Summary of Contents for Kohler rada Intelligent Care MX1 Series

- Page 1 Intelligent Care MX1 Wall Mounted Tap Installation Guide Please leave these instructions with the user 1367864-W2-C...

- Page 2 1367864-W2-C...

-

Page 3: Important Safety Information

General Make sure that the Rada MX1 is installed by a competent installer. The product commissioning, clock (date/time) and tap set up can only be done in conjunction with the “RADA AP1” available from the Apple APP store. Time and date setting is critical to ensure data reporting is correct. -

Page 4: Specification

Specification General Valve Maximum Ambient Temperature 50°C 40°C Minimum Ambient Temperature 1°C 1°C Maximum Humidity 95% rH 95% rH Electrical Valve Supply Voltage 100 - 240 V 50/60 Hz 12 V DC Rated Input Current 2.0 A Water Ingress Protection IP X4 IP X4 Protection Against Electric Shock... -

Page 5: Factory Default Settings

Factory Default Settings RADA App Tile / Section Adjustable Fixed Range Temperature Temperature Units Varient Varient Min Value Max Value 1. Valve Setup / 4. Installation Setup 1. Setup Advice Info Field 2. Valve Identity Editable Text Field 3. Outlet Type and Sub Type Info Field 4. - Page 6 Standard Standard Disabled, Disabled, Standard, Standard, Standard oscillation 2. Type Standard oscillation Standard Standard Disabled, Disabled, Standard, Standard, Standard 2. Type Standard Oscillation, Smart, Oscillation, Smart, Smart Oscillation Smart Oscillation Time 24 Hr 3. Activation Time 02:00 Hrs 02:00 Hrs Clock 4.

-

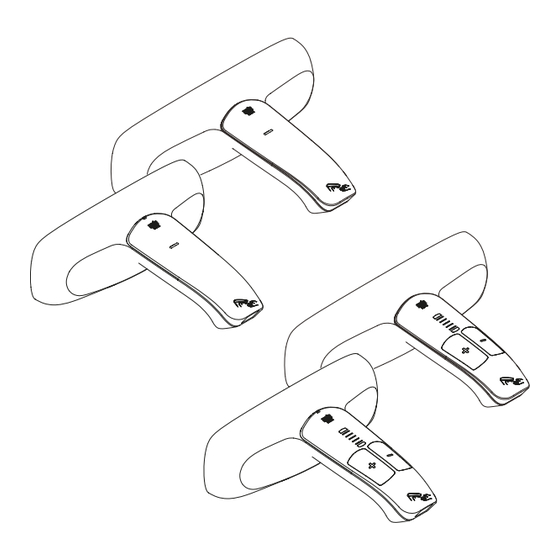

Page 7: Pack Contents

Pack Contents 1 x Tap 1 x Power Supply 1 x Rada Disable Key 1 x Template 1 x Backplate 1 x Adapter (for 150 mm Version Only) 2 x Connector 1 x Flush Pipe 2 x Screw 2 x Check valve / Filter Housing Assemblies 2 x Nut 4 x Wall Plug... - Page 8 Dimensions MX1 80 220 mm 150 mm 47 mm 55 mm 199 mm 100 mm 44 mm 220 mm 80 mm 26 mm 40 mm 170 mm 30º Connection to Power Supply Unit Total Cable Run: 1.18 m Total Cable Run with Extension Cable: 3.68 m PSU Mains Cable PSU 12V Cable Extension Cable...

- Page 9 MX1 60 262 mm 200 mm 47 mm 55 mm 199 mm 100 mm 44 mm 262 mm 80 mm 26 mm 40 mm 170 mm 30º Connection to Power Supply Unit Total Cable Run: 1.18 m Total Cable Run with Extension Cable: 3.68 m PSU Mains Cable PSU 12V Cable Extension Cable...

