Table of Contents

Advertisement

Quick Links

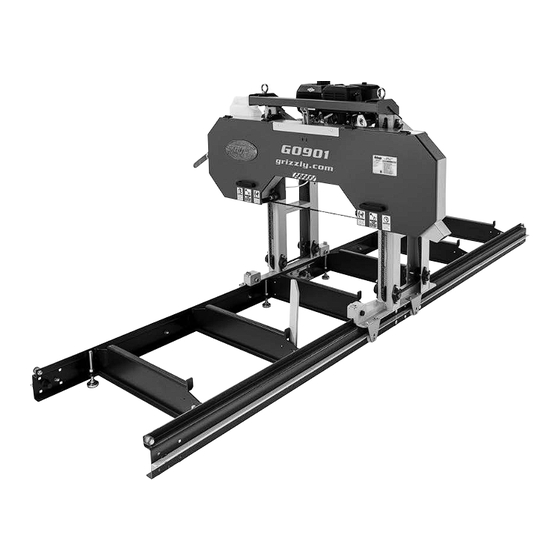

MODEL G0901

28" PORTABLE SAWMILL

OWNER'S MANUAL

(For models manufactured since 09/19)

COPYRIGHT © DECEMBER, 2019 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#AI20609 PRINTED IN TAIWAN

V1.12.19

Advertisement

Table of Contents

Summary of Contents for Grizzly G0901

- Page 1 (For models manufactured since 09/19) COPYRIGHT © DECEMBER, 2019 BY GRIZZLY INDUSTRIAL, INC. WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC. #AI20609 PRINTED IN TAIWAN V1.12.19...

- Page 2 This manual provides critical safety instructions on the proper setup, operation, maintenance, and service of this machine/tool. Save this document, refer to it often, and use it to instruct other operators. Failure to read, understand and follow the instructions in this manual may result in fire or serious personal injury—including amputation, electrocution, or death.

-

Page 3: Table Of Contents

Table of Contents INTRODUCTION ..........2 SECTION 4: ACCESSORIES ......32 Contact Info............ 2 SECTION 5: MAINTENANCE ......34 Manual Accuracy ........... 2 Schedule ............34 Identification ........... 3 Cleaning & Protecting ........34 Controls & Components ......... 4 Lubrication ........... 34 Glossary Of Terms ......... -

Page 4: Introduction

ID label (see below). This information is required for us to provide proper tech support, and it helps us determine if updated documenta- tion is available for your machine. Manufacture Date Serial Number Model G0901 (Mfd. Since 09/19) -

Page 5: Identification

Brakes To reduce your risk of Clamp serious injury, read this entire manual BEFORE using machine. Adjustable Foot Scan this code to see a video summary of the G0901, including features, controls, and operations! Support Model G0901 (Mfd. Since 09/19) -

Page 6: Controls & Components

Use CLOSED ( ) posi- tion if starting engine warm. Blade Tension Handle: Increases/decreas- es blade tension (refer to Page 23 for more C. Starter Rope: Pull several times to start information). engine. Slowly retract starter once engine starts. Model G0901 (Mfd. Since 09/19) - Page 7 M. Carriage Brake: Secures carriage during ensure flat cuts. service and maintenance. R. Log Clamp: Secures log against log support. IMPORTANT: Log support and log clamp must be angled to stay below saw blade height during operation. Model G0901 (Mfd. Since 09/19)

-

Page 8: Glossary Of Terms

The following is a list of common definitions, terms and phrases used throughout this manual as they relate to this sawmill and milling in general. Become familiar with these terms for assembling, adjusting or operat- ing this machine. Your safety is VERY important to us at Grizzly! Board Foot: Unit of measurement for volume Parallel: Being an equal distance apart at every of lumber cut from a log. -

Page 9: Machine Data Sheet

Blade Width ................................1 in. Blade Thickness ..............................0.035 in. Blade Guides ................................Roller Operation Feed System ................................. Manual Lift System ................................Manual Clutch ................................Centrifugal Log Supports ..........................2 Supports & Log Clamp Model G0901 (Mfd. Since 09/19) Model G0901 Page 1 of 2... - Page 10 Manual Lift System Raises 1" per Revolution with 1/16 in. Stop Increments Easy-Set Blade Tensioning Low-to-the-Ground Bed Adjustable Log Supports and Log Clamp Blade Lubrication System Easy Shipping and Assembly Model G0901 (Mfd. Since 09/19) Page 2 of 2 Model G0901...

