Table of Contents

Advertisement

Quick Links

WIDOS

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax

Working Instructions

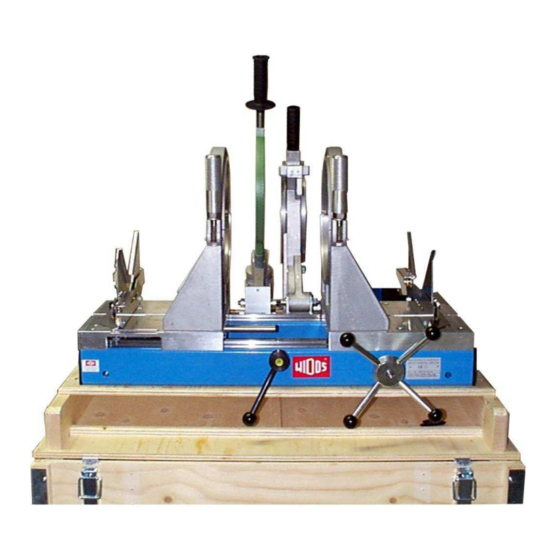

Heating element butt welding machine

Headquarters: D-71254 Ditzingen-Heimerdingen Country court Stuttgart HRB 200973 Managing director: Jürgen Dommer

Einsteinstr. 5

website: www.widos.de

Translation

WIDOS 2500 / OD 250

Keep for further use!

Phone ++49 (0)7152 / 9939 - 0

++49 (0)7152 / 9939 - 40

email: info@widos.de

Kunststoffschweißtechnik

Advertisement

Table of Contents

Summary of Contents for widos 2500 / OD 250

- Page 1 ++49 (0)7152 / 9939 - 40 website: www.widos.de email: info@widos.de Kunststoffschweißtechnik Working Instructions Translation Heating element butt welding machine WIDOS 2500 / OD 250 Keep for further use! Headquarters: D-71254 Ditzingen-Heimerdingen Country court Stuttgart HRB 200973 Managing director: Jürgen Dommer...

- Page 2 ++49 371 / 8 15 73 - 0 Phone: ++41 71 / 388 89 79 Fax: ++49 371 / 8 15 73 - 20 Fax: ++41 71 / 388 89 73 01.02.2012 Working instructions WIDOS 2500 / OD 250 Page 2 of 45...

- Page 3 01.02.2012 WIDOS W. Dommer Söhne GmbH Einsteinstraße 5 D-71254 Ditzingen-Heimerdingen All rights reserved. Reprinting only allowed with permission of the corporation. Any changes are subject to technical innovations. 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 3 of 45...

-

Page 4: Table Of Contents

Safety measures........................6 1.3. Conformity ..........................6 1.4. Marking of the product ......................7 1.4.1.Technical data ..........................7 1.4.1.1.WIDOS 2500 / OD 250 General data..................7 1.4.1.2.Heating element ........................7 1.4.1.3.Planer ............................7 1.4.2.Equipment and accessories ......................8 SAFETY RULES ....................9 2.1. Explanation of the symbols and indications..............9 2.2. - Page 5 9.2. Clamping device........................32 9.3. Pipe supports ........................34 9.4. Planer ...........................37 9.5. Planer holder ........................39 9.6. Heating element ........................41 9.7. Heating element holder ......................43 DECLARATION OF CONFORMITY ..............45 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 5 of 45...

-

Page 6: Description Of Product

1.1. Usage and purpose-oriented use The WIDOS 2500 / OD 250 is made for the heating element butt welding of pipes and fittings out of PE, PP and PVDF with a diameter range of Ø = 50 - 250 mm (optional Ø = 20 – 40 mm). -

Page 7: Marking Of The Product

It contains the type, the serial number and the year of construction of the machine. 1.4.1. Technical data 1.4.1.1. WIDOS 2500 / OD 250 General data Dimensions of pipes: outside-Ø = 50 - 250 mm (optional, outside-Ø = 20 - 40 mm) -

Page 8: Equipment And Accessories

Torx-screw driver T10 Tool bag for 10 parts See spare parts list for order numbers and single parts. In case of an order please always give the machine number! 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 8 of 45... -

Page 9: Safety Rules

T h e r e g u l a t i o n s f o r t h e p r e v e n t i o n o f a c c i d e n t s a r e v a l i d ( U V V ) . 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 9 of 45... -

