Summary of Contents for SCHUNK MPG-plus 12

- Page 1 Translation of the original manual Assembly and operating manual MPG-plus 2-finger parallel gripper...

- Page 2 Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Any reproduction, processing, distribution (making available to third parties), translation or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

-

Page 3: Table Of Contents

Table of Contents Table of Contents General........................ 5 About this manual .................... 5 1.1.1 Presentation of Warning Labels ............... 5 1.1.2 Applicable documents ................ 6 1.1.3 Sizes ...................... 6 1.1.4 Variants..................... 6 Warranty ...................... 6 Scope of delivery .................... 6 1.3.1 Accessory pack.................. 7 Accessories ...................... 7 1.4.1 Sealing kit .................... 7 Basic safety notes .................... - Page 4 Table of Contents Assembly ........................ 18 Assembly and connection................... 18 Connections...................... 20 5.2.1 Mechanical connection................ 20 5.2.2 Pneumatic connection................ 22 Mounting the sensor .................. 23 5.3.1 Overview of sensors ................ 23 5.3.2 Switch-off hysteresis for magnetic switches .......... 24 5.3.3 Mounting programmable magnetic switch MMS-PI2 ...... 24 5.3.4 Mounting inductive proximity switches IN 30, IN 40...... 27 5.3.5 Mounting the magnetic switch MMS 22-IOL.......... 29 5.3.6 Analog magnetic sensor MMS 22‑A............ 31...

-

Page 5: General

General 1 General 1.1 About this manual This manual contains important information for a safe and appropriate use of the product. This manual is an integral part of the product and must be kept accessible for the personnel at all times. Before starting work, the personnel must have read and understood this operating manual. -

Page 6: Sizes

The documents marked with an asterisk (*) can be downloaded on our homepage schunk.com 1.1.3 Sizes This operating manual applies to the following sizes: • MPG-plus 10 • MPG-plus 12 • MPG-plus 16 • MPG-plus 20 • MPG-plus 25 • MPG-plus 32 •... -

Page 7: Accessories

• 2 x screw plug for hose connections • 2 x threaded pin for MPG-plus 16/25 ID.-No. of the accessory pack ID number MPG-plus MPG-plus Size high-temperature (V/HT) MPG-plus 10 1382755 MPG-plus 12 1382763 MPG-plus 16 5522565 395522565 MPG-plus 20 5522566 395522566 MPG-plus 25 5510172... -

Page 8: Basic Safety Notes

Use of unauthorized spare parts Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction. • Use only original spare parts or spares authorized by SCHUNK. 13.00 | MPG-plus | Assembly and operating manual | en | 389216... -

Page 9: Gripper Fingers

Basic safety notes 2.5 Gripper fingers Requirements for the gripper fingers Stored energy within the product creates the risk of serious injuries and significant property damage. • Arrange the gripper fingers in a way that the product reaches either the position "open" or "closed" in a de-energized state. •... -

Page 10: Personal Protective Equipment

Basic safety notes 2.8 Personal protective equipment Use of personal protective equipment Personal protective equipment serves to protect staff against danger which may interfere with their health or safety at work. • When working on and with the product, observe the occupational health and safety regulations and wear the required personal protective equipment. -

Page 11: Transport

Basic safety notes 2.10 Transport Handling during transport Incorrect handling during transport may impair the product's safety and cause serious injuries and considerable material damage. • When handling heavy weights, use lifting equipment to lift the product and transport it by appropriate means. •... -

Page 12: Protection During Handling And Assembly

Basic safety notes 2.13.1 Protection during handling and assembly Incorrect handling and assembly Incorrect handling and assembly may impair the product's safety and cause serious injuries and considerable material damage. • Have all work carried out by appropriately qualified personnel. •... -

Page 13: Protection Against Dangerous Movements

Basic safety notes 2.13.3 Protection against dangerous movements Unexpected movements Residual energy in the system may cause serious injuries while working with the product. • Switch off the energy supply, ensure that no residual energy remains and secure against inadvertent reactivation. •... -

Page 14: Notes On Particular Risks

Basic safety notes 2.14 Notes on particular risks DANGER Risk of fatal injury from suspended loads! Falling loads can cause serious injuries and even death. Stand clear of suspended loads and do not step within their • swiveling range. Never move loads without supervision. •... - Page 15 Secure the end positions of the product with SCHUNK SDV-P • pressure maintenance valves. 13.00 | MPG-plus | Assembly and operating manual | en | 389216...

