schmersal PSC1 Series Installation Manual

Hide thumbs

Also See for PSC1 Series:

- Installation manual (166 pages) ,

- Installation manual (177 pages) ,

- Installation manual (174 pages)

Summary of Contents for schmersal PSC1 Series

- Page 1 Installation manual PSC1 modules Series PSC1-C-100 PSC1-E-2x PSC1-E-37 PSC1-E-13x...

- Page 2 Information and specifications may be changed at any time. Please obtain information on the latest version at: www.schmersal.net. K. A. Schmersal GmbH & Co. KG Möddinghofe 30 D - 42279 Wuppertal HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx...

- Page 3 Installation manual Revision history Version-No. Date Comment V 1.0 Feb 2 , 2017 Release - V 2.0 May 2 , 2018 Editorial changes V 2.1 Oct 31 , 2018 Terminal designation CPU-ENC/ENC adapted, DC value specified for 2x Proxy 2, X22 without function with PSC1-E-(1)33-..., CANopen added, Reference to protective circuit for contactors, etc.,...

-

Page 4: Table Of Contents

Installation manual Contents IMPORTANT NOTES ..................... 7 DEFINITIONS ......................7 Reference documents ..........................8 Abbreviations used ..........................9 SAFETY INSTRUCTIONS ..................10 Intended use ............................10 Usage in regions with UL/CSA requirement ..................11 General safety instructions ........................12 Operating and service ........................... 13 Transport/storage .......................... - Page 5 Installation manual 4.3.5.2 Example circuits for safe digital outputs I/O (IQQx) ............87 4.3.5.3 Overview of achievable PL for digital safety outputs ............93 CONNECTION AND INSTALLATION ..............95 General installation instructions ......................95 Installation and mounting PSC1 module ....................96 Mounting backplane bus ........................

- Page 6 Installation manual COMMISSIONING ....................151 Procedure ............................151 Sequences for switching on ........................ 151 Reset behaviour ..........................153 7.3.1 Reset types and triggering element ..................154 7.3.2 Reset timing ........................155 7.3.3 Reset function ........................155 7.3.3.1 Example reset function with protection against incorrect usage ........157 LED indication .............................

-

Page 7: Important Notes

Installation manual 1 Important notes Definition of the individual target groups Designers of safe drive systems: Engineers and technicians Mounting, electrical installation, maintenance and device replacement Industrial electricians and service engineers Commissioning, operation and configuration: Technicians and engineers 2 Definitions The term PSC1 is used as the generic term for all derivatives of the PSC1 product line. -

Page 8: Reference Documents

Installation manual 2.1 Reference documents Description Reference Configuration of the PSC1 module Programming manual SafePLC2 with the "SafePLC2" programming system Validation report on the parameter Safety-related test with acceptance configuration implemented and the report PLC program Acceptance for general safety-related Certificate on the type test for safety applications control according to Machinery directive... -

Page 9: Abbreviations Used

Installation manual 2.2 Abbreviations used Abbreviation Meaning Alternating Current Instruction List BGIA (IFA) Institute for Industrial Safety at the DGUV (German Statutory Accident Prevention Association) Here: SSI systems clock Central Processing Unit Direct Current Deutsches Institut für Normung Digital Output ECFS EtherCAT Fail Safe;... -

Page 10: Safety Instructions

TB(1) T bus connector (backplane bus) PELV Protective Extra Low Voltage Programmable Logic Controller SD bus (on request) Serial diagnostic bus for electronic Schmersal safety switches SDDC (on request) Safe Device-Device Communication SELV Safety Extra Low Voltage SMMC (on request) -

Page 11: Usage In Regions With Ul/Csa Requirement

Directive as well as the EC EMC Directive 2014/30/EU Cf. Appendix EC declaration of conformity 3.2 Usage in regions with UL/CSA requirement The PSC1 series has a cULus approval with the following standards: Basic standard(s): UL 61010-1, 3rd Edition, May 11, 2012, Revised July 15 2015, CAN/CSAC22.2 No. -

Page 12: General Safety Instructions

Installation manual 3.3 General safety instructions Safety instructions: • To prevent injury and damage, only qualified personnel are allowed to work on the device. Qualified personnel are personnel who have electrical engineering training and who are familiar with the applicable rules and standards of electrical engineering. •... -

Page 13: Operating And Service

Installation manual WARNING: The usage of our devices contrary to the rules and conditions stated here can result in the injury or the death of persons, as well as damage to the devices and machines connected! This usage will also render void any claim under the warranty or any claim for claim damages against the manufacturer. -

Page 14: Transport/Storage

Installation manual 3.5 Transport/storage The instructions on transport, storage and correct handling are to be followed. The climatic specifications as per the sec. "Technical data" are to be met. Device types The series PSC1-C-100 comprises The basic devices PSC1-C-100 optionally with Integrated communication modules Standard fieldbus PSC1-C-100-FBx ) or... -

Page 15: Module Overview

Installation manual 3.6 Module overview Basic modules Expansion modules Designation PSC1-E-131- PSC1-E-133- PSC1-E-37-14DI- PSC1-E- PSC1-E-22- PSC1-E-23- PSC1-E-24- PSC1-C-100(-FBx 12DI-10DIO 12DI-6DIO-4RO 4DO-2RO-RIO 21-SDM1 SDM1-2** SDM2 SDM2-2 General data Max. number of expansion modules Safe digital inputs Safe digital I/O Safe digital outputs switching / pp switching Safe analogue inputs Relay outputs (1-channel) -

Page 16: Device Characteristic Data

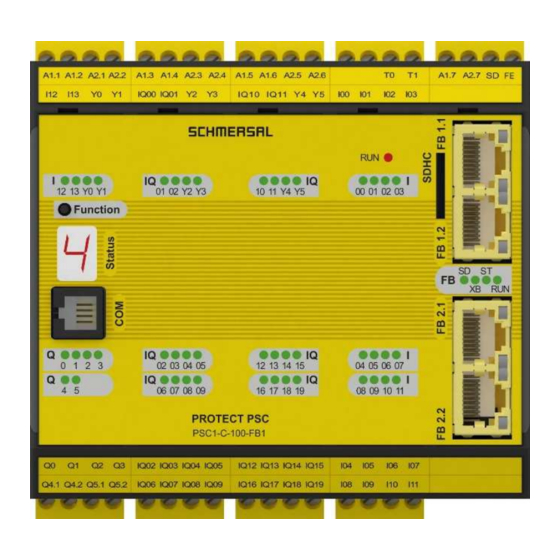

Installation manual 3.7 Device characteristic data 3.7.1 Basic modules 3.7.1.1 PSC1-C-100 (-FBx ) (-MC) Type designation Device features Version of the module with following peripherals: digital inputs pulse outputs digital I/Os relay outputs (1-channel) pn or pp switching outputs signal outputs diagnostics and configuration interface... - Page 17 Installation manual • Parameter administration for expansion modules in the basic device • Contact multiplication or contact rating increase by means of external contactors in conjunction with integrated monitoring possible • Comprehensive diagnostic functions integrated in the firmware • Coded status indication via 7-segment display and status LEDs on front •...

- Page 18 Installation manual 3.7.1.1.1 Tech. characteristic data PSC1-C-100 (-FBx Safety-related characteristic data PL according to EN ISO 13849 max. PL e PFH / architecture 12.2 * 10 / KAT 4 SIL according to IEC 61508 SIL 3 Proof test interval 20 years = max. service life General data Max.

- Page 19 Installation manual Environmental data Temperature 0°C … +50°C operation -25C° … +70C° storage, transport Degree of protection IP 20 Climatic class 3k3 according to DIN 60 721-3 Minimum, maximum relative humidity 5% - 85% (no condensation) EN 61000-6-2, EN 61000-6-4, EN 61000-6-7, EN 61800-3, EN 61326-3, EN 62061 Use of operating equipment 2000m...

-

Page 20: Central Expansion Modules

Installation manual 3.7.2 Central expansion modules 3.7.2.1 Expansion module PSC1-E-21-SDM1 Type designation Device features Version of the module with following peripherals: axis encoder interfaces (*) digital inputs status LED status LEDs for inputs Properties of the module: • Movement monitoring on an axis up to PL e according to EN ISO 13849-1 or SIL 3 as per IEC 61508 o Velocity monitoring o Speed monitoring... - Page 21 Installation manual 3.7.2.1.1 Tech. characteristic data PSC1-E-21-SDM1 Safety-related characteristic data PL according to EN ISO 13849 PL e /architecture 3 * 10 / KAT 4 SIL according to IEC 61508 SIL 3 Proof test interval 20 years = max. service life General data Max.