Page 10: Obligations Of The Owner

A person who is being trained may only work at the machine under supervision of an • experienced person. 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 10 of 45... -

Page 11: Specific Dangers

• If necessary, wear hair-net. • Do not touch the faces of the planer. • Take care that no person is standing in the swiveling area of the planer. 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 11 of 45... -

Page 12: Risk Of Injury By Noise

• Machine parts that are not in perfect condition are to be replaced immediately. • Only use original WIDOS spare and wear parts. 2.9. Warranty and liability Fundamentally our "General Sales and Delivery Conditions" are valid. -

Page 13: Functional Description

(cooling time). The welded pipes can be unclamped, the welding process is finished. Heating element heats the pipes up to welding temperature Finished welding with internal and external bead 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 13 of 45... -

Page 14: Operating And Indicating Elements

Support for pipes, right- / left-hand - Support the pipes Cross handle - Opening / shutting of the support. - Application of the adjusting force and of the jointing force 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 14 of 45... -

Page 15: Elements At The Planer And Heating Element

- Blinking: the heating element temperature is maintained by a certain pulse-position ratio. - On: signalizes that the heating element is heated up at the moment. The desired temperature has not been reached yet. 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 15 of 45... -

Page 16: Starting And Operating

• Connect the heating element to the local power supply (230 V / 16 A / 50 Hz) / (110 V / 16 A / 50-60 Hz). The machine can be operated now. 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 16 of 45... -

Page 17: How To Mount The Pipe Supports

(10). If the control lamp (no. 11) blinks, the nominal temperature has been reached and is maintained by means of a defined pulse-pause ratio. 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 17 of 45... -

Page 18: Welding Process

• The mismatch compensation is carried out by further tightening or releasing of the clamping nuts. In case mismatch compensation was carried out, planing must be repeated afterwards. 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 18 of 45... -

Page 19: Adjusting

• Built up the welding force, arrest the support by the lever and press the stop-watch. • If necessary, re-adjust the force during the cooling time (cooling force = adjusting force). 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 19 of 45... -

Page 20: End Of Welding

90°, 4 segments ( 6 welding surfaces) 90° Sawing angle = ----- = 15° Example: 2 bend of 45°, 3 segments ( 4 welding surfaces) 45° Sawing angle = ----- = 11,25° 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 20 of 45... -

Page 21: Welding Log And Tables

Phone ++49 (0)7152 / 9939 - 0 W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax ++49 (0)7152 / 9939 - 40 website: www.widos.de email: info@widos.de Kunststoffschweißtechnik 6. Welding log and tables 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 21 of 45... - Page 22 Welding log and tables Chapter 6 Kunststoffschweißtechnik 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 22 of 45...

- Page 23 [kp] min. over welding [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 13,6 17,6 01.02.2012 Working instructions WIDOS manual machine page 23 / 1 of 45...

- Page 24 [kp] min. over welding [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 17,6 13,6 13,6 17,6 13,6 01.02.2012 Working instructions WIDOS manual machine page 23 / 2 of 45...

- Page 25 [kp] min. over welding [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 17,6 13,6 13,6 10,3 17,6 13,6 10,1 12,3 01.02.2012 Working instructions WIDOS manual machine page 23 / 3 of 45...

- Page 26 [kp] min. over welding [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 13,6 10,0 12,3 15,1 17,6 13,6 11,4 14,0 17,1 01.02.2012 Working instructions WIDOS manual machine page 23 / 4 of 45...

- Page 27 [kp] min. over welding [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 10,3 13,6 12,7 15,7 19,2 23,3 17,6 11,8 13,6 14,6 17,9 21,9 01.02.2012 Working instructions WIDOS manual machine page 23 / 5 of 45...

- Page 28 [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 10,2 17,6 10,7 13,3 13,6 16,4 20,1 20,1 24,6 11,4 17,6 11,9 14,7 13,6 18,2 22,4 27,4 01.02.2012 Working instructions WIDOS manual machine page 23 / 6 of 45...

- Page 29 [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 10,8 12,8 17,6 13,4 16,6 13,6 20,5 25,2 30,8 11,9 14,2 17,6 14,8 18,4 13,6 22,7 27,9 34,2 01.02.2012 Working instructions WIDOS manual machine page 23 / 7 of 45...

