Summary of Contents for SKF GTP-C

- Page 1 Operating instructions Mobile Filling Pumps of Series GTP-C acc. to Machinery Directive 2006/42/EC for pumping lubricants from grease drums Version 01 951-181-023-EN...

-

Page 2: Ec Declaration Of Conformity

EU Declaration of Conformity EC Declaration of Conformity acc. to Machinery Directive 2006/42/EC, Appendix II Part 1A The manufacturer, SKF Lubrication Systems Germany GmbH, Walldorf Plant, Heinrich-Hertz-Str. 2-8, DE - 69190 Walldorf, hereby declares conformity of the machinery Designation: Mobile filling pump for pumping lubricants from separate grease drums... -

Page 3: Masthead

Manufacturer SKF Lubrication Systems Germany GmbH Training Disclaimer of liability Address of manufacturer plants SKF conducts detailed training in order to The manufacturer shall not be held liable for Headquarters enable the maximum safety and efficiency. damage resulting from: Walldorf Plant SKF recommends taking advantage of this ○... -

Page 4: Table Of Contents

Inspections before start-up ..............33 1.19 Warning labels on the product ............14 Transporting the filling pump to the place of use ......34 1.19.1 Pump version GTP-C -*T** ............15 6.3.1 Lifting by the transport bracket ............35 1.20 Residual risks ..................16 - 4 -... - Page 5 Table of contents Inserting the GTP-C filling pump into a grease reservoir ....36 Malfunctions, causes, and remedies ........49 Assembly of the wired remote control ..........37 11.1 Malfunctions table ................49 Installing adapters on the customer's lubrication pump 11.2 Vent the pump ..................51 and on the GTP-C filling hose ..............39...

-

Page 6: Explanation Of Symbols And Signs

Explanation of symbols, signs, and abbreviations Explanation of symbols and signs You will find these symbols, which warn of specific dangers to persons, material assets or the environment, next to all safety instructions. Read the safety instructions thoroughly and follow them. General warning Risk of electrical shock Risk of slipping... - Page 7 Explanation of symbols, signs, and abbreviations Abbreviations and conversion factors regarding °C degrees Celsius °F degrees Fahrenheit approx. approximately Kelvin ounce i.e. that is Newton fl. oz. Fluid ounce etc. et cetera hour inch poss. possibly second pounds per square inch If necessary if necessary sq.in.

-

Page 8: Safety Instructions

1. Safety instructions 1. Safety instructions 1.1 General safety instructions ○ Any malfunctions which may affect safety ○ Any unclear points regarding proper ○ The operator must ensure that the in- must be remedied immediately. In ad- condition or correct assembly/operation structions are read by all persons tasked dition to these instructions, the statu- must be clarified. -

Page 9: Intended Use

1.3 Intended use 1.4 Foreseeable misuse ○ If protective and safety mechanisms The GTP-C filling pump is a compact, Any usage of the product other than as must be removed, they must be rein- mobile, and powerful electric filling pump for specified in this manual is strictly prohibited. -

Page 10: Modifications To The Product

1. Safety instructions 1.5 Modiications to the product 1.7 Inspections prior to delivery ○ Use in areas with damaging radiation Unauthorized modifications and changes The following tests were performed prior to (e.g., ionizing radiation) can have an unpredictable effect on safety. delivery: Unauthorized modifications and changes ○... -

Page 11: Notes On The Type Plate

Article 4, Paragraph 1, Subpara- Material description graph (a) item (i) and is, pursuant to Article 4, Paragraph 3, excluded from the scope of Material number Pressure Equipment Directive 2014/68/EU. SKF Lubrication Systems Germany GmbH 370W / /IP54/max. bar/ Barcode Made in Germany... -

Page 12: Persons Authorized To Use The Product

1. Safety instructions 1.11 Persons authorized to use 1.11.3 Qualiied electrician 1.14 Operation the product A person with appropriate technical training, The following must be observed during first 1.11.1 Operator knowledge, and experience who can recog- start-up and operation: A person competent due to training, knowl- nize and avoid hazards that may result from ○... -