-

Page 22: Expansion Module Psc1-E-22-Sdm1-2

Installation manual 3.7.2.2 Expansion module PSC1-E-22-SDM1-2 Type designation Device features Version of the module with following peripherals: expanded axis encoder interfaces (*) digital inputs status LED status LEDs for inputs Properties of the module: • Movement monitoring on an axis up to PL e according to EN ISO 13849-1 or SIL 3 as per IEC 61508 o Velocity monitoring o Speed monitoring... - Page 23 Installation manual 3.7.2.2.1 Tech. characteristic data PSC1-E-22-SDM1-2 Safety-related characteristic data PL according to EN ISO 13849 PL e /architecture 3 * 10 / KAT 4 SIL according to IEC 61508 SIL 3 Proof test interval 20 years = max. service life General data Max.

-

Page 24: Expansion Module Psc1-E-23-Sdm2

Installation manual 3.7.2.3 Expansion module PSC1-E-23-SDM2 Type designation Device features Version of the module with following peripherals: axes encoder interfaces (*) digital inputs status LED status LEDs for inputs Properties of the module: • Movement monitoring on an axis up to PL e according to EN ISO 13849-1 or SIL 3 as per IEC 61508 o Velocity monitoring o Speed monitoring... - Page 25 Installation manual 3.7.2.3.1 Tech. characteristic data PSC1-E-23-SDM2 Safety-related characteristic data PL according to EN ISO 13849 PL e 3 * 10 / KAT 4 /architecture 6.5 * 10 / KAT 4 SIL according to IEC 61508 SIL 3 Proof test interval 20 years = max.

-

Page 26: Expansion Module Psc1-E-24-Sdm2-2

Installation manual 3.7.2.4 Expansion module PSC1-E-24-SDM2-2 Type designation Device features Version of the module with following peripherals: expanded axes encoder interfaces (*) digital inputs status LED status LEDs for inputs Properties of the module: • Movement monitoring on an axis up to PL e according to EN ISO 13849-1 or SIL 3 as per IEC 61508 o Velocity monitoring o Speed monitoring... - Page 27 Installation manual 3.7.2.4.1 Tech. characteristic data PSC1-E-24-SDM2-2 Safety-related characteristic data PL according to EN ISO 13849 PL e 6,5 * 10 / KAT 4 /architecture SIL according to IEC 61508 SIL 3 Proof test interval 20 years = max. service life General data Max.

-

Page 28: Expansion Modules Psc1-E-131 And Psc1-E-133

Installation manual 3.7.2.5 Expansion modules PSC1-E-131 and PSC1-E-133 Type designation Device features Version of the module with following peripherals: digital inputs 10/6 digital I/O pulse outputs signal outputs relay outputs (1-channel) (PSC1-E-131/133) status LEDs for inputs status LEDs for relay outputs (PSC1-E-131/133) 10/6 status LEDs for I/O... - Page 29 Installation manual 3.7.2.5.1 Tech. characteristic data: PSC1-E-131 and PSC1-E-133 Safety-related characteristic data PL according to EN ISO 13849 PL e /architecture 9.2 * 10 /KAT 4 + on PSC1-E-133 1-channel per relay 2 * 10 (KAT 1) 2-channel per relay 1 * 10 (KAT 4) SIL according to EN 61508 SIL 3...

- Page 30 Installation manual Mechanical data Size PSC1-E-131 = 100x115x45 (HxDxW [mm]) PSC1-E-133 = 100x115x67.5 Weight PSC1-E-131 = 300 g PSC1-E-133 = 400 g Attachment Can be snapped to DIN rail Number of T-bus connector Included in the scope of delivery PSC1-E-131 PSC1-E-133 Min.

-

Page 31: Decentral Expansion Module

Installation manual 3.7.3 Decentral expansion module 3.7.3.1 PSC1-E-37 Type designation Device features Version of the module with following peripherals: digital inputs pulse outputs relay outputs (1-channel) pn or pp switching outputs signal outputs 7-segment display status LED status LEDs for inputs status LEDs for relay outputs status LEDs for outputs Properties of the module:... - Page 32 Installation manual 3.7.3.1.1 Tech. characteristic data: PSC1-E-37 Safety-related characteristic data PL according to EN ISO 13849 PL e /architecture 12.6 * 10 / KAT 4 SIL according to EN 61508 SIL 3 Proof test interval 20 years = max. service life General data Connection RJ45 (SDDC)

-

Page 33: Psc1-E-37

Installation manual Environmental data Temperature 0°C … +50°C operation -25C° … +70C° storage, transport Degree of protection IP 20 Climatic class 3k3 according to DIN 60 721-3 Minimum, maximum relative humidity 5% - 85% (no condensation) EN 61000-6-2, EN 61000-6-4, EN 61000-6-7, EN 61800-3, EN 61326-3, EN 62061 Use of operating equipment 2000m... -

Page 34: Optional Universal Communication Interface

Options: on request Properties of the universal communication interface: • Optional version of the communication interface for the PSC1 series • The different versions can be combined. See "Possible combinations". • For more detailed information, please refer to the installation manuals for the related fieldbus modules. -

Page 35: Tech. Characteristic Data: Optional Universal Communication Interface

Installation manual 3.7.4.1 Tech. characteristic data: Optional universal communication interface Safety-related characteristic data PL according to EN ISO 13849 n.a. PFH / architecture n.a. SIL according to EN 61508 n.a. Proof test interval n.a. General data Decentral communication interfaces 2x RJ 45* Fieldbus interfaces -FB1 2x RJ 45**... -

Page 36: Using The Memory Card

Installation manual Possible combinations FBx module is built into the following devices and not available separately. Versions -FB1 -FB2 SDDC SMMC PSC1-C-100 PSC1-E-131 PSC1-E-133 PSC1-E-37 Options: In preparation/always with option –FB1/2 or integrated into the module PSC1-E-37 On request/always with option –FB1/2 3.7.4.2 Using the memory card Any industrial microSD card between 2 MB and 16 GB may be used with FAT16 or FAT32 file system. -

Page 37: Encoder Specifications

Installation manual 3.7.5 Encoder specifications Encoder Connection Diagnostics Value type SIN/COS; TTL X1; X2 Max. frequency 200 kHz X3; X4 Max. frequency 250 kHz Amplitude SIN/COS 1 Vpp +/- 0.3 V Type of connection Sub-D 9-pin SSI absolute X1; X2 Clock frequency Master mode 150 kHz / slave mode max. -

Page 38: Marking

Installation manual 3.9 Marking The type plate is attached to the left side wall of the module and contains the following information: 3.9.1 Type plate • Type designation • Part number/item number • Serial number • Hardware release identifier • Software release identifier •... -

Page 39: Items Supplied

Installation manual 3.9.2 Items supplied Included in the items supplied: • PSC1 module: • Connectors for all signal terminals not including encoder connection Not included in the items supplied: • SafePLC2 software package (order designation: PSC1-A-91-SAFEPLC2) consisting of: o CD with configuration software o Licence dongle o Installation manual o Programming manual... -

Page 40: Safety-Related Features

Installation manual 4 Safety-related features 4.1 General layout, safety-related architecture and characteristic data The internal layout of the PSC1 series comprises two separate channels with mutual result comparison. High-quality diagnostics are undertaken in each of the two channels for fault detection. - Page 41 Installation manual Specifically, a differentiation must be made between the following cases: a) Axis module with safety function related to one axis or use of safe inputs on an expansion module and shutdown channel via outputs on the basic module SDDC Sensor Kommunikation...

- Page 42 Installation manual d) Axis module with safety function related to one axis or usage of safe inputs on an expansion module and shutdown channel via outputs on an expansion module SDDC SDDC Kommunikation Kommunikation Aktuator Basisbaugruppe Erweiterungsbaugruppe Erweiterungsbaugruppe PSC1-C-100 -System = PFH + PFH + PFH...

- Page 43 Installation manual Characteristic data: • SIL 3 as per IEC 61508 Max. achievable safety class • Category 4 as per EN945-1 • Performance Level e as per EN ISO 13849-1 2-channel with diagnostics (1oo2) according to System structure IEC 61508 Architecture category 4 according to EN ISO 13849 "High demand"...

-

Page 44: Safety-Related Characteristic Data And Circuitry For Sensors Connected

Installation manual 4.2 Safety-related characteristic data and circuitry for sensors connected The PSC1 modules have completely redundant signal processing paths for each safety input. In addition, measures for obtaining the highest possible DC values are implemented. 4.2.1 Digital sensors The digital inputs are completely redundant. The details for the categorisation, the DC and the achievable PL or SIL are listed in the following. -

Page 45: Dc Digital Sensors/Inputs

Installation manual 4.2.1.2 DC digital sensors/inputs The PSC1 modules provide wide-ranging diagnostic functions for the input sub-system. These are designed as continuous, or optional (cross-circuit monitoring using pulse detection, cross comparison, 2-channel or multiple-channel sensor with/without time monitoring, startup test). Continuously active diagnostic functions: Cross comparison: The inputs on the PSC1 modules are in principle designed internally as dual-channel. - Page 46 Installation manual Start-up testing: Each time the safety module is switched on (=PSC1 module), the input element must be tested in the low signal status direction (= defined safe status), e.g. actuation of the emergency stop button or a door lock after system start. Operative / organisational tests: Beyond the diagnostic measures on the PSC1 modules stated above, cyclic testing can be undertaken in the application.

