Summary of Contents for Meritor MTC-4208X Series

- Page 1 MAINTENANCE MANUAL MM-0861 July 2020 MTC-4208X/XL/XP/XLEV/XLEC, MTC-4210X/XL/XP/ XLEV/XLEC & MTC-4213X SERIES TRANSFER CASES MM-0861 / Revised July 2020 Page FC Copyright Meritor, Inc., 2020 Printed in USA...

-

Page 2: About This Manual

For more information on MTC-4208, MTC-4210, and MTC-4213GS Series transfer cases, refer to Maintenance Manual MM-0146 - Visit Literature on Demand at meritor.com to access and order addi- Transfer Cases. To obtain this publication, visit Literature on Demand at tional information. -

Page 3: Table Of Contents

Clean and Dry Parts............51 Hazard Alert Messages ..........89 Inspect Parts ..............52 Install the Transfer Case ..........89 Oil Cooler Line Connections ........... 89 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page i... -

Page 4: Section 1: Exploded Views

Drain & Replace the Oil ..........101 Transfer Case Inspection ..........101 Section 11: Torque Specifi cations ....104 Standard MTC-4213X, MTC-4208XP, & MTC-4210XP .............. 104 Standard MTC-4208X/XL/XLEV & MTC-4210X/XL/XLEV ..........106 MM-0861 / Revised July 2020 Page ii Copyright Meritor, Inc., 2020 Printed in USA... -

Page 5: Mtc-4208X/Xp Transfer Case Rear Cover

On vehicles equipped with a neutral air control, the solenoid allows this cavity to exhaust. MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 1... -

Page 6: Mtc-4208X/Xp Transfer Case Front Cover

Exploded Views MTC-4208X/XP Transfer Case Front Cover FRONT OUTPUT DECLUTCH FRONT 4007389a MM-0861 / Revised July 2020 Page 2 Copyright Meritor, Inc., 2020 Printed in USA... - Page 7 Oil Pump Assembly Oil Fill Plug Bearing Cone Shift Piston Shim Shift Piston O-ring Input Bearing Cage Shipping Protector Bearing Cage Capscrew and Washer Shift Cylinder MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 3...

-

Page 8: Mtc-4208Xl Transfer Case Rear Cover

Exploded Views MTC-4208XL Transfer Case Rear Cover 4007101a MM-0861 / Revised July 2020 Page 4 Copyright Meritor, Inc., 2020 Printed in USA... - Page 9 Blow-by Breather Oil Pump Inlet Tube Neutral Breather Tube Assembly, Without Oil Cooler Shipping Protector Oil Pump Inlet Fitting Neutral Breather Fitting Fitting, Without Oil Cooler MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 5...

-

Page 10: Mtc-4208Xl Transfer Case Front Cover

Exploded Views MTC-4208XL Transfer Case Front Cover 27 50 22 39 4007102a MM-0861 / Revised July 2020 Page 6 Copyright Meritor, Inc., 2020 Printed in USA... - Page 11 Locating Dowel Pin Front Output Shaft Elbow Needle Bearing Oil Spacer Helical Driven Gear Shim Fill Plug O-ring Magnetic Drain Plug Input Bearing Cage Yoke Sleeve MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 7...

-

Page 12: Mtc-4208Xlev/Xlec Transfer Case Rear Cover

Exploded Views MTC-4208XLEV/XLEC Transfer Case Rear Cover WITHOUT OIL COOLER XLEC VARIANT 4011708c MM-0861 / Revised July 2020 Page 8 Copyright Meritor, Inc., 2020 Printed in USA... - Page 13 Neutral Breather Fitting Pipe Plug, 1/4-18 NPT Speed Sensor Socket Head Bolt Capscrew and Washer P-Clamp Bearing Cups Angle Bracket Shims Lock Nut Bearing Cone Double Idler Gear MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 9...

-

Page 14: Mtc-4208Xlev/Xlec Transfer Case Front Cover

Exploded Views MTC-4208XLEV/XLEC Transfer Case Front Cover 25 26 30 31 4011709b MM-0861 / Revised July 2020 Page 10 Copyright Meritor, Inc., 2020 Printed in USA... - Page 15 Needle Bearing Input Bearing Cage Front Output Shaft Bearing Cage Capscrew and Washer Shift Fork Input Oil Seal Front Output Clutch Collar Yoke Sleeve Magnetic Drain Plug MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 11...

-

Page 16: Mtc-4210X/Xp Transfer Case Rear Cover

Exploded Views MTC-4210X/XP Transfer Case Rear Cover 4007388a MM-0861 / Revised July 2020 Page 12 Copyright Meritor, Inc., 2020 Printed in USA... - Page 17 On vehicles equipped with a neutral air control, the solenoid allows this cavity to exhaust. MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 13...

