Daktronics BA-515 Display Manual

Single-section outdoor generation iii led scoreboards

Hide thumbs

Also See for BA-515:

- Display manual (208 pages) ,

- Installation, maintenance, and specifications manual (144 pages)

Table of Contents

Advertisement

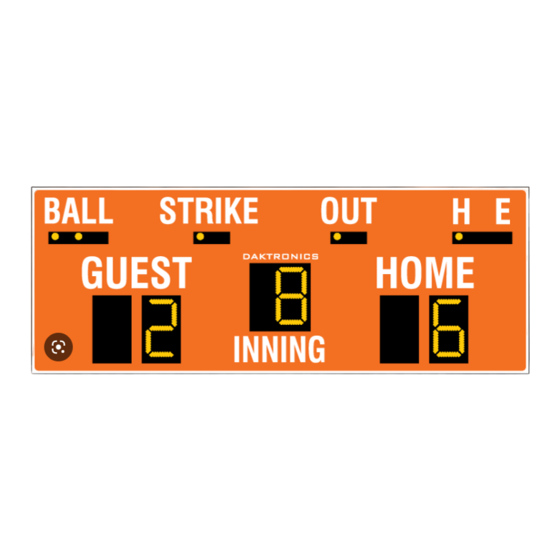

Single-Section Outdoor

Generation III

LED Scoreboards

Display Manual

ED-13770

BA-515

BA-2014

BA-518

BA-2016

BA-618

BA-2017

BA-624

BA-2019

BA-718

BA-1018

CR-2002

BA-2003

CR-2003

BA-2004

BA-2005

CT-2001

BA-2010

CT-2002

BA-2011

Rev 16 – 25 October 2006

Models

FB-824

MS-2012

TI-215

FB-2005

TI-218

FB-2410

RO-2010

TI-418

RO-2011

TI-2003

MS-915

TI-2010

MS-918

SO-918

TI-2012

MS-2002

SO-2008

TI-2015

MS-2003

SO-2009

TI-2019

MS-2004

SO-2010

TI-2024

MS-2006

SO-2013

MS-2011

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Daktronics BA-515

- Page 1 Single-Section Outdoor Generation III LED Scoreboards Display Manual ED-13770 Rev 16 – 25 October 2006 Models BA-515 BA-2014 FB-824 MS-2012 TI-215 BA-518 BA-2016 FB-2005 TI-218 BA-618 BA-2017 FB-2410 RO-2010 TI-418 BA-624 BA-2019 RO-2011 TI-2003 BA-718 MS-915 TI-2010 BA-1018 CR-2002 MS-918...

- Page 2 – without written permission of the publisher. ® ® All Sport and PanaView are trademarks of Daktronics, Inc. Other trademarks used in this manual are the property of their respective owners.

-

Page 3: Table Of Contents

Scoreboard Mounting ................6-6 Mounting Method 1................6-7 Mounting Method 2................6-8 Scoreboard Mounting Using Spacers ..........6-9 Ad Panel Mounting................6-10 Models BA-515-11 and BA-518-11..........6-10 Section 7: Electrical Installation ..............7-1 Power 7-1 Grounding................... 7-2 Power Installation................7-3 Power and Signal Connection.............. - Page 4 LED Drivers ....................8-4 Segmentation and Digit Designation ............8-5 Lightning Protection.................. 8-6 Replacement Parts ..................8-6 Troubleshooting..................8-9 Daktronics Exchange and Repair and Return Programs......8-10 Exchange Program ................8-10 Repair and Return Program.............. 8-11 How to reach us................8-11 Section 9: Team Name Message Center Maintenance.........9-1...

- Page 6 List of Figures Figure 1: Daktronics Drawing Label..................1-1 Figure 2: Scoreboard ID Label..................... 1-2 Figure 3: Lifting the Display....................6-4 Figure 4: Clamp Mounting Method, Side View..............6-7 Figure 5: Mounting with C-channel, Side View ..............6-8 Figure 6: Mounting with Spacers..................6-9 Figure 7: Power Terminal Block..................

