Summary of Contents for Optimum OPTIturn TX 6222

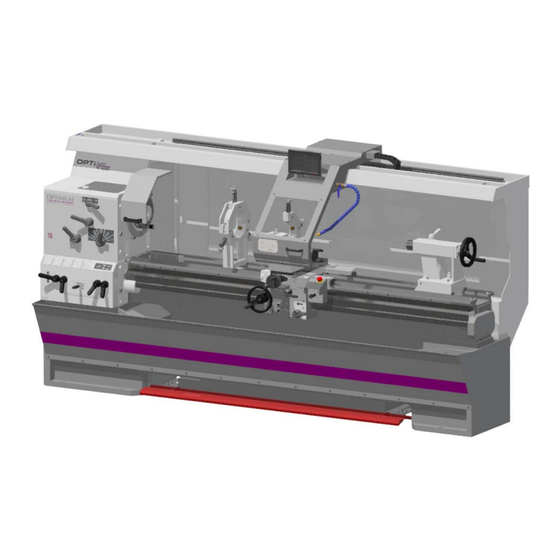

- Page 1 OPTIMUM ® M A S C H I N E N - G E R M A N Y Operating Manual Version 1.0.1 Lathe Part no. 3432460...

-

Page 2: Table Of Contents

OPTIMUM ® M A S C H I N E N - G E R M A N Y Table of contents Safety Type plate ..............................7 Safety instructions (warning notes)....................... 8 1.2.1 Classification of hazards ......................... 8 1.2.2 Other pictograms ..........................8 Intended use .............................. - Page 3 OPTIMUM ® M A S C H I N E N - G E R M A N Y 3.4.1 Forklift ............................24 3.4.2 Crane .............................25 Installation conditions ..........................26 3.5.1 Foundation and floor ........................26 3.5.2 Local requirements for delivery ......................26 3.5.3...

- Page 4 OPTIMUM ® M A S C H I N E N - G E R M A N Y 4.19.2 Turning short tapers with the top slide ..................47 4.19.3 Turning of cones with high precision ..................... 48 4.20 Displacing the top slide on the cross slide....................51 4.21...

- Page 5 OPTIMUM ® M A S C H I N E N - G E R M A N Y 7.15 Drehfutterschutz - Lathe chuck protection....................106 7.16 Mitlaufende Lünette - Follow rest ......................107 7.17 Feststehende Lünette - Steady rest ......................108 7.18...

- Page 6 Dear customer, Thank you very much for purchasing a product made by OPTIMUM. OPTIMUM metal working machines offer a maximum of quality, technically optimum solutions and convince by an outstanding price performance ratio. Continuous enhancements and prod- uct innovations guarantee state-of-the-art products and safety at any time.

-

Page 7: Safety

The serial number is located on the type plate. INFORMATION If you are unable to rectify an issue using these operating instructions, please contact us for advice: Optimum Maschinen Germany GmbH Dr. Robert-Pfleger-Str. 26 D-96103 Hallstadt, Germany Email: info@optimum-maschinen.de... -

Page 8: Safety Instructions (Warning Notes)

OPTIMUM ® M A S C H I N E N - G E R M A N Y Safety instructions (warning notes) 1.2.1 Classification of hazards We classify the safety warnings into different categories. The table below gives an overview of the classification of symbols (ideogram) and the warning signs for each specific danger and its (possible) consequences. -

Page 9: Intended Use

"Technical specification“ on page 20 In order to achieve optimum cutting performance, it is essential to choose the right turning tool, feed, tool pressure, cutting speed and coolant. WARNING! Extremely severe injuries due to non-intended use. -

Page 10: Reasonably Foreseeable Misuses

OPTIMUM ® M A S C H I N E N - G E R M A N Y It is forbidden to make any modifications or alternations to the operation values of the lathe. They could endanger the personnel and cause damage to the lathe. -

Page 11: Qualification Of Personnel

OPTIMUM ® M A S C H I N E N - G E R M A N Y INFORMATION Everyone involved in the assembly, commissioning, operation and maintenance must be duly qualified, and strictly follow these operating instructions. -

Page 12: Authorized Persons

OPTIMUM ® M A S C H I N E N - G E R M A N Y Qualified personnel Due to their professional training, knowledge and experience as well as knowledge of relevant regulations, qualified personnel are able to perform the assigned tasks and to independently recognise and avoid any possible dangers. -