-

Page 16: Technical Data

* For use in dirty ambient conditions (e.g. sprayed water, vapors, abrasion or processing dust) SCHUNK offers corresponding product options as standard. SCHUNK also offers customized solutions for special applications in dirty ambient conditions. 13.00 | MPG-plus | Assembly and operating manual | en | 389216... -

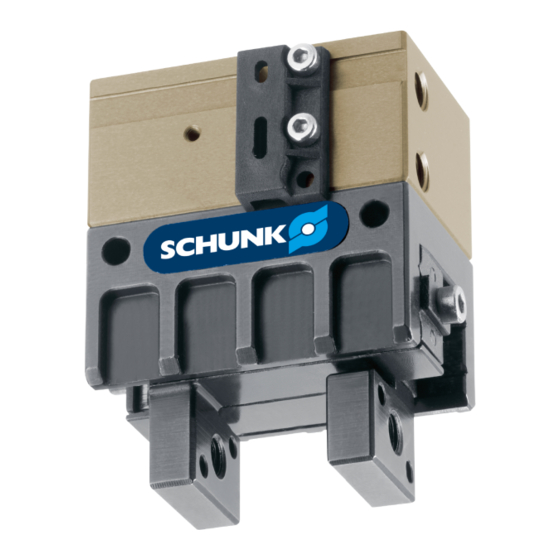

Page 17: Design And Description

Design and description 4 Design and description 4.1 Configuration 2-finger parallel gripper Housing Main air connections Base jaws 4.2 Description 2-finger parallel gripper with smooth roller guides on the base jaws 13.00 | MPG-plus | Assembly and operating manual | en | 389216... -

Page 18: Assembly

Assembly 5 Assembly 5.1 Assembly and connection WARNING Risk of injury due to unexpected movements! If the power supply is switched on or residual energy remains in the system, components can move unexpectedly and cause serious injuries. Before starting any work on the product: Switch off the power •... -

Page 19: Connections

Assembly Check the evenness of the mounting surface, Ø Mechanical connection 20]. Only open the required air connections (main connection or Ø direct connection), Pneumatic connection 22]. Connect the product via the hose-free direct connection. Ø Use O-rings from the accessory pack. ✓... - Page 20 < 0.05 Connections at the The product can be mounted from three sides. housing When selecting the fastening screws, observe the values prescribed by SCHUNK, see following table. 13.00 | MPG-plus | Assembly and operating manual | en | 389216...

- Page 21 Assembly Assembly options MPG-plus Item Mounting 10 12 16 20 25 32 40 50 64 Side A Mounting screw M2 M M3 M4 M4 M5 M5 Max. depth of 2.2 2.3 4 5.5 7.4 8.9 8.9 10.9 10.9 engagement from locating surface [mm] Centering sleeve Ø2 Ø2.5 Ø3 Ø4 Ø5 Ø6 Ø6 Ø8 Ø8 Side B...

-

Page 22: Pneumatic Connection

* For this size, the hose clips are pre-assembled at the factory and the compressed air hoses prescribed by SCHUNK must be used, see catalog data sheet. Procedure for leaking compressed air connection, see section "Troubleshooting". 13.00 | MPG-plus | Assembly and operating manual | en | 389216... -

Page 23: Mounting The Sensor

– The assembly and operating manual and catalog datasheet are included in the scope of delivery for the sensors and are available at schunk.com. • Information on handling sensors is available at schunk.com or from SCHUNK contact persons. 5.3.1 Overview of sensors... -

Page 24: Switch-Off Hysteresis For Magnetic Switches

Assembly 5.3.2 Switch-off hysteresis for magnetic switches Sensors MMS 22, MMS-P 22, MMS 22-PI1 and MMS 22-PI2 The smallest detectable difference in stroke is defined in the following table: The smallest detectable difference in stroke based on the nominal stroke For grippers with X mm Min. - Page 25 Assembly Adjustment dimensions Size L1 [mm] Size L1 [mm] MPG-plus 25 MPG-plus 40 MPG-plus 25-AS 2.0 / 2.5 MPG-plus 40-AS MPG-plus 25-IS MPG-plus 40-IS -17.8 MPG-plus 32 MPG-plus 50 MPG-plus 32-AS -4.0 MPG-plus 50-AS -2.2 MPG-plus 32-IS MPG-plus 50-IS -14.8 5.3.3.2 Size MPG-plus 25 AS For the variant "O.D.

- Page 26 Assembly 5.3.3.3 Size MPG-plus 64 For this size, there is no bracket necessary. The sensor is fastened in the gripper's vertical slot. Fastening the sensor in the horizontal slot is not possible. If there is a slot nut (1), move the slot nut to dimension L3 (see Ø...

