Summary of Contents for Frontier SB1388

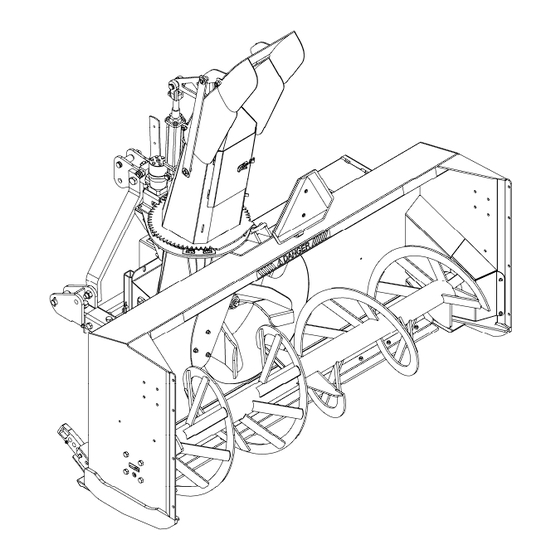

- Page 1 OPERATOR'S MANUAL SNOWBLOWER SB1388 Serial #: 1XFSB13X_E0140001 & plus OM0437SB1388 Rev1 11-15...

-

Page 3: Table Of Contents

TABLE OF CONTENT SPECIFICATIONS ............................3 INTRODUCTION – TO THE PURCHASER ....................4 SAFETY PRECAUTIONS .......................... 5-10 General Information..........................5 Notice ..............................6 The Snowblower ......................... 6 Before Operation ........................6 Snowblower Operation ......................6 Stay Clear of Rotating Drivelines .................... 8 The Tractor ............................ - Page 4 TABLE OF CONTENT OPERATION ............................29-31 General Preparation ..........................29 Operating Controls ..........................29 Raising and Lowering the Snowblower ................29 Work and Travel Speed ..................... 29 PTO Operation ........................29 Chute Rotation Orientation ....................29 Hydraulic Chute Deflector Orientation ................30 Adjustments ............................

-

Page 5: Specifications

SPECIFICATIONS Specifications SB1388 General 2 phases Type Direction of impeller rotation 55 - 85 Hp PTO power requirements Shipping weight (without chute) 1531 Lbs Operating weight, incl. chute & hyd. deflect. 1607 Lbs Set-up time 90 min 88 1/2" Working width 41"... -

Page 6: Introduction - To The Purchaser

INTRODUCTION O THE URCHASER All products are designed to give safe, dependable Illustrations service if they are operated and maintained The illustrations may not necessarily reproduce according to instructions. Read and understand the full detail and the exact shape of the parts or this manual before operation. -

Page 7: Safety Precautions

SAFETY PRECAUTIONS SAFETY FIRST This symbol, the industry's "Safety Alert Symbol", is used throughout this manual and on labels on the machine itself to warn of the possibility of personal injury. Read these instructions carefully. It is essential that you read the instructions and safety regulations before you attempt to assemble or use this unit. -

Page 8: Notice

SAFETY PRECAUTIONS - continued OTICE A safe operator is the best insurance against accidents. All operators, no matter how experienced they may be, should read this Operator's Manual and all other related manuals before attempting to operate an implement. Please read the following section and pay particular attention to all safety recommendations contained in this manual and those labeled on the implements and on the tractor. -

Page 9: Snowblower Operation

SAFETY PRECAUTIONS- continued Snowblower Operation 11. Do not run the engine indoors except when Before leaving tractor/snowblower starting engine and transporting attachment in unattended, take all possible precautions. or out of building. Carbon monoxide gas is Park the tractor/snowblower on level colorless, odorless and deadly. -

Page 10: Stay Clear Of Rotating Drivelines

SAFETY PRECAUTIONS- continued Stay Clear of Rotating Drivelines 1. Entanglement in rotating driveline can cause serious injury or death. 2. Keep tractor master shield and driveline shields in place at all times. Make sure rotating shields turn freely. 3. Wear close fitting clothing. Stop the engine and be sure that PTO driveline is stopped before making adjustments, connections, or cleaning out PTO driven equipment. -

Page 11: The Tractor

SAFETY PRECAUTIONS- continued RACTOR General Information 14. A minimum 20% of tractor and equipment 1. Read the operator's manual carefully before weight must be on the tractor front wheels when attachments are in transport position. using tractor. Lack of operating knowledge Without this weight, tractor could tip over, can lead to accidents. -

Page 12: Maintenance

SAFETY PRECAUTIONS- continued AINTENANCE 11. Do not operate a snowblower that is defective or ALWAYS USE GE NUINE PARTS WHEN REPLACEMENT PARTS ARE REQUIRED missing parts. Make sure that recommended maintenance procedures are 1. Keep the tractor and snowblower properly completed before operating the snowblower. -

Page 13: Safety Decals

SAFETY DECALS Replace immediately if damaged OM 0437SB1388-A... - Page 14 SAFETY DECALS Replace immediately if damaged OM 0437SB1388-A...