-

Page 18: Mtc-4210X/Xp Transfer Case Front Cover

Exploded Views MTC-4210X/XP Transfer Case Front Cover FRONT OUTPUT DECLUTCH FRONT 4007389a MM-0861 / Revised July 2020 Page 14 Copyright Meritor, Inc., 2020 Printed in USA... - Page 19 Magnetic Drain Plug Oil Pump Assembly Oil Fill Plug Shim Shift Cylinder Input Bearing Cage Shift Piston O-ring Bearing Cage Capscrew and Washer Shipping Protector Lock Nut MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 15...

-

Page 20: Mtc-4210Xl Transfer Case Rear Cover

Exploded Views MTC-4210XL Transfer Case Rear Cover 4007101a MM-0861 / Revised July 2020 Page 16 Copyright Meritor, Inc., 2020 Printed in USA... - Page 21 Blow-by Breather Oil Pump Inlet Tube Neutral Breather Tube Assembly, without Oil Cooler Shipping Protector Oil Pump Inlet Fitting Neutral Breather Fitting Fitting, without Oil Cooler MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 17...

-

Page 22: Mtc-4210Xl Transfer Case Front Cover

Exploded Views MTC-4210XL Transfer Case Front Cover 24 25 22 23 18 19 4007102a MM-0861 / Revised July 2020 Page 18 Copyright Meritor, Inc., 2020 Printed in USA... - Page 23 O-ring Front Output Clutch Collar Input Bearing Cage Drain Plug Bearing Cage Capscrew and Washer Magnetic Drain Plug Input Oil Seal Fill Plug Yoke Sleeve Elbow MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 19...

-

Page 24: Mtc-4210Xlev/Xlec Transfer Case Rear Cover

Exploded Views MTC-4210XLEV/XLEC Transfer Case Rear Cover WITHOUT OIL COOLER XLEC VARIANT 4011708c MM-0861 / Revised July 2020 Page 20 Copyright Meritor, Inc., 2020 Printed in USA... - Page 25 Neutral Breather Fitting Pipe Plug, 1/4-18 NPT Speed Sensor Socket Head Bolt Capscrew and Washer P-Clamp Bearing Cups Angle Bracket Shims Lock Nut Bearing Cone Double Idler Gear MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 21...

-

Page 26: Mtc-4210Xlev/Xlec Transfer Case Front Cover

Exploded Views MTC-4210XLEV/XLEC Transfer Case Front Cover 25 26 30 31 4011709b MM-0861 / Revised July 2020 Page 22 Copyright Meritor, Inc., 2020 Printed in USA... - Page 27 Needle Bearing Input Bearing Cage Front Output Shaft Bearing Cage Capscrew and Washer Shift Fork Input Oil Seal Front Output Clutch Collar Yoke Sleeve Magnetic Drain Plug MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 23...

-

Page 28: Mtc-4213X Transfer Case Rear Cover

Exploded Views MTC-4213X Transfer Case Rear Cover 19 20 20 12 13 13A 4007103a MM-0861 / Revised July 2020 Page 24 Copyright Meritor, Inc., 2020 Printed in USA... - Page 29 Housing O-ring Rear Housing Neutral Breather Capscrew and Washer Neutral Breather Fitting Elbow Plug Breather Speed Sensor Capscrew and Washer Capscrew Switch Assembly Washer Spacer O-ring Shims MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 25...

-

Page 30: Mtc-4213X Transfer Case Front Cover

Exploded Views MTC-4213X Transfer Case Front Cover FRONT 4007104a MM-0861 / Revised July 2020 Page 26 Copyright Meritor, Inc., 2020 Printed in USA... - Page 31 Front Output Shaft Input Oil Seal Helical Drive Gear Input Yoke Needle Bearing Flat Washer Drain Plug Lock Nut Magnetic Drain Plug Plug Oil Fill Plug MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 27...

-

Page 32: Mtc-4208Xp & Mtc-4210Xp Declutch/Pto

Exploded Views MTC-4208XP & MTC-4210XP Declutch/PTO 4000182a MM-0861 / Revised July 2020 Page 28 Copyright Meritor, Inc., 2020 Printed in USA... - Page 33 Connector Switch Assembly - Disengage (Optional) Shipping Protector Push Rod Shifter Piston O-ring O-ring Cover Plate Clutch Collar Shift Fork Bearing Assembly PTO Housing PTO Shaft Oil Seal Assembly MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 29...