- Page 47 Installation manual For the safety-related assessment of the overall system, it is therefore possible in principle to use the following diagnostics for the input sensors: Characteristics Tests that can be Definition of the Comment of the input configured / operative measure element tests...

- Page 48 Installation manual Safety instructions: • For a safety-related assessment of the sensor sub-system, the information from the manufacturer (MTTF , PFH figures etc.) is to be used. • The DC values stated in the table should be used conservatively and compliance with the boundary conditions (see "Comments"...

-

Page 49: Classification Of The Safe Digital Inputs

Installation manual 4.2.1.3 Classification of the safe digital inputs 4.2.1.3.1 Digital inputs I00 … I13 Digital inputs Performance Level Remark that can be achieved Suitable for all types of input elements, with / I00 … I03 without pulses, achievable PL dependent on PL e I08 …... - Page 50 Installation manual 4.2.1.3.2 Digital inputs I/O (IQIx) Digital inputs Achievable Remark Performance Level Without pulse, single-channel static signal -> Auxiliary input Without pulse, dual-channel static signal At least one demand/day due to PL e application Fault detection only on demand Without pulse, dual-channel static signal PL d Less than one demand/day due to...

-

Page 51: Connection Examples, Digital Sensors/Safety Switch

Installation manual 4.2.1.4 Connection examples, digital sensors/safety switch Attention! Identifiers for "Xxy" terminal blocks, e.g. X14, are not printed on the terminal blocks. They are used in Section Fehler! Verweisquelle konnte nicht gefunden werden. Fehler! Verweisquelle konnte nicht gefunden werden. to find the individual terminals more quickly, e.g. - Page 52 Installation manual On the usage of a single-channel sensor with test pulses, one connection is connected to the test pulse output T0 or T1 of the PSC1. The pulse assignment must then also be carried out in the SafePLC2. The use of a single-channel sensor with test pulses detects: Short-circuit to the supply voltage DC 24 V Short-circuit to DC 0 V Cable break (interruption of power is safe state! )

- Page 53 Installation manual 4.2.1.4.3 Dual-channel sensor without time monitoring and without cross-circuit testing Faults are detected as a minimum on demand. The DC is medium and can be changed to the high category by using cyclic tests (start tests, operative/organisational tests) depending on the test frequency.

- Page 54 Installation manual • PL d or higher according to EN ISO 13849-1 is achieved on the usage of switching elements / sensors with positively opening contacts or positive actuation according to EN 60947-5-1. When using sensors with non positive break contacts, the "Universal Input Module" macro (group) must be used in SafePLC2.

- Page 55 Installation manual 4.2.1.4.4 Dual-channel sensor with time monitoring and cross-circuit testing By using two independent test pulse signals on the homogeneous sensor, all cross-circuits and connections to DC 24 V and DC 0 V can be detected. PL d or higher according to EN ISO 13849-1 can be achieved on: •...

-

Page 56: Overview Of Achievable Pl For Digital Safety Inputs

Installation manual 4.2.1.5 Overview of achievable PL for digital safety inputs Type of Input Tests that can be Achieva Fault exclusion for Condition for input sensor / configured / ble PL input element element input operative tests accordi element ng to EN ISO 13849-1 Input element proven in... - Page 57 Installation manual Type of Input Tests that can be Achieva Fault exclusion for Condition for input sensor / configured / ble PL input element element input operative tests accordi element ng to EN ISO 13849-1 Short-circuit on the Connection in the switch input/signal wire cabinet or protected laying Stuck / positive opening...

-

Page 58: Sensors For Speed And/Or Position Acquisition

Installation manual 4.2.2 Sensors for speed and/or position acquisition 4.2.2.1 General safety-related layout of sensor interface for position and/or speed Optionally, the expansion modules in the PSC1-C100 series have one (PSC1-E-21-SDM1, PSC1-E-23-SDM2) or two encoder interfaces (PSC1-E-22-SDM1-2, PSC1-E-24-SDM2-2) per axis. Different safety levels can be achieved depending on the encoder type and encoder combination. -

Page 59: General Diagnostic Measures For Encoder Interface

4.2.2.2 General diagnostic measures for encoder interface For fault detection in the sensor system, a series of diagnostic measures is implemented in the PSC1 series depending on the encoder type selected and their combination. The measures are activated automatically with the selection of the encoder type. -

Page 60: Encoder Types And Their Combinations, Diagnostic Characteristic Data

Installation manual 4.2.2.3 Encoder types and their combinations, diagnostic characteristic data The following cases must be considered for use of the axis monitoring modules: PSC1-E-21-SDM1: • 1 independent axis: o Axis 1: Combination table: Column X1/X2, optional 2: o Designation on device: Axis 1: X1 optional X23 ... - Page 61 Installation manual PSC1-E-24-SDM2-2: • 2 axes each with 2 encoders (so-called extended axes) o Axis 1: Combination in table: Encoder 1: Column X1/X2, encoder 2: Column X3/X4 o Axis 2: Combination in table: Encoder 1: Column X1/X2, encoder 2: Column X3/X4 ...

- Page 62 Installation manual Type Type Type Safe Safe Safe Fault exclusion speed directio position Encoder on Encoder on Encoder on interface interface X 23 1-channel 2-channel 2-channel X1/2 X3/4 sub-system sub-system sub-system Input dynamic non- dynamic (I04…I07) (standstill monitoring) Fault exclusion mech. shaft fracture, positive 1 x proximity locking encoder shaft connection required if switch...

- Page 63 Installation manual 1 x proximity Incremental n.a. 90-95% switch 2 x proximity Incremental n.a. 90-95% switch 90° Incremental SIN/COS n.a. Incremental n.a. 90-95% Type Type Type Safe Safe Safe Fault exclusion speed directio position Encoder on Encoder on Encoder on interface interface X 23...

- Page 64 Installation manual Type Type Type Safe Safe Safe Fault exclusion speed directio position Encoder on Encoder on Encoder on interface interface X 23 1-channel 2-channel 2-channel X1/2 X3/4 sub-system sub- sub-system Input system non- dynamic dynamic (I04…I07) (standstill monitoring) SIN/COS n.a.

- Page 65 Installation manual Type Type Type Safe Safe Safe Fault exclusion speed directio position Encoder on Encoder on Encoder on interface interface X 23 1-channel 2-channel 2-channel X1/2 X3/4 sub-system sub- sub-system Input system non- dynamic dynamic (I04…I07) (standstill monitoring) Fault exclusion mech. shaft fracture, positive 80-90% locking encoder shaft connection required 2 x proximity...

-

Page 66: Specific Diagnostic Measures In Relation To The Encoder Type Used

Installation manual 4.2.2.4 Specific diagnostic measures in relation to the encoder type used Encoder type Incremental SIN/COS Proximity switch 2 x count input Proximity switch 1 x count input Incremental Resolver SIN_COS Options: Only in the high-resolution mode in preparation HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 66 of 201 Version: 25F... -

Page 67: Safety-Related Shutdown Thresholds, Encoder Systems For Position And Speed Acquisition

Installation manual 4.2.2.5 Safety-related shutdown thresholds, encoder systems for position and speed acquisition As a basic measure, plausibility tests between the two measurement channels A and B for speed and position on the PSC1 module are undertaken with the actual values for position and speed and tested against configured thresholds. - Page 68 Installation manual Value Acceleration [rev/min/s] Resolution Graph of acceleration resolution, rotary (values in rev/min/s) Value Acceleration [mm/s ] and [m/s ² ² Resolution Graph of acceleration resolution, linear (values in mm/s and m/s²) HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 68 of 201 Version: 25F...

- Page 69 Installation manual Safety instructions: • The error can be optimised by the suitable selection of the sensor resolution for the related application. • For applications with limited resolution and/or time variance in the sampled signal, the functionality of the monitoring functions used can be improved by the usage of a mean value filter.

-

Page 70: Safety-Related Assessment Of The Encoder Types And Their Combination

Installation manual 4.2.2.6 Safety-related assessment of the encoder types and their combination Due to the monitoring functions implemented in the PSC1 series, in applications with encoder systems there are initially no special requirements on the internal layout of the encoder electronics, i.e. - Page 71 Installation manual • When using compact encoders with a dual-channel internal layout, e.g. SSI + incremental/SinCos, the instructions from the manufacturer in relation to the safety- related properties of diagnostic measures, mechanical connection and measures for the supply of power must be followed. The encoder's safety level must correspond as a minimum to the safety level required for the overall arrangement.