-

Page 11: Section 1: Safety

Never operate under the influence of drugs or injury or blindness from flying particles. Everyday alcohol, when tired, or when distracted. eyeglasses are NOT approved safety glasses. Model G0901 (Mfd. Since 09/19) - Page 12 Make sure they are properly installed, you experience difficulties performing the intend- undamaged, and working correctly BEFORE ed operation, stop using the machine! Contact our operating machine. Technical Support at (570) 546-9663. -10- Model G0901 (Mfd. Since 09/19)

-

Page 13: Additional Safety For Sawmills

If normal safety pre- respect. Failure to do so could result in cautions are overlooked or ignored, seri- serious personal injury, damage to equip- ous personal injury may occur. ment, or poor work results. -11- Model G0901 (Mfd. Since 09/19) -

Page 14: Section 2: Setup

IMPORTANT: Save all packaging materials until you are completely satisfied with the machine and have resolved any issues between Grizzly or the shipping agent. You MUST have the original pack- aging to file a freight claim. It is also extremely helpful if you need to return your machine later. -

Page 15: Inventory

—Hex Bolts M10-1.5 x 180 ......2 —Flat Washers 10mm ........ 8 —Hex Nuts M10-1.5 ........6 —Carriage Bolts M10-1.5 x 25 ....16 —Flat Washers 10mm ......16 —Lock Nuts M10-1.5 ........ 16 -13- Model G0901 (Mfd. Since 09/19) -

Page 16: Hardware Recognition Chart

Hardware Recognition Chart USE THIS CHART TO MATCH UP HARDWARE DURING THE INVENTORY AND ASSEMBLY PROCESS. Flat Head Screw -14- Model G0901 (Mfd. Since 09/19) -

Page 17: Site Considerations

Only install in an or remove doors/covers as required by the main- access restricted location. tenance and service described in this manual. See below for required space allocation. 144" Dust Exhaust 75" Figure 9. Working clearances. -15- Model G0901 (Mfd. Since 09/19) -

Page 18: Assembly

(see Figure 10). track sections and place them in assembly location, oriented as shown in Figure 11. Lift Bar Front Track Rails Figure 11. Track section orientation. Figure 10. Lift bar installed on carriage. -16- Model G0901 (Mfd. Since 09/19) - Page 19 Note: Pay attention to the order hardware is added to the hex bolt as it is inserted through track sections. Figure 15. Securing threaded rod. Track Bracket Hex Bolt Figure 13. Properly assembled track bracket hardware. -17- Model G0901 (Mfd. Since 09/19)

- Page 20 20 hex bolts, 8mm lock washers, and 8mm flat washers (see Figure 18). Caster Bracket with Brake Figure 16. Attaching guide rail. Caster Bracket Guide Rail Figure 18. Caster brackets installed on carriage. Figure 17. Guide rail installed. -18- Model G0901 (Mfd. Since 09/19)

- Page 21 26. Attach second log support to log bunk on rear track section with (4) M6-1 x 12 hex bolts, 6mm lock washers, and 6mm flat washers (see Figure 19). Support Log Bunk Figure 19. Log support attached to log bunk. -19- Model G0901 (Mfd. Since 09/19)

-

Page 22: Test Run

Read and rectly. Congratulations! The Test Run is understand entire Grizzly manual and follow complete. all safety precautions. — If the machine does start with blade cover Fill engine to required fuel and oil levels. -

Page 23: Section 3: Operations

Regardless of the content in this sec- 12. Pulls carriage back to start position. tion, Grizzly Industrial will not be held liable for accidents caused by lack of training. 13. Lowers blade for next cut or shuts down engine. -

Page 24: Workpiece Inspection

Open blade cover and support it on blade cover latch (see Figure 22). Blade Cover Latch Figure 22. Blade cover supported by blade cover latch. Slide blade off top of wheels, then remove blade from bottom of wheels. -22- Model G0901 (Mfd. Since 09/19) -

Page 25: Tensioning Blade

If more precision is Adjust blade tension, then adjust guide roll- required, consider using a blade tensioning gauge ers (see Tensioning Blade on this page and (see Page 32). Adjusting Guide Rollers on Page 24). -23- Model G0901 (Mfd. Since 09/19) -

Page 26: Adjusting Guide Rollers

Tighten hex bolt and hex nut (see Figure 26). DISCONNECT SPARK PLUG WIRE! Loosen hex nut and hex bolt (see Figure 26). Hex Bolt Hex Nut Guide Roller Figure 26. Guide roller adjustment components. -24- Model G0901 (Mfd. Since 09/19) -