-

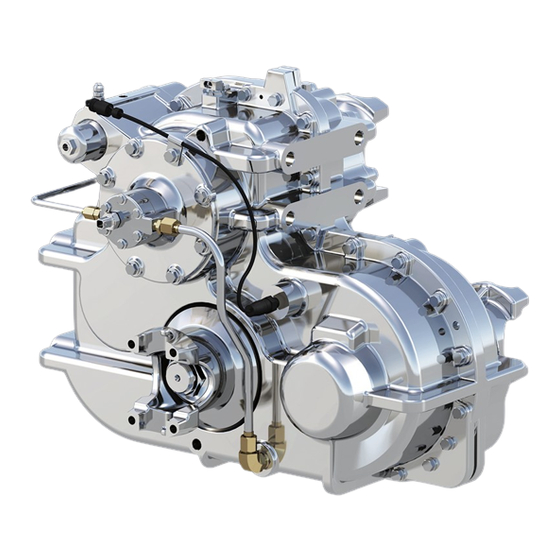

Page 34: Section 2: Introduction

4 = Four-Shaft Design L = Rear Mount Pump* P = PTO Equipped* (space) = PTO Ready* *MTC-4208 and MTC-4210 only, not available for MTC-4213 4006921c Figure 2.1 MM-0861 / Revised July 2020 Page 30 Copyright Meritor, Inc., 2020 Printed in USA... -

Page 35: Description

Figure 2.7. Series are designed specifi cally for use in 4x4 vehicles (the MTC-4213 Series is designed specifi cally for 6x6) as part of the Meritor medi- Optional switches for full-torque PTOs indicate full engagement or um-duty 4x4 drive system. Figure 2.2. - Page 36 GEAR SHAFT OUTPUT SHAFT SHAFT DOUBLE REAR IDLER GEAR OUTPUT SHAFT SHAFT FRONT OUTPUT SHAFT NEEDLE BEARING FRONT OUTPUT 4011711a SHAFT 4000184c Figure 2.5 Figure 2.7 MM-0861 / Revised July 2020 Page 32 Copyright Meritor, Inc., 2020 Printed in USA...

-

Page 37: Operation

OIL PUMP PUMP OUTLET performance, or observing the optional indicator light in the cab. COVER TO COOLER INLET TUBE REAR INLET TUBE FITTING 4007121a Figure 2.9 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 33... - Page 38 MTC-4208/10 XLEC PASSENGER SIDE MOUNTED COOLER 4016829a Figure 2.13 MTC-4208/10 XLEC VARIANT PUMP OIL PUMP COVER OUTLET TO COOLER OIL PUMP CROSSOVER PUMP INLET TUBE CONNECTION CONNECTION 4014941d Figure 2.11 MM-0861 / Revised July 2020 Page 34 Copyright Meritor, Inc., 2020 Printed in USA...

- Page 39 When operating the PTO in Neutral range, do not exceed 2,000 rpm. PORT Control the transmission shift range and engine rpm to ensure this limit is not exceeded. 4000191d Figure 2.14 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 35...

-

Page 40: Section 3: Removal

Drain and discard the oil correctly. Clean the magnetic drain plug. Figure 3.1, Figure 3.2, and Figure 3.3. MTC-4208X/XP, MTC-4210X/XP, & AND MTC-4213X OUTLET TO FRONT FRONT OIL COOLER DRAIN PLUG 4007120a Figure 3.1 MM-0861 / Revised July 2020 Page 36 Copyright Meritor, Inc., 2020 Printed in USA... - Page 41 OIL PUMP CROSSOVER 11. Carefully remove the transfer case with the hydraulic jack. PUMP INLET TUBE CONNECTION CONNECTION 4014941d Figure 3.4 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 37...

- Page 42 16. Attach a suitable lifting device to the eyebolts to lift the transfer case. Use suitable brackets to mount the case in the repair stand. Figure 3.7 and Figure 3.8. MM-0861 / Revised July 2020 Page 38 Copyright Meritor, Inc., 2020 Printed in USA...

-

Page 43: Section 4: Disassembly

(for input shaft repairs only) If necessary, the input shaft may be removed without separating the transfer case halves. Once the transfer case is removed from the ve- hicle and the oil drained, Meritor recommends checking and recording DRAIN FILL... -

Page 44: Disassemble The Transfer Case

NOTE: The MTC-4213X has a two piece through shaft. Because of this design, only the forward half of the input shaft will be removed while the upper rear output shaft will remain in place. MM-0861 / Revised July 2020 Page 40 Copyright Meritor, Inc., 2020 Printed in USA... - Page 45 MTC-4208/10 XLEC VARIANT INLET TUBE PUMP FITTING OIL PUMP COVER OUTLET 4007121a TO COOLER Figure 4.5 OIL PUMP CROSSOVER PUMP INLET TUBE CONNECTION CONNECTION 4014941d Figure 4.7 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 41...

