Table of Contents

Advertisement

Quick Links

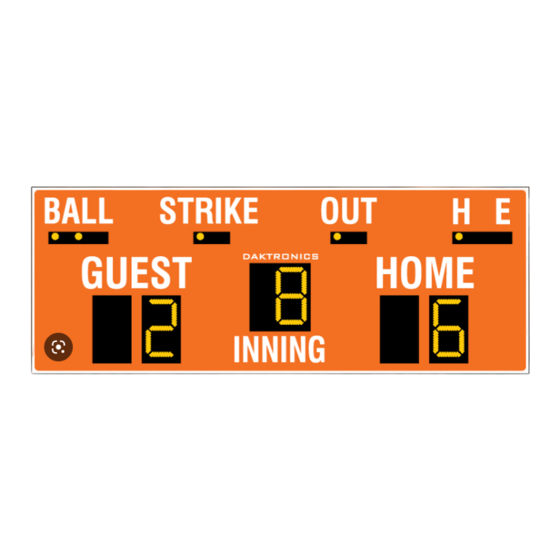

Single-Section Outdoor

Incandescent Scoreboards

Installation, Maintenance,

and Specifications Manual

All Sport

Deoxit

and Cailube

BA-515

BA-718

BA-518

BA-1018

BA-618

BA-2003

BA-624

BA-2004

ED11974

Product 1091

Rev 9 – 13 August 2002

Copyright © 2002 Daktronics, Inc.

All rights reserved. While every precaution has been taken in the

preparation of this manual, the publisher assumes no responsibility for errors

or omissions. No part of this book covered by the copyrights hereon may be

reproduced or copied in any form or by any means – graphic, electronic

or mechanical, including photocopying, taping, or information storage

and retrieval systems – without written permission of the publisher.

Note: Please fill in the information below for

your display, and use it as a reference when

calling Daktronics for assistance.

Serial No. ___________________________

Model No.___________________________

Date Installed ________________________

®

is a registered trademark of Daktronics, Inc

are trademarks of their respective manufacturers.

MODEL NUMBERS

CT-2001

MS-915

CT-2002

MS-918

FB-824

MS-2002

FB-2340

MS-2004

PO Box 5128 331 32nd Ave Brookings SD 57006

Tel 605-697-4036 or 877-605-1115 Fax 605-697-4444

www.daktronics.com e-mail: helpdesk@daktronics.com

ED11974

MS-2006

SO-2008

MS-2011

TI-218

SO-824

TI-418

SO-918

TI-2003

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Daktronics BA-515

- Page 1 Single-Section Outdoor Incandescent Scoreboards Installation, Maintenance, and Specifications Manual ED11974 ® All Sport is a registered trademark of Daktronics, Inc Deoxit and Cailube are trademarks of their respective manufacturers. MODEL NUMBERS BA-515 BA-718 CT-2001 MS-915 MS-2006 SO-2008 BA-518...

-

Page 3: Table Of Contents

Table of Contents Section 1: Introduction....................1-1 How To Use This Manual ..................1-1 Product Safety Approval ....................1-1 Manual Overview .......................1-2 Daktronics Exchange and Repair and Return Programs ..........1-2 Section 2: Model Identification..................2-1 Section 3: Specifications ....................3-1 Single-Section Scoreboards..................3-2 230 Volt Single-Section Scoreboards.................3-7 Section 4: Component Locations.................4-1... - Page 4 Section 9: Team Name Message Centers Maintenance and Troubleshooting ..9-1 TNMC Schematics..................... 9-1 Service Procedures..................... 9-2 Removing a Module....................9-2 Removing a Lampbank ....................9-2 Replacing a Lampbank ....................9-3 Replacing the Module....................9-3 Lamp Testing and Replacement................. 9-3 Individual Lamp Replacement ................... 9-4 Lens Position and Sequence ..................

-

Page 5: Introduction

Drawing A-69945. Reference drawings are grouped and inserted in alphanumeric order in Appendix A. The serial and model number of a Daktronics scoreboard can be found on the ID label, located on the display. This label will be similar to the one shown in Figure 2. -

Page 6: Manual Overview

If a component fails, Daktronics sends the customer a reconditioned replacement within 24 hours. The customer, in turn, sends the failed component to Daktronics. This not only saves money but also decreases scoreboard downtime. This service is provided to qualified customers who follow the program guidelines explained below. - Page 7 If the defective equipment is not shipped to Daktronics within 30 working days from the invoice date, it is assumed you are purchasing the replacement part, and you will be invoiced for it. This second invoice represents the difference between the exchange price and the full purchase price of the equipment.