-

Page 15: Assembly

ASSEMBLY RACTOR REPARATION See Dealer for Tractor Preparation information. NOWBLOWER SSEMBLY The snowblower is assembled at the factory except for the parts in the hardware bag provided with the snowblower, the chute and the options if appropriate. Use the present manual and lay out all parts for assembly. -

Page 16: Installation Of Three Point Hitch

ASSEMBLY Installation of Three Point Hitch (Figures 3-4) NOTE: Do not tighten the bolts during assembly. The bo lts are tightened to the last step. NOTE: The three point hitch can be installed in two positions; close to the tractor o r distant. -

Page 17: Installation Of The 5Rdf0072 Or 5Rdf0073 Chute, And The Hydraulic Rotation

ASSEMBLY Installation of the 5RDF0072 or 5RDF0073 Chute, and the Hydraulic Rotation (Figures 5-6-7-8) 1. Figure 5: Remove the motor of the rotation (item 1) from its transport location by removing the hardware: bolts, flat washers, nylon insert lock nuts (items 2-3- 4). -

Page 18: Installation Of The 5Rdf0071 Hydraulic Deflector For 2 Part Chute

ASSEMBLY Installation of the 5RDF0071 Hydraulic Deflector for 2 part Chute (Figures 9-9a) 3. Figure 9: Remove a circlip (items 1-4) from each cylinder pin (items 2-3) and remove the pins. Placing the hydraulic ports in the position shown on figure, attach the fixed end of the cylinder (item 6) to the chute base (item 5) and the rod end to the deflector with the pins... -

Page 19: Installation Of The Hydraulic Hoses

ASSEMBLY Installation of the Hydraulic Hoses (Figures 10-11-11a) A- HOSES OF THE CHUTE ROTATION 1. Figure 10: Install the hydraulic motor Figure 10 hoses of the chute (item 1) on the hose support in the lower hole. 2. Figure 10: Attach the hose clamps using a 3/8"NC x 1 3/4"... - Page 20 ASSEMBLY 3. Figure 11a: Attach hoses (item 2) to the CAUTION: hose support previously installed by To avoid serious personal injury. Escaping running them inside the hose clamp. hydraulic/ diesel fluid under pressure penetrate the skin causing serious injury 4. Figure 11a: Attach hoses (item 2) to the hose support located on the three point ...

-

Page 21: Installation Of Second Auger - 5Rdf0063

ASSEMBLY Installation of Second Auger – 5RDF0063 OPTION (Figure 12) 1. Remove the chain guard (item 1) and loosen 5. On the upper auger, install the sprocket 1 1/4"- drive chain as per instructions in the Chain 3 1/2" c/c holes (item 3) using four 3/8"NC x 1 Idler Adjustment section at page 33 then 1/2"... -

Page 22: Installation Of Serrated Auger 5Rdf0067

ASSEMBLY Installation of Serrated Auger - 5RDF0067 OPTION (Figure 13) 5. Slide the spacer (item 10) and the flange bearings 1. Remove the chain guard (item 1) and loosen drive chain as per instructions in (items 9) on the serrated auger. Do not tighten the the Chain Idler Adjustment section at setscrews on the flange bearings for now. -

Page 23: Installation Of Drift Cutters - 5Rdf0074

ASSEMBLY Installation of Drift Cutters - 5RDF0074 OPTION (Figure 14) Install the drift cutters (items 1-2) on the exterior of each snowblower side by aligning the top and bottom holes and fasten with eight 1/2"NC x 1 3/4" lg plow bolts, 1/2" lockwashers and 1/2"NC nuts (items 3-4-5). -

Page 24: Installation Of Lower Hitches For Quick Hitch - 5Rdf0077

ASSEMBLY Installation of Lower Hitches for Quick Hitch – OPTION 5RDF0077 (Figure 16) NOTE: If the three point hitch is not already 3. Remove the lower three point hitches (item 1) installed on the snowblower; refer to the by removing the two vertical 3/4"NC x 5 1/2" "Installation of the three point hitch"... -