Page 13: Operator Positions

OPTIMUM ® M A S C H I N E N - G E R M A N Y Operator positions The operator position is in front of the lathe. Safety measures during operation CAUTION! Danger due to inhaling dust and mist that are hazardous to health. -

Page 14: Safety Devices

OPTIMUM ® M A S C H I N E N - G E R M A N Y Safety devices Use the lathe only with properly functioning safety devices. Stop the lathe immediately if there is a failure on the safety device or if it is not functioning for any reason. -

Page 15: Protective Cover Of The Headstock

OPTIMUM ® M A S C H I N E N - G E R M A N Y Turn the knob to the right to unlock and release the emergency stop button. CAUTION! Only press the emergency-stop button in a genuine emergency. Do not use the emergency stop button to stop the machine during normal operation. - Page 16 OPTIMUM ® M A S C H I N E N - G E R M A N Y Check that prohibition, warning and information signs and the labels on the lathe are legible (clean them, if necessary) are complete.

-

Page 17: Personal Protective Equipment

OPTIMUM ® M A S C H I N E N - G E R M A N Y 1.11 Personal protective equipment For certain work personal protective equipment is required. Protect your face and your eyes: Wear a safety helmet with facial protection when performing work where your face and eyes are exposed to hazards. -

Page 18: Safety During Maintenance

Check that they are working properly! 1.14 Accident report Inform your supervisors and Optimum Maschinen Germany GmbH immediately in the event of accidents, possible sources of danger and any actions which almost led to an accident (near misses). There are many possible causes for "near misses". -

Page 19: Electronics

OPTIMUM ® M A S C H I N E N - G E R M A N Y INFORMATION We provide information about the dangers of working with and on the lathe in these work descriptions. 1.15 Electronics Have the machine and/or the electric equipment checked regularly. Immediately eliminate all defects such as loose connections, defective wires, etc. -

Page 20: Technical Specification

OPTIMUM ® M A S C H I N E N - G E R M A N Y Technical specification The following information represents the dimensions and indications of weight and the manu- facturer‘s approved machine data. Electrical connection... -

Page 21: Slides

OPTIMUM ® M A S C H I N E N - G E R M A N Y Slides Travel lathe saddle [mm] 2120 Travel cross slide [mm] Travel top slide [mm] Offset length top slide mounting Tailstock Quill diameter [mm]... -

Page 22: Spindle Seat

OPTIMUM ® M A S C H I N E N - G E R M A N Y 2.14 Spindle seat DIN ISO 702-2 No. 8 (Camlock) 2.15 Emissions The airborne noise of the lathe is 75 to 80 dB (A) at the operator position and operating condi-... -

Page 23: Delivery, Interdepartmental Transport, Unpacking

OPTIMUM ® M A S C H I N E N - G E R M A N Y Delivery, interdepartmental transport, unpacking INFORMATION The machine is pre assembled. It is delivered in a transport box. After the unpacking and the transportation to the installation site it is necessary to mount and assemble the individual com- ponents of the machine. -

Page 24: Unpacking

OPTIMUM ® M A S C H I N E N - G E R M A N Y The machine can be lifted underneath the machine substructure using a forklift truck. Unpacking Install the machine close to its final position before unpacking. If the packaging shows signs of having possibly been damaged during transport, take the appropriate precautions to prevent the machine being damaged when unpacking. -

Page 25: Crane

OPTIMUM ® M A S C H I N E N - G E R M A N Y 1360 Center of Gravity 3.4.2 Crane The machine is lifted with slings. The bedslide and the tailstock must be driven to the end of the machine bed in order to achieve a balanced load. -

Page 26: Installation Conditions

OPTIMUM ® M A S C H I N E N - G E R M A N Y Installation conditions In order to achieve sufficient safety against falls by slipping, the accessible area in the mechani- cal machining zone of the machine must be equipped with a slip resistance. The slip resistant mat and/or the slip resistant floor must be at least R11 according to BGR 181. -

Page 27: Installation Plan

OPTIMUM ® M A S C H I N E N - G E R M A N Y 3.5.3 Installation plan 1739 Main switch 2585 Coolant tank moved out 3605 Electrical connection Img. 3-3: Assembly and installation, initial operation WARNING! The machine may only be commissioned after proper installation. -

Page 28: Vibration-Free Assembly

OPTIMUM ® M A S C H I N E N - G E R M A N Y 3.6.2 Vibration-free assembly Optional vibration dampers Attaching of 6 pieces SE2 vibration dampers on levelling points between the foundation and machine foot. -