-

Page 8: Introduction

This manual explains the installation of Daktronics Single-Section Outdoor Generation III LED Scoreboards and provides details for display maintenance. With questions regarding the safety, installation, operation, or service of these systems, contact Daktronics. Daktronics Customer Service telephone number is listed in Section 8.9 of this manual. -

Page 9: Figure 2: Scoreboard Id Label

For example, this manual would be referred to as ED-13770. The serial and model numbers of a Daktronics scoreboard can be found on the ID label on the display. The label will be similar to the one shown in Figure 2. When calling Daktronics Customer Service, please have this information available to ensure quick service. -

Page 10: Daktronics Nomenclature

Daktronics Nomenclature To fully understand Daktronics drawings, it is necessary to know how various components are labeled in drawings. This information is useful when trying to communicate maintenance or troubleshooting efforts. The label “A” on a drawing item typically denotes an assembly. An assembly can be a single circuit board or a collection of components that function together, usually mounted on a single plate or in a single enclosure. -

Page 11: Product Overview

Contains ED-7244, a detailed instruction on scoreboard lifting and eyebolts. Product Overview The Daktronics outdoor LED scoreboards are part of a family of scoring and timing displays designed to offer easy installation, readability and reliability. Microprocessor control assures consistent operation and accuracy. -

Page 12: Model Names

-11 are outdoor scoreboards, 120 V, and feature red digits; -21 are outdoor scoreboards, 120 V, and feature amber digits. Product Safety Approval Daktronics outdoor scoreboards are ETL listed and tested to CSA standard for outdoor use. Contact Daktronics with any questions regarding testing procedures. Introduction... -

Page 14: Model Identification

Section 2: Model Identification Use the following drawings to determine the model number of your scoreboard. The drawings listed here are located in Appendix A: Reference Drawings; where they are inserted in alphanumeric order by drawing number. Reference Drawings: Single-Section LED Scoreboard Models ........Drawing A-142912 Single-Section LED Scoreboard Models ........Drawing A-152950 Model Identification... -

Page 16: Specifications

Section 3: Specifications The table on the following pages shows all of the mechanical specifications, circuit specifications and maximum power requirements for each model in this manual. Models are listed in alphanumeric order. Specifications... -

Page 17: Single-Section Scoreboards

Single-Section Scoreboards Note: Signal wires must be a minimum of 22 AWG with shield. Daktronics recommends using W-1234. Models with an –11 or –12 suffix feature red digits and indicators; suffixes –21 and –22 indicate amber digits. Model Dimensions Weight... - Page 18 Model Dimensions Weight Digit Size Maximum Power Amps Driver Height, Width, Depth Uncrated Wattage Number Digit Color Line Crated (Single Address Phase) BA-1018-11/21 H6'-0", W14'-0", D6" 216 lb 18" (457 mm) 300 W 120 V AC 2.5 A (1829 mm, 4267 mm, 152 mm) (98 kg) -11: red 410 lb...

- Page 19 Model Dimensions Weight Digit Size Maximum Power Amps Driver Height, Width, Depth Uncrated Wattage Number Digit Color Line Crated (Single Address Phase) BA-2005-11/21 H6'-6", W20'-0", D6" 720 lb Time, ball, 1100 W 120 V AC 9.2 A w/TNMC (1981 mm, 6096 mm, 152 mm) (327 kg) strike, out: (w/red...

- Page 20 Model Dimensions Weight Digit Size Maximum Power Amps Driver Height, Width, Depth Uncrated Wattage per Line Number Digit Color (Single Crated Phase) Address BA-2016-11/21 H6'-0", W14'-0", D6" 216 lb SOP, ball, 600 W 120 V AC 5.0 A (1829 mm, 4267 mm, 152 mm) (98 kg) strike, out Inning, runs: 18"...

- Page 21 Model Dimensions Weight Digit Size Maximum Power Amps Driver Height, Width, Depth Uncrated Wattage Number Digit Color Line Crated (Single Address Phase) CR-2002-11/21 H5'-7", W5'-7", D6" 90 lb 15" (381 mm) 300 W 120 V AC 2.5 A (1524 mm, 1524 mm, 152 mm) (41 kg) -11: red 180 lb...

- Page 22 Model Dimensions Weight Digit Size Maximum Power Amps Driver Height, Width, Depth Uncrated Wattage Number Digit Color Line Crated (Single Address Phase) MS-915-11/21 H4’-0", W8’-0", D6" 88 lb (40 kg) 15" (381 mm) 300 W 120 V AC 2.5 A (1219 mm, 2438 mm, 279 mm) 167 lb (76 kg) -11: red...

