Summary of Contents for Bentone BF1 RME

- Page 1 178 116 35-5 2017-12–05 Providing sustainable energy solutions worldwide Installation- and maintenance instruction BF1 RME...

-

Page 3: Table Of Contents

5.1.6 Air intake and intake cone service _________________ 5.1.7 Fan wheel checks ________________________________________ 5.1.7.1 Inspection ______________________________________________ 5.1.7.2 Cleaning, alternative 1 __________________________________ 5.1.7.3 Cleaning, alternative 2 __________________________________ 5.1.8 Electrical module _________________________________________ 5.1.8.1 Replacement of complete electrical package __________ 5.1.8.2 Replacement of individual electrical components ______ Bentone BF1... -

Page 4: General Instructions

This applies in particular to oil-related parts such as the pump, solenoid valve, oil ilter and hoses. It is very important when carrying out a service to replace old parts with new parts of the same quality. Bentone BF1... -

Page 5: Installation Instructions

• Install a draught regulator (dilutes the lue gases during operation and dries them up during standstill) • Increase the oil quantity • Raise the lue gas temperature by removing turbulators, if any, in the boiler. Detailed ecodesign information can be downloaded at: www.bentone.com/ecodesign Bentone BF1... -

Page 6: Model Bf1 Fuv

Protrusion from lange, measurement B Flange Length of blast tube 1.1.1 Burner output/ Basic settings kg/h 22,0 20,0 18,0 16,0 14,0 12,0 10,0 -0,5 Burner output, kW Burner output, kW Scale value applies to 0 mbar furnace pressure. Bentone BF1... -

Page 7: Model Bf1 Kv

1.2.1 Burner output/ Basic settings kg/h 4 ,0 3 ,5 3 ,0 2 ,5 2 ,0 1 ,5 1 ,0 0 ,5 0 ,0 -0 ,5 1 0 0 Burner output, kW Scale value applies to 0 mbar furnace pressure. Bentone BF1... -

Page 8: Technical Data

General 2. TECHNICAL DATA 2.1 Dimensions BF1 2.1.1 Dimensions, fl anges Flange 1 Flange 2 ø89,7 ø89,5 130–150 136–150 Flange 3 Flange 4 ø90 ø90 125–150 Scale value applies to 0 mbar furnace pressure. Bentone BF1... -

Page 9: Recommended Nozzles And Pressures

/s (cSt) at a density of 830 kg/m 2.3.1 Burner with preheater Allow for a reduction in oil quantity of 5–20% with preheating owing to: • Temperature increases at the nozzle. • Nozzle design. • Capacity (the higher the capacity the lower the difference). Bentone BF1... -

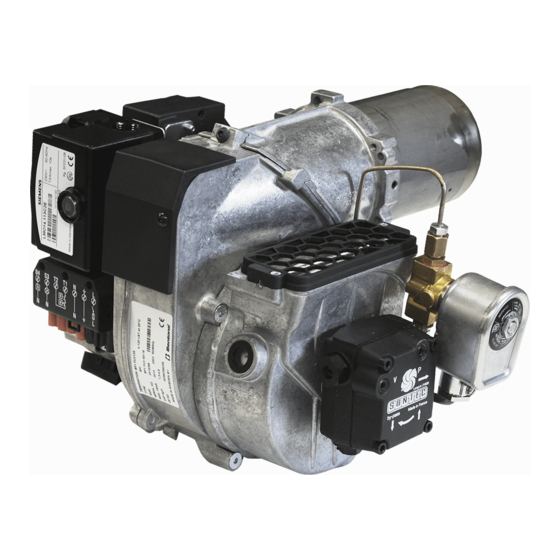

Page 10: Description

Separating screw Blast tube Oil burner control Grid Solenoid valve Electrical contact X3 (refer to wiring diagram) Motor Oil pump Capacitor Air regulator Preheater, where itted Air intake Ignition electrode Air low indicator Ignition cable Fan housing, rear Bentone BF1... - Page 11 General Bentone BF1...

-

Page 12: Installation

(Refer to basic settings). Note that this only refers to the basic setting; the setting must be adjusted after the burner has been started. At this time lue gas analysis and soot measurement must be carried out. Bentone BF1... -

Page 13: Burner Installation

X4 in accordance with the wiring diagram. Disconnect the power at the main switch. Wire the Eurostecker X4 as in alt. 1–3 (refer to Electrical equipment). Connect the Eurostecker X4 to the burner. Switch on the power at the main switch. Bentone BF1... -

Page 14: Basic Settings

Nozzle: 0,75 Gph Pump pressure: 9,5 bar * Caloric value Light oil 11,86 kWh/kg 4.1.2 Basic setting Setting values for 30 kW according to basic settings tables. (Refer to Technical data FUV 63-16). Air setting 11,0 Insert setting Bentone BF1... -

Page 15: Nozzle Assembly Adjustment

STD position to achieve good starts and operations. (A cast-in arrow on the fan housing indicates the position of the inlet cone. In addition to the scale on the inlet cone casting, there is also a mark (M) indicating the factory setting.) Bentone BF1... -

Page 16: Air Intake Rotation

A hose connection air duct is available in three different dimensions: 48, 68, and 78 mm outer diameter (D). The air duct is installed on the air intake at the place where the grille is attached in the standard model Bentone BF1... -