Page 29: Anchored Assembly

OPTIMUM ® M A S C H I N E N - G E R M A N Y 3.6.3 Anchored assembly On a light foundation, square holes with side length of approximately 200mm and 250mm depth are made . -

Page 30: Aligning The Machine

OPTIMUM ® M A S C H I N E N - G E R M A N Y 3.6.4 Aligning the machine Once the bases are in place proceed to level according to the following description: Fit precision spirit levels on the cross slide. -

Page 31: Cleaning The Machine

This process is not reversible, i.e. the binder cannot be etched again and again. The company Optimum Maschinen Germany GmbH does not assume any guarantee for sub- sequent damages due to unsuitable cooling lubricants. Delivery, interdepartmental transport, unpacking TX6222 Version 1.0.1 dated 2017-11-16... -

Page 32: Electrical Connection

OPTIMUM ® M A S C H I N E N - G E R M A N Y Electrical connection WARNING! The three-phase electrical connection may only be performed by an electrician or under the guidance and supervision of an electrician. -

Page 33: Operation

OPTIMUM ® M A S C H I N E N - G E R M A N Y Operation Control and indicating elements Pos. Designation Pos. Designation Speed selector switch Change wheel and feed table Lathe chuck protection Selector switch feed gear mechanism... -

Page 34: Safety

OPTIMUM ® M A S C H I N E N - G E R M A N Y Safety Commission the lathe only under the following conditions: The lathe is in proper working order. The lathe is used as prescribed. -

Page 35: Speed Setting

OPTIMUM ® M A S C H I N E N - G E R M A N Y Speed setting ATTENTION! Only change speeds (gear settings) when the machine is at a stop. 4.8.1 Rotational direction The rotational direction lever (1) activates the lathe. The lathe can only be switched on, when the lathe chuck protection is closed. -

Page 36: Cross Feed Selection

OPTIMUM ® M A S C H I N E N - G E R M A N Y Position the control handles as shown on the chart. Example: Feed 0.1mm / spindle revolution = 1/1 - B - 1 - M - Set the feed lever on headstock to 1/1 ... -

Page 37: Fasten Workpiece Holder

OPTIMUM ® M A S C H I N E N - G E R M A N Y INFORMATION Mark each workpiece holder for instance by a nick in order to facilitate the recover of the precision of the concentric run and the axial run-out deviation. -

Page 38: Speed Information, Maintenance Recommendations

OPTIMUM ® M A S C H I N E N - G E R M A N Y Spare chucks must be designed for the maximum rotational speed of the machine, the permis- siblechuck speed must be marked on the chuck. The minimum distance to the machine bed must not be less than 25 mm. -

Page 39: Maintenance Of Chucks

OPTIMUM ® M A S C H I N E N - G E R M A N Y The permissible speeds can be determined in accordance with VDI Guideline 3106 "Determin- ing the permissible speed for lathe chucks (jaw chucks). This guideline also allows for the resid- ual tensioning force at a specified speed to be determined. -

Page 40: Clamping Long Workpieces

OPTIMUM ® M A S C H I N E N - G E R M A N Y Clamping diameter too Larger large. lathe necessary. Support over center, enlarged jaw. Workpiece is too heavy Enlarged jaws are not and clamping jaw is too available for this three-jaw short. - Page 41 OPTIMUM ® M A S C H I N E N - G E R M A N Y Workpieces that require a high concentricity precision are machined between the centres. For holding purposes, a centre hole is drilled into both plain machined faces of the workpiece.

-

Page 42: Mounting Workpiece Holder

OPTIMUM ® M A S C H I N E N - G E R M A N Y 4.13 Mounting workpiece holder DANGER! Please observe the maximum permissible rotational speed of chucks and face plates with individually tensionable jaws. -

Page 43: Bed Insert

OPTIMUM ® M A S C H I N E N - G E R M A N Y Follow rest 4.15 Bed insert Remove the bed insert if the diameter of the workpiece turned is larger. By removing the bed insert, the rotational diameter can be increased. -

Page 44: Face Turning And Recessing

OPTIMUM ® M A S C H I N E N - G E R M A N Y 4.16.2 Face turning and recessing In the facing operation, the tool feeds per- pendicular to the axis of rotation of the workpiece. -

Page 45: Straight Turning

OPTIMUM ® M A S C H I N E N - G E R M A N Y PREVENTIVE MEASURES! Switch off the automatic feed of the lathe saddle about 4 or 5 mm before the turret stop. 4.18.1 Straight turning ... -