- Page 46 MTC-4208/10 XLEC, refer to the MTC-4208/10 XLEV instructions WASHER throughout this section for disassembly of XLEC variants. PUMP HOUSING PUMP BOLT COVER MTC-4208XL/XLEV & MTC-4210XL/XLEV 4007122a Figure 4.10 MM-0861 / Revised July 2020 Page 42 Copyright Meritor, Inc., 2020 Printed in USA...

- Page 47 If the input shaft retaining nut cannot be removed, it will not be possible to remove the front input shaft before opening the housing. Skip this procedure. MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 43...

- Page 48 Use a pry bar and mallet to loosen the input cage cover and internal pump assembly, if equipped. Figure 4.16. 4006310c Figure 4.16 Remove the shim pack. Figure 4.16. MM-0861 / Revised July 2020 Page 44 Copyright Meritor, Inc., 2020 Printed in USA...

- Page 49 As the rear cover is lifted, verify the high and low shift shaft remains in the case by placing pressure on the shaft while separating the transfer case halves. MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 45...

- Page 50 Press the output shaft DOWNWARD to remove the front roller 11. Remove the shift cylinder and push rod from the front case. bearing. 12. Remove the two locating dowel pins. Note their correct location. MM-0861 / Revised July 2020 Page 46 Copyright Meritor, Inc., 2020 Printed in USA...

- Page 51 Install the shaft assembly into a press. Press the shaft assembly DOWNWARD until the bearing is free from the shaft. MTC-4213 4000199a Figure 4.29 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 47...

- Page 52 Inspect and replace bearing cones with new as needed. Replace bearing cones and cups as a set. Inspect the shafts and gears for wear or damage. MM-0861 / Revised July 2020 Page 48 Copyright Meritor, Inc., 2020 Printed in USA...

- Page 53 BEARING CUP PULLER 4007155a Figure 4.33 Clean and save the shims so they can be used to measure the shim pack thickness during reassembly, if necessary. MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 49...

-

Page 54: Section 5: Prepare Parts For Assembly

NEVER clean ground or polished parts in a hot solution tank, water, steam, or alkaline solution to avoid damaging the surfaces. MM-0861 / Revised July 2020 Page 50 Copyright Meritor, Inc., 2020 Printed in USA... -

Page 55: Inspect Parts

Replace worn or cracked shafts, fl anges, and yokes. Verify oil passages in the shafts are clean and free of debris. MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 51... - Page 56 TRANSFER continue to operate satisfactorily with higher noise. SPALLING • Chipped or worn shifting splines on the input shaft. MM-0861 / Revised July 2020 Page 52 Copyright Meritor, Inc., 2020 Printed in USA...

- Page 57 • Gouges on the inside of the shift cylinder. • Torn or feathered areas on the o-ring. • Deep gouges in the shifting bores of the case halves. MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 53...

- Page 58 Refer to the Service Notes page on the front inside cover of this manual to obtain new seals and installation tools. Refer to page 70 for seal and sleeve installation instructions. MM-0861 / Revised July 2020 Page 54 Copyright Meritor, Inc., 2020 Printed in USA...

-

Page 59: Section 6: Assembly

CAUTION 4006923b Figure 6.1 ALTHOUGH MERITOR DOES NOT RECOMMEND ITS USE IN TRANSFER CASES, IF A FORMED-IN-PLACE GASKET Turn the shaft over and reinstall it into the holding fi xture. Refer to IS USED FOR REPAIRS, EXTREME CAUTION MUST BE tool “Holding Fixture (905473-140)”... - Page 60 Install the needle bearing onto the rear half of the output shaft WARNING and lubricate it with a light coat of lithium-based grease, Meritor specifi cation O-668. The needle bearing is a slip fi t assembly. TO AVOID SERIOUS PERSONAL INJURY AND DAMAGE TO Figure 6.3.

- Page 61 Install the internal oil pump using the following procedure. correctly seated. Pack lithium-complex grease, Meritor specifi cation O-668, Rotate the shaft so the rear half of the shaft is facing UP. Use into the pump oil inlet port before assembling the oil pump to a sleeve, tool number 905473-92, and press to push the rear the input bearing cage.

- Page 62 Install the internal oil pump, if equipped, using the following procedure. Spline side of gear DOWN MTC-4208X/XP & MTC-4210X/XP transfer cases only: Pack lithium-complex grease, Meritor specifi cation O-668, REAR 4005170a into the pump oil inlet port before assembling the oil pump to Figure 6.9 the input bearing cage.