Page 13: Transport, Assembly, Maintenance, Malfunction, Repair, Shutdown, Disposal

1. Safety instructions 1.16 Transport, assembly, maintenance, malfunction, repair, shutdown, ○ Take appropriate measures to ensure ○ Observe any possible wearing spots. Pro- disposal that moving, detached parts are im- tect components appropriately. mobilized during the work and that no ○... -

Page 14: Initial Commissioning, Daily Startup

1. Safety instructions 1.17 Initial commissioning, 1.18 Cleaning 1.19 Warning labels on the product daily startup ○ There is a fire hazard from the use of The following warning labels are affixed to Ensure that: flammable cleaning agents. Use only the product. -

Page 15: Pump Version Gtp-C -*T

1. Safety instructions 1.19.1 Pump version GTP-C -*T** Table 1 Positioning of warning labels, Fig. 1 Item Warning or information label Order No. Item 4 Item 5 MS-WN1021.038 Note direction of motor rotation (arrow) Item 3 Warning of crushing hazard between:... -

Page 16: Residual Risks

1. Safety instructions 1.20 Residual risks Possible in Residual risk Avoidance / Remedy lifecycle Electric shock due to defective power B, C, D, E, Inspect the power lead/power plug for damage before starting the product. lead/power plug F, G, H Disconnect the power plug (cut power) before performing any work on electrical Electric shock from open electric motor components. - Page 17 1. Safety instructions Possible in Residual risk Avoidance / Remedy lifecycle Be careful when filling the reservoir and then connecting or disconnecting the lubri- Personal injury / property damage due to A, B, C, D, E, cant lines. Use only hydraulic screw unions and lubrication piping suitable for the specified pressure.

-

Page 18: Lubricants

To fulfill the task, lubricants and/or damage to the centralized lubrication must meet various requirements to varying SKF Lubrication Systems considers lubri- system. degrees. The most important requirements cants to be an element of system design. -

Page 19: Material Compatibility

(e.g., "bleeding"). cording to the manufacturer’s aluminum data sheet are not suitable for Please contact SKF if you have further ques- ○ NBR, FKM (FPM), ABS, PA, PU use in centralized lubrication tions regarding lubricants. systems (e.g., incompatibility... -

Page 20: Overview, Functional Description

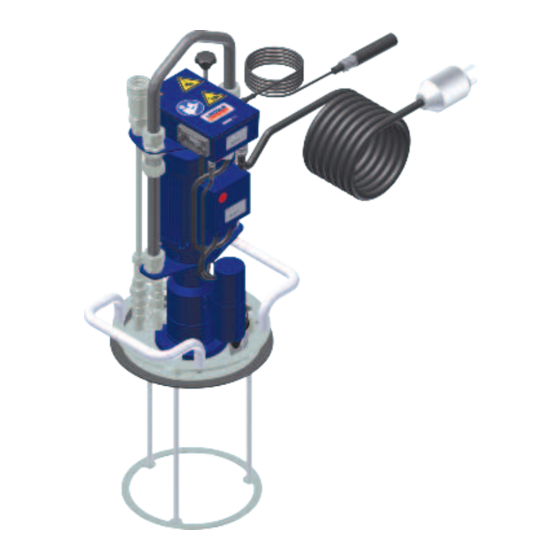

3. Overview, functional description 3. Overview, functional description 3.1 Control and display elements Overview, Fig. 2 Item Description Transport bracket Electric motor Electric terminal box (see Page 21) Gear Gerotor pump Pump frame with grease follower plate and fixation (see Page 35) Vent (see Page 51) Handles... - Page 21 3. Overview, functional description Overview, Fig. 2.1 Item Designation/function Graphic Power plug The pump is available in three different designs, which differ in terms of power plugs. Electricity Electricity supply: supply: 105-127V AC 220-240 V AC 60 Hz 50 Hz NEMA 5-15P Grounded plug NEMA 5-30P...

