Advertisement

Quick Links

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for EP Equipment EPT20-20RA

- Page 2 We have the right to improve the truck, maybe there are some difference between your product and the description in this manual. If you have any questions please keep in touch with the sales department of E-P Equipment or let the dealer know. EP EQUIPMENT EQUIPMENT EQUIPMENT EQUIPMENT CO.,LTD.

- Page 3 WARNING WARNING! ! ! ! WARNING WARNING TO PREVENT PREVENT PREVENT PREVENT SETIOUS SETIOUS SETIOUS SETIOUS RISK RISK RISK RISK OF OF INJURY INJURY INJURY INJURY TO YOUORSELF OTHERS OBSERVE YOUORSELF YOUORSELF YOUORSELF AND AND OTHERS OTHERS OTHERS OBSERVE OBSERVE OBSERVE THE FOLLOWING FOLLOWING...

- Page 4 with good practice. Cylinders, valves and other similar parts shall be checked to assure that "drift" has not developed to the extent that it would create a hazard. 10. Truck shall be kept in a clean condition to minimize fire hazards facilitate detection of loose or detective parts.

-

Page 5: Table Of Contents

Catalog Catalog Catalog Catalog Correct Correct application application Correct Correct use use and and application application................... 1 1. 1. 1. 1. Truck Truck Truck Description Description Truck Description Description......................2 1.1Application......................2 1.2 Assemblies......................3 1.2.1Control Handle..................... 4 1.2.2Key switch....................4 1.2.3Battery discharge indicator................. - Page 6 5.1Operational safety and environmental protection..........22 5.2Maintenance Safety Regulations................22 5.3Servicing and inspection..................24 5.3.1Maintenance Checklist................25 5.3.2 Lubrication Schedule................27 5.3.3 Maintenance Instructions................. 28 5.4Decommissioning the industrial truck..............30 5.4.1Prior to decommissioning................30 5.4.2 Restoring the truck to operation after decommissioning.......31 5.5Safety checks to be performed at regular intervals and following any unusual incidents........................

-

Page 7: Application

Correct Correct application application Correct Correct use use and and application application The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are supplied with the truck. The guidelines form part of these operating instructions and must be observed. National regulations apply in full. The truck described in the present operator manual is an industrial truck designed for lifting and transporting load units. - Page 8 1. 1. 1. 1. Truck Truck Truck Truck Description Description Description Description 1.1Application 1.1Application 1.1Application 1.1Application The truck is a tiller operated electric pallet truck with a folding operator platform and side arms. The truck is designed for lifting and transporting goods on a level surface. The truck can pick up, outside the load wheel area, open bottom or diagonal board pallets as well as roll cages .

-

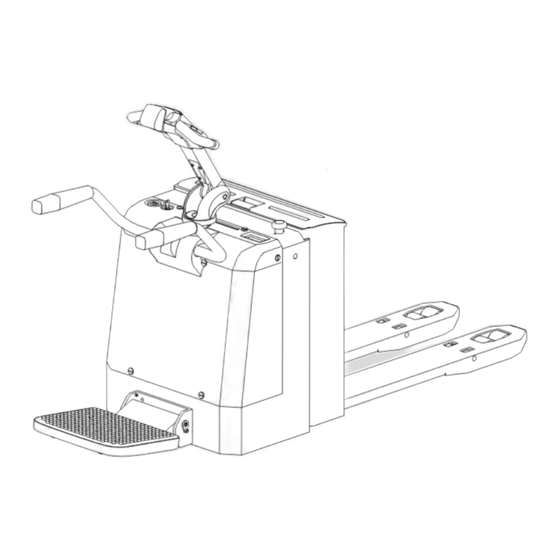

Page 9: Assemblies

1.2 Assemblies Assemblies Assemblies Assemblies Item Description Item Description Travel switch Caster wheel Tiller Drive wheel Key switch Pressure sensitive mat Battery discharge indicator Folding operator platform Emergency brake switch Ram protection Side arm... -

Page 10: Key Switch

1.2.1Control 1.2.1Control Handle Handle 1.2.1Control 1.2.1Control Handle Handle “Lower” button Lowers load forks. “Lift” button Raises load forks. Travel switch Controls the driving speed and direction Warning signal Triggers a warning signal. button Collision safety Safety function which, when activated, forces the truck to switch reverse until the switch restored to neutral. - Page 11 1.2.3 1.2.3 Battery Battery discharge discharge indicator indicator 1.2.3 1.2.3Battery Battery discharge discharge indicator indicator The LEDs (1) represent battery residual capacity, The LCD (2) displays the operating hours Battery Battery Battery Battery Discharge Discharge Discharge Discharge Indicator Indicator Indicator Indicator(1) When the truck has been released via the key switch, the battery charge...