-

Page 10: Installation

Installation Installation of the Tap on the Stud wall and IPS panel For Correct Height Refer to HBN00-10 Part C Use the installation template provided, level and mark the positions of the holes. Ø25 mm Ø2 mm Ø15 mm Drill the holes to the dimensions shown. 1367864-W2-C... - Page 11 Install the PSU (Power Supply Unit) in an area that you can access easily for servicing and maintenance purposes. MX1 60 (200 mm Centres) Secure the backplate using the supplied fixing screws. DO NOT overtighten. 1367864-W2-C...

- Page 12 Fit the inlet connectors with isolation hex facing downwards, aligning with the holes in the backplate. Attach the backnuts (supplied) leaving approx. 10-15 mm float allowing access to the spanner flats. Make the plumbing connections. DO NOT use jointing paste when making plumbing connections.

- Page 13 Tighten the backplate nut. DO NOT overtighten. Pass the power cable through the backplate. MX1 80 (150 mm Centres) Secure the backplate using the supplied fixing screws. DO NOT overtighten. Fit the inlet connectors with isolation hex facing downwards, aligning with the holes in the backplate.

- Page 14 Tighten the backplate nut. DO NOT overtighten. Pass the power cable through the backplate. Install the Check valves Hot Inlet - Red Cold Inlet - Blue The check valves / filter housings are identified by a coloured dot that indicates hot and cold connections.

- Page 15 Flush the Pipework Note: The procedure is similar for Panel, Stud and IPS Panel configurations. Note: Failure to flush pipework may lead to tap failure and invalidate warranty Using a suitable screwdriver, turn the Reinstate the supply to the check valve/ screw fully clockwise to isolate the water filter housings.

- Page 16 1 min Using a suitable screwdriver, unscrew the screw to bleed the supply pipework. After bleeding, refit the components in reverse order. DO NOT open the isolator on the check valve/filter housing. Connect the power cable to the tap and push the cable through into the wall cavity. 1367864-W2-C...

- Page 17 Secure the tap using the supplied screws. DO NOT overtighten. Open the isolator on the check valve / filter housing. Restore the water supplies and turn on supplies at the check valve/flow regulator. 1367864-W2-C...

- Page 18 Pull off the cover from tap. Commissioning The Rada MX1 wall mounted tap will operate to factory settings when first installed. Download the “RADA AP1” from the Apple APP Store and follow the on screen instructions. Note: Run the tap for 30 seconds in order for self calibration to take place. 1367864-W2-C...

-

Page 19: Operation

Operation The Rada MX1 wall mounted tap will operate to factory settings when first installed. Download the “RADA AP1” from the Apple APP Store and follow the on screen instructions. Note: For Type 3 valves in UK Healthcare installations the maximum blend temperature is determined by the application, refer to the TMV3 Requirements Manual which is available to view or download from our website www.radacontrols.com. - Page 20 Note: This tap has an over temperature limiting device, should blend temperature exceed safe conditions, the valve will shut down and reset automatically once temperature returns to a safe state. 1367864-W2-C...

-

Page 21: Fault Diagnosis

Fault Diagnosis As with most electronic equipment re-setting the mixing valve by powering it down at the mains, waiting a few seconds and powering it up again can often cure any issues. Symptoms Probable Cause Possible Remedy No water flow / will not Product has entered an error mode Refer to Error Log indicated by a flashing “spanner”... - Page 22 Symptoms Probable Cause Possible Remedy Flow rate too low Inlet water supply isolators not fully Check and remedy. turned on Inlet filters or check valves blocked Check and remedy. Outlet spout, hose or handset Check and remedy. blocked Reversed inlet supplies Check and remedy.

- Page 23 Symptoms Probable Cause Possible Remedy Keeps cutting out Product has entered an error mode Refer to Error Code Log indicated by a flashing “spanner” symbol Inlet water supply isolators not fully Check and remedy. turned on Inlet filters or check valves blocked Check and remedy.

- Page 24 Symptoms Probable Cause Possible Remedy Outlet temperature too Inlet water supply pressures are Ensure the water supply pressures cool (Continued) unstable or imbalanced are stable and nominally equal, refer to “Specifications”. Outlet pipe run is too long Ensure outlet pipe work is thermally lagged.