- Page 22 3. Overview, functional description Overview, Fig. 2.2 Item Designation/function Graphic Wired remote control Venting Starts/stops the filling process. Press the button (3.6.1) to start the filling process. close Release the button (3.6.1) to stop the filling process. The ON delay between two open motor starts is 5 seconds.

-

Page 23: Product Operation

It can be restarter by pressing the (5), and gerotor pump (6). the pressurized lubricating medium from pushbutton on the wired remote control The GTP-C is switched on via a thermal cir- being pressed back. again. cuit breaker (7). If the filling pump consumes... -

Page 24: Minimum Mounting Dimensions

3. Overview, functional description 3.3 Minimum mounting dimensions 3.3.1 Pump version GTP-*T-** GTP-C filling pumps, Fig. 3 See Figure 4 The minimum clearance dimensions must be maintained to ensure sufficient space to use the GTP-C filling pump. Minimum clearance dimensions, Fig. 4 4/4.1... - Page 25 3. Overview, functional description Drum size Pump width Pump frame for grease reservoir Total Type weight “max” height “min” height Diameter [kg] [lbs] [gal] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [in.] [kg] [lbs] None 46.1 16-18 35-40 1000 39.4 27.2...

-

Page 26: Order Code

3. Overview, functional description 3.4 Order code GTP-C - 2 T 1 S - 0 0 0 + 7 5 8 Order example: - B C D E - F G H + Table: GTP-C series Plug Supply voltage Filling hose... -

Page 27: Technical Data

Electrical connectionPlug, NEMA 5-15 P Grounded plug cable length 3 m each NEMA 5-30 P Connect the GTP-C pump only to an electricity supply with protective earth (PE) conductor. IP protection class IP 54 - 27 - 951-181-023-EN Version 01... - Page 28 < 70 dB(A) Delivery rate, nominal 1.0 l/min (+20°C and 50 bar / at 70°F and 700 psi back pressure, tested with Fuchs Gleitmo 585 K) Weight GTP-C with frame -see Page 24 GTP-C without frame Approx. 21 kg / 42.5 lbs...

- Page 29 4. Technical data Lubricants Consistency class (NLGI Grade) NLGI 1 or NLGI 2 Flow pressure Max. 700 mbar / 10 psi Solids content Max. 5% Material compatible with Steel/brass/copper/aluminum/NBR/FKM (FPM)/PU Approved lubricants LGWM 2 Gleitmo 585 K Fuchs RENOCAL FN 745/94 Mobil SHC 460 WT (feedable down to –...

- Page 30 4. Technical data Grease reservoir sizes [kg] [lbs] [gal] [mm] [in.] Inner diameter, max. 11.20 16-18 35-40 Inner diameter, min. 10.04 Height Approx. 360 Approx. 14.17 Inner diameter, max. 13.20 Inner diameter, min. 12.00 Height Approx. 385 15.16 Inner diameter, max. 14.57 15.8 Inner diameter, min.

-

Page 31: Delivery, Returns, Storage

5. Delivery, returns, storage 5. Delivery, returns, storage 5.1 Supply ○ The permissible storage temperature After receipt of the supply, it must be in- spected for any shipping damage and for range corresponds to the operating tem- completeness according to the shipping perature range (see “Technical data”). -

Page 32: Assembly

Set up the GTP-C filling pump only out- GTP-C filling pump. side the operating range of moving parts, o Avoid damaging the filling hose. During... -

Page 33: Inspections Before Start-Up

6. Assembly 6.2 Inspections before start-up See Figure 5 The pump with power plug type - All parts are correctly installed. To ensure safety and functionality, the per- NEMA 5-15P can temporarily draw All warning and information labels son specified by the operator is required to more than 15 A of current during on the machine are fully present, visible, perform certain inspections prior to first... -