Page 46: Face Turning

OPTIMUM ® M A S C H I N E N - G E R M A N Y Set the cross-feed / longitudinal feed (feed rod) (5) movement control handle on the apron to the up position. The engaging lever for thread-cutting (lead screw, apron nut open) must be set to the neutral position. -

Page 47: Turning Tapers

OPTIMUM ® M A S C H I N E N - G E R M A N Y 4.19 Turning tapers 4.19.1 Cross-adjustment of the tailstock The cross-adjustment of the tailstock is used for turning long, thin bodies. ... -

Page 48: Turning Of Cones With High Precision

OPTIMUM ® M A S C H I N E N - G E R M A N Y 4.19.3 Turning of cones with high precision D = large diameter [mm] d = small diameter [mm] α 2 ⁄ L = cone length [mm] Lw = workpiece length [mm] α... - Page 49 OPTIMUM ® M A S C H I N E N - G E R M A N Y The infeed is performed with the handwheel of the top slide. The depth of cut is advanced with the handwheel of the cross slide.

- Page 50 OPTIMUM ® M A S C H I N E N - G E R M A N Y The calculated value "Vr" is the offset measure of the tailstock. The offset is monitored with the gauge (also the return travel).

-

Page 51: Displacing The Top Slide On The Cross Slide

OPTIMUM ® M A S C H I N E N - G E R M A N Y 4.20 Displacing the top slide on the cross slide Loosen the four clamping screw at the top slide. Twist the top slide to the left and right until the four clamping screws are visible. -

Page 52: Thread Cutting

OPTIMUM ® M A S C H I N E N - G E R M A N Y 4.22 Thread cutting 4.22.1 Module and D.P. threads INFORMATION In countries where the Anglo-American system of measurement is used, its inverse is used as a "diametrical pitch"... -

Page 53: Feed And Thread Cutting Table

OPTIMUM ® M A S C H I N E N - G E R M A N Y 4.22.3 Feed and thread cutting table Metric threads Inch threads Cross feed / Longitudinal feed D.P. thread Module thread CAUTION! The acceptable maximum feed speed for thread cutting is 0.5 meters per minute. Thread cutting is always done using the lowest speed adjustment. -

Page 54: Multiple-Layered Threads

OPTIMUM ® M A S C H I N E N - G E R M A N Y The tool is withdrawn with the lead screw nut engaged and the thread cut- ting tool disengaged by actuating the Thread undercut "Direction of rotation control lever". - Page 55 OPTIMUM ® M A S C H I N E N - G E R M A N Y ISO-trapezoid Tr 40 x 7 thread Tr 40 x 14 P7 (one- and multi- ple- threaded) Bolt Round thread RD DIN 405 Bolt 1“...

-

Page 56: Metric Threads (60° Flank Angle)

OPTIMUM ® M A S C H I N E N - G E R M A N Y 4.22.6 Metric threads (60° flank angle) pitch P depth of thread of the bolt h2=0.6134 x P depth of thread of the nut H1 = 0.5413 x P rounding r = 0.1443 x P... - Page 57 OPTIMUM ® M A S C H I N E N - G E R M A N Y M 30 27.727 25.706 26.211 2.147 1.894 0.505 26.5 M 36 33.402 31.093 31.670 2.454 2.165 0.577 M 42 39.077 36.479 37.129...

-

Page 58: British Thread (55° Flank Angle)

OPTIMUM ® M A S C H I N E N - G E R M A N Y 4.22.7 British thread (55° flank angle) BSW (Ww.): British Standard Withworth Coarse Thread Series is the most common coarse thread in Great Britain and corresponds in its usage category to the metric coarse-pitch thread. -

Page 59: Indexable Inserts

OPTIMUM ® M A S C H I N E N - G E R M A N Y 22.226 30.20 15/16 23.813 1" 25.401 33.25 1 1/8 28.576 1 1/4 31.751 41.91 1 3/8 34.926 1 1/2 38.101 47.80 1 5/8 41.277... -

Page 60: Cooling Lubricants

OPTIMUM ® M A S C H I N E N - G E R M A N Y As for thread cutting there are other conditions as for longitudinal turning, the forward cutter must show a larger clearance as the pitch angle of the thread. -

Page 61: Cooling Lubricants

Consider this fact when selecting your cool- ing lubricant. The company Optimum Maschinen Germany GmbH does not assume any guarantee for sub- sequent damages due to unsuitable cooling lubricants. The flashpoint of the emulsion must be higher than 140°C. - Page 62 OPTIMUM ® M A S C H I N E N - G E R M A N Y TX6222 Operation Page 62 Translation of the original instructions Version 1.0.1 dated 2017-11-16...