- Page 12 1.3 Identification Identification Identification Identification points points points points and and data data data data plates plates plates plates Description Item Logo decal Decal hook-up caution Hook decal Plate data Decal operation warning AC power decal...

- Page 13 1.3.1 1.3.1 Truck Truck data data plate plate 1.3.1 1.3.1Truck Truck data data plate plate Item Description Item Description Manufacturer Fork length(mm) Model name (Recommendation) Battery capacity( Ah) Type Net weight w.o. battery(kg) Rated capacity(kg) Serial no. Fork width(mm) For queries regarding the truck or ordering spare parts always quote the truck serial number (9).

-

Page 14: Dimensions

1.4.1 1.4.1 Performance Performance data data standard standard trucks trucks 1.4.1 1.4.1Performance Performance data data for for standard standard trucks trucks Item Description parameter Unit Load capacity 2000 Load center laden km/h Travel speed unladen km/h 0.056 laden Lifting speed unladen 0.060 0.057... - Page 15 1.4.2Dimensions 1.4.2Dimensions 1.4.2Dimensions 1.4.2Dimensions Item Description parameter Unit Load distance (Raised/ Lowered) 916/ 982 937/ 1003 mm Wheelbase 1420 1440 Lift height Tread load side 370/ 515 Fork height lowered 1150 Height of tiller arm in operating position 1470 Overall length 1860 1930 Length to face of forks...

-

Page 17: Transport

2. 2. 2. 2.Transport Transport Commissioning Transport Transport and and Commissioning Commissioning Commissioning Transport 2.1Transport Transport Transport Lifting truck crane Lifting Lifting Lifting the the truck truck truck by by crane crane crane There are two way to pack the truck: one is use a stock, the other is use a box. - Page 18 2.3During 2.3During 2.3During 2.3During brake-in brake-in brake-in brake-in We recommended operating the machine under light load conditions for the first stage of operation to get the most from it. Especially the requirements given below should be observed while the machine is in a stage of 100 hours of operation. Please Must prevent the new battery from over discharging when early used.

- Page 19 3. 3. 3. 3.Operation Operation Operation Operation 3.1Safety 3.1Safety Regulations Regulations Operation Operation Operation of of of of Forklift Forklift Forklift Trucks Trucks 3.1Safety 3.1Safety Regulations Regulations for for the the Operation Forklift Trucks Trucks Driver Driver Driver Driver authori authori authori authoris s s s ation:...

-

Page 20: Preparing

3.2 Operate Operate Operate Operate and and run run the the truck truck truck truck 3.2.1 3.2.1 3.2.1 P P P P reparing reparing reparing 3.2.1 reparing Before the truck can be commissioned, operated or a load unit lifted, the driver must ensure that there is nobody within the hazardous area. - Page 21 travelling through swing doors etc. make sure that the doors do not activate the collision safety button (3). Steering Steering Steering Steering In narrow bends the driver extends beyond the geometry of the truck. – Move the tiller (5) to the left or right. Braking Braking Braking...

- Page 22 The truck can brake in three different ways: – by plugging – by using the operating brake – with the emergency brake swich (Emergency Disconnect) Plugging: Plugging: Plugging: Plugging: – When travelling, set the controller (8) to the opposite direction. The truck brakes regeneratively until it starts to move in the opposite direction.

- Page 23 ·Do not lift other people on the load handler. ·Insert the forks as far as possible underneath the load. Lift Lift Lift Lift Press “Lift” button(8) until the height you Warning! Warning! Warning! Warning! need. Don't lift to tiptop, to avoid shorted life of Lower Lower oil cylinder.

- Page 24 4.Battery Maintenance Maintenance & & & & Charging Charging 4.Battery 4.Battery 4.Battery Maintenance Maintenance Charging Charging Safety Safety regulations regulations handling handling acid acid batteries batteries 4.1 Safety Safety regulations regulations for for handling handling acid acid batteries batteries Park the truck securely before carrying out any work on the batteries. Maintenance Maintenance Maintenance...