Page 17: Burner Servicing

When servicing or replacing components that affect combustion, analyses and soot tests must be carried out on the installation. Bentone BF1... -

Page 18: Service Position 3

Connect the Eurostecker and switch on the power at the main switch. Start the burner and check the combustion. When servicing or replacing components that affect combustion, analyses and soot tests must be carried out on the installation. Bentone BF1... -

Page 19: Preheater Replacement

Connect the Eurostecker and switch on the power at the main switch. Start the burner and check the combustion. When servicing or replacing components that affect combustion, analyses and soot tests must be carried out on the installation. Bentone BF1... -

Page 20: Oil Pump Replacement

Turn the valve forward and detach it from the pump. Reassemble in reverse order. i g 1 When servicing or replacing components that affect combustion, analyses and soot tests must be carried out on the installation. Bentone BF1... -

Page 21: Fan Motor Replacement

Connect the Eurostecker and switch on the power at the main switch. Start the burner and check the combustion. When servicing or replacing components that affect combustion, analyses and soot tests must be carried out on the installation. Bentone BF1... -

Page 22: Air Intake And Intake Cone Service

Connect the Eurostecker and switch on the power at the main switch. Start the burner and check the combustion. When servicing or replacing components that affect combustion, analyses and soot tests must be carried out on the installation. Bentone BF1... -

Page 23: Cleaning, Alternative 1

Connect the Eurostecker and switch on the power at the main switch. Start the burner and check the combustion. When servicing or replacing components that affect combustion, analyses and soot tests must be carried out on the installation. Bentone BF1... -

Page 24: Cleaning, Alternative 2

Only use electrical components recommended by Enertech. When servicing or replacing components that affect combustion, analyses and soot tests must be carried out on the installation. Bentone BF1... -

Page 25: Replacement Of Complete Electrical Package

When replacing the electrical components transformer and control box included in the electrical package, the junction box lid need not be removed. When servicing or replacing components that affect combustion, analyses and soot tests must be carried out on the installation. Bentone BF1... -

Page 26: Pump Instructions

7–14 bar Oil temperature: max. 60°C 6.1.2 Components Nozzle connection G 1/8” Vacuum manometer connection G 1/8” Manometer connection G 1/8” Filter Suction line G 1/4” Metal plug G 1/4” Return plug Return line G 1/4” Pressure regulation Bentone BF1... -

Page 27: Filter Replacement

6.1.5 Two-pipe system Conversion to two-pipe system Remove the metal plug (7) G ¼”, i t the return plug (8) in the return line (9). Return plug are not included in products with one-pipe system, separately sold. 6.1.6 Solenoid valve Bentone BF1... -

Page 28: Function Anv47C

At that same moment the nozzle line is closed. This provides a sharp cut-off. The on and off functions can be controlled independent of motor rpm, and react very quickly. When the solenoid valve is not activated torque is low up to full motor rpm. Bentone BF1... -

Page 29: Suction Pipe Tables Anv47C

The tables give the total suction line length in meters with a nozzle capacity of 2.1 kg/h. Max. permissible pressure on the suction and return lines is 2.0 bar. For a two-pipe system the Q 46 l/h pump capacity at 0 bar applies. Bentone BF1... -

Page 30: Preheater

If the oil temperature is low and the oil low high, the preheater thermostat may open owing to the PTC element’s inability to maintain oil temperature. In this case it is important to use oil burner controls with a preheater holding circuit. Bentone BF1... -

Page 31: Electrical Equipment

General 8. ELECTRICAL EQUIPMENT LMO1..2..4.. 8.1 Wiring diagram Alt 2 Alt 3 Alt 4 Alt. 1 According to DIN 4791 Bentone BF1... -

Page 32: Component List

If burner operations are interrupted via the main switch or thermostat, a new start will be initiated when conditions according to point 1 are fulilled. Oil burner control blocks Red light on the oil burner control illuminates. The burner is re- started by pressing the reset button. Bentone BF1... -

Page 33: Technical Data

5,5 µA 5,5 µ A Ingress Protection: IP 40 IP 40 LOA not to be used within EU Photocell current checks Photocell current is measured with a direct current ammeter (mulitimeter μA) connected in series with the photocell. Bentone BF1... -

Page 34: Colour Codes Lmo14/24

If the reset button is instead kept pressed a second time for at least 3 seconds, you can, via an interface, obtain the corresponding information on a computer or lue gas analyser. To return to normal operation: Press the reset button for 1 second Bentone BF1... -

Page 35: Fault Location

(refer to technical data) Delayed ignition Check ignition electrodes Too strong a draught not damaged Too great a pressure drop at brake plate Check high voltage wiring Check position of nozzle assembly adjustment Correct the boiler draught Adjust the burner Bentone BF1... -

Page 36: Declaration Of Conformity

10. DECLARATION OF CONFORMITY... -

Page 37: Oil Burners Maintenance Instructions

11. OIL BURNERS MAINTENANCE OIL BURNERS MAINTENANCE INSTRUCTIONS INSTRUCTIONS If the burner starts but does not ignite General information Keep the boiler room clean. Ensure that the boiler Make an attempt to start the burner. room has permanent fresh air intake. Switch off before Never make close repeated start attempts. - Page 40 Enertech AB. P.O Box 309, SE-341 26 Ljungby. www.bentone.se, www.bentone.com...

Need help?

Do you have a question about the BF1 RME and is the answer not in the manual?

Questions and answers