-

Page 9: Model Identification

Section 2: Model Identification Use the following drawings to determine your scoreboard model number. The drawings, located in the Appendix, are inserted in alphanumeric order by drawing number. Reference Drawings: Single-Section Scoreboard Models............Drawing A-124342 Single-Section Scoreboard Models w/TNMC........Drawing A-127262 Single Section Scoreboard Models ............ -

Page 11: Specifications

Section 3: Specifications The following tables include all of the mechanical specifications, circuit specifications, and maximum power requirements for each model in this manual. Models are listed in alphanumeric order. Section 3.1: Single-Section Scoreboards ..................3-2 Section 3.2: 230-Volt Single-Section Scoreboards..............3-5 Specifications... -

Page 12: Single-Section Scoreboards

Single-Section Scoreboards Note 1: Signal wires must be a minimum of 22- gauge with shield. Daktronics recommends using W-1234. Note 2: 120/240 or two lines of 120 V AC from a 120/208 WYE service. Model Dimensions Weight Digit Size Wattage... - Page 13 Model Dimensions Weight Digit Size Wattage Power Amps per Line Driver Number (Height, Width, Uncrated and Matrix (See Note 2) (Single Phase) and Address Lamp Maximum Depth) (Crated) BA-718 H4’-0", W12’-0", D6" 160 lb Inning, Time, 25 W 2555 W 120 V AC 22 A (1219 mm, 3658 mm,...

- Page 14 Model Dimensions Weight Digit Size Wattage Power Amps per Line Driver Number (Height, Width, Uncrated and Matrix (See Note 2) (Single Phase) and Address Lamp Maximum Depth) (Crated) CT-2002 H2’-7", W7’-0", D11" 75 lb All digits 25 W 1500 W 120 V AC 15 A (610 mm, 2133 mm,...

- Page 15 Model Dimensions Weight Digit Size Wattage Power Amps per Line Driver Number (Height, Width, Uncrated and Matrix (See Note 2) (Single Phase) and Address Lamp Maximum Depth) (Crated) MS-2002 H4’-6", W16’-0", D6" 250 lb Clock, scores 25 W 4325 W 120/240 or 17 A (1372 mm, 4877 mm,...

- Page 16 Model Dimensions Weight Digit Size Wattage Power Amps per Line Driver Number (Height, Width, Uncrated and Matrix (Single Phase) and Address Lamp Maximum (See Note 2) Depth) (Crated) SO-918 H4’-0", W12’-0", D6" 225 lb 18" 3x5 25 W 2925 W 120/240 or 11 A (1219 mm, 3658 mm,...

-

Page 17: Volt Single-Section Scoreboards

230 Volt Single-Section Scoreboards Note 1: Signal wires must be a minimum of 22-gauge with shield. Daktronics recommends using W-1234. Model Dimensions Weight Digit Size Wattage Power Amps per Line Driver Number (Height, Width, Uncrated and Matrix (Single Phase) and Address... -

Page 19: Component Locations

Use the following drawings to determine the location of scoreboard components. The drawings are listed below in alphanumeric order by model number. In the Appendix, they are inserted in alphanumeric order by drawing number. Model Drawing Name Drawing No. BA-515 Component Locations, BA-515 A-126083 BA-518 Component Locations, BA-518 A-126084 BA-618 Component Locations, BA-618... -

Page 21: Schematics

Use the following table to determine the schematic for your scoreboard model. The drawings are listed below in alphanumeric order by model number. In the Appendix, they are and inserted in alphanumeric order by drawing number. Model Schematic Name Drawing No. BA-515 Schematic, 1 Driver 8 Column A-124298 BA-518 Schematic, 1 Driver 8 Column A-124298 BA-518, 230 V AC Schematic, 1 Driver 16 Col. -

Page 23: Mechanical Installation

Section 6: Mechanical Installation Mechanical installation consists of installing concrete footings and steel beams, and mounting the scoreboard and accompanying ad panels to the beams. Footings and Beams Reference Drawings: Installation Specifications; BA 515 ............Drawing A-55003 Installation Specifications; BA 518 ............Drawing A-55004 Installation Specifications;... -

Page 24: Lifting The Scoreboard

The columns and footings and all connection details must be designed and certified by a professional engineer licensed to practice in the state in which scoreboard will be installed. Daktronics does not assume any liability for any installation derived from the information and drawings provided in this manual or designed and installed by others. -

Page 25: Scoreboard Mounting

If you must use this method, ensure a minimum angle between the chain and scoreboard of at least 45°. Note: Daktronics assumes no liability for scoreboard damage resulting from incorrect setup or incorrect lifting methods. -