-

Page 72: Safety-Related Characteristic Data And Circuitry For The Outputs

Installation manual 4.3 Safety-related characteristic data and circuitry for the outputs The PSC1 modules have safe outputs of a different type. In the circuitry the related characteristic as per the description below is to be taken into account. 4.3.1 Characteristics of the output elements Single-channel output PSC1 and single-channel actuator without diagnostics Single-channel output PSC1 and single-channel actuator with diagnostics Single-channel output PSC1 (Q 4/5, Q0/2_P, Q1/3_N) and dual-channel actuator... - Page 73 Installation manual Single-channel output PSC1 with internal dual-channel processing (IQQx) and dual-channel actuator with dual- channel diagnostics Dual-channel output PSC1 and dual-channel actuator with diagnostics Dual-channel output PSC1 and dual-channel actuator with dual-channel diagnostics HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 73 of 201 Version: 25F...

-

Page 74: Diagnostics In The Shutdown Circuit

Installation manual 4.3.2 Diagnostics in the shutdown circuit The shutdown circuits have diagnostic functions with a fixed implementation and diagnostic functions that can be configured. Certain diagnostic functions also include the external part of the shutdown circuit. The various DC values are dependent on the usage of these diagnostic functions. -

Page 75: Overview Of Dc In Relation To Selected Diagnostic Functions

Installation manual 4.3.2.2 Overview of DC in relation to selected diagnostic functions Measure Comment Usage Monitoring of outputs by one 0-90% DC dependent on the Monitoring of channel without dynamic test switching frequency electromechanical, pneumatic or hydraulic When using elements for actuators / outputs increasing the switching rating (external relays or contactors),... -

Page 76: Permissible Capacitive And Inductive Load On Safe Outputs

Installation manual 4.3.3 Permissible capacitive and inductive load on safe outputs The safe outputs on the PSC1 are of an OSSD character. I.e. the outputs are shut down cyclically to test the shutdown capability and the status read back. The test on the shutdown capability is undertaken based on the following criteria / functions: After the shutdown of the output, the output voltage is allowed to be max. -

Page 77: Digital Outputs

4.3.4 Digital outputs The modules • PSC1-C-100 • PSC1-E-131-..., PSC1-E-133-..., PSC1-E-37-... each have identical outputs. The PSC1 series provides different types of outputs that can be connected together either separately or in groups. Output Architecture Remark according to EN ISO 13849-1... - Page 78 Installation manual Safety instructions: • For applications with frequent demand for the safety shutdown, testing should be at short intervals, e.g. at the start of the shift, 1 x per week. However, a test should be undertaken cyclically at least 1 x per year. •...

-

Page 79: Example Circuits, Basic Outputs

Installation manual 4.3.4.1 Example circuits, basic outputs Attention! Identifiers for "Xxy" terminal blocks e.g. X21 are not printed on the terminal blocks. They are used in Section Fehler! Verweisquelle konnte nicht gefunden werden. Fehler! Verweisquelle konnte nicht gefunden werden. to find the individual terminals more quickly, e.g. - Page 80 Installation manual 4.3.4.1.2 Single-channel switching relay or semiconductor output with external device for increasing the switching rating and testing On the usage of an external device for increasing the switching rating, or downstream electromechanical, pneumatic or hydraulic components, a device for testing the complete chain and a signalling/warning device on the detection of a fault are required to achieve PL c or higher.

- Page 81 Installation manual 4.3.4.1.3 Single-channel switching relay or semiconductor output with dual-channel external circuit with testing For safety applications from PL c according to EN ISO 13849-1, it is recommended or required that two external shutdown elements are operated. In addition, a device for testing the complete chain and a signalling/warning device on the detection of a fault are required to achieve PL c or higher –...

- Page 82 Installation manual Q0_P Q1_N Q2_P Q3_N Single-channel switching output Q0_P with dual-channel external circuit as combination of electromechanical element and hydraulic/pneumatic valve monitoring on two inputs Safety instructions: • Only recommended to a limited extent for safety applications! On this topic, see also the information in EN ISO 13849-1 on usage and the fault exclusions necessary.

- Page 83 Installation manual 4.3.4.1.4 Dual-channel switching relay output with external monitoring - collective feedback For safety applications from PL d according to EN ISO 13849-1, two relays are used in the PSC1-C-100 module and two external contactors. Q4.1 Q4.2 Q5.1 Q5.2 Dual-channel switching relay output with external monitoring –...

- Page 84 Installation manual 4.3.4.1.5 Dual-channel output with relay output and semiconductor output – external control circuit with monitoring For safety applications from PL d and higher according to EN ISO 13849-1. The external circuit is operated using two channels via one relay output and one semiconductor output. Each of the two external shutdown paths is monitored.

- Page 85 Installation manual 4.3.4.1.7 Dual-channel output with semiconductor output and external control circuit in PL e For safety applications from PL d and higher according to EN ISO 13849-1. The external circuit is operated using two channels via semiconductor outputs. PL e is required for the external circuit for PL e according to EN ISO 13849-1.

-

Page 86: Digital Outputs I/O (Iqqx)

Installation manual 4.3.5 Digital outputs I/O (IQQx) The modules PSC1-C-100, PSC1-E-131-… and PSC1-E-133-… have a different number of configurable safe digital I/Os (see section 3.1 Module overview). Configured as an output, this connection acts as a safe digital pp switching output (IQQx). 4.3.5.1 Classification of the I/O (IQQx) when used as an output Classification Achievable... -

Page 87: Example Circuits For Safe Digital Outputs I/O (Iqqx)

Installation manual 4.3.5.2 Example circuits for safe digital outputs I/O (IQQx) Attention! Identifiers for "Xxy" terminal blocks e.g. X12 are not printed on the terminal blocks. They are used in Section Fehler! Verweisquelle konnte nicht gefunden werden. Fehler! Verweisquelle konnte nicht gefunden werden. to find the individual terminals more quickly, e.g. - Page 88 Installation manual 4.3.5.2.2 Single-channel circuit with testing When using a dual-channel output (IQQx) in conjunction with a single-channel external circuit with testing. In particular, positively driven auxiliary contacts are required for electromechanical devices, or valve position signal contacts are required for this purpose for hydraulic or pneumatic components.

- Page 89 Installation manual 4.3.5.2.3 Circuit with safe shutdown circuit For safety applications from PL c and higher according to EN ISO 13849-1. The external circuit is operated directly using a dual-channel output. The achievable PL according to EN ISO 13849-1 is dependent on the usage of dynamic testing (see 4.3.2.1 DC) as well as the PL for the downstream device.

- Page 90 Installation manual Safety instructions: • For the safety-related assessment of the output sub-system, on the usage of external elements in the shutdown circuit, e.g. for increasing the switching rating, the information from the manufacturer (MTTF , PFH figures, B10d value etc.) is to be used. •...

- Page 91 Installation manual 4.3.5.2.5 Redundant dual-channel output Suitable for PL d or higher according to EN ISO 13849-1. Use of two outputs IQQx in conjunction with a dual-channel external circuit. 4.3.5.2.5.1 Dual-channel circuit in same group IQQ00 IQQ01 IQQ02 IQQ03 IQQ04 IQQ05 IQQ06 IQQ07...

- Page 92 Installation manual 4.3.5.2.5.2 Dual-channel circuit in different groups IQQ00 IQQ01 IQQ02 IQQ03 IQQ04 IQQ05 IQQ06 IQQ07 IQQ08 IQQ09 Redundant dual-channel outputs in different groups in conjunction with dual-channel shutdown circuit Safety instructions: • For the safety-related assessment of the output sub-system, the data from the manufacturer (MTTFD, FIT figures, B10d value, etc.) must be used when using external elements in the shutdown circuit, e.g.

-

Page 93: Overview Of Achievable Pl For Digital Safety Outputs

Installation manual 4.3.5.3 Overview of achievable PL for digital safety outputs Output Actuator / Catego MTTF Achie Boundary condition Fault PSC1 external actuat vable exclusion shutdown accord circuit ing to accor EN ISO ding 13849- to EN 13849- Single- Single-channel Cat. - Page 94 Installation manual Output Actuator / Catego MTTF Achiev Boundary condition Fault PSC1 external actuat able exclusion shutdown accord circuit ing to accord EN ISO ing to 13849- EN ISO 13849- Dual-channel Dual-channel Cat. 3 Monitori Medium Contactor and Short-circuit without Contactor, valve, ng in or high...

