Asyril Asycube 240 Operating Manual

Hide thumbs

Also See for Asycube 240:

- Programming manual (83 pages) ,

- User manual (46 pages) ,

- Integration manuallines (14 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Asyril Asycube 240

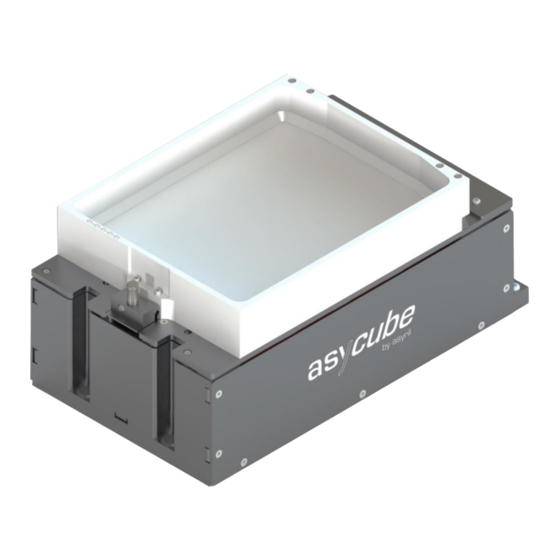

- Page 1 Asycube 240 Operating Manual Asyril_ASYCUBE-240_Operating_Manual_EN Document 000.100.500 Version Date 13.01.2020...

-

Page 2: Table Of Contents

Additional platform ......................22 Backlight ..........................25 Cables ..........................25 Hopper ..........................26 Calibration plate ........................29 TRANSPORTATION, HANDLING AND INSTALLATION ............32 ........32 ACKAGING OF THE PRODUCT TRANSPORTATION AND HANDLING ....................32 NPACKING INSTRUCTIONS 000.100.500 Asycube 240 - Operating Manual 2/52... - Page 3 Recover IP address using default IP address ..............43 ......................45 ECHNICAL SUPPORT For better service … ......................45 Contact ..........................45 ANNEXES ............................46 ..................46 ONDITION OF USE OF BACKLIGHT CE C ........................50 ERTIFICATE 000.100.500 Asycube 240 - Operating Manual 3/52...

-

Page 4: Introduction

For more information on a specific subject, the reader should read other manual, or refer to other paragraph. WARNING! Asyril shall not be liable whatsoever for any loss or damage arising from a failure to observe the items specified in “Safety Precautions.” The customer is responsible to provide the necessary instruction to the persons concerned. -

Page 5: Safety Precautions

DANGER ! Do not unscrew the housing of the system controls. Serious injury or death could result from electric shock. Only authorized personnel from Asyril SA are allowed to access this part of the system for maintenance or for repair. -

Page 6: Danger

(characteristics of screens or goggles to choose based on wavelength which operators are exposed). Refer to “5.1 Condition of use of backlight" on page 46 for the complete calculation sheet on minimal distance to respect for each kind of backlight. 000.100.500 Asycube 240 - Operating Manual 6/52... -

Page 7: Warranty Information

Figure 1-2 :Specific warnings Warranty information You will find all the Asyril warranty information (duration, scope of warranty …) on the general conditions of sale. 000.100.500 Asycube 240 - Operating Manual... -

Page 8: Description

For more information on the procedure to control the platform vibrations, please refer to the HMI manual For more information on the backlight color and the procedure to exchange the backlight, please refer to “4.3.1 Exchanging / installing the backlight” on page 38 000.100.500 Asycube 240 - Operating Manual 8/52... -

Page 9: General Characteristics

“2.6.1 Additional platform” on Interchangeable vibration surface page 22 for more information. Vibration frequency up to 100 Hz configurable Maximal weight on the platform 0.4 kg Digital Output for hoppers Digital Input Analog Output RoHS 000.100.500 Asycube 240 - Operating Manual 9/52... -

Page 10: Overall Dimensions

Asycube 240 Operating Manual 000.100.500 Version: A6 Overall dimensions Figure 2-2 : overall dimensions Asycube 240 Characteristic Footprint 171 mm 300 mm D’ 45 mm Size of vibration 150 mm platform 195 mm 132 mm 105 mm Weight with platform and backlight 7.8 kg... - Page 11 Additional space is needed around the Asycube to be able to remove the platform module with the integrated tool : Figure 2-3 : overall dimensions with "lever" Refer to “4.2.2 Remove the platform module” on page 36 for more information on how to remove the platform. 000.100.500 Asycube 240 - Operating Manual 11/52...

