Subscribe to Our Youtube Channel

Summary of Contents for Bentone B 30A

- Page 1 178 122 51-1 2019-08-15 Providing sustainable energy solutions worldwide Installation- and maintenance instruction B 30A...

- Page 2 Bentone...

-

Page 3: Table Of Contents

10.1 Burner will not start ________________________________34 10.2 Burner will not start after normal use _________________34 10.3 Delayed ignition ___________________________________35 10.4 Noise in pump ____________________________________35 10.5 Pump pressure ___________________________________35 11. Log of flue gas analysis _____________________________36 12. Oil burners maintenance instructions ________________37 Bentone... -

Page 4: General Information

• Burner pipes, fan wheels and air dampers may contain sharp edges. • The surface temperature of the burner’s components can exceed 60 °C. • Caution: The burner has moving parts, and there is risk of crushing injuries. 165 105 01 Bentone... - Page 5 - fitting and installation work has been completed and approved - electrical installation has been correctly performed - flue gas ducts and combustion air ducts are not blocked - all actuators and control and safety devices are in working order and correctly set Bentone...

- Page 6 Delivery check • Make sure everything is delivered and the goods have not been damaged during transit. • If something is wrong with a delivery, report it to the supplier. • Transport damage must be reported to the shipping company. Bentone...

-

Page 7: Technical Data

• Water heating generators • Hot air generators (these require LMO 24 255 C2E) 2.1 Dimensions B 30 Ø B Ø C B 30 187/315 * Min. recommended distance to floor. ø108 2.2 Dimensions flange 165 105 22 Bentone... -

Page 8: Working Field B 30

100 110 120 130 140 150 160 170 180 190 200 210 2.3.1 Electric Specification Burner correspond to IP 20 Type Motor Complete Sound burner B 30 180W 1,3A 230V 230V 2,5A 84 dBA ± 0,5 50Hz 5µF 50Hz Bentone... -

Page 9: Setting Of Brake Plate And Air Flow

45° Solid/semisolid 60° Solid/semisolid 80° Solid/semisolid Pump pressure 10 bar (8-25 bar) 2.6 Burner installation 2.6.1 Hole patten Make sure the hole pattern on the boiler is designed for burner flange. Combustion device B 30 ø 110 ø 160-200 Bentone... -

Page 10: Nozzle Table

27,33 31,83 34,19 7,50 26,47 29,28 33,95 36,47 8,00 28,24 31,23 36,07 38,74 8,50 30,00 33,18 38,19 41,02 9,00 31,77 35,14 The table applies to oil with a viscosity of 4.4 mm /s at a density of 830 kg/m Bentone... - Page 11 768 660 67,77 70,66 14,00 67,96 71,84 75,55 896 770 79,09 82,43 16,00 77,67 82,11 86,34 1024 880 90,36 1072 94,20 1117 The table applies to oil with a viscosity of 4.4 mm /s at a density of 830 kg/m Bentone...

-

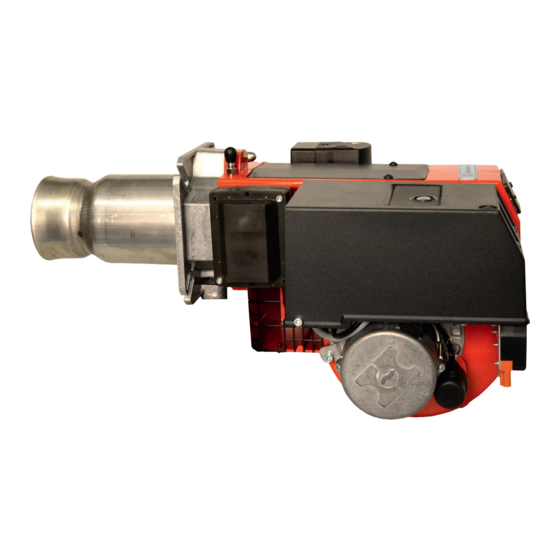

Page 12: Description B 30

Cover, inspection glass 16. Air damper Nozzle Ignition electrodes 10. Fan wheel 17. Solenoid valve Nozzle assembly 11. Motor 18. Air intake Ignition cable 12. Photo cell 19. Pump Ignition transformer 13. Nozzle assembly adjustment Control box 14. Blast tube Bentone... -

Page 13: General Instructions

The system must be fine-tuned at start-up. The temperature in the chimney must be at least 60 °C at 0.5 m down in the chimney to prevent condensation. 165 105 03 Bentone... -

Page 14: Installation

4. Installation 4.1 Handling and lifting instruktion The lifting aid are available as spare parts, Bentone... -

Page 15: Acceptance Inspection

• The connection should be made in accordance with the wiring diagram. • Fuse rating is as required If any electrical connection is used other than that recommended by Bentone, there may be a danger of damage to property and personal injury. -

Page 16: Mount The Burner On The Boiler

Once the burner has been installed and commissioned, the seals of the various coupling elements should be checked (A). When a leak is detected, it is usually sufficient to tighten the coupling element that is leaking. 165 105 47 Bentone... -

Page 17: Air Setting

The nozzle assembly control is used to achieve the most favourable pressure drop across the brake plate as possible at the various effect stages. The nozzle assembly is adjusted manually (B) in order to obtain the optimum pressure drop for good combustion. 165 105 24 Bentone... -

Page 18: Burner Installation

flame. Once the burner has started and established a flame, it will be necessary to adjust the settings so that they are adapted to the installation in question and the fuel used at the time. 165 105 13-1 2018-10-10 Bentone... -