-

Page 63: Cutting Speeds

OPTIMUM ® M A S C H I N E N - G E R M A N Y Cutting speeds Selecting the cutting speed The variety of factors makes it impossible to present universal indications about the "correct“ cutting speed. -

Page 64: Table Cutting Speeds

Table cutting speeds Reference values for cutting speeds in m/min when turning high speed steel and hard metal. (Excerpt from VDF 8799, Gebr. Boehringer GmbH, Göppingen) Tensile Infeed f in mm/rev. and setting angle k strength 0.063 0.16 0.25 0.63 Material Cutting material High-speed steel... -

Page 65: Dp700 Quick Start Guide

OPTIMUM M A S C H I N E N - G E R M A N Y DP700 Quick start guide For the complete manual please download from: http://newall.com , Click technical Support to access the download page. Warnings The mains supply is connected into a switch mode power supply (separate from your DP700) via a detachable supply cord supplied. - Page 66 OPTIMUM M A S C H I N E N - G E R M A N Y Understanding the Keypad Message Axis 1 Display Axis 2 Axis 3 Power Digifind / Reference Axis Selection Key Switches between Zero and Axis Preset modes...

- Page 67 OPTIMUM M A S C H I N E N - G E R M A N Y Setting up the Unit How to enter setup F U N C S s e t u p display shows Until display shows...

-

Page 68: Maintenance

OPTIMUM ® M A S C H I N E N - G E R M A N Y Maintenance In this chapter you will find important information about Inspection Maintenance Repair of the lathe. ATTENTION! Properly performed regular maintenance is an essential prerequisite for ... -

Page 69: Restarting

OPTIMUM ® M A S C H I N E N - G E R M A N Y 6.1.2 Restarting Before restarting, run a safety check. "Safety check“ on page 15 WARNING! Before starting the lathe, you must check that there is no danger for persons and that the lathe is not damaged. - Page 70 OPTIMUM ® M A S C H I N E N - G E R M A N Y Check Interval Where? What? How? Clean the interior of the lathe and the chip sump. Use a tenterhook to pull out long cips.

- Page 71 OPTIMUM ® M A S C H I N E N - G E R M A N Y Check Interval Where? What? How? Check for liquid level, concentration, pH value, bac- teria and fungal decay. Status con- trol ...

- Page 72 OPTIMUM ® M A S C H I N E N - G E R M A N Y Check Interval Where? What? How? For oil change use an appropriate collecting con- tainer with sufficient capacity. Unscrew the screw from the drain hole.

-

Page 73: Recommended Wearing Parts

OPTIMUM ® M A S C H I N E N - G E R M A N Y Check Interval Where? What? How? "Inspection plan for water-mixed cooling lubricants“ on page 81 Replacing Cleaning Disinfect If the tailstock clamping wears off. Shorten the clamping distance by adjusting the nut below the tailstock. -

Page 74: Maintenance

This process is not reversible, i.e. the binder cannot be etched again and again. The company Optimum Maschinen Germany GmbH does not assume any guarantee for sub- sequent damages due to unsuitable cooling lubricants. 6.4.3 Replacement of the shear pin on the feed rod A shear pin protects the feed gear at the output shaft to the feed rod. -

Page 75: Adjusting The Spindle Nut On The Top Slide

OPTIMUM ® M A S C H I N E N - G E R M A N Y Drive out the shear pin using a pin punch. Insert a new shear pin. Shear pin electric magnetic clutch Img. -

Page 76: Adjusting The Spindle Nut On The Cross Slide

OPTIMUM ® M A S C H I N E N - G E R M A N Y 6.4.5 Adjusting the spindle nut on the cross slide The cross spindle nut consists of two parts. Slightly loosen both hexagon sockets in the centre of the cross slide. -

Page 77: Feed Rod, Lead Screw

OPTIMUM ® M A S C H I N E N - G E R M A N Y 6.4.9 Feed rod, Lead screw The feed rod and lead screw is guided on the tailstock side by plane bearings in the radial direction. -