- Page 23 Model Dimensions Weight Digit Size Maximum Power Amps Driver Height, Width, Depth Uncrated Wattage Number Digit Color Line Crated (Single Address Phase) MS-2004-11/21 H5'-0", W18'-0", D6" 300 lb 18" (457 mm) 600 W 120 V AC 5.0 A (1524 mm, 5486 mm, 152 mm) (136 kg) -11: red 570 lb...

- Page 24 Model Dimensions Weight Digit Size Maximum Power Amps Driver Height, Width, Depth Uncrated Wattage Number Digit Color Line Crated (Single Address Phase) MS-2011-11/21 H4'-6", W20'-0", D6" 505 lb Clock, scores: 500 W 120 V AC 4.2 A w/TNMC (1372 mm, 6096 mm, 152 mm) (229 kg) 24”...

- Page 25 Model Dimensions Weight Digit Size Maximum Power Amps Driver Height, Width, Depth Uncrated Wattage Number Digit Color Line Crated (Single Address Phase) SO-918-11/21 H4'-0", W12'-0", D6" 180 lb 18" (457 mm) 300 W 120 V AC 2.5 A (1219 mm, 3658 mm, 152 mm) (81 kg) -11: red 410 lb...

- Page 26 Model Dimensions Weight Digit Size Maximum Power Amps Driver Height, Width, Depth Uncrated Wattage Number Digit Color Line Crated (Single Address Phase) SO-2010-11/21 H4'-0", W12'-0", D6" 180 lb Clock, scores: 300 W 120 V AC 2.5 A (1219 mm, 3658 mm, 152 mm) (81 kg) 18"...

- Page 27 Model Dimensions Weight Digit Size Maximum Power Amps Driver Height, Width, Depth Uncrated Wattage Number Digit Color Line Crated (Single Address Phase) TI-2003-11/21 H3'-0", W4'-0", D6" 88 lb 30" (762 mm) 150 W 120 V AC 1.3 A (914 mm, 1219 mm, 152 mm) (40 kg) -11: red 167 lb...

-

Page 28: Component Locations

Appendix A: Reference Drawings, where they are inserted in alphanumeric order by drawing number. Model Drawing Title Drawing BA-515 Component Locations; BA-515-11/-21, G3 A-178600 BA-518 Component Locations; BA-518-11/-21, G3 A-178696 BA-618 Component Locations;... - Page 29 Model Drawing Title Drawing FB-824 Component Locations; FB-824-11/-21, G3 A-182543 FB-2005 Component Locations; FB-2005-11/-21, G3 A-228192 FB-2410 Component Locations; FB-2410-11/21, G3 A-274863 MS-915 Component Locations; MS-915-11/-21, G3 A-180365 MS-918 Component Locations; MS-918-11/-21, G3 A-227840 MS-2002 Component Locations; MS-2002-11/-21, G3 A-235932 MS-2002 TNMC Component Locations;...

- Page 30 Model Drawing Title Drawing TI-215 Component Locations, TI-215-11/-21, G3 A-201607 TI-218 Component Locations; TI-218-11/-21, G3 A-181701 TI-418 Component Locations; TI-418-11/-21, G3 A-181177 TI-2003 Component Locations; TI-2003-11/-21, G3 A-182702 TI-2010 Component Locations; TI-2010-11/-21, G3 A-182110 TI-2012 Component Locations; TI-2012-11/-21, G3 A-182081 TI-2015 Component Locations;...

-

Page 32: Schematics

A-178235. Wiring diagrams for both drivers, in master and slave configurations, are shown on the schematics, Drawings A-177931, A-177935, A-179541, A-179790, A-180081, A-180637, B-181354 and B-210454. Driver Schematic Model Driver Drawing Drawing BA-515 8-column driver A-178197 A-177935 BA-518 8-column driver A-178235 A-177935 BA-618... - Page 34 Model Driver Driver Drawing Schematic BA-2019 16 column driver/slaves A-179541 BA-2019 TNMC 16 column driver/slaves A-180081 CR-2002 16 column driver A-178197 A-177931 CR-2003 16 column driver A-178197 A-180637 CT-2001 8-column driver A-178235 A-177935 CT-2002 8-column driver A-178235 A-177935 FB-824 16-column driver A-178197 A-177931 FB-2005...