- Page 63 Place the assembly into a holding fi xture (Refer to “Holding Fixture (905473-140)” on page 107) and install the yoke assembly. 10. Install the washer and yoke nut. Tighten the yoke nut to 700-900 lb-ft (949-1220 N∙m). MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 59...

-

Page 64: Gear & Shaft Installation Into The Transfer Case Halves

Lubricate all bearing cups and cones, gears, and shaft assemblies before installation into the case. Use SAE Grade full-synthetic 40W or 50W oil, Meritor specifi cation O-81. Use a mallet or press and sleeve to install the bearing cups into the bore until correctly seated. -

Page 65: Install The Front Input Shaft, Input Bearing Cage, & Internal Oil Pump Assembly Installation (If Equipped)

Lubricate the input bearing cage large o-ring, internal oil pump, if equipped, helical drive gear, and bearing cone before installation. Use SAE Grade full-synthetic 40W or 50W oil, Meritor 15. Verify the locating dowel pins have engaged both the case and specifi... -

Page 66: Install The Upper Rear Output Shaft (Mtc-4213X Only)

0.036” half. (0.91 mm) or use the same thickness as removed. Figure 6.20. SPACER SHIMS 4007369a Figure 6.20 MM-0861 / Revised July 2020 Page 62 Copyright Meritor, Inc., 2020 Printed in USA... -

Page 67: End Play Check & Adjustment

This will be the starting shim pack thickness to use when setting the respective shaft’s end play. BALL BEARING RECESSED AREA SHAFT 4012328a Figure 6.23 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 63... -

Page 68: Front Output Shaft End Play (All Models)

After performing all bearing end play measurements, separate the transfer case halves as necessary to adjust the shims and achieve the correct end play on the shaft requiring adjustment. MM-0861 / Revised July 2020 Page 64 Copyright Meritor, Inc., 2020 Printed in USA... - Page 69 • If the end play is less than 0.002” (0.051 mm): Remove shims to increase end play. Bearing shims come in 0.003”, 0.005”, and 0.010” (0.08, 0.13, and 0.25 mm) thicknesses. MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 65...

-

Page 70: Mtc-4213X Rear Output Shaft End Play

• If bearing end play is out of specifi cation: Remove the rear output shaft and install an appropriate spacer and shim combination between the bearing cones. 4000206a Figure 6.28 MM-0861 / Revised July 2020 Page 66 Copyright Meritor, Inc., 2020 Printed in USA... - Page 71 Tighten the capscrews to 85-115 lb-ft (115-156 N∙m). Recheck the input shaft bearing end play. Adjust the end play as necessary. MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 67...

- Page 72 After selecting the correct shim combination, place the shims in the bottom of the bearing bore. Refer to the exploded views starting on page 1 in this manual. MM-0861 / Revised July 2020 Page 68 Copyright Meritor, Inc., 2020 Printed in USA...

-

Page 73: Final Assembly

Grease all o-ring seals. Use a light coat of lithium-based grease, Lubricate and install the o-ring into the rear cover push rod Meritor specifi cation O-668. Refer to Figure 6.31 for shifter journal. Use a light coat of lithium-based grease, Meritor component arrangement. - Page 74 Install the outer shift piston outer snap ring onto the shift shaft. Input Shaft Oil Seal & Yoke Figure 6.33. For all transfer cases: Install the input seal and sleeve using Meritor kits 2728T1 and 2728T2 respectively. Install the forward output shaft seal using Meritor Kit 4454.

- Page 75 Figure 6.34 the seal. Use a dead-blow hammer and the appropriate driver to install the seal onto the input bearing cage. Figure 6.37. 4000212a Figure 6.37 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 71...

- Page 76 Figure 6.38. Output Shaft Oil Seal & Yoke For all transfer cases: Install the input seal and sleeve using Meritor kits 2728T1 and 2728T2 respectively. Install the forward output shaft seal using Meritor Kit 4454.

- Page 77 Figure 6.42 Apply a 0.125” (3.175 mm) bead of Loctite 518 sealant around the rear housing face. Figure 6.43. SEALANT MTC-4208XL/XLEV & MTC-4210XL/XLEV 4007116a Figure 6.43 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 73...

- Page 78 12. Use a 7/16” socket and tighten the bolts in a criss-cross pattern SEALANT to 10-13 lb-ft (14-18 N∙m). PUMP REVERSING Align PUMP COVER MTC-4208XL/XLEV & MTC-4210XL/XLEV 4006326d Figure 6.45 MM-0861 / Revised July 2020 Page 74 Copyright Meritor, Inc., 2020 Printed in USA...