Page 25: Installation Of Snowblower With Three Point Hitch

ASSEMBLY Installation of the Snowblower with the Three Point Hitch (Figure 17) 1. Attach the tractor lower hitch arms (item 1) to 4. To level side to side, use leveling crank on right the snowblower lower hitches (item 7) with the lower lift arm. -

Page 26: Installation Of Snowblower With Quick Hitch

ASSEMBLY Installation of the Snowblower with a Quick Hitch (Figure 18) Note: Installation of the Snowblower with a Quick Hitch requires the 5RDF0077 kit of Lower Hitches for Quick Hitch. 1. Install the 1 1/8" x 6 1/4" lg Cat. 2 (item 2) in CAUTION: Before connecting... -

Page 27: Preparation Of The Driveline

ASSEMBLY Preparation of the Driveline ECOMMENDATIONS FOR RIVELINE NGLES IMPORTANT: The universal joint angle is directly related with To obtain the proper universal the life of driveline. In order to reduce the angle, joint angles, it is recommended to adjust the it is necessary to increase the distance between three point hitch at the furthest point from the the snowblower and the tractor. -

Page 28: Determining Driveline Length

ASSEMBLY ETERMINING RIVELINE ENGTH IMPORTANT: Before using the equipment, make sure the driveline is not too long. L = X – Y working position, the two half drivelines must intersect each other sufficiently to insure maximum efficiency but there must not be any 3 PTS HITCH interference. - Page 29 ASSEMBLY NOTE: Before cutting, make sure the two shafts intersect by at least 5" when in working position that is when the snowblower rests on the ground. 3. Hold the two half-shaft side by side and locate the "L" length between the two center-to-center half- shaft universal joints.

-

Page 30: Driveline Installation

ASSEMBLY Driveline Installation Removing Snowblower from Tractor (Figure 23) Find a level surface. Lower the parking stand. Remove the driveline from the tractor PTO. 1. Remove the paint from the gearbox shaft Remove the hydraulic hoses. Detach the top link. (item 1) and grease the driveline sliding Detach the right lower link then detach the left surfaces and yoke. -

Page 31: Operation

OPERATION ENERAL REPARATION PERATING ONTROLS 1. Read the operator’s manual carefully Raising and Lowering Snowblower before using the tractor and snowblower. Move the three point lever down or forward to Be thoroughly familiar with the controls and lower, and up or rearward to raise. proper use of the equipment. -

Page 32: Hydraulic Chute Deflector Orientation

OPERATION DJUSTMENTS Chute Door Adjustment Figure B: CAUTION : To avoid personal injury, be sure the tractor engine is off, the driv e shaft The 3-part chute has a removable access door at the front. The use of this door increases visibility disengaged, and all movement has stopped when a curtain of snow comes out of the front of BEFORE making any adjustments. -

Page 33: Snow Removal Methods

OPERATION EMOVAL ETHODS When removing snow, do not use the snowblower as a dozer blade to push snow. Let the snowblower work its way through deep drifts. If the speed of your tractor is too fast, the snowblower may become overloaded and clog. -

Page 34: Maintenance

MAINTENANCE AINTENANCE WARNING: Provide adequate blocking before working under the snowblower when in the raised position. Driveline Shearbolts IMPORTANT: When the snowblower is not used Check the shearbolts indicated on the figure below at frequent intervals for proper tightness for more than two weeks, perform driveline to be sure the blower is in safe working maintenance and always store it in a dry place, condition. -

Page 35: Chain Idler Adjustment

MAINTENANCE Chain Idler Adjustment (Figures A-B) A - COMPRESSION SPRING (Fig. A): C - SECOND AUGER CHAIN TENSION (Fig. B): 1. Every ten operating hours check the height of 1. At the end of the operating season, check the the compression spring (item 1), to have chain chain elongation measuring... -

Page 36: Lubrication

MAINTENANCE UBRICATION Use oil or a grease gun and lubricate as follows: DESCRIPTION INTERVAL LUBRICATION REQUIRED Grease each universal joint. Separate the sliding parts 8 hours and cover each one of them with grease. Driveline 16 hours Oil the sliding sleeve collar 4 hours Chain Lubricate with chain lube... -

Page 37: Driveline - Troubleshooting

MAINTENANCE RIVELINE ROUBLESHOOTING AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS Quick-disconnect pin tight or Quick-disconnect pin dirty Clean, oil and follow service UICK DISCONNECT YOKE completely seized. (insufficient maintenance). instructions. Quick-disconnect pin Replace quick-disconnect pin. Quick-disconnect pin defective (forced ... - Page 38 MAINTENANCE AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS Cross arms broken. Extreme torque peak or Use appropriate safety device. ROSS shock load. Change to a larger driveline Axial loads too high. size. Shorten driveline shaft. ...