Page 78: Aligning The Headstock

OPTIMUM ® M A S C H I N E N - G E R M A N Y We recommend that the electrical cabinet is cleaned every 1000 operating hours . 6.4.12 Aligning the headstock ATTENTION! First check that the machine is level before you align the headstock. -

Page 79: Repair

If the repairs are carried out by qualified technical personnel, they must follow the indications given in these operating instructions. Optimum Maschinen Germany GmbH accepts no liability nor does it guarantee against damage and operating malfunctions resulting from failure to observe these operating instructions. -

Page 80: Cooling Lubricants And Tanks

OPTIMUM ® M A S C H I N E N - G E R M A N Y Cooling lubricants and tanks CAUTION! The cooling lubricant can cause diseases. Avoid direct contact with cooling lubricant or parts covered in cooling lubricant. -

Page 81: Inspection Plan For Water-Mixed Cooling Lubricants

OPTIMUM ® M A S C H I N E N - G E R M A N Y 6.6.1 Inspection plan for water-mixed cooling lubricants Company: No.: Date: used cooling lubricant size to be checked Inspection methods Inspection Procedure and comment... -

Page 82: Ersatzteile - Spare Parts

OPTIMUM ® M A S C H I N E N - G E R M A N Y Ersatzteile - Spare parts Ersatzteilbestellung - Ordering spare parts Bitte geben Sie folgendes an - Please indicate the following : Seriennummer - Serial No. -

Page 83: Spindelgetriebe - Headstock

OPTIMUM ® M A S C H I N E N - G E R M A N Y Spindelgetriebe - Headstock Ersatzteile - Spare parts TX6222 DE | EN Version 1.0.1 2017-11-16 Originalbetriebsanleitung... - Page 84 OPTIMUM ® M A S C H I N E N - G E R M A N Y Spindelgetriebe - Headstock DE | EN TX6222 Ersatzteile - Spare parts Originalbetriebsanleitung Version 1.0.1 2017-11-16...

- Page 85 OPTIMUM ® M A S C H I N E N - G E R M A N Y Spindelgetriebe - Headstock Ersatzteile - Spare parts TX6222 DE | EN Version 1.0.1 2017-11-16 Originalbetriebsanleitung...

- Page 86 OPTIMUM ® M A S C H I N E N - G E R M A N Y Spindelgetriebe - Headstock DE | EN TX6222 Ersatzteile - Spare parts Originalbetriebsanleitung Version 1.0.1 2017-11-16...

- Page 87 OPTIMUM ® M A S C H I N E N - G E R M A N Y Ersatzteilliste Spindelgetriebe - Spare parts list headstock Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. Gehäuse Housing 03432460101 Spindel Spindle...

- Page 88 OPTIMUM ® M A S C H I N E N - G E R M A N Y Ersatzteilliste Spindelgetriebe - Spare parts list headstock Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. Scheibe Washer 03432460178 Zahnrad Gear...

- Page 89 OPTIMUM ® M A S C H I N E N - G E R M A N Y Ersatzteilliste Spindelgetriebe - Spare parts list headstock Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. Innensechskantschraube Socket head screw ISO 4762 - M8 x 12...

-

Page 90: Vorschubgetriebe - Feed Gear

OPTIMUM ® M A S C H I N E N - G E R M A N Y Vorschubgetriebe - Feed gear 105 108 DE | EN TX6222 Ersatzteile - Spare parts Originalbetriebsanleitung Version 1.0.1 2017-11-16... -

Page 91: Vorschubgetriebe - Feed Gear

OPTIMUM ® M A S C H I N E N - G E R M A N Y Vorschubgetriebe - Feed gear Ersatzteile - Spare parts TX6222 DE | EN Version 1.0.1 2017-11-16 Originalbetriebsanleitung... - Page 92 OPTIMUM ® M A S C H I N E N - G E R M A N Y Ersatzteilliste Vorschubgetriebe - Spare parts list feed gear Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. Welle Shaft 03432460301 Zahnrad...

- Page 93 OPTIMUM ® M A S C H I N E N - G E R M A N Y Ersatzteilliste Vorschubgetriebe - Spare parts list feed gear Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. Zahnrad Gear 03432460387 Flansch...

-

Page 94: Schlosskasten - Apron

OPTIMUM ® M A S C H I N E N - G E R M A N Y Schlosskasten - Apron DE | EN TX6222 Ersatzteile - Spare parts Originalbetriebsanleitung Version 1.0.1 2017-11-16... - Page 95 OPTIMUM ® M A S C H I N E N - G E R M A N Y Ersatzteilliste Schlosskasten - Spare parts list apron Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. Gehäuse Housing 03432460401 Schlossmutter Clasp nut...