-

Page 27: Mounting Inductive Proximity Switches In 30, In 40

5.3.4 Mounting inductive proximity switches IN 30, IN 40 Mounting kit To use the inductive sensor, the gripper has to be retrofitted with a special mounting kit. This mounting kit is available from SCHUNK for the models below. CAUTION Risk of damage to the sensor during assembly! Observe the maximal tightening torque. - Page 28 Assembly Adjustment NOTE For sizes MPG-plus 10 – 20, it is not possible to monitor the "Part gripped" position. Gripper open Gripper open Part gripped Part gripped Gripper closed Gripper closed Bring gripper into the position in which it is to be set. Ø...

-

Page 29: Mounting The Magnetic Switch Mms 22-Iol

Assembly 5.3.5 Mounting the magnetic switch MMS 22-IOL CAUTION Risk of damage to the sensor during assembly! Observe the maximal tightening torque. • 5.3.5.1 Size MPG-plus 25 – 50 For these sizes, there is a bracket in vertical direction mounted standardly. - Page 30 Assembly 5.3.5.2 Size MPG-plus 64 For these sizes no holder is necessary, but the sensor is secured in the vertical groove of the gripper. Mounting the sensor in the horizontal groove is not possible. If a T-nut (1) is available, set the T-nut to dimension L3, see Ø...

-

Page 31: Analog Magnetic Sensor Mms 22-A

Assembly 5.3.6 Analog magnetic sensor MMS 22‑A CAUTION Risk of damage to the sensor during assembly! Observe the maximal tightening torque. • 5.3.6.1 Size MPG-plus 25 – 50 For these sizes, there is a bracket in vertical direction mounted standardly. Loosen the screws at the bracket. - Page 32 Assembly 5.3.6.2 Size MPG-plus 64 For this size, a bracket is not necessary. The sensor is fastened in the gripper's vertical slot. Fastening the sensor in the horizontal slot is not possible. If there is a slot nut (1), move the slot nut to dimension L3 (see Ø...

-

Page 33: Mounting The Programmable Magnetic Switch Mms-P 22

Assembly 5.3.7 Mounting the programmable magnetic switch MMS-P 22 CAUTION Risk of damage to the sensor during assembly! Observe the maximal tightening torque. • 5.3.7.1 Size MPG-plus 25 – 50 For these sizes, there is a bracket in vertical direction mounted standardly. - Page 34 Assembly Protrusion of the sensor to be mounted Adjustment dimensions Size L1 [mm] L2[mm] Size L1 [mm] L2 [mm] MPG-plus 25 MPG-plus 40 MPG-plus 25 AS -6.0 MPG-plus 40-AS -19.0 MPG-plus 25 IS MPG-plus 40-IS MPG-plus 32 MPG-plus 50 MPG-plus 32 AS MPG-plus 50-AS -16.5 MPG-plus 32 IS...

-

Page 35: Mounting The Flexible Position Sensor Fps

Assembly Adjustment dimensions of slot nuts and the sensor L1, L2 Protrusion of the sensor L3, L4 Distance of housing to front side of the sensor Adjustment dimensions Size L1 [mm] L2 [mm] L3 [mm] L4[mm] MPG-plus 64 MPG-plus 64 IS MPG-plus 64 AS 5.3.8 Mounting the flexible position sensor FPS The flexible position sensor FPS consists of a control unit output... - Page 36 Assembly and Operating Manual for the sensor. Size MPG-plus 40 / 50 For these sizes, a holder must be mounted. This holder is available from SCHUNK. Secure holder (1) with screws (2). Ø Secure sensor (4) with screws (3).

- Page 37 Ø sensor, see the Assembly and Operating Manual for the sensor. Size MPG-plus 64 For this size, a holder must be mounted. This holder is available from SCHUNK. Secure holder (1) with screws (2). Ø Secure sensor (4) with screws (3).

-

Page 38: Mounting The Object-Distance Sensor Oas

Assembly Secure control cam (5) with screw (6) on the base jaw. Ensure Ø that the magnets are facing the sensor surface. Connect the torque sensor system controller and adjust the Ø sensor, see the Assembly and Operating Manual for the sensor. 5.3.9 Mounting the object-distance sensor OAS Fix sensor (1) with screws (2) at the housing (3). -

Page 39: Mounting The Inductive Proximity Switch In 5

5.3.10 Mounting the inductive proximity switch IN 5 Mounting kit To use the inductive sensor, the gripper has to be retrofitted with a special mounting kit. This mounting kit is available from SCHUNK for the models below. Remove the name plate. - Page 40 Assembly The sensors can be set to perfrom the following queries: Position "opened" Move the gripper into the required position. Ø Push the sensor to the switching lug. Ø Slowly pull the sensor back until it switches. Then retract the Ø...