- Page 39 MAINTENANCE AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS Excessive wear of shield Insufficient lubrication. Follow lubrication instructions. HIELD bearings. Incorrect chain mounting. Mount chain to allow Shield interfering with maximum angularity. Avoid contact of the shields implement.

-

Page 40: Parts

PARTS NTRODUCTION All parts are illustrated in "exploded views" which show the individual parts in their normal relationship to each other. Reference numbers are used in the illustrations. These numbers correspond to those in the "Reference Number" (REF) column, and are followed by the description and quantity required. O/L - "Obtain Locally"... -

Page 41: Chain Idler

PARTS HAIN DLER ESCRIPTION Chain Idler 5RD670405 Spacer ring 5RD670974 Idler sprocket 3/4" hole 80A11 5RD654756 Idler Lever 5RD670865 Spring guide 5RD670866 Compression spring 5RD664876 Plastic bushing 5RD4300124 Bolt hex 3/8"NC x 1" Gr. 5 PTD Shoulder screw 5/8"NC x 1/2'' 5RD3200023 Bolt hex 3/4"NC x 2 3/4"... -

Page 42: Snowblower Assembly - Front Part

PARTS – F NOWBLOWER SSEMBLY RONT OM 0437SB1388-A... - Page 43 PARTS – F NOWBLOWER SSEMBLY RONT ESCRIPTION Housing 5RD670878 Auger 5RD670973 Chain guard 5RD670935 Restriction plate 5RD670996 S.M.V. sign support 5RD668090 Cutting edge 5RD670966 Spacer 5RD671137 Chain #80 X 79 links inc. connecting link & offset link 5RD3300061 - Offset link #80 5RD655550 - Connecting link 5RD655549...

-

Page 44: Snowblower Assembly - Rear Part

PARTS – R NOWBLOWER SSEMBLY OM 0437SB1388-A... - Page 45 PARTS – R NOWBLOWER SSEMBLY ESCRIPTION Spacer 5RD670975 Driveline shield 5RD670937 Driveline shield support 5RD670936 Chute guide 5RD670944 Retaining plate 5RD670933 Anti friction plate 5RD670945 Protection plate 5RD670977 Parking stand 5RD662252 Skid shoe – swivel base 5RD670885 Slide bar of the swivel skid shoe 5RD670899 Pin "L"...

-

Page 46: Three Point Hitch

PARTS HREE OINT ITCH OM 0437SB1388-A... - Page 47 PARTS HREE OINT ITCH ESCRIPTION Upper hitch 5RD670963 Hitch - RH 5RD670961 Hitch - LH 5RD670962 Lower hitch 5RD670960 Brace 5RD670939 Reinforcement plate 5RD668117 Hose support 5RD670938 Pin 1 1/8" x 6 1/4" lg Cat. 2 5RD4600042 Pin 1" x 6 1/16" lg Cat. 2 5RD4600052 Linchpin 7/16"...

-

Page 48: Hydraulic Rotation

PARTS YDRAULIC OTATION ESCRIPTION Hydraulic Motor 315cc with safety valve 5RD3910105 - Safety valve (included with the motor 5RD3910105) 5RD3910100 - Seal kit, O-Ring included 5RD3910104 - Key 1/4" x 1/4" x 1 1/4" (not shown) 5RD654643 Bolt 8mm x 1.25mm x 25mm lg gr.5 PTD - for motor Eagle ... -

Page 49: Driveline

PARTS - 5RD662538 RIVELINE ESCRIPTION Quick disconnect yoke assembly - slide collar 5RD4700083 Universal joint kit 5RD663134 Outer yoke 5RD663136 Outer tube 5RD663140 Inner tube 5RD663142 Inner yoke 5RD663144 Yoke and hub assembly 5RD663145 Bolt and nut 5RD662199 Grease fitting 5RD663148 Ball 5RD663162... -

Page 50: Gearbox Comer

PARTS 5RD662195 - COMER IDENTIFIED ESCRIPTION Gear Box assembly 5RD662195 Casing 5RD656640 Seal kit 35 x 72 x 10 5RD659845 External retaining ring 5RD656652 Spacer 5RD656649 Bearing 5RD659844 Spacer 5RD656648 Internal retaining ring 5RD656654 Bearing 5RD656647 Shaft 5RD656651 Gear 5RD656645 External retaining ring 5RD656646 Bearing... -