Page 34: Transporting The Filling Pump To The Place Of Use

6.3 Transporting the illing pump to the place of use See Figure 5 WARNING WARNING The GTP-C filling pump is typically trans- Personal injury/property damage Risk of death ported to the place of use in a transport Do not tilt or drop the product. -

Page 35: Lifting By The Transport Bracket

See Figure 5 Lifting by the transport bracket, Fig. 5 • Secure the grease follower plate (1) using a fixing screw (2). • Ensure that the GTP-C filling pump (3) is completely lowered into the transport Minimum permissible tensile load drum (4). -

Page 36: Inserting The Gtp-C Filling Pump Into A Grease Reservoir

6. Assembly 6.4 Inserting the GTP-C illing pump into a grease reservoir See Figure 6 Before inserting the GTP-C filling pump • Release the fixation (2). into the grease reservoir, check whether the The grease follower plate (1) descends WARNING... -

Page 37: Assembly Of The Wired Remote Control

• Check the wired remote control (1) for damage. • Connect the plug (2) of the wired remote control to the mating part on the GTP-C filling pump. Removal of the wired remote control is performed in reverse order. - Page 38 Remove any contamination before installation. 6.7.1 Installing a filling hose with quick coupling • Remove the cap (1) from the hydraulic socket on the GTP-C filling pump. • Remove the cap (2) from the hydraulic plug on the filling hose.

-

Page 39: Installing Adapters On The Customer's Lubrication Pump And On The Gtp-C Filling Hose

6. Assembly 6.6 Installing adapters on the customer's lubrication pump and on the GTP-C illing hose 6.6.1 Lubrication pumps of SKF series KFG and P203 with G1/4 adapter See Figure 9, see Chapter 15, "Accessories” Installing the G1/4 adapter, Fig. 9 Install the filling coupling socket on the filling hose of the GTP-C filling pump If necessary, remove any existing adapter from the filling hose. -

Page 40: Lubrication Pumps Of Skf Series Kfg With 20X1.5 Adapter

6.6.2 Lubrication pumps of SKF series KFG with 20x1.5 adapter See Figure 10, see Chapter 15, "Accessories” Install the G1/2 coupling on the filling hose of the GTP-C filling pump. Installing the G1/4 adapter, Fig. 10 If necessary, remove any existing adapter from the filling hose. -

Page 41: Lubrication Pumps Of Skf Series P 203, P 223, P 233, P 243, P 603, And P 653

6. Assembly 6.7 Lubrication pumps of SKF series P 203, P 223, P 233, P 243, P 603, and P 653 See Figure 11, see Chapter 15, "Accessories” Install the connection fitting on the filling hose of the GTP-C filling pump Installing the 22x1.5 adapter, Fig. -

Page 42: First Start-Up

Do not touch cables or plugs of the Pay attention to the position of the must be done exclusively by a specialist GTP-C with wet or moist hands. filling hose while working. After competent and authorized to do so. Connect the GTP-C filling pump... -

Page 43: Commissioning

7. First start-up 7.2 Commissioning See Figure 12 The GTP-C mobile filling pump has been Due to the nature of the system, pumping factory-tested for proper functioning with problems may occur on first start-up or IMPORTANT NOTE testing oil. Therefore observe the following after extended pump downtime. -

Page 44: Operation

Always monitor the filling process. pump to a different circuit or, op- Do not touch cables or plugs of the timally, remove or switch off other GTP-C with wet or moist hands. loads on the circuit. Connect the GTP-C filling pump IMPORTANT NOTE only to an electricity supply with protective earth (PE) conductor. -

Page 45: Operating The Gtp-C Filling Pump

8. Operation Operating the GTP-C illing pump See Figure 12 • Insert the filling pump into the grease • Release the pushbutton on the wired reservoir in accordance with Chapter 6.4. remote control (2) once the maximum fill level is reached. -