-

Page 41: Troubleshooting

Unused air connections open. Close unused air connections. Flow control valve closed. Open the flow control valve. Component part defective. Replace component or send it to SCHUNK for repair. 6.2 Product is not executing the complete stroke Possible cause Corrective action Dirt deposits between cover and piston. -

Page 42: Gripping Force Is Dropping

Pressure drops below minimum. Check air supply. Pneumatic connection 22] Component part defective. Replace component or send it to SCHUNK for repair. 6.5 Product does not achieve the opening and closing times Possible cause Corrective action Compressed air lines are not installed If present: Open the flow control couplings optimally. -

Page 43: Maintenance

Maintenance 7 Maintenance 7.1 Notes Original spare parts Use only original spare parts of SCHUNK when replacing spare and wear parts. Exchange of housing and base jaws The base jaws and the guidance in the housing are matched. To exchange these parts, send the product with a repair order to SCHUNK. -

Page 44: Lubricants/Lubrication Points (Basic Lubrication)

Maintenance 7.3 Lubricants/Lubrication points (basic lubrication) SCHUNK recommends the lubricants listed. During maintenance, treat all greased areas with lubricant. Thinly apply lubricant with a lint-free cloth. Lubricant point Lubricant Cross roller guide microGLEIT GP 360 All seals Renolit HLT 2 7.4 Servicing the product... -

Page 45: Sizes 10-12

Maintenance 7.5.1 Sizes 10-12 Assembly of sizes 10–12, variant without maintenance of gripping force Wearing part, replace during maintenance. Included in the seal kit. Seal kit can only be ordered completely. Positions are adapted to each other and can not be replaced by the customer. -

Page 46: Sizes 16-20

Maintenance 7.5.2 Sizes 16–20 "O.D. gripping" version "I.D. gripping" version Version without (AS) (AS) maintenance of gripping force Assembly of sizes 16-20 Wearing part, replace during maintenance. Included in the seal kit. Seal kit can only be ordered completely. Positions are adapted to each other and can not be replaced by the customer. -

Page 47: Size 25-50

Maintenance 7.5.3 Size 25-50 "O.D. gripping" version "I.D. gripping" version Version without (AS) (AS) maintenance of gripping force Assembly of sizes 25-50 Wearing part, replace during maintenance. Included in the seal kit. Seal kit can only be ordered completely. Positions are adapted to each other and can not be replaced by the customer. -

Page 48: Size 64

Maintenance 7.5.4 Size 64 "O.D. gripping" version "I.D. gripping" version Version without (AS) (AS) maintenance of gripping force Assembly of size 64 Wearing part, replace during maintenance. Included in the seal kit. Seal kit can only be ordered completely. Positions are adapted to each other and can not be replaced by the customer. -

Page 49: Translation Of Original Declaration Of Incorporation

8 Translation of original declaration of incorporation in terms of the Directive 2006/42/EG, Annex II, Part 1.B of the European Parliament and of the Council on machinery. Manufacturer/ SCHUNK GmbH & Co. KG Spann- und Greiftechnik Distributor Bahnhofstr. 106 – 134 D-74348 Lauffen/Neckar... -

Page 50: Annex To Declaration Of Incorporation

Annex to Declaration of Incorporation 9 Annex to Declaration of Incorporation according 2006/42/EG, Annex II, No. 1 B 1.Description of the essential health and safety requirements pursuant to 2006/42/EC, Annex I that are applicable and that have been fulfilled with: Product designation 2-finger parallel gripper Type designation MPG-plus... - Page 51 Annex to Declaration of Incorporation Protection against mechanical hazards 1.3.1 Risk of loss of stability 1.3.2 Risk of break-up during operation 1.3.3 Risks due to falling or ejected objects 1.3.4 Risks due to surfaces, edges or angles 1.3.5 Risks related to combined machinery 1.3.6 Risks related to variations in operating conditions 1.3.7...

- Page 52 Annex to Declaration of Incorporation Maintenance 1.6.1 Machinery maintenance 1.6.2 Access to operating positions and servicing points 1.6.3 Isolation of energy sources 1.6.4 Operator intervention 1.6.5 Cleaning of internal parts Information 1.7.1 Information and warnings on the machinery 1.7.1.1 Information and information devices 1.7.1.2 Warning devices 1.7.2...

Need help?

Do you have a question about the MPG-plus 12 and is the answer not in the manual?

Questions and answers