Page 51: Gearbox (Other)

PARTS 5RD662195 ESCRIPTION Gear Box assembly 5RD662195 Seal kit 35 x 72 x 10 5RD659845 Bearing 5RD659844 Bearing 5RD656647 Bearing 5RD656641 Seal kit 40 x 80 x 12 5RD4500170 Plug 5RD4500169 This side identified "662195" OM 0437SB1388-A... -

Page 52: 5Rdf0072 - Two Part Chute

PARTS - 5RDF0072 WO PART HUTE ESCRIPTION Chute base 5RD671009 Deflector 5RD671008 Hinge pin 5RD670884 Adjustment tube 5RD654076 Adjustment rod 5RD654074 Grease fitting 1/4" NF 5RD654106 Stover lock nut 1/2"NC PTD Cotter pin 1/4" x 2" PTD Round wire lock pin 1/4" x 2" 5RD1900006 OM 0437SB1388-A... -

Page 53: 5Rdf0073 - Three Part Chute

PARTS - 5RDF0073 HREE PART HUTE ESCRIPTION Chute base 5RD670880 Middle deflector 5RD670881 Chute upper part 5RD670882 Chute door 5RD670984 Hinge pin 5RD670884 Cylinder 2" x 8" 5RD3900022 - Seal kit 5RD3900205 Flat bar 5RD670985 Hose 3/8" x 140" 5RD3700270 Quick coupler 1/2"NPT male 5RD656480 Dust cap... -

Page 54: 5Rdf0071 - Hydraulic Deflector

PARTS - 5RDF0071 YDRAULIC EFLECTOR ESCRIPTION Hose support 5RD670948 Cylinder 2" x 8" 5RD3900022 - Seal kit 5RD3900205 Flow restrictor, 90° elbow 3/8"NPT M x 3/8"NPT SWF 5RD3900204 Hose 3/8" x 140" 5RD3700270 Quick coupler 1/2"NPT male 5RD656480 Dust cap 5RD664898 Hose clamp - double 5RD666583... -

Page 55: 5Rdf0077 - Lower Hitches For Quick Hitch

PARTS - 5RDF0077 OWER ITCHES FOR UICK ITCH ESCRIPTION Lower hitch 5RD671069 Pin Cat.2 - 1 1/8" x 6 1/4" PTD 5RD4600042 Lower bushing CAT. 2 5RD668608 Upper bushing CAT. 2 5RD668607 Spring pin 5/16" X 2" 5RD1600034 Linchpin 7/16" PTD 5RD1900003 OM 0437SB1388-A... -

Page 56: 5Rdf0063 - Second Auger

PARTS - 5RDF0063 ECOND UGER ONVERSION ESCRIPTION Upper auger 5RD671043 Chain idler 5RD655782 Chain guard 5RD670980 Spacer 1/4" thick 5RD671084 Sprocket #60A32, hole Ø1 1/4" 5RD3300063 Sprocket #H60C15 5RD665397 Sprocket #60A32, hole Ø1 1/4” 5RD654167 Flange bearing 1 1/4" 4 holes 5RD4300118 Chain #60 x 88 links &... -

Page 57: Other Options: Drift Cutters - Stainless Skid Shoes

PARTS THER PTIONS – S –C – S RIFT UTTERS TAINLESS HOES UTTING DGES ERRATED UGER ESCRIPTION 5RDF0074 RIFT UTTERS Plow bolt 1/2"NC x 1 3/4" Gr.5 PTD 5RD0400030 (incl.in the kit) Lockwasher 1/2" PTD (incl.in the kit) Nut hex 1/2"NC PTD (incl.in the kit) 5RDF0062 TAINLESS HOES... -

Page 58: Torque Specification Table

TORQUE SPECIFICATION TABLE ENERAL SPECIFICATION TABLE SE THE FOLLOWING TORQUES WHEN SPECIAL TORQUES ARE NOT GIVEN Note:These values apply fasteners as received from supplier dry, or when lubricated with normal engine oil. They do not apply if special graphited or moly sidulphide greases or other extreme pressure lubricants are used. These values apply to dry conditions;... - Page 60 PART NO. 5RDSB1388A3 All Rights Reserved...

Need help?

Do you have a question about the SB1388 and is the answer not in the manual?

Questions and answers