- Page 79 Otherwise, install a nut and washer into the open port. Reinstall all other pipe threaded plugs using Loctite 592 threadlocker. MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 75...

-

Page 80: Transfer Case Shifting Check

Have someone hold the output shafts to prevent them from turning while spinning the input. 12. Remove the air pressure. 13. Remove the transfer case from the stand. MM-0861 / Revised July 2020 Page 76 Copyright Meritor, Inc., 2020 Printed in USA... -

Page 81: External Oil Pump Priming Procedure (Mtc-4208Xl/Xlev & Mtc-4210Xl/Xlev)

fi tting upper cap and add SAE Grade full-synthetic 40W or meter) pressure hose and the pressure gauge onto the other end. 50W oil, Meritor specifi cation O-81, to the tee fi tting until the tee Connect the female fi tting to the unused port of the diagnostic tee fi... -

Page 82: Optional Oil Pressure Test & Oil Fill Check

Turn the vehicle off. Do not repeat the test or damage to manufacturer (OEM) instructions to start the vehicle. components can result. Call the Meritor OnTrac™ Customer Call Center at 866-668-7221 for further assistance. Verify the vehicle primary and secondary air pressures are at least 90 psi (6.2 bar). -

Page 83: Mtc-4208/10 Xlec Oil Fill & Pump Pressure Test

Check and, if necessary, fi ll the transfer case, cooler and lines ROAD TEST. DAMAGE TO COMPONENTS CAN RESULT. as follows. Use Meritor-approved lubricant, full-synthetic 50W or 40W oil. Refer to publication TP-90114 - Transmission Lubricant Check the pump pressure gauge to verify it has reached an Specifi... -

Page 84: Section 7: Power Take-Off (Pto)

This section provides instructions on installing a power take-off (PTO) Hazard Alert Messages assembly onto Meritor MTC-4208 & MTC-4210 transfer cases using Kit 2540. Refer to Table C and Figure 7.1. Refer to the Service Notes Read and observe all Warning and Caution hazard alert messages in page on the front inside cover of this manual to obtain this kit. -

Page 85: Exploded View

O-ring, 1.46” (37 mm) Diameter Special Screw O-ring, 1.80” (46 mm) Diameter Capscrew, 1.25” (32 mm) Long Cover Plate Capscrew, 5.75” (146 mm) Long Switch Assembly, Standard Washer (Optional) MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 81... -

Page 86: Remove The Transfer Case Rear Access Cover

Washer, 0.47” (12 mm) Inside Diameter Lock Nut, Yoke Mounting Capscrew, 1.25” (32 mm) Long Switch and Connector Assembly Capscrew, 5.75” (146 mm) Long Dowel Pin MM-0861 / Revised July 2020 Page 82 Copyright Meritor, Inc., 2020 Printed in USA... -

Page 87: Install The Yoke Onto The Pto

Use a press and an applied press force of 500-1500 lbs (227- Install the Yoke onto the PTO 680 kg) to install a Meritor yoke, spline code RAI, onto the PTO shaft. Figure 7.2. A Meritor yoke with the spline code “RAI” must be installed onto the PTO. -

Page 88: Install The Pto Onto The Transfer Case

Apply 90 psi (6.2 bar) of air pressure. Check for leaks in the PTO air control line. Cycle the air control pressure. Follow the procedures below to verify the PTO clutch engages correctly. MM-0861 / Revised July 2020 Page 84 Copyright Meritor, Inc., 2020 Printed in USA... -

Page 89: Test The Transfer Case With Pto Assembly Installed

If the pressure decreases by more than 2 psi (0.14 bar) in 10 minutes: Check for external leaks at the fi ttings. Correct any leaks. Recheck the pressure. Install the breather. MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 85... -

Page 90: Pto Assembly

Install the cover plate with the o-ring seal in place. Figure 7.9 Lightly lubricate all parts with SAE Grade full-synthetic 40W or 50W oil, Meritor specifi cation O-81. Install the shaft assembly into the housing. Slide the bearing spacer onto the splined end of the shaft. - Page 91 With the correct fi tting installed into the air control port, apply a pressure of 90 psi (6.2 bar). Shut off the air supply. MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 87...

-

Page 92: Section 8: Installation

Connect any switch or speed sensor wiring. Fill the transfer case with the correct quantity of specifi ed lubricant. Refer to “Lubrication & Maintenance” on page 97. MM-0861 / Revised July 2020 Page 88 Copyright Meritor, Inc., 2020 Printed in USA... - Page 93 TUBE PUMP OIL PUMP COVER OUTLET TO COOLER REAR INLET TUBE FITTING OIL PUMP CROSSOVER 4007121a PUMP INLET TUBE CONNECTION Figure 8.2 CONNECTION 4014941d Figure 8.4 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 89...