Page 27: Types Of Lumber

Because flatsawn lumber is fast- est and most plentiful to produce, it is the most Lock affordable lumber on the market. The majority of Lever construction quality lumber is flatsawn. Figure 29. Left guide roller lock lever. -25- Model G0901 (Mfd. Since 09/19) -

Page 28: Drying Lumber

Understand the drying environ- ment and type of wood in order to ensure the end Figure 31. Example of live sawing a cant into product meets your needs. dimensional lumber. -26- Model G0901 (Mfd. Since 09/19) -

Page 29: Cant Sawing

If a square cant was the goal of the operation, congratulations, you are finished! To cut the cant into dimensional labor, proceed to Live Sawing on Page 28. Figure 33. First cut to saw a cant. -27- Model G0901 (Mfd. Since 09/19) -

Page 30: Live Sawing

Note: Live-sawing a square cant will produce lum- Clamp ber than does not need to be edged. However, it typically produces more waste than live-sawing a log and edging it.. Figure 35. First cuts to live saw a log. -28- Model G0901 (Mfd. Since 09/19) -

Page 31: Edging

Support Clamp Figure 37. Flitches secured to track bed for edging. Figure 39. Flitches secured to track in preparation for second edging. Repeat Steps 2–3 until all flitches have been edged on both sides. -29- Model G0901 (Mfd. Since 09/19) -

Page 32: Quarter Sawing

Figure 42). Set board aside for now. Thick Thin Slab Slab Support Cant Cant Clamp Pith Cant Thick Slab Figure 42. Two rectangular cants and pith to be Figure 40. Thick slabs to be removed from log. removed. -30- Model G0901 (Mfd. Since 09/19) - Page 33 18. Load slab from Step 3 or 4 to track bed, using used. See Edging on Page 29. log supports to ensure slab is perpendicular to track (see Figure 45). Take care that log clamp is holding slab tight against supports. -31- Model G0901 (Mfd. Since 09/19)

-

Page 34: Section 4: Accessories

Grizzly. NOTICE Refer to our website or latest catalog for additional recommended accessories. Figure 48. Replacement blades for the G0901. H5408—Blade Tensioning Gauge T31677—6' Bed Extension Rails The Blade Tensioning Gauge ensures long blade These modular track extensions can be quickly... - Page 35 Figure 53. T26419 Syn-O-Gen Synthetic Grease. Figure 51. T30904 AccuMASTER Duo Pro Pin & Pinless Moisture Meter. www.grizzly.com 1-800-523-4777 order online at or call -33- Model G0901 (Mfd. Since 09/19)

-

Page 36: Section 5: Maintenance

Cleaning & Protecting Grease Fitting Grease Cleaning the Model G0901 is relatively easy. Fitting Vacuum excess wood chips and sawdust, and wipe off the remaining dust with a dry cloth. If any resin has built up, use a resin dissolving cleaner to remove it. -

Page 37: Section 6: Service

4. Replace blade (Page 23). 5. Wrong blade type or TPI. 5. Use correct blade. 6. Excessive feed rate/pressure. 6. Reduce feed rate/pressure. 7. Blade wheels are not coplanar. 7. Adjust wheels to be coplanar (Page 39). -35- Model G0901 (Mfd. Since 09/19) - Page 38 2. Throttle cable damaged, corroded, or has 2. Remove cable from housing. Clean/replace cable. not slow to excessive builup inside housing. an idle when throttle handle is released. Note: Refer to the Briggs & Stratton engine manual for engine-related troubleshooting. -36- Model G0901 (Mfd. Since 09/19)

-

Page 39: Tensioning/Replacing V-Belts

", belt is — If deflection is approximately correctly tensioned and no adjustment is The G0901 uses V-belts as tires on the blade necessary. wheels. The drive belt transfers power from the engine to the wheels. The blade and drive belt —... -

Page 40: Adjusting Blade Tracking

⁄ ", adjust blade position and repeat Step 2. — If gullets do not remain an equal distance from front of wheel, proceed to Adjusting Wheel Shaft Position on Page 39. -38- Model G0901 (Mfd. Since 09/19) - Page 41 Release blade tension by turning blade ten- Nuts Hex Bolt sion handle counterclockwise until handle slackens. Bottom Vertical Loosen hex nuts on wheel adjustment hub Tilt Hex Bolt (see Figure 60). Figure 60. Wheel adjustment hub. -39- Model G0901 (Mfd. Since 09/19)

- Page 42 (see Page 39) as needed. Figure 63. Horizontal tilt hex bolt location. — To tilt outside of wheel forward, turn hex bolt clockwise. — To tilt outside of wheel backward, turn hex bolt counterclockwise. -40- Model G0901 (Mfd. Since 09/19)

