 152: Touch Panel Check

Self-check Touch panel check This check tests the touch panel for proper operation. [Touch panel check]. The sides to be checked go white. Place your finger on a mark on the edge of a side and trace the side to the other mark on the side. -

Page 153: Lan Check

Self-check LAN check This check tests the LAN cable for malfunction such as disconnection. [LAN check]. Enter an IP address used for connecting to LAN in the [Address] box. Tap [Start]. Check the transmission/reception result on the screen. Tap [Close]. -

Page 154: Media Check

Self-check Media check This check tests the storage devices for malfunction. [Media check]. Tap the [Media] box and choose a storage device from the list. The screen displays the information of the chosen storage device. [Read/Write check]. The read/write check starts. Check the transmission/reception result on the screen. -

Page 155: System Configuration Check

Cleaning the Instrument System configuration check You can check the functions and devices installed in the instrument in a list. > [System] > [System information] Item Description System You can check the system configuration, software version, and board configuration version of the instrument. Module You can check the model number, name, resolution, sampling rate, and configuration... -

Page 156: Disposing Of The Instrument (Removing The Lithium Battery)

Disposing of the Instrument (Removing the lithium battery) 6.6 Disposing of the Instrument (Removing the lithium battery) When disposing of this instrument, remove the lithium battery and dispose of the battery and instrument in accordance with local regulations. The instrument contains the lithium battery for memory backup. - Page 157 Disposing of the Instrument (Removing the lithium battery) Cover (1 screw) If SSD unit or HD unit is installed (3 Torx screws) Rear panel (9 screws) Left panel (3 screws) Upper panel (4 screws) Media box (1 screw) Right panel (4 screws) Lithium battery Handle (4 socket head...

- Page 158 Index Index Acceleration sensor ..........49 Help function............. 33 Aliasing ..............71 Analog channel ............72 Auto-range ..............81 Auto-save ..............78 IN1 ..............16, 56 IN2 ..............16, 56 Initializing the instrument ........139 Input channel ............72 Beep ............... 140 Blank panel ...............

- Page 159 Index TRIG.OUT ............16, 56 Option ................. 5 OUT1 ..............16, 56 OUT2 ..............16, 56 USB flash drive ............59 Power key ..............63 Warm-up ..............63 Probe compensation signal output ......42 Warning ..............142 Probe ratio ..............74 Waveform viewer ............

- Page 160 Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 TestEquipmentDepot.com...

Need help?

Do you have a question about the MR6000 and is the answer not in the manual?

Questions and answers