- Page 36 Model Driver Driver Drawing Schematic SO-918 16-column driver A-178197 A-177931 SO-2008 16-column driver A-178197 A-177931 SO-2008 TNMC 16-column driver A-178197 A-179790 SO-2009 16-column driver A-178197 A-177931 SO-2010 16-column driver A-178197 A-177931 SO-2013 16-column driver A-178197 A-177931 TI-215 4-column MASC driver B-179349 A-165028 TI-218...

-

Page 38: Mechanical Installation

Note: Some users install devices to protect the scoreboard from projectiles. Scoreboard protection devices not provided by Daktronics must be approved by Daktronics prior to installation. Failure to follow this approval procedure will void the scoreboard warranty. Footings and Beams Use the following drawings to determine the correct installation drawing for your scoreboard. - Page 39 BA-2010 Installation Specifications, BA-2010-11 A-179304 Model Drawing Title Drawing BA-2011 Installation Specifications; A-152777 BA-2004/2005/2011/2014 BA-2014 Installation Specifications; A-152777 BA-2004/2005/2011/2014 BA-2016 Installation Specifications; BA-2016 A-61904 BA-2017 Installation Specifications; BA-2017 A-61904 BA-2019 Installation Specifications; BA-2019-11/21 A-233487 CR-2002 Installations Specifications CR-2002 A-235517 CR-2003 Installations Specifications CR-2003 A-248966 CT-2001...

- Page 40 Model Drawing Title Drawing RO-2010 Installation Specs; RO-2010 A-185216 RO-2011 Installation Specs; TI-418/RO-2011/ A-169380 CT-2001/TI-2019 SO-918 Installation Specifications, SO-918, SO-2009, A-55010 SO-2010 SO-2008 Installation Specifications, SO-2008 A-149074 SO-2008 TNMC Installation Specifications, SO-2008 A-149074 SO-2009 Installation Specifications, SO-918, SO-2009, A-55010 SO-2010 SO-2010 Installation Specifications, SO-918, SO-2009, A-55010...

-

Page 41: Figure 3: Lifting The Display

Note: Daktronics does not assume any liability for any installation derived from the information provided in this manual or installations designed and installed by others. - Page 42 45 degrees. Note: Daktronics assumes no liability for scoreboard damage resulting from incorrect setup or incorrect lifting methods Eyebolts are intended for lifting only. Do not attempt to permanently support the display by the eyebolts.

-

Page 43: Scoreboard Mounting

Scoreboard Mounting There are two basic styles for mounting Daktronics single-section outdoor scoreboards. Installation procedures are detailed later in this section. Use the following tables to determine the mounting method required for each scoreboard: Method 1 BA-618 BA-2016 MS-2011 BA-624... -

Page 44: Mounting Method 1

Mounting Method 1 Reference Drawings: Display Mounting .............Drawing A-44412 Ad Panel Mounting ..........Drawing A-52187 Drawing A-44412 shows the hardware used for mounting the scoreboard to the beams. Mounting hardware includes inner and outer mounting clamps, clip angles, -13 x 15" threaded rods, -16 x 2"... -

Page 45: Mounting Method 2

5. Make final adjustments in the positioning of the scoreboard. Tighten the " bolts in the mounting clamps. 6. Make sure that the threaded rods are perpendicular to the scoreboard and tighten all of the " nuts. Mounting Method 2 Reference Drawing: Scoreboard Mounting.......... -

Page 46: Scoreboard Mounting Using Spacers

Reference Drawing: Scoreboard Mtg; Scoreboard with Spacers....Drawing A-182909 Many Daktronics customers add message centers or advertising panels to the top or bottom of their scoreboards, and in some cases the depth of the add-on component may not match the depth of the scoreboard. (Scoreboards in this series are typically 6"... -

Page 47: Ad Panel Mounting

Models BA-515-11 and BA-518-11 With Models BA-515-11 and BA-518-11, ad panels can be mounted directly to the end of the scoreboard. Refer to Drawings A-52585 and A-52811 for mounting details. -

Page 48: Electrical Installation

Schematic; BA-2011/2007 Gen III .......Drawing B-181354 Schematic; Gen III, OD LED, 1 Drvr w/ S.O.P.....Drawing B-210454 Daktronics outdoor LED scoreboards have been designed for easy access to components, and the power and control signal hookup has been simplified. Front panels are removable to allow access to the digits, cabling, and other electronic components. -

Page 49: Grounding

Daktronics recommends a resistance-to-ground of 10 ohms or less. The electrical contractor performing the electrical installation can verify ground resistance. Daktronics Sales and Service personnel can also provide this service. The display system must be connected to an earth electrode installed at the display. -