-

Page 25: Parking The Truck Securely

4.3Charging 4.3Charging 4.3Charging 4.3Charging the the battery battery battery battery 4.3.1 4.3.1 Exposing Exposing battery battery 4.3.1 4.3.1Exposing Exposing the the battery battery Park the truck securely . – Drawing back the emergency brake switch (3). Lift up the battery panel (1) using the grip mould (2) and fold it back. - Page 26 4.4Battery 4.4Battery 4.4Battery 4.4Battery removal removal removal removal and and installation installation installation installation When transporting batteries using a crane ensure that the crane is of adequate capacity ( the battery weight indicated on the battery data plate on the battery container) .

- Page 27 Warning Warning! ! ! ! Warning Warning 1. Do not use dry cloth or fibre cloth to clean the battery,avoiding static to bring the explosion. 2. Unfixing battery plug. 3. Cleaning with wet cloth. 4. Wearing glasses for protecting eyes rubber overshoes and rubber glove. 4.6Battery Battery Battery...

- Page 28 5.Forklift Truck Maintenance 5.Forklift 5.Forklift 5.Forklift Truck Truck Truck Maintenance Maintenance Maintenance 5.1Operational 5.1Operational safety safety environmental environmental protection protection 5.1Operational 5.1Operational safety safety and and environmental environmental protection protection – The servicing and inspection operations contained in this chapter must be performed in accordance with the intervals indicated in the servicing checklists.

- Page 29 If the truck is to be cleaned with a water jet or a high-pressure cleaner, all electrical and electronic components must be carefully covered beforehand as moisture can cause malfunctions. Do not clean with pressurised water. After cleaning the truck, carry out the activities detailed in the “Recommissioning (on page 30)”...

- Page 30 5.3Servicing 5.3Servicing 5.3Servicing 5.3Servicing and and inspection inspection inspection inspection Thorough and expert servicing is one of the most important requirements for the safe operation of the industrial truck. Failure to perform regular servicing can lead to truck failure and poses a potential hazard to personnel and equipment. The service intervals stated are based on single shift operation under normal operating conditions.

- Page 31 5.3.1Maintenance 5.3.1Maintenance Checklist Checklist 5.3.1Maintenance 5.3.1Maintenance Checklist Checklist 保养间隔 Standard = ★ Cold Store = ☆ ★ Brake Check magnetic brake air gap. ★ Electrics Test instruments, displays and control switches. ☆ ★ Test warning and safety device. ★ Check fuse ratings. ★...

- Page 32 ★ Truck Test the operator’s platform and check for design damage. ★ Check chassis for damage and screw connections. ★ Check labels. ★ Hydraulic Check operation, wear and setting. operation ★ Check forks for wear and damage. ☆ ★ Test hydraulic system. ☆...

- Page 33 5.3.2 5.3.2 Lubrication Lubrication Schedule Schedule 5.3.2 5.3.2 Lubrication Lubrication Schedule Schedule...

- Page 34 Fuels, Fuels, Fuels, Fuels, coolants coolants coolants coolants and and lubricants lubricants lubricants lubricants Handling Handling consumables: consumables: Handling Handling consumables: consumables: Consumables must always be handled correctly. Follow the manufacturer’s instructions. Improper handling is hazardous to health, life and the environment. Consumables must only be stored in appropriate containers.

- Page 35 Removing Removing Removing Removing the the front front front front panel panel panel panel Trucks with folding operator platform: – Fold down the operator platform (4). – Unlock the panel latches (2). – Lift off the panel (3) and place it next to the truck.

- Page 36 Checking Checking electrical electrical fuses fuses Checking Checking electrical electrical fuses fuses – Prepare the truck for maintenance and repairs (See 5.3.3 Maintenance Instructions Page28 ). – Dismantle the front panel. – Check rating of all fuses in accordance with table, replace if necessary. Item To protect: Rating...

- Page 37 –Lubricate the truck in accordance with the maintenance schedule (See 5.3.2 Warning Warning Warning Warning! Lubrication Schedule P27 ). Charge every months: – Charge the battery (See 4.3Charging – Charge the battery. the battery P19). Battery powered trucks: – Disconnect the battery, clean it and The battery must be charged at apply grease to the terminals.

- Page 38 A thorough test of the truck must be undertaken with regard to its technical condition from a safety aspect. The truck must also be examined for damage caused by possible improper use. A test report shall be provided. The test results must be kept for at least the next 2 inspections.

-

Page 39: Charging The Battery

6.Troubleshooting 6.Troubleshooting 6.Troubleshooting 6.Troubleshooting This chapter is designed to help the user identify and rectify basic faults or the results of incorrect operation. When locating a fault, proceed in the order shown in the table. Fault Possible cause Action Truck does –...

Need help?

Do you have a question about the EPT20-20RA and is the answer not in the manual?

Questions and answers