Table of Contents

Advertisement

Installation and

Operating Instructions

STERIFLO

for

Water Treatment System

Models SF1000S mkII & SF2500S mkII

Maximum operating pressure for stainless steel UV chambers is 850kPa (125

psi). If this pressure can be exceeded or if operating close to this pressure

fit a suitable pressure limiting valve in the supply to the UV chamber.

Plastic UV chambers have a maximum operating pressure of 400kPa (60 psi).

WARNING: The UV Chamber operates under pressure. Under no

circumstances should the UV Chamber be disassembled unless the internal

pressure of the unit has been relieved. Failure to observe this warning will

expose persons to the possibility of personal injury and may result in

damage to the UV system or other property.

Ultra violet radiation is harmful to skin & eyes.

DO NOT LOOK AT UV LAMP WHILE LAMP IS OPERATING.

DO NOT DISASSEMBLE ANY COMPONENTS UNTIL YOU HAVE FULLY READ

THESE INSTRUCTIONS!

This unit is designed to treat water at ambient temperatures (5

Contact your dealer for details of UV systems suitable for hot water service.

Please pass these instructions onto the operator

Ultra Violet

of this equipment.

Distributed in Australia by Davey Water Products Pty Ltd.

®

o

C to 45

o

C).

Advertisement

Table of Contents

Summary of Contents for Davey STERIFLO SF1000S mkII

-

Page 1: Operating Instructions

This unit is designed to treat water at ambient temperatures (5 C to 45 Contact your dealer for details of UV systems suitable for hot water service. Please pass these instructions onto the operator of this equipment. Distributed in Australia by Davey Water Products Pty Ltd. -

Page 2: Table Of Contents

Table of Contents Introduction Page 3 Preparing your system Page 3 Choosing a Site Page 4 ® Housing your Steriflo System Page 4 Power Connection Page 5 Electrical Power Surge Protection Page 5 - 6 Pipe Connections Page 6 Pre-treatment (drinking water) Page 6 Lamp Installation Page 7... -

Page 3: Introduction

® Congratulations on your purchase of a high quality, New Zealand made Steriflo Ultra Violet water treatment system. All components have been designed and manufactured to give trouble free, reliable operation. Your new Steriflo ® system incorporates a lamp failure system design feature that enables you to be warned of a lamp failure by :- 1. -

Page 4: Choosing A Site

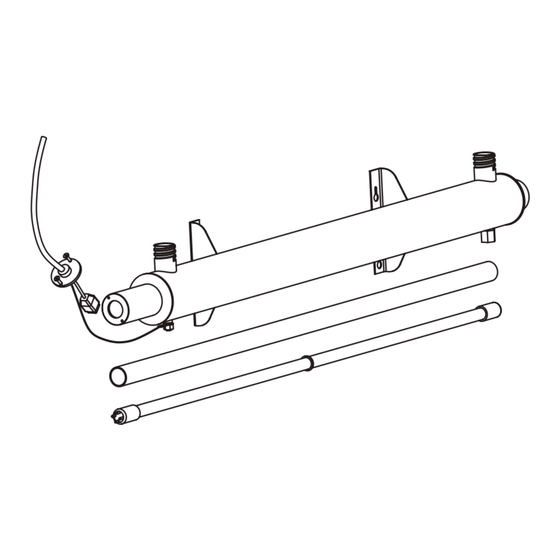

Choosing a Site Choose a site with a firm mounting position. Allow room for removal of the lamp and sleeve during servicing. Leave a chamber lengths space at the lamp connector end for lamp removal, with 100mm free at the other end for access to the end nut. -

Page 5: Power Connection

Power Connection WARNING: When servicing or attending your Steriflo ® , always ensure power is switched off and lead unplugged. Electrical connections should be serviced only by qualified persons. If the electrical supply lead of this system is damaged, it must only be replaced by a qualified service personnel. -

Page 6: Electrical Power Surge Protection

Electrical Power Surge Protection An electrical power surge or spike can travel on the supply lines and cause serious damage to your electrical equipment. The Steriflo ® control box has a 2 Amp fuse to protect the circuit. The fuse is not a lightning arrestor and may not protect the Steriflo ®... -

Page 7: Pre-Treatment (Drinking Water)

If added as a shot dose it should be rinsed out through a nearby tap. Davey Water Products Limited can not accept responsibility for loss or damage resulting from incorrect or unauthorised installations. -

Page 8: Maintenance

Maintenance Lamp changing (every year of operation) : 1. Shut valve(s) so that water cannot flow through steriliser. 2. Switch off steriliser by unplugging mains. 3. Undo end cover screws. 4. Unplug lamp connector. 5. Remove lamp. Reverse procedure when replacing lamp, ensuring that lamp is centrally located in the chamber. -

Page 9: Water Quality

Maintenance continued... Reverse procedure when replacing sleeve. When replacing quartz sleeve after cleaning, the sleeve should stick out about 1cm at each end. Place o-ring over closed nut end and fit closed nut, fastening it hand tight. Hold the other end of the sleeve in position during the tightening with the other hand, then fit open end o-ring and cap. -

Page 10: Part Numbers

Trouble Shooting continued... c) UV LAMP OUT, ALARM ON 1. Lamp failed. 2. Poor connection to lamp (check/clean connector/lamp pins). 3. Ballast failed (unlikely). d) LAMP ON, ALARM ON 1. Faulty circuit board. e) LAMP OUT, ALARM OFF 1. Loose connection or faulty circuit board, possibly short in lamp circuit. WARNING: When servicing or attending your Steriflo ®... -

Page 11: Warning - Uv Radiation

For assistance in locating your nearest dealer, contact Davey Water Products Limited in New Zealand on 0800 654 333, by fax on 0800 654 334 or by email to sales@daveywaterproducts.co.nz, or in Australia contact Davey Water Products Pty Ltd, customer service centre on 1300 367 866 or visit davey.com.au. - Page 12 & Consumer Protection Legislation of the various Australian states, or the Consumers Guarantee Act 1993 (NZ), Davey shall not be liable for any loss of profits or any consequential, indirect or special loss, damage or injury of any kind whatsoever arising directly or indirectly from the product or any defect.

Need help?

Do you have a question about the STERIFLO SF1000S mkII and is the answer not in the manual?

Questions and answers