Page 50: Power Installation

The support structure of the display cannot be used as an earth-ground electrode. The support is generally embedded in concrete, and if it is in earth, the steel is usually primed or it corrodes, making it a poor ground in either case. Power Installation There are two types of power installation: installation with ground and neutral conductors provided, and installation with only a neutral conductor provided. -

Page 51: Figure 7: Power Terminal Block

Note: Driver enclosures in some earlier Daktronics scoreboards included a 120 V power receptacle. There is no 120 V receptacle in Generation III displays. If you want power to operate the control console at the scoreboard for troubleshooting, Daktronics recommends that you have the installation electrician provide a 120 V outlet close to the disconnect box specifically for this purpose. -

Page 52: Multiple Driver Connections

For additional information on signal connection, refer to the All Sport 5000 Series or All Sport 3000 Series control console operation manuals, ED-11976 and ED-12126. Multiple Driver Connections Some models in the single-section outdoor scoreboard line require multiple drivers, and those models have been configured to operate with a master/slave driver system. Master and slave drivers function identically, but slave units lack the power termination block and signal surge suppression card. -

Page 54: Scoreboard Maintenance And Troubleshooting

Cabinet Specifications Cabinets for the Daktronics outdoor LED scoreboards are constructed of heavy- gauge aluminum. Exact dimensions and weights for each model are listed in the chart in Section 3. Removable panels for digits and indicators and for component access are detailed in each model’s component locations drawing, listed in Section... -

Page 55: Replacing A Digit

Remove the nuts and lift the digit off the standoff screws. (The push nuts can be removed in several ways, but Daktronics recommends using a " nut driver.) 4. Position a new digit over the screws and tighten the nuts. -

Page 56: Replacing A Digit Segment

Replacing a Digit Segment Reference Drawing: Digit Assemblies; Gen III LED Digits .....Drawing B-177679 When a digit malfunctions, in most cases it is necessary to replace the entire digit circuit board. Some larger digits (24", 30", 36"), however, are constructed in segments, as shown in Figure 11, and it may be possible to make repairs by removing only the defective segment. -

Page 57: Schematic

Drawings A-177935, A-177931, A-179790, A-179541, A-180081, A-180637, B-181354, and B-210454 are the schematic diagrams for the 8- and 16-column drivers used in Daktronics outdoor single-section scoreboards. The schematics include power and signal inputs and all wiring for the models described in this manual. -

Page 58: Segmentation And Digit Designation

In the scoreboard, the LED drivers perform the task of switching digits on and off. Refer to Drawings A-178197 and A-178235. Each driver has up to19 connectors providing power and signal inputs to the circuit and outputs to the digits and indicators. -

Page 59: Lightning Protection

The same surges that may damage the scoreboard’s driver can also damage the console’s circuit. Replacement Parts Refer to the following table for Daktronics scoreboard replacement parts. Description Location Daktronics Part No. - Page 60 Description Location Daktronics Part No. Digit, 18" ones, 7-seg outdoor LED, Scoreboard 0P-1192-0217 amber Digit segment, 24" outdoor LED, Scoreboard 0P-1192-0205 red (horizontal) Digit segment, 24" outdoor LED, Scoreboard 0P-1192-0204 red (vertical) Digit segment, 24" outdoor LED, Scoreboard 0P-1192-0219 amber (horizontal) Digit segment, 24"...

- Page 61 Description Location Daktronics Part No. 8 Segment Breakout Board FB-2410 0P-1192-0326 60” Red Hor Half Seg FB-2410 0P-1192-0280 60” Red Vert Half Seg FB-2410 0P-1192-0281 60” Amber Hor Half Seg FB-2410 0P-1192-0282 60” Amber Vert Half Seg FB-2410 0P-1192-0283 Scoreboard Maintenance...

-

Page 62: Troubleshooting

Troubleshooting This section lists potential problems with the scoreboard and indicates possible causes and corrective actions. This list does not include every possible problem, but does represent some of the more common situations that may occur. Symptom/Condition Possible Cause Scoreboard will not light Console not connected or poor connection No power to control console No power to the scoreboard... -

Page 63: Daktronics Exchange And Repair And Return Programs

Exchange Program Daktronics unique Exchange Program is a quick, economical service for replacing key parts in need of repair. If a part requires repair or replacement, Daktronics sends the customer a replacement, and the customer sends the problem part to Daktronics. - Page 64 For items not subject to exchange, Daktronics offers a Repair and Return Program. To send a part for repair, follow these steps.