-

Page 12: Visual Signals

24V on input 1 green 24V on input 2 (10) (11) green Platform vibrating yellow 24V on output 1 yellow 24V on output 2 Figure 2-4 : Asycube Operating Indicator LEDs 000.100.500 Asycube 240 - Operating Manual 12/52... -

Page 13: Maximum Permissible External Force On The Platform

(in addition to the maximum 400 gr platform weight) Maximum plate displacement Maximum displacement x ±1.5 mm Maximum displacement y ±2 mm Maximum displacement z ±1.5 mm Plate Z repeatability Platte Z repeatability ±20 µm 000.100.500 Asycube 240 - Operating Manual 13/52... -

Page 14: Performance

(corresponding to the sum movements four actuators in each corner of the platform). Figure 2-6 : predefined displacement of the parts The figure on the right shows the predefined standard movements. 000.100.500 Asycube 240 - Operating Manual 14/52... - Page 15 Asycube 240 Operating Manual 000.100.500 Version: A6 Advanced movement On the Asycube 240, advanced movements can be achieved. Indeed, possible center components along the long side or the short side of the plate, as represented on the figure on the right.

-

Page 16: Electrical Interfaces

Digital and analog Output 2 for hopper Figure 2-8 : Electrical interfaces to the Asycube NOTE : The cables are not part of the feeder but can be ordered separately. (Please, refer chapter 2.6.3 "Cables") 000.100.500 Asycube 240 - Operating Manual 16/52... -

Page 17: Power Connection

In any case, both “Power” and “S-Power” have to be supplied for using the backlight. 000.100.500 Asycube 240 - Operating Manual 17/52... - Page 18 Figure 2-10 Figure 2-11 Power connection without safety relay Power connection with safety relay NOTE: Both Power and S-Power can be connected to a single power supply or to two different power supplies 000.100.500 Asycube 240 - Operating Manual 18/52...

-

Page 19: Communication

+24 V pulse black (illumination synch.) Connector type (on Asycube side) : M8, 3P, male Figure 2-13 : Backlight synchronization NOTE : The Asycube Backlight illumination time corresponds to the length of the pulse signal. 000.100.500 Asycube 240 - Operating Manual 19/52... -

Page 20: Digital Input 1 And 2

: Signal Hopper 0V GND Analog Output 1 0…10VDC 0V GND Digital Output 1 +24VDC Connector type (on Asycube side) : M8, 4P, female Figure 2-15 : Digital output for hoppers 000.100.500 Asycube 240 - Operating Manual 20/52... -

Page 21: Mechanical Interfaces

The holes in the base plate of the Asycube can be used to attach it with four M6 screws. Repeatable positioning of the Asycube can be done by using positioning pins (possible on both sides). Figure 2-16 : attachment of the Asycube 000.100.500 Asycube 240 - Operating Manual 21/52... -

Page 22: Accessories And Optional Modules

In order to improve the availability of certain components on the surface of the feeder, it is possible to structure the plate surface. Asyril can provide various types of plates on request. Frequently used structures on Asycube 240 are as follows: Plate Example –... - Page 23 Ex : Pins NOTE : For more information on these bespoke platforms, contact Asyril customer’s service. The customer can also make his own platforms, in this case plate fixation kits can be ordered by Asyril 000.100.500...

- Page 24 Asycube 240 Operating Manual 000.100.500 Version: A6 Mechanical interfaces of the platform 000.100.500 Asycube 240 - Operating Manual 24/52...

-

Page 25: Backlight

For more information on the backlight color and the procedure to exchange the backlight, please refer to “4.3.1 Exchanging / installing the backlight” on page 38 NOTE : For more information on these bespoke backlights, contact Asyril customer’s service. Cables Following cables are available:... -

Page 26: Hopper

230V (+10%/-15%), 50Hz, 6A 230V (+10%/-15%), 60Hz, 6A Hopper Linear Asycube vibrator Control unit OUT 1 (or OUT 2) 1.5 m L = 1 or brown N = 2 or blue PE = green/yellow 000.100.500 Asycube 240 - Operating Manual 26/52... - Page 27 Asycube 240 Operating Manual 000.100.500 Version: A6 Control unit The vibration intensity of the hopper can be adjusted with the potentiometer NOTE : place the control unit in order to reach the potentiometer 000.100.500 Asycube 240 - Operating Manual 27/52...

- Page 28 Asycube 240 Operating Manual 000.100.500 Version: A6 Hopper interfaces The hopper is delivered with fixation feet ready to be screwed (4x M8x20) 2 litres version 3 litres version 000.100.500 Asycube 240 - Operating Manual 28/52...

-

Page 29: Calibration Plate

NOTE: There are different ways to perform the calibration depending on the application. Please contact Asyril to define the corresponding tooling if necessary. The 240 calibration plate contains the checkerboard used to perform the pixel/mm calibration and the reference holes used to perform the robot/vision calibration. - Page 30 (for which the maximum accuracy can be found in the calibration plan). The part numbers for the riser kits can be found in the products list 000.100.500 Asycube 240 - Operating Manual 30/52...

- Page 31 Version: A6 Robot calibration help tool To facilitate robot/vision calibration using the calibration plates, a "robot calibration kit" is available for the Asycube 240 and 530. The part number for this tool is available in the products list ROBOT 000.100.500...