- Page 94 NOTE: The P-clamp bracket is intended to support the crossover tube. Make certain there is no tension applied to the crossover tube once the fasteners have been tightened. MM-0861 / Revised July 2020 Page 90 Copyright Meritor, Inc., 2020 Printed in USA...

-

Page 95: Section 9: Troubleshooting

Reassemble transfer case. 1. Replace the breather. Breather 2. Determine if the breather clogged? is mounted in the correct location. Call the Meritor OnTrac™ Customer Call Center at 866-OnTrac1 (668-7221) for additional information. Does oil blow-out from the breather? Inspect seals 1. - Page 96 Repair as necessary. 2. Determine if the transfer Remove case requires an oil leaking seal. cooler. Call the Meritor OnTrac™ Customer Call Center at 866-OnTrac1 (668-7221) for additional information. Check the yoke journal for burrs, rough edges or wear grooves.

-

Page 97: Excessive Noise And Vibration Diagnostics

Problem transfer case shafts for determine if corrected? excessive wear. Repair as noise/vibration necessary. is still present. Return the vehicle to service. 4001527b Figure 9.3 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 93... -

Page 98: Pto Does Not Engage/Disengage Diagnostics

Reassemble and install the PTO on the transfer case. Road test the vehicle to confirm the problem is corrected. Return the vehicle to service. 4001528d Figure 9.4 MM-0861 / Revised July 2020 Page 94 Copyright Meritor, Inc., 2020 Printed in USA... -

Page 99: Front Axle Declutch Does Not Engage/Disengage Diagnostics

Repair all damaged components. Reinstall the transfer case onto the vehicle. Road test the vehicle to confirm the problem is corrected. Return the vehicle to service. 4001529d Figure 9.5 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 95... -

Page 100: High/Low Gear Shifting Diagnostics

Reassemble and check the transfer case shifts correctly. 866-OnTrac1 (668-7221). Reinstall transfer case Contact OnTrac™ Problem in vehicle and return Customer Call Center at fixed? vehicle to service. 866-OnTrac1 (668-7221). 4001530c Figure 9.6 MM-0861 / Revised July 2020 Page 96 Copyright Meritor, Inc., 2020 Printed in USA... -

Page 101: Section 10: Lubrication & Maintenance

For complete lubrication information for Meritor’s transfer cases, refer to Maintenance Manual 1 - Preventive Maintenance and Lubrication. To obtain a copy of this publication or access it on Meritor’s website, refer to the Service Notes page on the inside front cover of this manual. - Page 102 Always replace unitized seals after yokes have been removed. MLS seals may be reused if they are not damaged or leaking. Meritor has released the multiple-lip seal (MLS) for use in the INPUT POSITION ONLY on the MTC-4208, MTC-4210, and MTC-4213 trans- fer cases.

-

Page 103: Check & Adjust The Oil Level

FER CASE, WHICH CAN CAUSE THE TRANSFER CASE TO OVERHEAT. DAMAGE TO COMPONENTS CAN RESULT. NOTE: Meritor recommends the oil cooler lines should be routed to prevent oil fl ow back into the transfer case sump. This can be accomplished by routing lines with a P-trap confi guration for both the oil cooler inlet and outlet lines. -

Page 104: Drain & Replace The Oil

If the oil level is below the fi ll/level plug hole: Add SAE Grade full synthetic 40W or 50W oil, Meritor Add SAE Grade full-synthetic 40W or 50W oil, Meritor Specifi cation 0-81, until oil is even with the bottom of the fi ll hole. - Page 105 3 Meritor-approved full-synthetic oil for Meritor manual transmissions • All oil cooler equipped transfer cases will use additional oil to is also approved for Meritor transfer cases. Refer to publication TP- compensate for the cooler and cooler lines. OEM’s and vehicle 90114 - Transmission Lubricant Specifi...