-

Page 66: Team Name Message Center Maintenance

Section 9: Team Name Message Center Maintenance IMPORTANT NOTES: 1. Disconnect power before doing any repair or maintenance work on the message centers. 2. Permit only qualified service personnel to access the internal electronics of the display. Disconnect power when the scoreboard is not in use. Team Name Message Center System Overview Team name message centers (TNMCs) are available in two sizes: an 8x32 matrix model with four 8x8-pixel modules, and an 8x48 model comprised of six 8x8... -

Page 67: Maintenance And Troubleshooting Overview

Maintenance and Troubleshooting Overview Standard Daktronics outdoor LED scoreboards typically are front-accessible, but some models may be ordered with rear service access. For that reason, Daktronics team name message centers have been designed so that they may be accessed from both the front and rear for easy maintenance and repair of internal components. -

Page 68: Power Summary

2. The signal then travels through the driver/power enclosure to the J1 connector on the current loop interface card. 3. Data exits at J42 via current loop harness, and connects with P43 at the TNMC controller assembly. An interconnect harness carries the signal to the first module, and the signal relays from module to module, in daisy- chain style, until it reaches the last module on the message center. -

Page 69: Tnmc Controller

TNMC Controller Reference Drawings: 4 Column MASC LED Driver Specifications ..Drawing A-166216 Component Locations; 832/848 Red/Amb LED TNMC, G3 ......Drawing A-187987 Component Locations; 832/848 Red/Amb LED TNMC, G4 ......Drawing A-257029 The TNMC controller, located on the rear-access panel, receives signal directly from the control console and sends data to the modules. - Page 70 The following table explains the operation and functions of each of the diagnostic LEDs. Color Function Operation Summary CL signal Steady on DS1 will be on or blinking when the or blinking driver is receiving signal and off when there is no signal with CL (current loop).

-

Page 71: Figure 15: Tnmc Internal Components (Modules Removed)

Removing/Changing the Controller Reference Drawings: Exploded Front View; Single Panel Module..Drawing B-126111 Exploded Rear View; Single Panel Module ..Drawing B-126112 Component Locations; 832/842 Red/Amb LED TNMC, G3 ......Drawing A-187987 Use this reference drawing after 11/29/05 Component Locations; 832/848 Red/Amb LED, TNMC, G4 ...... -

Page 72: Modules And Drivers

Note: To access the controller from the rear of the TNMC, as shown in Figure 16 (on previous page), remove the appropriate rear-access panel from the TNMC by loosening all four of the screws. Slide the access panel sideways to the larger part of the keyhole and carefully lift it off the TNMC. - Page 73 Drawings B-126111 and B-126112 illustrate the various module components. Individual components such as louvers can be removed for service, but Daktronics recommends that the module be kept intact and that the entire assembly be sent in for repair or replacement.

-

Page 74: Power Supplies

When installing a module, reverse the previous steps and take note of the following points. • The weather-stripping on the back edge of the module must be intact and in good condition if it is to prevent water from seeping into the display. •... -

Page 75: Troubleshooting

cabinet to remove dust/dirt buildup that may interfere with airflow. Water Intrusion – Water stain marks Water can enter the display where weatherstripping has come loose or deteriorated; where fasteners have come loose, allowing gaps in the panels; or where moisture may be entering around hardware. Check electronic components for corrosion. -

Page 76: Initialization Information At Startup

Symptom/Condition Possible Cause/Remedy A section of the display is not Replace the first module/driver on the left working; the section extends all the side of the first module that is not working. way to the right side of the display. Replace the second module that is not working. - Page 77 Red LED TNMC, 848 0A-1192-2552 0A-1192-3166 To prevent theft, Daktronics recommends purchasing a lockable cabinet to store manuals and replacement and spare parts. Refer to Section 8.9 for information on the Daktronics Exchange and Repair and Return programs. 9-12 TNMC Maintenance...