-

Page 95: Connection And Installation

Installation manual 5 Connection and installation 5.1 General installation instructions It is imperative you follow the safety instructions during installation! Degree of protection IP20 Lay all signal wires for connection to the digital inputs and contact monitoring separately. In all circumstances, separate voltages of 230 VAC from low-voltage wires if these voltages are used in relation to the application The length of the cables for the digital inputs and outputs should in general not exceed 30 m. -

Page 96: Installation And Mounting Psc1 Module

Installation manual • All contactors in the area of the converter must be equipped with an appropriate suppressor circuit. • All contactors or comparable switching amplifiers must be equipped with appropriate protective circuitry (e.g. free-wheeling diodes). • Suitable measures for protection against overvoltages are to be taken. 5.2 Installation and mounting PSC1 module The module is only installed in switch cabinets that meet degree of protection IP54 as a minimum. -

Page 97: Arrangement Examples

Installation manual 5.3.1 Arrangement examples 5.3.1.1 PSC1-C-100-FBx + PSC1-E-23-SDM2 PSC1-E-23-SDM2 PSC1-C-100-FBx 5.3.1.2 PSC1-C-100 + PSC1-E-24-SDM2-2 PSC1-E-24-SDM2-2 PSC1-C-100 HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 97 of 201 Version: 25F... -

Page 98: Mounting The Modules

Installation manual 5.4 Mounting the modules The modules are mounted on standard C rails using a snap-action catch 5.4.1 5.4.1 Mounting on C rail The devices are fitted to the rail from above at an angle and snapped downward. They are removed using a screwdriver that is inserted in the slot on the catch protruding from the bottom of the device and then moved upward. -

Page 99: Mounting On Backplane Bus

Installation manual 5.4.2 Mounting on backplane bus The device can be installed after mounting the backplane bus. For this purpose the module is fitted to the connector at an angle from above and snapped to the C rail Fit module at an angle from above Snap down onto the C rail HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 99 of 201... -

Page 100: Installation And Configuration Of Master Master (Smmc) And Master Slave (Sddc)

Installation manual The backplane connection can be retrofitted. In this way the system configuration can be expanded with additional modules. Snap backplane bus element to C rail and insert in the mating piece by pushing to the side 5.5 Installation and configuration of master master (SMMC) and master ... -

Page 101: Schematic Diagram Of The Network Topology

Installation manual 5.5.1 Schematic diagram of the network topology SMMC SDDC CAN (central) SDDC ETH (decentral) Communication of a PSC1 compact with • Central expansion modules via SDDC CAN backplane bus • SMMC via Ethernet Communication of a PSC1 modular with •... -

Page 102: Installation Of I/O Expansion

Installation manual 5.6 Installation of I/O expansion Note: Max. eight PSC1-E-13x modules can be operated using a basic device. 5.6.1.1 Physical address configuration for the slave modules (central/decentral) The bus address must be set on the PSC1-E-13x modules with the aid of the address switch. The address is set on the rear panel depending on the slot (mounting position) of the module. -

Page 103: Terminal Assignment

Installation manual 5.7 Terminal assignment Attention! Identifiers for "Xxy" terminal blocks, e.g. X41, are not printed on the terminal blocks. They are used in this Section to find the individual terminals more quickly, e.g. "A1.1" in the diagrams and the terminal assignment. HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 103 of 201 Version: 25F... -

Page 104: Terminal Assignment Psc1-C-100 (-Fbx/-Mc)

Installation manual 5.7.1 Terminal assignment PSC1-C-100 (-FBx/-MC) Option FB1/FB2 Terminal assignment Unit Terminal Description Note 1 – A1.1 Device power supply +24 VDC 2 – A1.2 Device power supply +24 VDC outputs 3 – A2.1 Device power supply 0 VDC 4 –... - Page 105 Installation manual Unit Termina Description Note 1 – A1.3 Device power supply +24 VDC 2 – A1.4 Device power supply +24 VDC outputs 3 – A2.3 Device power supply 0 VDC 4 – A2.4 1 – IQ00 Safe digital inputs, outputs pp switching 2 –...

-

Page 106: Terminal Assignment Psc1-E-21-Sdm1

Installation manual 5.7.2 Terminal assignment PSC1-E-21-SDM1 Unit Terminal Description Note 1 – UE1+ Encoder power supply DC (X1) 2 – UE1- Encoder power supply 0V DC (X1) 3 – NC No function 4 – NC 1 – I 00 2 – I 01 3 –... -

Page 107: Terminal Assignment Psc1-E-22-Sdm1-2

Installation manual 5.7.3 Terminal assignment PSC1-E-22-SDM1-2 Encoder Ext. Unit Terminal Description Note 1 – UE1+ Encoder power supply DC (X1) 2 – UE1- Encoder power supply 0V DC (X1) 3 – NC No function 4 – NC 1 – I 00 2 –... - Page 108 Installation manual 1 – I 08 2 – I 09 3 – I 10 4 – I 11 1 – UE3+ Encoder power supply DC (X3) 2 – UE3- Encoder power supply 0V DC (X3) 3 – UR3 U reference X3 4 –...

-

Page 109: Terminal Assignment Psc1-E-23-Sdm2

Installation manual 5.7.4 Terminal assignment PSC1-E-23-SDM2 Unit Terminal Description Note 1 – UE1+ Encoder power supply DC (X1) 2 – UE1- Encoder power supply 0V DC (X1) 3 – NC No function 4 – NC 1 – I 00 2 – I 01 3 –... - Page 110 Installation manual Unit Terminal Description Note 1 – UE2+ Encoder power supply DC (X2) 2 – UE2- Encoder power supply 0V DC (X2) 3 – NC No function 4 – NC 1 – NC 2 – NC 3 – NC 4 –...

-

Page 111: Terminal Assignment Psc1-E-24-Sdm2-2

Installation manual 5.7.5 Terminal assignment PSC1-E-24-SDM2-2 Encoder Ext. Encoder Ext. Unit Terminal Description Note 1 – UE1+ Encoder power supply DC (X1) 2 – UE1- Encoder power supply 0V DC (X1) 3 – NC No function 4 – NC 1 – I 00 2 –... - Page 112 Installation manual 1 – I 08 2 – I 09 3 – I 10 4 – I 11 1 – UE3+ Encoder power supply DC (X3) 2 – UE3- Encoder power supply 0V DC (X3) 3 – UR3 U reference X3 4 –...

- Page 113 Installation manual Unit Terminal Description Note 1 – UE2+ Encoder power supply DC (X2) 2 – UE2- Encoder power supply 0V DC (X2) 3 – NC No function 4 – NC 1 – NC 2 – NC 3 – NC 4 –...

-

Page 114: Terminal Assignment Psc1-E-131

Installation manual 5.7.6 Terminal assignment PSC1-E-131 Terminal assignment Unit Terminal Description Note 1 – A1.1 Device power supply +24V DC Attention: see: "External 24 VDC 2 – A1.2 Device power supply +24V DC power supply" 3 – A2.1 Device power supply 0V DC 4 –... -

Page 115: Terminal Assignment Psc1-E-133

Installation manual 5.7.7 Terminal assignment PSC1-E-133 EXT-REL Note: The read-back contacts 0.11/12, 1.11/12, 2.11/12, 3.11/12 of the internal relays Q0, Q1, Q2, Q3 must be monitored for feedback loop monitoring (EMU) in addition to the read-back contacts of the connected contactors or other switching amplifiers. Terminal assignment Unit Terminal... - Page 116 Installation manual HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 116 of 201 Version: 25F...

- Page 117 Installation manual Terminal assignment Unit Terminal Description Note 1 – NC No function 2 – NC 3 – T0 Pulse outputs 4 – T1 1 – I 00 2 – I 01 3 – I 02 4 – I 03 1 –...

-

Page 118: Terminal Assignment Psc1-E-37

Installation manual 5.7.8 Terminal assignment PSC1-E-37 Terminal assignment Unit Terminal Description Note 1 – A1.1 Device power supply +24 VDC 2 – A1.2 Device power supply +24 VDC outputs 3 – A2.1 Device power supply 0 VDC 4 – A2.2 1 –... -

Page 119: Terminal Assignment Psc1-C-100-Fbx

Installation manual 5.7.9 Terminal assignment PSC1-C-100-FBx Please refer to the installation manual for PSC1 fieldbuses for the terminal assignments of the fieldbus or SDDC/SMMC interfaces of the various communication modules. HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 119 of 201 Version: 25F... -

Page 120: External 24 Vdc Power Supply

Installation manual 5.8 External 24 VDC power supply The PSC1 module requires a power supply of 24 VDC (on this topic see SELV or PELV, EN50178). During the planning and installation of the power supply unit to be used, attention is to be paid to the following boundary conditions: It is imperative the minimum and maximum tolerance on the supply voltage is observed. - Page 121 Q4.1 A1.1 A1.2 Q4.2 A2.1 Q5.1 A2.2 Q5.2 IQ02 IQ06 IQ03 IQ01 A1.3 IQ00 IQ03 A1.4 IQ07 IQ04 IQ02 IQ01 IQ04 IQ08 IQ05 A2.3 IQ05 A2.4 IQ09 IQ06 IQ12 A1.5 IQ16 IQ13 IQ11 IQ10 IQ13 A1.6 IQ14 IQ12 IQ17 IQ11 IQ14 A2.5 IQ18...

