Summary of Contents for ESAB TXH Series

- Page 1 TXHt Tig- torches TXHt 120, TXHt 150, TXHt 200, TXHt 250w, TXHt 400w Instruction manual Èíñòðóêöèÿ ïî ýêñïëóàòàöèè 2006- -04- -25 Valid for serial no. 616 0460 031 027 0460 031...

- Page 2 Ðóññêèé ..........ENGLISH .

-

Page 3: Table Of Contents

Ðóññêèé 1 ÒÅÕÍÈÊÀ ÁÅÇÎÏÀÑÍÎÑÒÈ ........2 ÂÂÅÄÅÍÈÅ... -

Page 4: Òåõíèêà Áåçîïàñíîñòè

ÒÅÕÍÈÊÀ ÁÅÇÎÏÀÑÍÎÑÒÈ Ïîëüçîâàòåëè ñâàðî÷íîãî îáîðóäîâàíèÿ ESAB îòâå÷àþò çà âûïîëíåíèå ïðàâèë òåõíèêè áåçîïàñíîñòè ëèöàìè, ðàáîòàþùèìè íà îáîðóäîâàíèè è ðÿäîì ñ íèì. Ïðàâèëà òåõíèêè áåçîïàñíîñòè äîëæíû îòâå÷àòü òðåáîâàíèÿì ê áåçîïàñíîé ýêñïëóàòàöèè ñâàðî÷íîãî îáîðóäîâàíèÿ ýòîãî òèïà. Ïîìèìî ñòàíäàðòíûõ ïðàâèë òåõíèêè áåçîïàñíîñòè è îõðàíû... -

Page 5: Ââåäåíèå

îáîðóäîâàíèþ Ïåðåä íà÷àëîì ìîíòàæà è ýêñïëóàòàöèè âíèìàòåëüíî èçó÷èòå ñîîòâåòñòâóþùèå èíñòðóêöèè. ÇÀÙÈÒÈÒÅ ÑÅÁß È ÄÐÓÃÈÕ! Êîìïàíèÿ ESAB ãîòîâà ïðåäîñòàâèòü âàì âñå çàùèòíîå ñíàðÿæåíèå è ïðèíàäëåæíîñòè, íåîáõîäèìûå äëÿ âûïîëíåíèÿ ñâàðî÷íûõ ðàáîò. ÂÂÅÄÅÍÈÅ TIG ãîðåëêà TXH 120 -TXH 400w ïðåäíàçíà÷åíà äëÿ ðó÷íîé ñâàðêè... -

Page 6: Òåõíè×Åñêèå Õàðàêòåðèñòèêè

ÒÅÕÍÈ×ÅÑÊÈÅ ÕÀÐÀÊÒÅÐÈÑÒÈÊÈ ÂÍÈÌÀÍÈÅ! Òåõíè÷åñêèå õàðàêòåðèñòèêè tig-ãîðåëêè ïðèâåäåíû íà ñòðàíèöå Ðàáî÷èé öèêë Ðàáî÷èé öèêë ïðåäñòàâëÿåò ñîáîé äîëþ (â %%) äåñÿòèìèíóòíîãî èíòåðâàëà, â òå÷åíèå êîòîðîé ìîæíî ïðîèçâîäèòü ñâàðêó ïðè îïðåäåëåííîé íàãðóçêå áåç ïåðåãðóçêè. Êëàññ çàùèòû Êëàññ çàùèòû ãîðåëêè IP3X íà ñòîðîíå ìàøèíû (EN 60 529): Êîä... -

Page 7: Øëèôîâêà

Òàáëèöà âûáîðà A / ~ A / – 6.4/ 8.0 10--60 15--100 70--80 20--100 6.4/8.0/9.8 50--100 60--90 70--160 80--140 80--160 9.8/11.2 /2.7 100--160 90--130 110--200 150--210 120--230 11.2/12.7 130--180 140--190 150--205 220--320 200--305 12.7 180--230 200--250 180--270 330--420 250--420 Øëèôîâêà Øëèôîâêà... -

Page 8: Åæåäíåâíî

Ïî÷èñòèòå èëè çàìåíèòå. ãàçîâîé ëèíçå èëè ãàçîâîì êîëïàêå. ÇÀÊÀÇ ÇÀÏÀÑÍÛÕ ×ÀÑÒÅÉ Çàïàñíûå ÷àñòè ìîæíî çàêàçòú ó áëèæàéøåãî ê Âàì ESAB, (ñì. ïåðå÷åíú íà ïîñëåäíåé ñòðàíèöå äàííîé áðîøþðû). Ïåðå÷åíü çàïàñíûõ ÷àñòåé, ïîñòàâëÿåìûõ êîìïàíèåé ESAB äëÿ äàííîãî èçäåëèÿ, ïðèâåäåí â èíòåðíåòå íà ñàéòå www.esab.com. - Page 9 ENGLISH 1 DIRECTIVE ............2 SAFETY .