-

Page 78: Scoreboard Options

Section 10: Scoreboard Options The following options are available for the Daktronics single-section scoreboards to make them more adaptable to individual scoring and timing needs: Team name caption kits for certain models Trumpet horn for football and soccer Radio control Portable power pack 10.1 Team Name Captions: Model BA-624-11... -

Page 79: 10.2 Trumpet Horn

CAUTION The aluminum caption changer can conduct electricity. Do not use it within 20 feet of power lines. Be careful when using the caption changer in high or gusting winds. Wind may catch the panel and unhook it from the changer. The surface area of the caption panel could also act as a sail, making it difficult to maintain a grip on the pole. -

Page 80: Dc Trumpet Horn Installation (Externally Mounted)

6. Screw the trumpet into the horn body. The trumpet will tilt down about 10 degrees to allow moisture drainage. 7. Connect to power to the scoreboard. 8. Connect the control console to the scoreboard. 9. Test the horn by pressing the key labeled HORN on the control console. DC Trumpet Horn Installation (Externally Mounted) Caution: Disconnect scoreboard power before installing the horn! Refer to Drawings A-128938 and A-162102 for complete installation information. -

Page 81: 10.3 Radio Control

17. Test the horn by pressing the key labeled HORN on the control console. 10.3 Radio Control Radio control is an option with all Daktronics outdoor LED scoreboards, the system providing scoreboard control via a 2.4 GHz, extra-high frequency FM signal. -

Page 82: Appendix A: Reference Drawings

Display Mounting ................Drawing A-44412 Lifting Scoreboard ................Drawing A-44548 Caption Changing................Drawing A-44549 Ad Panel Mounting ................Drawing A-52187 Assembly, Ad Panel, BA-515 ............Drawing A-52585 Ad Panel Mounting, BA-518 .............Drawing A-52811 Installation Specifications, BA-515 ............Drawing A-55003 Installation Specifications, BA-518 ............Drawing A-55004 Installation Specifications, BA-718 ............Drawing A-55005 Installation Specifications, BA-618 &... - Page 83 Driver, Gen III Outdoor LED, 16 Col Master ........Drawing A-178197 Driver Assy; Gen III Outdoor LED, 8 Col Master ......Drawing A-178235 Component Locations; BA-515-11/-21, G3........Drawing A-178600 Component Locations; BA-518-11/-21, G3........Drawing A-178696 Component Locations; BA-718-11/-21, G3........Drawing A-178784 Installation Specifications, BA-2010 ..........

- Page 84 Component Locations; BA-624-11/21, G3 ........Drawing A-227767 Component Locations; MS-918-11/21 G3........Drawing A-227840 Component Locations; BA-618-11/21, G3 ........Drawing A-227949 Component Locations; FB-2005-11/21, G3 ........Drawing A-228192 Component Locations; SO-2013-11/21, G3........Drawing A-228598 Component Locations; BA-2004-11/21, G3 ........Drawing A-228668 Component Locations; MS-2011-11/21, G3........Drawing A-229459 Component Locations; MS-2004-11/21, G3........Drawing A-229758 Harness Assembly Diagram;...

- Page 211 Appendix B: Eyebolts Eyebolts ......................ED-7244 Eyebolts...

- Page 212 Eyebolts Almost every display that leaves Daktronics is equipped with eyebolts for lifting the display. There are two standard sizes of eyebolts: ½″ and ⅝″. Load Increase Factor: The load increases as the lift angle (θ) decreases. The allowable load on the eyebolts also decreases with the lift angle due the bending stress on the eyebolts.

- Page 213 F. Eyebolts should never be painted or otherwise coated when used for lifting. Such coatings may cover potential flaws in the eyebolt. G. To attain the safe working loads listed for regular eyebolts, 90% of the thread length must be engaged. Copyright © 1996-2001 ED-7244 Daktronics, Inc. Rev. 4 – 14 March 2001...

- Page 214 Appendix C...

- Page 215 WARRANTY AND LIMITATION OF LIABILITY This Warranty and Limitation of Liability (the “Warranty”) sets forth the warranty provided by Daktronics with respect to the Equipment. By accepting delivery of the Equipment, Purchaser agrees to be bound by and accept these terms and conditions. All defined terms within the Warranty shall have the same meaning and definition as provided elsewhere in the Agreement.

- Page 216 In no event shall Daktronics be liable to Purchaser or any other party for loss, damage, or injury of any kind or nature arising out of or in connection with this Warranty in excess of the purchase price of the Equipment actually delivered to and paid for by the Purchaser.

Need help?

Do you have a question about the BA-515 and is the answer not in the manual?

Questions and answers