-

Page 122: Connection Of The External Encoder Supply

Installation manual 5.9 Connection of the external encoder supply 5.9.1 Incremental, HTL, SIN/COS, SSI UE3- UE4- UE3+ UE4+ UE2- UE1- UE1+ UE2+ PSC1 Spannungs- überwachung der externen Geber- versorgungs- spannungen Options: Only PSC1-E-22 and PSC1-E-24 Only PSC1-E-23 and PSC1-E-24 Only PSC1-E-24 The PSC1 module supports encoder voltages of 5 V, 8 V, 10 V, 12 V and 24 V that are monitored internally as per the configuration selected. - Page 123 Installation manual Monitoring of the supply voltage as per the nominal voltage selected: Nominal voltage Minimum voltage Maximum voltage 5 VDC 4.4 VDC 5.6 VDC 8 VDC 7 VDC 9 VDC 10 VDC 8 VDC 12 VDC 12 VDC 10 VDC 14 VDC 24 VDC 20 VDC...

-

Page 124: Resolver

Installation manual 5.9.2 Resolver UE3- UE4- PSC1 Referenz- Referenz- Signal- Signal- generierung generierung Only PSC1-E-22 and PSC1-E-24 Only PSC1-E-24 When using resolvers in master mode, an additional power supply with 24 V DC is required to generate the reference signal. The encoder supply must be protected with maximum 2 A. -

Page 125: Connection Of The Digital Inputs

Installation manual 5.10 Connection of the digital inputs • The PSC1 has 14 (PSC1-C-100 (-FBx) and PSC1-E-37) or 12 (PSC1-E-21-SDM1, PSC1-E-22-SDM1-2, PSC1-E-23-SDM2, PSC1-E-24-SDM2-2, PSC1-E-131/133) safe digital inputs. These are suitable for the connection of single or dual-channel signals with and without test pulses, or without cross-circuit testing. •... -

Page 126: Connection Of Position And Speed Sensors

Installation manual 5.11 Connection of position and speed sensors 5.11.1 General instructions Depending on the module type, the PSC1-C-100 axis expansion modules (PSC1-E-21-SDM1, PSC1-E-22-SDM1-2, PSC1-E-23-SDM2, PSC1-E-24-SDM2-2) have (2/4) external encoder interfaces for the connection of the usual industrial incremental and absolute encoders. The encoder interfaces can be configured for incremental, SIN/COS, absolute SSI encoders or for proximity switches. - Page 127 Installation manual Attention: The encoder connections are not allowed to be connected or disconnected in operation. Electrical components on the encoder may be irreparably damaged. Disconnect the connected encoders and the PSC1 module from the electrical supply before connecting or disconnecting the encoder connections. For externally supplied encoders, pay attention to shutting down the external supply voltage (e.g.

-

Page 128: Pin Assignment On The Encoder Interface

Installation manual 5.11.2 Pin assignment on the encoder interface X1/X2 X3/X4 HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 128 of 201 Version: 25F... -

Page 129: Connection Variants

Installation manual 5.11.3 Connection variants 5.11.3.1 Connection of an absolute encoder as master n.c. Pin 1 Ground Pin 2 GND for the supply voltage 24 V DC Pin 3 n.c. Pin 4 CLK- Pin 5 DATA+ Sub-D- Absolut- Stecker Encoder (9 polig) (Master-Betrieb) Pin 6... -

Page 130: Connection Of An Absolute Encoder As Slave

Installation manual 5.11.3.2 Connection of an absolute encoder as slave n.c. Pin 1 Pin 2 Ground Pin 3 n.c. Pin 4 CLK- Pin 5 Sub-D- DATA+ Absolut- Stecker Encoder (9 polig) (Slave-Betrieb) Pin 6 DATA- n.c. Pin 7 CLK+ Pin 8 Pin 9 Versorgungsspannung externes Abtastsystem... -

Page 131: Connection Of An Incremental Encoder With Ttl Signal Level

Installation manual 5.11.3.3 Connection of an incremental encoder with TTL signal level n.c. Pin 1 Pin 2 Ground Pin 3 n.c. Pin 4 Pin 5 Sub-D- Inkremental Stecker Encoder (9 polig) Pin 6 n.c. Pin 7 Pin 8 Pin 9 Versorgungsspannung Pins 1, 3 and 7 remain open and are reserved for later expansions. -

Page 132: Connection Of A Sin/Cos Encoder

Installation manual 5.11.3.4 Connection of a SIN/COS encoder n.c. Pin 1 Pin 2 Ground Pin 3 n.c. Pin 4 COS- Pin 5 SIN+ Sub-D- SIN/COS Stecker Geber (9 polig) Pin 6 SIN- n.c. Pin 7 COS+ Pin 8 Pin 9 Versorgungsspannung Pins 1, 3 and 7 remain open and are reserved for later expansions. -

Page 133: Connection Of Resolver As Master

Installation manual 5.11.3.5 Connection of resolver as master Reference Out + Pin 1 Reference Out - Pin 2 Reference In + Pin 3 Pin 4 COS - Pin 5 Sub-D- SIN + Stecker Resolver (9 polig) (Master-Betrieb) Pin 6 SIN - Pin 7 Reference In - COS +... -

Page 134: Connection Of Resolver As Slave

Installation manual 5.11.3.6 Connection of resolver as slave HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 134 of 201 Version: 25F... -

Page 135: Connection Of Proximity Switches

Installation manual 5.11.3.7 Connection of proximity switches Connection is via the connector X23 to the digital inputs I04 … I07. The exact pin assignment is dependent on which encoder type is used and is given in the connection diagram in the programming software user interface. Note: On the usage of HTL encoder, it is to be noted that the tracks A+ and B+ or A- and B- must be combined correspondingly. -

Page 136: Connection Of Htl/Proximity Switches

Installation manual 5.11.3.8 Connection of HTL/proximity switches Connection is via the connectors X27 and X28, or X29 and X30 5.11.3.8.1 HTL encoders with A+/A- and B+/B- signal Klemmleiste Inkremental Encoder Klemmleiste Versorgungsspannung Klemmleiste Ground Spannungsversorgung Geber Options: PSC1-E-22 encoder 3 PSC1-E-24 encoder 4 HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 136 of 201... - Page 137 Installation manual 5.11.3.8.2 HTL encoder with A+ and B+- signal Klemmleiste Inkremental Encoder Klemmleiste Versorgungsspannung Klemmleiste Ground Spannungsversorgung Geber Options: PSC1-E-22 encoder 3 PSC1-E-24 encoder 4 HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 137 of 201 Version: 25F...

-

Page 138: Configuration Of The Measurement Sections

Installation manual 5.12 Configuration of the measurement sections 5.12.1 General description of the encoder configuration The most important input variables for the module's monitoring functions are safe position, speed and acceleration. These are generated from the sensor systems connected using two channels. - Page 139 Installation manual SSI format parameter configuration: Example: SSI-Frame length: 28 pulses Data length: 22 bits Status: 5 bits, 3 bits error + 2 bits warning/ready for operation HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 139 of 201 Version: 25F...

-

Page 140: Incremental Encoder

Installation manual 5.12.2.2 Incremental encoder: Physical layer: RS-422 compatible Measured signal A/B: Track with 90 degree phase difference Maximum input pulse frequency: 200 kHz or 500 kHz Options: Standard incremental HighRes incremental Diagnostics: Diagnostics Parameter Fault threshold Supply voltage monitoring Fixed values See section Fehler! 5 V, 8 V, 10 V, 12 V, 20 V,... -

Page 141: Proximity Switch

Installation manual Diagnostics: Diagnostics Parameter Fault threshold Supply voltage monitoring Fixed values See section Fehler! 5 V, 8 V, 10 V, 12 V, 20 V, Verweisquelle konnte nicht 24 V gefunden werden. SIN²+COS² amplitude Fixed value 1V 65% or 1 V +/- 2.5% monitoring (measuring tolerance) -

Page 142: Extended Monitoring With 2 Proximity Switches

Installation manual 5.12.2.6 Extended monitoring with 2 proximity switches The expanded monitoring detects the following faults: a) Failure of the supply voltage b) Failure of the output signal in the driver direction c) Proximity switch functional failure for high signal d) Signal path interruption e) Mechanical maladjustment of proximity switch / excessively large proximity switching distance... -

Page 143: Htl Sensor

Installation manual Logic processing: The following evaluation is to be undertaken in both channels: Signal A Signal B Result False High True High True High High True 5.12.2.7 HTL sensor Signal level: 24 V/0 V Physical layer: Push/pull Measured signal A/B: Track with 90°... - Page 144 Installation manual Ref. frequency monitoring Fixed values +/- 20% +/-5% (measuring 6 .. 12 kHz in steps from 1 tolerance) kHz, 14 kHz, 16 kHz Reference signal shape Sine, triangle, no monitoring 40% shape deviation Monitoring of quadrant count Fixed value +/- 45°...