- Page 30 • low additional pressure at unclamping • no additional pressure during further cooling down • load onto the workpieces only after being completely cooled down 01.02.2012 Working instructions WIDOS manual machine page 23 / 8 of 45...

- Page 31 [kp] min. over welding [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 17,6 17,6 I:\BETR_ANL\SW-Tabellen\T manuell [Kopie Grüna].xls Working instructions WIDOS manual machine page 24/ 1 of 45...

- Page 32 [kp] min. over welding [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 17,6 10,1 17,6 10,5 12,7 17,6 10,3 12,5 15,1 I:\BETR_ANL\SW-Tabellen\T manuell [Kopie Grüna].xls Working instructions WIDOS manual machine page 24/ 2 of 45...

- Page 33 [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 17,6 12,3 15,0 18,1 17,6 10,0 15,1 18,3 22,1 17,6 11,4 17,1 20,8 25,1 I:\BETR_ANL\SW-Tabellen\T manuell [Kopie Grüna].xls Working instructions WIDOS manual machine page 24/ 3 of 45...

- Page 34 [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 17,6 12,7 19,2 23,3 28,1 17,6 14,6 21,9 26,6 32,1 10,2 17,6 16,4 24,6 29,0 36,1 I:\BETR_ANL\SW-Tabellen\T manuell [Kopie Grüna].xls Working instructions WIDOS manual machine page 24/ 4 of 45...

- Page 35 [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 11,4 17,6 18,2 27,4 33,2 12,8 17,6 20,5 30,8 37,4 14,2 17,6 22,7 34,2 I:\BETR_ANL\SW-Tabellen\T manuell [Kopie Grüna].xls Working instructions WIDOS manual machine page 24/ 5 of 45...

- Page 36 • low additional pressure at unclamping • no additional pressure during further cooling down • load onto the workpieces only after being completely cooled down I:\BETR_ANL\SW-Tabellen\T manuell [Kopie Grüna].xls Working instructions WIDOS manual machine page 24/ 6 of 45...

- Page 37 [kp] min. over welding [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 10,0 10,0 11,0 01.02.2012 Working instructions WIDOS manual machine page 25 / 1 of 45...

- Page 38 [kp] min. over welding [kp] time [mm] [mm] [daN] [mm] time pressure [daN] [min] 12,5 13,5 10,5 10,8 15,0 11,0 11,9 16,5 12,5 13,5 01.02.2012 Working instructions WIDOS manual machine page 25 / 2 of 45...

-

Page 39: Maintenance / Storage / Transport

DVS gives the advice of inspection work after 1 year. For machines with a specially high usage percentage the testing cycle should be shortened. The work should be performed at the WIDOS GmbH company or by an authorized partner. 7.2. Clamping elements For a long service life clean and grease regularly the threaded spindles and the joint parts •... -

Page 40: Wiring Diagram

Phone ++49 (0)7152 / 9939 - 0 W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax ++49 (0)7152 / 9939 - 40 website: www.widos.de email: info@widos.de Kunststoffschweißtechnik 8. Wiring diagram 8.1. Wiring diagram 230 V 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 27 of 45... - Page 41 Ø 160: 460 W, 110 V, 4,2 A Ø 160: 950 W, 110 V, 8,6 A Ø 250: 1500 W, 110 V, 13,6A Ø 250: 1050 W, 110 V, 9,5A Ø 350: 2000 W, 110 V, 18,1 A Ø 350: 2000 W, 110 V, 9,5 A...

-

Page 42: Spare Parts List

9. Spare parts list 9.1. Basic machine with motion 4 / 5 8 - 10 11 / 12 9 / 10 / 13 14 / 15 / 20 14 / 15 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 29 of 45... - Page 43 (view from below) 23 / 24 25 / 42 25 / 26 43 / 44 39 / 45 (view from below) 34 / 36 - 37 14 / 41 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 30 of 45...

- Page 44 Spare parts list Chapter 9 Kunststoffschweißtechnik Basic Machine with Motion WIDOS 2500 / OD 250 Pos. Name Piece Order no. Bolt for planer device 3804081 Support, movable 380103 Thread insert M 8x9 GEWK-M8 NSK-guide carriage L20CLZ Pan-head screw M 5x12 DIN 912...

- Page 45 Spare parts list Chapter 9 Kunststoffschweißtechnik Basic Machine with Motion WIDOS 2500 / OD 250 Pos. Name Piece Order no. Bearing for support, movable 380136 Pan-head screw M 6x40 DIN 912 0912F040 Hexagonal socket screw key size 4 with T-grip...