-

Page 96: Planschlitten, Bettschlitten - Cross Slide, Bed Slide

OPTIMUM ® M A S C H I N E N - G E R M A N Y Planschlitten, Bettschlitten - Cross slide, bed slide DE | EN TX6222 Ersatzteile - Spare parts Originalbetriebsanleitung Version 1.0.1 2017-11-16... - Page 97 OPTIMUM ® M A S C H I N E N - G E R M A N Y Ersatzteilliste Planschlitten, Bettschlitten - Spare parts list top slide, cross slide Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. Bettschlitten...

-

Page 98: Oberschlitten - Top Slide

OPTIMUM ® M A S C H I N E N - G E R M A N Y Oberschlitten - Top slide Ersatzteilliste Oberschlitten - Spare parts list top slide, cross slide Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. -

Page 99: Späneschutz - Chip Safety

OPTIMUM ® M A S C H I N E N - G E R M A N Y 7.10 Späneschutz - Chip safety Ersatzteile - Spare parts TX6222 DE | EN Version 1.0.1 2017-11-16 Originalbetriebsanleitung... -

Page 100: Antrieb, Unterbau - Drive, Substructure

OPTIMUM ® M A S C H I N E N - G E R M A N Y 7.11 Antrieb, Unterbau - Drive, substructure DE | EN TX6222 Ersatzteile - Spare parts Originalbetriebsanleitung Version 1.0.1 2017-11-16... -

Page 101: Maschinenbett - Machine Bed

OPTIMUM ® M A S C H I N E N - G E R M A N Y 7.12 Maschinenbett - Machine bed Ersatzteile - Spare parts TX6222 DE | EN Version 1.0.1 2017-11-16 Originalbetriebsanleitung... -

Page 102: Steuerung - Control

OPTIMUM ® M A S C H I N E N - G E R M A N Y 7.13 Steuerung - Control Ersatzteilliste - Spare parts list Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. Abdeckung Cover 03432460801 Bettbrücke... - Page 103 OPTIMUM ® M A S C H I N E N - G E R M A N Y Ersatzteilliste - Spare parts list Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. Maschinenlampe Machine lamp 03432460840 Scharnier Hinge 03432460841...

-

Page 104: Reitstock - Tailstock

OPTIMUM ® M A S C H I N E N - G E R M A N Y 7.14 Reitstock - Tailstock DE | EN TX6222 Ersatzteile - Spare parts Originalbetriebsanleitung Version 1.0.1 2017-11-16... - Page 105 OPTIMUM ® M A S C H I N E N - G E R M A N Y Ersatzteilliste Reitstock - Spare parts list tailstock Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. Grundplatte Base plate 03432460901 Gehäuse...

-

Page 106: Drehfutterschutz - Lathe Chuck Protection

OPTIMUM ® M A S C H I N E N - G E R M A N Y 7.15 Drehfutterschutz - Lathe chuck protection Ersatzteilliste Drehfutterschutz - Spare parts list lathe chuck protection Menge Grösse Artikelnummer Bezeichnung Designation Qty. -

Page 107: Mitlaufende Lünette - Follow Rest

OPTIMUM ® M A S C H I N E N - G E R M A N Y 7.16 Mitlaufende Lünette - Follow rest Mitlaufende Lünette - Follow rest Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. Hülse... -

Page 108: Feststehende Lünette - Steady Rest

OPTIMUM ® M A S C H I N E N - G E R M A N Y 7.17 Feststehende Lünette - Steady rest Feststehende Lünette - Steady rest Menge Grösse Artikelnummer Bezeichnung Designation Qty. Size Item no. Oberteil... -

Page 109: Schaltplan - Wiring Diagram

OPTIMUM ® M A S C H I N E N - G E R M A N Y 7.18 Schaltplan - Wiring diagram Ersatzteile - Spare parts TX6222 DE | EN Version 1.0.1 2017-11-16 Originalbetriebsanleitung... - Page 110 OPTIMUM ® M A S C H I N E N - G E R M A N Y DE | EN TX6222 Ersatzteile - Spare parts Originalbetriebsanleitung Version 1.0.1 2017-11-16...

- Page 111 OPTIMUM ® M A S C H I N E N - G E R M A N Y Ersatzteile - Spare parts TX6222 DE | EN Version 1.0.1 2017-11-16 Originalbetriebsanleitung...