-

Page 145: Response Times Of The Psc1

Installation manual 6 Response times of the PSC1 The response time is an important safety-related property and must be taken into account for each application / safety function. In the following section the response times for individual functions, in some case also as a function of other parameters, are listed. If this information is inadequate for a specific application, the actual response must be validated against the required behaviour by means of specific measurements. -

Page 146: Response Times In Standard Operation

Installation manual 6.1 Response times in standard operation The basis for the calculation of response times is the cycle time of the PSC1. system. This can be selected in 3 stages and is in operation T_cycle = 16 / 24 / 32 ms. The response times stated correspond to the related maximum propagation time within the PSC1-C-100 module for the specific application. -

Page 147: Response Times For Fast_Channel

Installation manual 6.2 Response times for FAST_CHANNEL FAST_CHANNEL refers to a property of the PSC1-C-100 to react faster to speed requirements than is possible on processing the safety program in the normal cycle (= 16 / 24 / 32 ms). The sampling time of the FAST_CHANNEL is 2 ms + 2 ms for the signalling on the bus. - Page 148 Installation manual 0,60 Resp Resp Fault 0,50 V m. Overspeed Distanz [m/s] 0,40 V ohne Overspeed 0,30 Distanz [m/s] 0,20 0,10 0,02 0,06 0,1 0,14 0,18 0,22 0,26 0,3 0,34 0,38 0,42 0,46 0,5 0,14 0,12 0,10 0,08 0,06 s m. Overspeed Distanz [m] 0,04 s ohne Overspeed...

-

Page 149: Response Times When Using The Inputs And Outputs On The Expansion Modules

Installation manual For the V and s curves with overspeed distance the following applies: Parameter Acceleration method Remark Value from PSC1 response time data Delay in external shutdown Resp + delay in external shutdown chain chain from relay / contactor, brake manufacturer data etc. - Page 150 Installation manual Determination of the total response time TOTAL Example 1: Input on expansion module, activation of SLS and processing in PLC, output on basic module + 6 ms + T + 0 ms = 2 * T + 6 ms; TOTAL IN_Exp OUT_Base...

-

Page 151: Commissioning

Installation manual 7 Commissioning 7.1 Procedure Commissioning is only allowed to be undertaken by qualified personnel! Please follow the safety instructions during commissioning! 7.2 Sequences for switching on Each time after restarting the module, if there are no errors, the following phases are run through and displayed on the seven-segment display on the front: Mode Description... - Page 152 Installation manual When using the PSC1-C-100 with slave modules, bus errors may occur. The bus status messages are described in the following: Effect on Indication Description Reset condition system Can be reset by Initialisation/synchronisation with All outputs are switching off/on b0003 slave module.

-

Page 153: Reset Behaviour

Installation manual 7.3 Reset behaviour The reset function differentiates between a startup function after the return of the power supply = general reset and a status/alarm reset = "internal reset". The latter is triggered via the front button or an input configured accordingly = start/reset element with activated "alarm reset or logic reset"... -

Page 154: Reset Types And Triggering Element

Installation manual 7.3.1 Reset types and triggering element Reset type Triggering element Remark General reset Return of supply of power / device startup Reset function after completely switching off and on the device Internal reset The internal reset is triggered using the Reset button on the front Configuration of a... -

Page 155: Reset Timing

Installation manual 7.3.2 Reset timing An "Internal Reset" is triggered with the falling edge of the reset input. 7.3.3 Reset function Function unit General Internal Function Reset Reset Fatal error Reset error Alarm Reset alarm Monitoring functions Resetting a triggered monitoring function Flip-flop Status = Reset Timer... - Page 156 Installation manual Process value (speed) => no change to the output status on reset in the alarm state Time-based function => reset the output status, triggering if limit exceeded again Safety instructions: • For time-based functions, e.g. monitoring of the timing of complementary input signals, the output status is reset and a state defined as erroneous only detected if the (time) limit is exceeded again.

-

Page 157: Example Reset Function With Protection Against Incorrect Usage

Installation manual 7.3.3.1 Example reset function with protection against incorrect usage Function: • On a machine, the hazard area must be protected in normal operation by a guard and in setup up mode by an enable button in conjunction with standstill monitoring and safely limited speed. - Page 158 Installation manual Application-related measure: • Using an operator in the PLC program, the activation of the outputs while bypassing the alarm state for this time is prevented. Example 1: • The enable function for the outputs (AND function) is also linked to a "reset timer". This operator prevents the activation of the outputs for t >...

- Page 159 Installation manual Example 2: • The enable function for the outputs (AND function) is also linked to FF. This operator prevents the activation of the outputs after a reset if there is a fault present in the input circuit. The outputs are only enabled after an error-free input signal has been applied once.

-

Page 160: Led Indication

Installation manual 7.4 LED indication Colour Mode Description System OK, configuration Green "Flashing" validated System OK, configuration not yet Yellow "Flashing" validated "Flashing" Alarm "Continuous" Fatal error System OK, configuration not Yellow - red "Flashing" validated, SMMC configured but no bus user System OK, configuration Green - red "Flashing"... -

Page 161: Parameter Configuration

Installation manual 7.5 Parameter configuration The parameters are configured using the program SafePLC2. To be able to send the data to the module, a programming adapter is required; the user must install the driver for this adapter prior to use. For a description of the parameter configuration, see Programming manual 7.6 Function check To safeguard the safety of the module, a function test on the safety functions must be... -

Page 162: Safety-Related Check

Installation manual 8 Safety-related check To safeguard the safety functions implemented, the parameters and operators must be checked and documented by the user after completion of commissioning and parameter configuration. Support for this task is provided by the parameter configuration software SafePLC2 (see Programming manual). General information on the installation can be provided on the first two pages. -

Page 163: Maintenance

Installation manual 9 Maintenance 9.1 Modification / dealing with changes to the device Servicing work is only allowed to be undertaken by qualified personnel. It is not necessary to undertake regular servicing work. Repair Devices are always to be replaced completely. It is only possible to repair a device in the factory. -

Page 164: Technical Specifications

Installation manual 10 Technical specifications 10.1 Ambient conditions IP 20 Degree of protection 0 °C* ... 50 °C Ambient temperature 3k3 according to IEC 60721 Climatic class 20 years in 50 °C environment Service life (Tm, time to mission)) 10.2 Safety-related characteristic data •... -

Page 165: Switch Types

Installation manual 11 Switch types Switch symbol Truth table Function block Function Truth table behaves like an Öffner normally open contact, only the symbol is a normally closed contact Ausgang eSwitch_1o Normally open contact, like type Schließer Ausgang sSwitch_1s AND operation both inputs Öffner 1 Öffner 2 Ausgang... - Page 166 Installation manual Switch symbol Truth table Function Monitoring for NO = inactive and NC = active Öffner Schließer Ausgang eSwitch_1s1o Time monitoring Like 5, however with time monitoring of state changes. Öffner On signal change on one of the NC, complementary signal must Schließer follow within time t=3 s.

- Page 167 Installation manual Switch symbol Truth table Function Time monitoring Like 7, however with time monitoring of state changes. Öffner 1 On signal change on NO (attention common wire!) or NC, Öffner 2 complementary signal must follow within time t=3 s. If not Schließer change to fault and O=0 Ausgang...

- Page 168 Installation manual Time monitoring Like 8, however with time NC1 NC2 NC monitoring of state changes. Öffner 1 On signal change on one of the NC inputs the other inputs must Öffner 2 follow within time t=3 s. If not change to fault and O=0 Öffner 3 Ausgang...

- Page 169 Installation manual Switch symbol Truth table Function Two-hand Monitoring for NO1*NO2 = control inactive and NC1*NC2 = active Öffner 1 + time monitoring of this state. I.e. if there is a signal change on an NO from 1->0 or NC from 0- >1 then the other signals (i.e.

- Page 170 Installation manual Selector switch Unambiguous operator for the permissible switch positions Öffner Schließer Ausgang eMode_1s1o Selector switch Unambiguous operator for the S3 O permissible switch positions Schalter 1 Schalter 2 Schalter 3 Ausgang 1 eMode_3switch HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 170 of 201 Version: 25F...

-

Page 171: Notes For Designing, Programming, Validating And Testing Safety-Related Applications

Installation manual 12 Notes for designing, programming, validating and testing safety- related applications The following notes describe the procedures for designing, programming, validating and testing safety-related applications The notes are intended to assist the user in arranging, clearly understanding and applying all steps from the risk assessment to the system test. - Page 172 Installation manual Risk assessment according to EN ISO 13849-1 S – severity of injury S1 = slight, reversible injury S2 = serious, irreversible injury F – frequency and/or exposure to hazard F1= seldom, not cyclic F2 = frequent to continuous and/or exposure time is long, cyclic operation P –...