Page 26: Method 2

to the Installation Specifications drawing for your model to determine the center-to-center distance of the poles. Review the illustrations of the mounting hardware in Drawing A-44412, and then use the following procedure for each section. Loosely attach the inner and outer mounting clamps to the rear flanges of the scoreboard’s horizontal frame members, using the "... -

Page 27: Ad Panel Mounting

Models BA-515 and BA-518 Ad panels are mounted directly to the scoreboard for models BA-515 and BA-518. Refer to Drawings A-52585 and A-52811 for mounting details. -

Page 29: Electrical Installation

Refer to the chart in Section 3 to determine circuit specifications and maximum power requirements for the models described in this manual. Daktronics outdoor scoreboards have been designed for easy access to components, and the power and control signal hookup has been simplified. Front panels are removable to allow access to the digits, cabling and other electronic components. -

Page 30: Power Installation

Power Installation There are two basic considerations for power installation: installation with ground and neutral conductors provided, and installation with only a neutral conductor provided. These two power installations differ slightly, as described in the following paragraphs: Installation with Ground and Neutral Conductors Provided For this type of installation, the power cable must contain an isolated earth-ground conductor. -

Page 31: Power And Signal Connection

The scoreboard must be connected to earth ground. Proper grounding is necessary for reliable equipment operation. It also serves to provide protection to the equipment against damaging electrical disturbances and lightning. Failure to adhere to the following grounding methods will void the warranty. -

Page 33: Digit Maintenance And Troubleshooting

Section 8: Digit Maintenance and Troubleshooting IMPORTANT NOTES: 1. Disconnect power before doing any repair or maintenance work on the scoreboard! 2. Allow only qualified service personnel access to internal display electronics. 3. Disconnect power when not using the scoreboard. For assistance in the maintenance of the optional message center, refer to the manual that accompanies the message center or to Section 9 in this manual. -

Page 34: Lamp Replacement

Reference Drawing: Digit Service .................... Drawing A-27674 The primary service required for Daktronics baseball scoreboards is to periodically replace bad lamps. Refer to the table in Section 3 to determine the wattage of the lamps the scoreboard uses. Refer to Section 8.8 to determine the part numbers. -

Page 35: Fuses

Fuses Reference Drawings: Layout, 16 Column Driver III ..............Drawing A-123940 Layout, 8 Column Driver III ..............Drawing A-123941 The digit lamp driver has 17 fuses. There is one fuse to protect each digit circuit. F1 through F16 are located near each output connector under the driver’s metal cover. The lamp driver’s other fuse, F17 protects the driver’s logic circuit and fan. -

Page 36: Lightning Protection

Replacement Parts Refer to the following table for Daktronics outdoor scoreboard replacement parts. Refer to Section 9.14 for a listing of parts required for service of the team name message centers. Refer to Section 1.4 for details concerning the Daktronics Exchange and Repair and Return programs. -

Page 37: Troubleshooting

Daktronics Description Location Part No. 24" 4x7 shade screen 24" 4x7 digits 0S-1064-0002 15" 4x7 shade screen 15" 4x7 digits or 3x5 digits 0S-1064-0074 30" 4x7 shade screen 30" 4x7 digits 0S-1091-0002 *This part, X-1294, is intended for use with scoreboards shipped after October, 2001. Models shipped prior to that date will continue to use original equipment. -

Page 39: Team Name Message Centers Maintenance And Troubleshooting

Operating the display with dirty fan filters or without fan filters will void the warranty. 5. Daktronics product managers or engineering staff must approve any changes that may affect the weather-tightness of the display. This is to include, but is not limited to, border shrouding, back sheets, cooling fans, fan filter and filler panels. -

Page 40: Service Procedures

Service Procedures Reference Drawings: Lens Removal, Front Access..............Drawing A-99898 Lens Assy Removal, Front Access ............Drawing A-99899 Correct Lens Position, 1-1/2" ..............Drawing A-75204 Removing a Module For many maintenance or repair procedures, the first step is to remove a module. Each 8x16 lens assembly is secured to the frame by two spring-loaded latches, one on each side. -

Page 41: Replacing A Lampbank

A 3.58 W lamp is positioned behind each lens. Use the controller lamp test to locate bad lamps. Refer to Section 9.14 for the part numbers of replacement lamps and lenses. Daktronics-approved 3.58 W lamps have an estimated life of 17,000 hours if operated at 11.0 V. Always use Daktronics-approved lamps. -

Page 42: Individual Lamp Replacement

1. Remove the defective lamp using the lamp-extracting tool. 2. Replace defective lamps with Daktronics approved lamps of the same wattage. Refer to Section 9.14 for the correct replacement lamps. 3. Noting proper lens orientation, snap the lens back into the lens/reflector assembly (refer to Section 9.4). -