-

Page 10: Directive

SAFETY Users of ESAB welding equipment have the ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that apply to this type of welding equipment. -

Page 11: Introduction

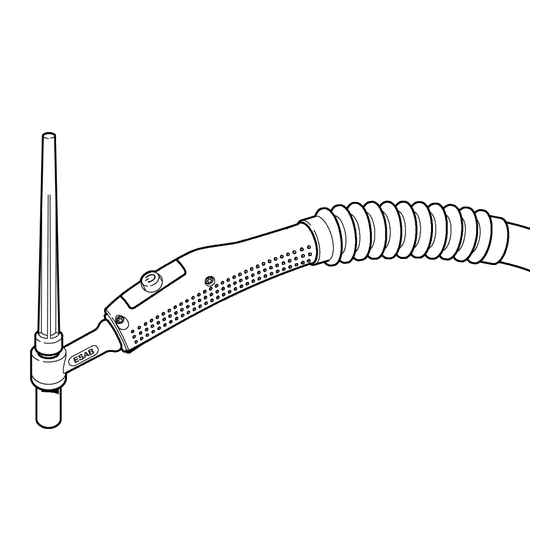

MALFUNCTION - - Call for expert assistance in the event of malfunction. READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING. PROTECT YOURSELF AND OTHERS! ESAB can provide you with all necessary welding protection and accessories. INTRODUCTION TIG torch TXH 120 --TXH 400w is intended for manual TIG welding and is available water or air cooled. -

Page 12: Operation

OPERATION General safety regulations for the handling of the equipment can be found on page 10. Read through before you start using the equipment! Please also read the operating instructions for the welding components, e.g. power source and connect accordingly. Connections Tighten the connections for the torch carefully to avoid overheating the connection, connection interference, mechanical damage or leakage of liquid or gas. -

Page 13: Grinding

Grinding Grind tungsten electrodes according to the following table: NOTE that tungsten electrodes must be ground lengthways. If they are ground incorrectly the arc may be unstable. When the welding current is increased the angle must also be increased. When welding with alternating current (AC) the electrode end must be gently rounded. -

Page 14: Fault- -Tracing

Clean or replace. ORDERING SPARE PARTS Spare parts may be ordered through your nearest ESAB dealer, see the last page of this publication. ESAB’s spare parts for the product , will be found on the internet www.esab.com. -

Page 15: Technical Data

Technical data 120V 120F 150V 150F 150/35 150/35 150/35 120/60 120/60 120/60 120/60 120/60 120/60 100/100 100/100 100/100 100/100 100/100 100/100 1.0--3.2 1.0--3.2 1.0--3.2 1.0--3.2 1.0--3.2 1.0--3.2 Ar/He Ar/He Ar/He Ar/He Ar/He Ar/He 4 & 8 m 4 & 8 m 4 &... -

Page 16: Îõëàæäàþùàÿ Ïðèíàäëåæíîñòè

Flow caracteristic Îõëàæäàþùàÿ ïðèíàäëåæíîñòè TXH 250w Flow characterstic TXH250w, TXH250wF and TXH 400w at 50 Hz TXH 250wF TXH 250w (l/min) TXH 400w (bar) P = Pressure Pump pressure Q = Flow rate Flow rate - - 16 - - bg19ft... -

Page 17: Íîìåð Çàêàçà

TXHt 400w Spare parts are to be ordered through the nearest ESAB agency as per the list on the back of the cover. Kindly indicate type of unit, serial number, denominations and ordering numbers according to the spare parts list. -

Page 18: Áûñòðîèýíàøèâåìûå Äåòàëè

TXH 120 - 400W Wear parts Áûñòðîèýíàøèâåìûå äåòàëè Ordering no. Ordering no. Tungsten Diameter Colour Code Current 175 mm 150 mm electrodes 0151 574 008 0151 574 208 Wolfram, pure ø 1.0 Green 0151 574 009 0151 574 209 Wolfram, pure ø... - Page 19 TXH 120 - 400W Nozzles, collets, collet bodies and gas lenses for TXHt torches Type Size Denomination TXH 140/250W TXH 150/200 TXH 400W No 4 Ø 6.4 Gas nozzles standard 0365 310 044 0157 123 052 0157 123 057 No 5 Ø...

-

Page 20: Äîïîëíèòåëüíûå Ïðèíàäëåæíîñòè

Accessories Äîïîëíèòåëüíûå ïðèíàäëåæíîñòè Ordering no. Denomination Notes Protective Cable 0366 960 049 Protective cable cover with zipper 3.6 m 0366 960 050 Protective cable cover with zipper 7.2 m 0366 960 066 Spote welding set for TXH 150, TXH 150F, TXH 150V, TXH 200, TXH 200V, TXH 200F Gas nozzle ø... - Page 21 - - 21 - - backpage...

Need help?

Do you have a question about the TXH Series and is the answer not in the manual?

Questions and answers