- Page 25 Symptoms Probable Cause Possible Remedy Noise The product will make a mechanical noise during (and just after) normal operation Digital Mixing valve air locking Check for correct installation practices, repeat commissioning procedure rearrange pipework to avoid airlock forming. Water Hammer Ensure all pipework is securely fixed.

- Page 26 A flashing “spanner” symbol indicates the product has gone in to an error mode. If repeated errors are logged this MUST be diagnosed and corrected by a technician. The “RADA AP1” can be used to disable the valve until fault diagnosis can be made. Using the “RADA AP1”, navigate to the Health Check Page tile 12, to read the error log.

- Page 27 Error Codes Probable Cause Possible Remedy Temp imbalance Non Product Fault - The supply Valve will self clear fault. conditions are out of specification Unstable supply Hot inlet water supply temperature Reduce inlet water is too hot or fluctuating temperature to between 55°C and 65°C, refer to “Specifications”.

- Page 28 Error Codes Probable Cause Possible Remedy Interface Error Software failure Re-set the product by turning electrical supply Interface CGF error seconds then re-apply power. IO expander error Loose internal wiring connections Ensure all wiring connections are (Interface and PCB) securely made. Interface failure Contact Rada.

-

Page 29: Maintenance

Maintenance Cleaning Caution! Risk of product damage. Many cleaners contain abrasive and chemical substances, and should not be used for cleaning stainless steel, enamel, plated or plastic fittings. These finishes should be cleaned using a mild washing up detergent or soap solution, rinsed and then wiped dry with a soft clean cloth. Note: Run the tap for 30 seconds in order for self calibration to take place. - Page 30 Clean the Filter Turn the screw fully clockwise to isolate the Unscrew and remove the filter. water supply. Clean the filter under running water. Refit the components in reverse order. 1367864-W2-C...

- Page 31 Replace the Check Valve Unscrew and remove the filter. Turn the screw fully clockwise to isolate Note: Filter must be removed to remove the water supply. Relieve the pressure by the checkvalve housing. operating the tap. Using a suitable spanner, remove the check valve housing. 1367864-W2-C...

- Page 32 Cold Supply - Blue Indices Remove the combined check valve and replace. Refit all the components in reverse order. Checkvalves are non-serviceable and must be discarded and replaced with new items. Refit, noting that the pin on the plunger will face into the check valve / filter housing. Hot Supply - Red Indices Remove the flow regulator and check valve.

-

Page 33: Spare Parts

Spare Parts 1264133 1264126 (76676-CP, (72946-CP, 97390-CP) 76670-CP) 1264114 (76670-CP, 76676-CP) 1264128 (no temp) (76676-CP, 1264113 (97390-CP, 97390-CP) 72946-CP) 1315132 1264127 (temp) (72946-CP, 76670-CP) 1264110 (72946-CP, 76670-CP, 76676-CP, 97390-CP) 1264111 1264132 (76670-CP, 76676-CP, 97390-CP, 72946-CP) 1264109 (76670-CP, 76676-CP) 1264124 (72946-CP, 766760-CP, 76676-CP, 97390-CP) - Page 34 Spare Parts 2L/min HOT - 1370884 4L/min COLD - 1370885 1372502 2L/min 1372501 4L/min 1395070 1372499 1264134 (x2) 1264135 (x20) 1372500 1395069 1264122 463.84 (x 3) 1372505 - Seal Pack - Components Identified ‘C’ 76705-NA - 2.5 m Extension Power Cable 1367864-W2-C...

- Page 35 1367864-W2-C...

-

Page 36: Customer Service

Rada Controls, Cromwell Road, Cheltenham, Gloucestershire GL52 5EP For Eire Only 01 531 9337 CustomerServiceEire@mirashowers.com Rada is a registered trade mark of Kohler Mira Limited. The company reserves the right to alter product specifications without notice. 14648 Kohler Mira Limited, September 2019...

Need help?

Do you have a question about the rada Intelligent Care MX1 Series and is the answer not in the manual?

Questions and answers