-

Page 46: Clamping Device

Spare parts list Chapter 9 Kunststoffschweißtechnik 9.2. Clamping device 1 - 3 11 - 12 5 - 6 8 - 10 13 - 14 15 - 16 17 - 19 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 32 of 45... - Page 47 Spare parts list Chapter 9 Kunststoffschweißtechnik Clamping Device WIDOS 2500 / OD 250 Pos. Name Piece Order no. Thrust washer 0134L 160109 Knurled bushing S3807 Thread spindle 160108 Rivet 160111 Sealing ring 5 DIN 6799 6799E Thread insert M 6x14...

-

Page 48: Pipe Supports

Pipe support for OD 50 – 160 mm 3 - 5 7 - 10 11 - 12 Pipe support for OD 180 – 250 mm 32 - 33 23 - 25 26 - 29 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 34 of 45... - Page 49 Spare parts list Chapter 9 Kunststoffschweißtechnik Pipe bracket with pipe supports 36 - 37 38 - 40 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 35 of 45...

- Page 50 Spare parts list Chapter 9 Kunststoffschweißtechnik Supports for pipes WIDOS 2500 / OD 250 Pos. Name Piece Order no. Pipe support OD 50 - 160 Support 380634 Sliding washer 380635 Flat-head screw M 5x12 DIN 7991 7991E012 Tooth lock washer M5 Form A DIN 6797...

- Page 51 Spare parts list Chapter 9 Kunststoffschweißtechnik Supports for pipes WIDOS 2500 / OD 250 Pos. Name Piece Order no. Pipe bracket with pipe supports Pipe bracket OD 250 380734 Knurled screw 010605 Disc S0103 Nut for T-slot M10 DIN 508...

-

Page 52: Planer

Spare parts list Chapter 9 Kunststoffschweißtechnik 9.4. Planer 2 - 3 4 - 5 8 - 12 15 - 20 21 - 22 25 - 27 31 - 34 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 37 of 45... - Page 53 Chain 3/8", 99 chain links K38099 Chain joint 3/8" KSCH38 Hexagon head screw M8x20 DIN 933 0933H020 Cylinder head screw M8x30 DIN 912 0912H030 Torx screw driver T 10 ZT10 01.02.2012 Working Instruction WIDOS 2500 / OD 250 Page 38 of 45...

-

Page 54: Planer Holder

Spare parts list Chapter 9 Kunststoffschweißtechnik 9.5. Planer holder 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 39 of 45... - Page 55 Spare parts list Chapter 9 Kunststoffschweißtechnik Planer Holder WIDOS 2500 / OD 250 Pos. Name Piece Order no. U-beam 3804041 Pan-head screw M 12x80 DIN 912 0912L080 Distance bushing for end stop of planer 380409 Washer M 12 DIN 125...

-

Page 56: Heating Element

Spare parts list Chapter 9 Kunststoffschweißtechnik 9.6. Heating element 14-15 17 - 19 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 41 of 45... - Page 57 Spare parts list Chapter 9 Kunststoffschweißtechnik Heating Element WIDOS 2500 / OD 250 Pos. Name Piece Order no. Heating element complete 1000 W, 230 V H0250E Heating plate new HP0250E Heating plate in exchange HPT0250E Heating element complete 1000 W, 110 V...

-

Page 58: Heating Element Holder

Spare parts list Chapter 9 Kunststoffschweißtechnik 9.7. Heating element holder 7 / 8 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 43 of 45... - Page 59 Spare parts list Chapter 9 Kunststoffschweißtechnik Heating Element Holder WIDOS 2500 / OD 250 Pos. Name Piece Order no. Washer M 12 DIN 125 0125L Pan-head screw M 12x80 DIN 912 0912L080 Pan head screw with low head M 6x14 DIN 7984...

-

Page 60: Declaration Of Conformity

3. EN 60555, EN 50082, EN 55014, Electro-magnetic resistance The complete technical documentation is available. The working instructions in the national language of the user are available. Ditzingen-Heimerdingen, the 01.02.2012 Martin Dommer (Technical director) 01.02.2012 Working Instructions WIDOS 2500 / OD 250 Page 45 of 45...

Need help?

Do you have a question about the 2500 / OD 250 and is the answer not in the manual?

Questions and answers