-

Page 43: Section 7: Wiring

Technical Support at (570) 546-9663. The photos and diagrams included in this section are best viewed in color. You can view these pages in color at www.grizzly.com. -41- Model G0901 (Mfd. Since 09/19) -

Page 44: Wiring Diagram

Wiring Diagram LIMIT SWITCH ENGINE AC-15 3A/240V STOP BUTTON KEYON KB2-BE101 Wiring Photos Figure 65. E-stop switch box. Figure 66. Blade cover limit switch. READ ELECTRICAL SAFETY -42- Model G0901 (Mfd. Since 09/19) ON PAGE 41! -

Page 45: Section 8: Parts

SECTION 8: PARTS We do our best to stock replacement parts when possible, but we cannot guarantee that all parts shown are available for purchase. Call (800) 523-4777 or visit www.grizzly.com/parts to check for availability. Track BUY PARTS ONLINE AT GRIZZLY.COM! -43- Model G0901 (Mfd. - Page 46 HEX BOLT M10-1.5 X 180 P0901140 PHILLIPS SCREWDRIVER P0901120 SET SCREW M8-1.25 X 30 P0901141 HEX WRENCH SET 2.5-10MM 7-PC P0901121 LOCK NUT M10-1.5 BUY PARTS ONLINE AT GRIZZLY.COM! -44- Model G0901 (Mfd. Since 09/19) Scan QR code to visit our Parts Store.

-

Page 47: Carriage

Carriage BUY PARTS ONLINE AT GRIZZLY.COM! -45- Model G0901 (Mfd. Since 09/19) Scan QR code to visit our Parts Store. - Page 48 HEX BOLT M10-1.5 X 40 P0901232 BALL BEARING 6001-2RS P0901265 CAP SCREW M8-1 X 16 P0901233 BALL BEARING 6002-2RS P0901266 STEEL CABLE 1800MM BUY PARTS ONLINE AT GRIZZLY.COM! -46- Model G0901 (Mfd. Since 09/19) Scan QR code to visit our Parts Store.

-

Page 49: Engine & Wheel Mounts

Engine & Wheel Mounts 347 341 BUY PARTS ONLINE AT GRIZZLY.COM! -47- Model G0901 (Mfd. Since 09/19) Scan QR code to visit our Parts Store. - Page 50 CAP SCREW M12-1.75 X 16 P0901326 COMPRESSION SPRING TH50-075 P0901353 SET SCREW M8-1.25 X 40 P0901327 ROD END CLEVIS P0901354 HEX NUT M10-1.5 BUY PARTS ONLINE AT GRIZZLY.COM! -48- Model G0901 (Mfd. Since 09/19) Scan QR code to visit our Parts Store.

-

Page 51: Blade & Wheels

V-BELT B59 P0901404 FENDER WASHER 24MM P0901409 CAP SCREW M6-1 X 20 P0901405 SAW WHEEL 19" CAST-IRON P0901410 EXT RETAINING RING 25MM BUY PARTS ONLINE AT GRIZZLY.COM! -49- Model G0901 (Mfd. Since 09/19) Scan QR code to visit our Parts Store. -

Page 52: Guide Rollers

HEX BOLT M6-1 X 16 P0901506 GASKET P0901514 HEX BOLT M8-1.25 X 40 P0901507 BALL BEARING 6203-2RS P0901515 HEX NUT M8-1.25 P0901508 DRIP TUBE FITTING BUY PARTS ONLINE AT GRIZZLY.COM! -50- Model G0901 (Mfd. Since 09/19) Scan QR code to visit our Parts Store. -

Page 53: Blade Cover

BLADE HEIGHT SCALE 24" P0901629 BUTTON HD CAP SCR M4-.7 X 16 P0901615 LIMIT SWITCH HIGHLY ED-1-3-62 3A 240V P0901630 BALL VALVE BUY PARTS ONLINE AT GRIZZLY.COM! -51- Model G0901 (Mfd. Since 09/19) Scan QR code to visit our Parts Store. -

Page 54: Labels & Cosmetics

Safety labels help reduce the risk of serious injury caused by machine hazards. If any label comes off or becomes unreadable, the owner of this machine MUST replace it in the original location before resuming operations. For replacements, contact (800) 523-4777 or www.grizzly.com. BUY PARTS ONLINE AT GRIZZLY.COM! -52- Model G0901 (Mfd. -

Page 55: Warranty & Returns

WARRANTY & RETURNS Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser from the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence, accidents, repairs or alterations or lack of maintenance.

Need help?

Do you have a question about the G0901 and is the answer not in the manual?

Questions and answers