Page 43: Louver Maintenance

If a filter media shows evidence of damage or wear, replace the filter with a Daktronics filter. If a filter other than the Daktronics standard filter is used, follow these criteria (refer to Section 9.14 for the part number of the filter): 1. -

Page 44: Filter Removal

Once the filters have been replaced, turn power back on. Make sure that the fans are turning properly. Note: Turn the power OFF after checking the fans. Periodically check airflow through the lenses to ensure that there are no obstructions in the lens exhaust holes. -

Page 45: Lens Airflow

2. Spin the fan blades with a pen or pencil to ensure that the bearings are free and the fan is still in balance. After 10 percent of the fans have been replaced, Daktronics recommends replacing all fans to reduce associated maintenance costs that may incur with increased heat buildup from fan failure. -

Page 46: Structural Inspection

9.11 Structural Inspection Perform a visual inspection annually. Check the paint and look for possible corrosion, especially at footings, structural tie points, and ground rods. Fasteners should be checked and tightened or replaced as required. At least once a year, check the inside of the display for signs of water intrusion (for example, water stain marks). -

Page 47: Replacement Parts List

9.14 Replacement Parts List Refer to the following table for Daktronics scoreboard replacement parts. Refer to Section 8.8 for a listing of parts required for the service of the scoreboards. Refer to Section 1.4 for Daktronics Exchange and Repair and Return programs. -

Page 48: Tnmc Exchange And Repair And Return Programs

T-1107 Weatherstripping, pile HS-1149 Weatherstripping, tape HS-1051 Weatherstripping, open cell, filter assembly HS-1039 9.15 TNMC Exchange and Repair and Return Programs Refer to Section 1.4 for information concerning Daktronics Exchange and Repair and Return programs. 9-10 TNMC Maintenance and Troubleshooting... -

Page 49: Scoreboard Options

Section 10: Scoreboard Options The following options are available for Daktronics outdoor scoreboards to make the displays more adaptable to scoring and timing needs: Team name caption kits for certain models. Trumpet horn for football and soccer. Remote start/stop console. -

Page 50: Trumpet Horn

10.2 Trumpet Horn Reference Drawings: Horn Installation ..................Drawing A-44197 Final Assembly, 12V DC Horn Mounting..........Drawing A-83333 Schematic; Football Trumpet Horn ............Drawing A-83329 The trumpet horn options are available only with scoreboards that have clocks. The two types of trumpet horns are: Internally mounted AC trumpet horn. - Page 51 4. Attach the horn enclosure to the inside of the scoreboard over the " holes using #10 tapping screws. 5. Attach the plate assembly to the horn enclosure using the #10 hardware provided. 6. Remove the 2" knockout in the horn panel. 7.

-

Page 53: Appendix A: Reference Drawings

Caption Changing ..................Drawing A-44549 Digit Segments, 3x5 and 4x7 ................ Drawing A-46653 Ad Panel Mounting ................Drawing A-52187 Assembly, Ad Panel, BA-515 ................ Drawing A-52585 Ad Panel Mounting, BA-518................Drawing A-52811 Installation Specifications, BA 515..............Drawing A-55003 Installation Specifications, BA 518..............Drawing A-55004 Installation Specifications, BA 718.............. - Page 54 Component Locations, CT-2001 ..............Drawing A-126429 Component Locations, CT-2002 ..............Drawing A-126430 Component Locations, FB-824 ..............Drawing A-126431 Component Locations, MS-915 ..............Drawing A-126432 Component Locations, S0-918 ..............Drawing A-126433 Component Locations, TI-2003..............Drawing A-126434 Component Locations, MS-2002 w/TNMC ..........Drawing A-127193 Installation Specifications, MS-2002 ............

- Page 141 Appendix B: Eyebolts Eyebolts............................ ED-7244 Eyebolts...

- Page 143 Eyebolts Almost every display that leaves Daktronics is equipped with eyebolts for lifting the display. There are two standard sizes of eyebolts: ½″ and A″. Load Increase Factor: The load increases as the lift angle (θ) decreases. The allowable load on the eyebolts also decreases with the lift angle due the bending stress on the eyebolts.

- Page 144 F. Eyebolts should never be painted or otherwise coated when used for lifting. Such coatings may cover potential flaws in the eyebolt. G. To attain the safe working loads listed for regular eyebolts, 90% of the thread length must be engaged. Copyright 1996-2001 ED-7244 Daktronics, Inc. Rev. 4 – 14 March 2001...

Need help?

Do you have a question about the BA-515 and is the answer not in the manual?

Questions and answers