Page 19: Setting Values For Nozzle Assembly B 30

See under Basic settings Note that it is simply a matter of a basic setting that should be adjusted retrospectively once the burner has started. A flue gas analysis and soot quantity measurement must be carried out when fine-tuning the burner. Bentone... -

Page 20: Burner Servicing

Close the boiler / spectacle flange. nozzles. Do not Turn on the main power. clean. Check combustion*. Note: When servicing/replacing components that affect combustion, an analysis and soot test shall be carried out on the installation. 165 105 23 Bentone... -

Page 21: Servicing Air Dampers

Refit the air damper and actuator. Install the intake grille for the air intake. Turn on the mains power. Check/adjust combustion.* Note: When servicing/replacing components that affect combustion, an analysis and soot test shall be carried out on the installation. Bentone... -

Page 22: Servicing The Fan

Disconnect the motor’s electrical cable Remove the motor Remove the drive shaft and drive coupling from the motor Disconnect the drive coupling from the pump Fit the coupling, pump, and motor. Make sure the drive shaft is connected correctly at both ends Bentone... -

Page 23: Replacement Of Oil Pump

Bleed the pump, start the burner and set the correct oil pressure (refer to technical data for correct output). Check combustion.* Note: When servicing/replacing components that affect combustion, an analysis and soot test shall be carried out on the installation. Bentone... -

Page 24: Vibration

Maximum vibration level are 5,0 mm/s • Check all bolts and nuts for correct torque • Check fan wheel for damage and contamination. Change when dirty/ unbalanced • Check motor bearings. If worn change motor/bearings Use lid screw hole for sensor mounting Bentone... -

Page 25: Instructions Pump

60°C Components Suction line G 1/4” Return line G 1/4”and internal by- pass plug Nozzle outlet G 1/8” Pressure gauge port G 1/8” Vacuum gauge port G 1/8” Pressure adjustment 165 105 20 Bentone... - Page 26 By-passed oil By-passed oil removed inserted returned to tank, removed inserted returned to tank, or to suction Return ONE PIPE TWO PIPE Return plugged or to suction Return Inlet plugged INSTALLATION INSTALLATION Return Inlet One pipe installation Two pipe installation Bentone...

- Page 27 (D-H) max. = 4,5 m 150 150 139 150 108 150 150 150 150 **Q = pump capacity @ 0 bar / Pumpenleistung bei 0 bar Two pipe lift system capacité de l'engrenage à 0 bar/portata della pompa a 0 bar. Bentone...

- Page 28 5 min. (a condition is that the pump is being lubricated during operation). The tables state the total suction line length in metres at a nozzle capacity of 9,5 Gph. Max. permissible pressure at the suction and pressure side is 2,0 bar. Bentone...

- Page 29 Removal and installation Close the oil supply to the burner Loosen the pump cover’s screws. Remove the filter and gasket Mount new gasket and filter Refit the cover Open the oil supply Start the burner and check seals and combustion Bentone...

- Page 30 Pressure regulator Shaft seal kit (lip seal + protective cone) By-pass plug G 1/4 gasket G 1/4 steel plug (1-pipe system) Filter Cover gasket Cover Pressure gauge port or vacuum gauge port screw, O-ring 10. Coil 11. Tube assy Bentone...

-

Page 31: Replacement Of Electrical Components

Turn on the mains power. Check the function of the new component. Start the burner. Check combustion.* Note: When servicing/replacing components that affect combustion, an analysis and soot test shall be carried out on the installation. 165 105 11 Bentone... -

Page 32: Oil Burner Control

* If there is no plug-in contact (X2) on the boiler, connect to the contact enclosed. In case the twin thermostat is in series on incoming phase L1, a loop between the terminals T1 and T2 is necessary. 165 105 29 Bentone... -

Page 33: List Of Components

Safety lock-out time: 10 s Reset time after lockout: ≈ 50 s Reaction time on flame failure: < 1 s Ambient temperature: -20 - +60°C Min. current with flame established: 65 µA Max. photo current at start: 5 µA Bentone... -

Page 34: Fault Location

Check preheater function Preheater temperature too low Adjust the preheater‘s set operating tem- New oil type perature Check that the oil used has the physical parameters that the burner is rated for. If not, change the oil. 165 105 09 Bentone... -

Page 35: Delayed Ignition

Change the oil or the pump's oil parameters Pump worn Replace the pump Pump run using impure oil that has worn the Replace pump and install self-cleaning pump out prematurely filter in the oil system Blocked pump filter Check, clean pump filter Bentone... -

Page 36: Log Of Flue Gas Analysis

11. Log of flue gas analysis Owner Adresss Tel. no: Installation Tel. no: Boiler Type Make Power Bentone Burner Type Model Serial no. Fuel Step 1 Step 2 Step 3 Draught in fireplace Fan Press mbar Filter smoke number Flue gas temp. °C... -

Page 37: Oil Burners Maintenance Instructions

12. Oil burners maintenance instructions General information If the burner starts but does not ignite Keep the boiler room clean. Ensure that the boiler Make an attempt to start the burner. room has permanent fresh air intake. Switch off before Never make close repeated start attempts. - Page 40 Enertech AB. P.O Box 309, SE-341 26 Ljungby. www.bentone.se, www.bentone.com...

Need help?

Do you have a question about the B 30A and is the answer not in the manual?

Questions and answers