-

Page 106: Standard Mtc-4213X, Mtc-4208Xp, & Mtc-4210Xp

Specifi cations Torque Specifi cations Standard MTC-4213X, MTC-4208XP, & MTC-4210XP OIL COOLER READY MODEL STANDARD MODEL MTC-4213X MTC-4208XP AND MTC-4210XP FRONT FRONT 4007123a Figure 11.1 MM-0861 / Revised July 2020 Page 102 Copyright Meritor, Inc., 2020 Printed in USA... -

Page 107: Section 11: Torque Specifi Cations

1 Apply Loctite 582 threadlocker to pipe threads 2 Apply Loctite 592 threadlocker 3 Apply Loctite 242 threadlocker 4 Apply Loctite 518 threadlocker to the fi rst three threads MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 103... -

Page 108: Standard Mtc-4208X/Xl/Xlev & Mtc-4210X/Xl/Xlev

Specifi cations Standard MTC-4208X/XL/XLEV & MTC-4210X/XL/XLEV MTC-4208X & MTC-4210X MTC-4208XL & MTC-4210XL 4007200a Figure 11.2 MM-0861 / Revised July 2020 Page 104 Copyright Meritor, Inc., 2020 Printed in USA... - Page 109 1 Apply Loctite 582 threadlocker to pipe threads 2 Apply Loctite 592 threadlocker 3 Apply Loctite 242 threadlocker 4011712a 4 Apply Loctite 518 threadlocker to the fi rst three threads Figure 11.3 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 105...

-

Page 110: Section 12: Vehicle Towing Instructions

FOLLOW TOWING PROCEDURES RECOMMENDED BY MER- ITOR TO PREVENT INTERNAL DAMAGE TO THE TRANSFER CASE. Meritor recommends using one of the two methods below when towing to prevent damage to the transfer case. NOTE: For complete towing information and instructions on axle shaft removal, refer to Technical Bulletin TP-9579 - Driver Instruction Kit. -

Page 111: Section 13: Tools

The following section provides details of tooling to facilitate service of the transfer case. Service tools may be manufactured using these drawings or contact Meritor for a price and delivery quotation. The manufacture of these tools should be carried out by professional machinists and certifi ed welders, following typical good workmanship procedures and safe practices. - Page 112 ø 2.70 ø 3.25 DIA. DIA. DIA. 0.03 R 0.12 R 0.03 X 45° 0.90 (2) PLCS. KNURL NOTE: Not available from Meritor. 4007160a Figure 13.3 MM-0861 / Revised July 2020 Page 108 Copyright Meritor, Inc., 2020 Printed in USA...

-

Page 113: Bearing Cone Driver (905473-92)

2. Install a 3/16" O.D. x 1/2" long roll pin through the 1/4 x 2-1/2" long slot of Tool A, Ø2.582 and into the 3/16" hole in Tool B. The roll pin can be obtained from McCaster Carr, part number 98296-A975. 4012347a Figure 13.5 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 109... -

Page 114: Bearing Driver ((4Fi20-27110-000008)

0.09 RAD. TYP . MIN. UNDERCUT 1.76 3.980 4.810 4.450 3.48 3.978 4.808 DIA. DIA. DIA. DIA. DIA. 45° 1.15 0.250 1.35 4.15 4007157a Figure 13.7 MM-0861 / Revised July 2020 Page 110 Copyright Meritor, Inc., 2020 Printed in USA... -

Page 115: Bearing Driver Guide (4Fi20-27110-000008-D02)

0.63 BEARING CUP DRIVER FOR DRILL AND CUPS JM207010 AND 33821 C’BORE FOR Ø3.063 1/2-30 SDC Ø3.454 HR SCR 4012345a SEE TOOL ASSEMBLY INSTRUCTIONS Figure 13.9 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 111... -

Page 116: Bearing Cup Driver (4Fi20-27110-000007)

0.09 RAD. TYP . MIN. UNDERCUT 4.997 3.980 4.980 3.48 4.637 3.978 4.976 4.995 DIA. DIA. DIA. DIA. DIA. DIA. 45° 1.09 0.250 1.56 1.50 4.34 4007158a Figure 13.10 MM-0861 / Revised July 2020 Page 112 Copyright Meritor, Inc., 2020 Printed in USA... -

Page 117: Bearing Cup Driver (910203-37)

Special Tools PTO Bearing Cone Driver 8.00 4.00 3.500 3.000 0.250 R 0.38 0.38 5.375 4.50 0.44 4007162a Figure 13.11 MM-0861 / Revised July 2020 Printed in USA Copyright Meritor, Inc., 2020 Page 113... -

Page 118: Modifi Ed Bearing Cup Puller

Remove – cup contact not needed Grind the corner Disassemble and for clearance turn the fingers out (both sides) 4012353a Figure 13.12 MM-0861 / Revised July 2020 Page 114 Copyright Meritor, Inc., 2020 Printed in USA... - Page 119 ...

- Page 120 Meritor Heavy Vehicle Systems, LLC 2135 West Maple Rd Troy, MI 48084 USA Printed in USA 866-OnTrac1 (668-7221) Copyright 2020 07-20 meritor.com Meritor, Inc. MM-0861...

Need help?

Do you have a question about the MTC-4208X Series and is the answer not in the manual?

Questions and answers