- Page 112 OPTIMUM ® M A S C H I N E N - G E R M A N Y Elektrische Ersatzteile - Electrical Parts Grösse Artikelnummer Bezeichnung Designation Size Item no. Hauptschalter Main switch 034640401S0 Sicherungsautomat Circuit breaker 034640401Q0 Antriebsmotor...

- Page 113 Viskosität Schmierstoffe Viskosity Kennzeich- Lubricant nung nach Viscosité ISO VG DIN 51502 Lubrifiant DIN 51519 mm²/s (cSt) Aral Degol BG BP Energol SPARTAN Klüberoil Mobilgear Shell Omala VG 680 CLP 680 Meropa 680 GR-XP 680 EP 680 GEM 1-680 Aral Degol BG BP Energol SPARTAN Klüberoil...

- Page 114 Techno Service GmbH ; Detmolder Strasse 515 ; D-33605 Bielefeld ; (++49) 0521- 924440 ; www.metaflux-ts.de haute vitesse Schneidöl Aquacut B, Kühlschmiermittel 5 L Gebinde, Artikel Nr. 3601751 Cooling lubricants EG Sicherheitsdatenblatt Chevron Aral Emusol BP Sevora Esso Kutwell Mobilcut Shell Adrana Soluble Oil B Lubrifiants de refroidis- http://www.optimum-daten.de/ sement data-sheets/EG- Datenblatt_Aquacut-B.pdf oil-compare-list.fm...

-

Page 115: Malfunctions

OPTIMUM ® M A S C H I N E N - G E R M A N Y Malfunctions Cause/ Malfunction Solution possible effects Machine does not turn on • Position switch spindle brake machine • Check position switch spindle brake,... - Page 116 OPTIMUM ® M A S C H I N E N - G E R M A N Y Cause/ Malfunction Solution possible effects Flank wear too high • Clearance angle too small (lathe tool • Increase clearance angle "pushes") •...

-

Page 117: Appendix 9.1 Copyright

OPTIMUM ® M A S C H I N E N - G E R M A N Y Appendix Copyright This document is protected by copyright. All derived rights are reserved, especially those of translation, re-printing, use of figures, broadcast, reproduction by photo-mechanical or similar means and recording in data processing systems, either partial or total. -

Page 118: Liability Claims/Warranty

V-belts, ball bearings, illuminants, filters, sealings, etc. - Non reproducible software errors Any services, which OPTIMUM GmbH or one of its agents performs in order to fulfil any additional warranty are neither an acceptance of the defects nor an acceptance of its obli- gation to compensate. -

Page 119: Storage

Example: not stackable - do not stack further packing case on top of the first one. Consult Optimum Maschinen Germany GmbH if the machine and accessories are stored for more than three months or are stored under different environmental conditions than those spec- ified here . -

Page 120: Decommissioning

OPTIMUM ® M A S C H I N E N - G E R M A N Y 9.6.1 Decommissioning CAUTION! Disused machines need to be decommissioned in a professional manner in order to avoid later misuse and endangerment of the environment or persons. -

Page 121: Disposal Via Municipal Collection Facilities

Modified settings Any experiences with the lathe which might be important for other users Recurring malfunctions Optimum Maschinen Germany GmbH Dr.-Robert-Pfleger-Str. 26 D-96103 Hallstadt, Germany Fax +49 (0) 951 - 96 555 - 888 email: info@optimum-maschinen.de Appendix TX6222 Version 1.0.1 dated 2017-11-16... - Page 122 M A S C H I N E N - G E R M A N Y EC - Declaration of Conformity Machinery Directive 2006/42/EC Annex II 1.A Optimum Maschinen Germany GmbH The manufacturer / distributor Dr.-Robert-Pfleger-Str. 26 D - 96103 Hallstadt, Germany...

- Page 123 OPTIMUM ® M A S C H I N E N - G E R M A N Y Index Protective equipment ............17 Accident report ............18 Protective cover Assembly ..............23 lathe chuck ............15 lead screw ............14 Bed insert ..............43 of the headstock ..........

-

Page 124: Dp700 Digital Readout

OPTIMUM ® M A S C H I N E N - G E R M A N Y DP700 Digital readout The detailed manual is available as a download. http://www.newall.co.uk/support/downloads/ digital_readouts/ The brief instructions is located here: „DP700 Quick start guide“...

Need help?

Do you have a question about the OPTIturn TX 6222 and is the answer not in the manual?

Questions and answers