-

Page 173: Technical Documentation Required

Installation manual The risks to be considered are also given in the applicable directives and standards and are to be considered specifically by the manufacturer based on the manufacturer's specific knowledge of the machine. For machines placed on the market in the EU, the risks to be considered as a minimum are specified in the EU Machinery Directive 2006/42/EC or in the latest version of this Directive. -

Page 174: Steps Required For Designing, Realisation And Testing

For the realisation of such functions with the aid of safety-related control and monitoring functions, the PSC1 series offers efficient support in the form of the system architecture (architecture cat. 4 according to EN ISO 13849-1) and above all also the programming language and tested safety functions. -

Page 175: Phases Of The V Model

Installation manual 12.3.1 Phases of the V model Description Description Design phase Validation phase Specification and Specification of all safety Check on all passive and active validation of all measures to be taken such as safety measures for their correct passive and active covers, barriers, max. -

Page 176: Specification Of The Safety Requirements (Breakdown)

Installation manual 12.3.2 Specification of the safety requirements (breakdown) The safety requirements must be analysed in detail based on the standards to be applied, e.g. product standards. Source: General specifications, extract BGIA Report 2/2008 on EN ISO 13849-1 HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 176 of 201 Version: 38F... - Page 177 Installation manual Example for an automatic handling system: Functional description: The automatic handling system is used to pick up varying height lorry cabs automatically. After pick-up the height of the cab is safely acquired so that the cab cannot be lowered below a certain height in the working area.

- Page 178 Installation manual Example for a hazard analysis: HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 178 of 201 Version: 38F...

-

Page 179: Specification Of The Functional Safety System

Installation manual 12.3.3 Specification of the functional safety system Derived from the general hazard and risk analysis for the machine, the active protection functions are to be identified and specified. Active protection functions are, e.g. safely limited speed in certain system states, monitored stop and standstill functions, range monitoring, processing of monitoring devices such as light grids, safety mats, etc. -

Page 180: Performance Level Required (Plr) (Additional Emergency Stop)

Installation manual 12.3.3.2 Performance Level required (PLr) (additional emergency stop) The Performance Level required must now be determined from the safety functions SF1….. stated above. The decision path can be seen in the example below. Example for SF1: Result PF = d (source Sistema) HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 180 of 201 Version: 38F... -

Page 181: Example - Specification Of The Safety Functions In Tabular Form

Installation manual 12.3.3.3 Example – specification of the safety functions in tabular form Seq. Safety function Ref. Measured Implementation in Required Input/ Response/ value /sensor software Parameter activation output Limitation of the max. 1 x WCS Monitoring using tested 550mm/s Continuous Operation speed of movement,... -

Page 182: Software Specification

Installation manual 12.3.4 Software specification The software specification relates to the prior specification of the safety functions. It can also be replaced by a correspondingly prepared specification of the safety functions if this contains all specifications (see example in 12.3.3.3). However, it is recommended to prepare an extracted list. - Page 183 Installation manual Example software specification Safety function Measured New solution Input/activation Response/output . no. value /sensor Monitoring V_rope in Digital Monitoring using tested function SLS Continuous Operating stop relation to V_required incremental + SAC with comparison of speed Monitoring of the encoder, ranges / analogue value range = SF 1.3.1...

-

Page 184: Hardware Specification

Installation manual 12.3.5 Hardware specification In the hardware specification, the complete system layout and in particular the components used here are to be described with their specific characteristic data. The hardware specification is used as the basis for determining the safety level achieved based on the architecture and the characteristic data of all devices involved in a safety function. -

Page 185: Examples For Hardware Specification

Installation manual 12.3.5.2 Examples for hardware specification Safety function Safely limited speed SF 2.2 Safely monitored limited speed with door open Type Description Function Designation Characteristic data Comment Archite MTTF B10d Source Source cture [1/h] [years] Sensor Sensor 1 Door locking – monitoring A 3.1 10000 Data... -

Page 186: Consideration Of Systematic Failures

Installation manual 12.3.5.3 Consideration of systematic failures In addition, systematic failures are also to be considered in the hardware specification. Example of measures against systematic failures: Loss of power during operation. If there is a hazard here, a power loss must be considered like an operating state. - Page 187 Installation manual Examples for fault exclusions and measures assigned: • Positive locking connection on mech. shaft connections • Dimensioning based on adequate theoretical principles related to fracture of components in the safety chain • Positive guidance in conjunction with positive separation on sticking of switching contacts •...

-

Page 188: Hardware And Software Design

Installation manual 12.3.6 Hardware and software design The specifications from the hardware and software specification are implemented in the actual system design. The specifications for the components to be used and their circuitry from the hardware specification are to be met as are the specifications for the fault exclusions. Both are to be safeguarded using suitable means and are to be documented. - Page 189 Installation manual As an example, a calculation according to EN ISO 13849-1 is shown: Safety function: Safely limited speed with open access door Schematic layout: Safety-related schematic layout: HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 189 of 201 Version: 25F...

- Page 190 Installation manual Calculation according to EN ISO 13849-1: Channel A – shutdown via mains contactor: Component MTTFd [years] Door locking B10d = 100000 = 99% Switch NOP = 30/working days = 9270/year (309 working days/year) MTTFd = = 108 Jahre 0,1 ∗...

-

Page 191: Verification Of Software (Program) And Parameters

Installation manual Resulting PL for both channels: Symmetrisation of MTTFd = MTTFd_A + MTTFd_B − = 21,5 Jahre both channels: MTTFd_A MTTFd_B MTTFd_Türz MTTFd_SinCos MTTFd_PES MTTFd_Schütz MTTFd_STO DCSwitch DCSinCos DCPES DCSchütz DCSTO DC average value DCavg = MTTFd_Türz MTTFd_SinCos MTTFd_PES MTTFd_Netzsch DCavg = 0,9776 ~ 98% MTTFd = 21.5 years = medium... - Page 192 Installation manual Example: Safety function: • Limitation of the max. travel speed of the running gear (FW) to 1.1 VMax • Monitoring of the maximum speed for < 1.1 VMax • Monitoring "FW Max Speed" is continuously activated and triggers if a speed of 550 rpm is exceeded.

-

Page 193: Validating Fup Against Il And Parameters Using Validation Report

Installation manual 12.3.8.2 Validating FUP against IL and parameters using validation report The programming in the FUP is to be compared with the IL listing in the validation report. Example IL listing in the validation report Validation report PLC program Index Command Operand Validated... - Page 194 Installation manual After checking the program, the parameters are to be checked against the parameters in the specifications by comparing. Example SLS: Validation report Safely Limited Speed (SLS) Index Parameter Value Validated SLS - 1 Selected axis: Speed threshold: SLS - 2 Selected axis: Speed threshold: SLS - 3...

-

Page 195: Performance Of System Tests / Fit Test (Fault Injection Test)

Installation manual General parameters correctly configured Parameters sensor 1 correct Parameters sensor 2 correct 12.3.9 Performance of system tests / FIT test ( F ault I njection T est) For the FIT test the manufacturer must prepare a complete list of functions to be tested. This list includes the safety functions defined as well as fault tests for checking the correct response of the SRP/CS to these faults. -

Page 196: Appendix

Installation manual 13 Appendix 13.1 Appendix A – categorisation of the switch types General note: The individual switches for the following input elements can be assigned as required to the digital inputs I0 to I13. Enable switch Switch type Remark PL categorisation SIL categorisation according to EN ISO... - Page 197 Installation manual 2 normally open Door monitoring for PL e SIL 3 contact + 2 normally increased requirement closed contact 2 normally open Monitored door monitoring PL e SIL 3 contact + 2 normally closed contact time monitored 3 normally closed Door monitoring for PL e SIL 3...

- Page 198 Installation manual Two-handed operation Switch type Remark Category SIL categorisation categorisation 2 change-over Two-hand button for Type III C PL e SIL3 contacts increased requirement 2 normally open Monitored two-hand button Type III A PL c SIL1 contacts Note: On these input elements there is a fixed pulse assignment that the user cannot change! Light curtain Switch type Remark...

- Page 199 Installation manual 1 normally open Sensor input for increased PL e SIL 3 contact + 1 normally requirement closed contact 1 normally open Monitored sensor input PL e SIL 3 contact + 1 normally closed contact time monitored HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 199 of 201 Version: 25F...

- Page 200 Installation manual Start / Reset Switch type Remark Category SIL categorisation categorisation 1 normally open Simple alarm reset (edge contact evaluation) 1 normally open Simple logic reset PL d SIL 2 contact 1 normally open Simple start monitoring contact (special function) Note: The alarm reset input can be operated with a continuous voltage of 24 V and is edge controlled.

-

Page 201: Hb-37420-810-01-25F-En Psc1-C-100 Installation Manual - V2.2.Docx

Installation manual 13.2 CE – declaration of conformity EC declaration of conformity for safety components in the context of the EC directive HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 201 of 201 Version: 25F...

Need help?

Do you have a question about the PSC1 Series and is the answer not in the manual?

Questions and answers