-

Page 32: Transportation, Handling And Installation

Table 3-1 : gross weight and dimensions of the product when packaged NOTE : If the items received do not match to your order, or are damaged, do not sign the receipt, and contact Asyril as soon as possible. Unpacking instructions NOTE : Do not remove the Asycube from its packaging until you are ready to install it. -

Page 33: Installation And Storage Environment

Do not use the product in an atmosphere of corrosive gases. Rust may form and reduce the structural strength of the product. Storage environment The storage environment should be similar to the operating environment. In addition, you should protect the Asycube against dust 000.100.500 Asycube 240 - Operating Manual 33/52... -

Page 34: Maintenance And Reparation

4. Maintenance and reparation Safety precautions General safety precautions WARNING ! There are no user serviceable parts inside the product. Contact Asyril or your local supplier to effect maintenance. In cases of non respectation, the product guarantee will expire. DANGER ! Do not operate the system when it is damaged. -

Page 35: Maintenance

Version: A6 Maintenance WARNING ! For any kind of maintenance, always use Asyril products. Periodic maintenance schedule Our Asycube are largely maintenance-free, however, simple inspections should be done at regular intervals to ensure optimum performances, and safety operating of your product. -

Page 36: Remove The Platform Module

Figure 4-2 : Platform WARNING : If the surface is damaged so as to obstruct vision or the behavior of parts, its replacement must be proceeded Step 2 Clean the surface of the platform 000.100.500 Asycube 240 - Operating Manual 36/52... -

Page 37: Reparation

This section gives a list of the components, which can be replaced directly by the customer. For any other repair, the product must be returned to the manufacturer. WARNING ! For any kind of reparation, always use Asyril products. Part name Backlight assembly Blue... -

Page 38: Exchanging / Installing The Backlight

DANGER ! Be sure that all power sources and other cables to the unit are disconnected before changing the backlight. Material needed : New backlight assembly delivered by Asyril Flat wrench size 5.5 Torx key size 10 Step 1 Unscrew the 7 screws on... - Page 39 Asycube 240 Operating Manual 000.100.500 Version: A6 Step 3 Unplug the backlight connector (C) Remove the old backlight (D) and insert the new backlight 000.100.500 Asycube 240 - Operating Manual 39/52...

- Page 40 (F) and tighten the four bolts (G) Use a flat wrench size 5.5 Step 6 Plug the backlight connector Step 7 Remount the covers (I) and (I') on both sides (I') 000.100.500 Asycube 240 - Operating Manual 40/52...

- Page 41 The password is important, because to write this parameter, you need to be logged in the firmware as Integrator. Password is 1234. For more information on the DLL, please refer to the integration guide documentation. 000.100.500 Asycube 240 - Operating Manual 41/52...

- Page 42 {wp7=1234} Login in integrator mode “x”: 0: Green 1: Red 2: Blue Write color of backlight {wp97=”x”} 3: IR 4: UV 5: White 99: None {df} Save configuration in flash memory {wp7=1} Logout 000.100.500 Asycube 240 - Operating Manual 42/52...

-

Page 43: Recover Ip Address Using Default Ip Address

Disconnect and reconnect the power cable (or switch off and switch on the power on the Asycube). The Asycube will take default parameters at startup : IP: 192.168.127.254 SubnetMask: 255.255.255.0 TCP Port: 4001 000.100.500 Asycube 240 - Operating Manual 43/52... - Page 44 Disconnect and reconnect the power cable (or switch off and switch on the power on the Step 6 Asycube). The Asycube will take the parameters defined by the new startup. Step 7 Replace the cover and screw the 3 screws (A) Use an torx key size 10 (0.9Nm) 000.100.500 Asycube 240 - Operating Manual 44/52...

-

Page 45: Technical Support

Contact You can find lot of information on our website: www.asyril.com You can also contact us by mail or through our web-site contact form: support@asyril.com +41 26 653 7190 000.100.500 Asycube 240 - Operating Manual 45/52... -

Page 46: Annexes

Asycube 240 Operating Manual 000.100.500 Version: A6 5. Annexes Condition of use of backlight 000.100.500 Asycube 240 - Operating Manual 46/52... - Page 47 Asycube 240 Operating Manual 000.100.500 Version: A6 000.100.500 Asycube 240 - Operating Manual 47/52...

- Page 48 Asycube 240 Operating Manual 000.100.500 Version: A6 000.100.500 Asycube 240 - Operating Manual 48/52...

- Page 49 Asycube 240 Operating Manual 000.100.500 Version: A6 000.100.500 Asycube 240 - Operating Manual 49/52...

-

Page 50: Ce Certificate

Asycube 240 Operating Manual 000.100.500 Version: A6 CE Certificate 000.100.500 Asycube 240 - Operating Manual 50/52... - Page 51 §2.6.4.3 : Modification some dimensions, §2.6.5 : Calibration plate, §4.3 : Removal of the item numbers and platform/fixation kit references, §5.2 : Update of the CE Certificate, § entire document: various minor corrections 000.100.500 Asycube 240 - Operating Manual 51/52...

- Page 52 This document is the property of Asyril S.A. and may not be copied or circulated without permission. The information contained in this document is subject to change without notice for the purpose of product improvement. asyril sa z.i. le vivier 22...

Need help?

Do you have a question about the Asycube 240 and is the answer not in the manual?

Questions and answers