Page 46: Temporary Shutdown

8. Operation 8.2 Temporary shutdown Temporary shutdown is performed by dis- Operating the GTP-C filling pump, Fig. 12 connecting the electrical and hydraulic sup- ply connections. Observe the instructions in the chapter “Operation” while doing so. If the product is to be shut down for an extended period of time, also follow the instructions in Chapter “Transport, delivery,... -

Page 47: Cleaning

9. Cleaning 9. Cleaning 9.1 Cleaning agents Only cleaning agents compatible with the materials can be used for cleaning (see IMPORTANT NOTE WARNING Chapter 2.3 for materials). Electric shock Perform cleaning work only on Execution, required protective Always completely remove resi- products that have been de-en- gear, cleaning agents, and equip- due of the cleaning agent on the... -

Page 48: Maintenance

10. Maintenance Maintenance Careful and regular maintenance is required in order to detect and remedy possible malfunctions in time. The specific intervals must always be determined by the operator according to the operating conditions and regularly reviewed and adapted where necessary. If necessary, copy the table for regular maintenance activities. Maintenance checklist Activity to be performed Electrical connection established correctly... -

Page 49: Malfunctions, Causes, And Remedies

IMPORTANT NOTE IMPORTANT NOTE of possible malfunctions and their causes. Contact the SKF Service department if you Only original SKF spare parts may be used. Dismantling of the pump unit (pump/gear/ cannot remedy the malfunction. Unauthorized alterations to products and motor) is prohibited and voids any claims. - Page 50 11. Malfunctions Troubleshooting Cause Remedy No lubricant delivery o Plug for empty signal not installed correctly or sensor defective (yellow • Check and, if applicable, install correctly or replace LED flashing) sensor o Electrical connection for wired remote control not established correctly •...

-

Page 51: Vent The Pump

11. Malfunctions 11.2 Vent the pump See Figure 13 Due to the nature of the system, pumping Proceed as follows: • Turn the elbow (5) back problems may occur on first start-up or after extended pump downtime. If this hap- •... -

Page 52: Repairs

11. Malfunctions / 12. Repairs Repairs If repair is necessary, this must be done by Fig. 13 SKF Service (see masthead). - 52 - 951-181-023-EN Version 01... -

Page 53: Shutdown, Disposal

13.3 Disposal disassembly Temporary shutdown is performed by: Waste should be avoided or minimized to ○ Switching off the GTP-C Permanent shutdown and disassembly of the extent possible. The disposal of prod- the product must be planned properly by the ucts contaminated with lubricant must be ○... -

Page 54: Spare Parts

The spare parts groups are used exclusively as replacement for defec- tive parts identical in construction. No modifications to existing products using the spare parts are permitted. GTP-C spare parts, Fig.14 Spare parts, legend 1 of 2 to Fig. 14 Spare parts for GTP-C... - Page 55 Designation A = Quick coupling B = Transport bracket C = Pump frame GTP-C pump assy. - see frame code Pump frame with grease follower plate, 5 gal. / 16-18 kg /35-40 lbs / 19 l 24-1722-2580 Pump frame with grease follower plate, 8 gal. / 25 kg / 55 lbs / 30 l 24-1722-2592 Pump frame with grease follower plate, 15.8gal.

-

Page 56: Accessories

15. Accessories Accessories Accessories, Table 1 of 4 SKF KFG lubrication pump and SKF P 203 lubrication pump, G1/4 connection Installation on the filling hose Item Illustration Description Order number Filler coupling socket assy. 24-0159-2111 Installation on customer-provided pump KFG G1/4 filler neck 995-000-705 P203 filler coupling assy., G1/4 /M22 x 1.5... - Page 57 15. Accessories Accessories, Table 2 of 4 SKF KFGS/KFGL/KFGC lubrication pump for wind energy systems Installation on the filling hose Item Illustration Description Order number G1/2 coupling for fill connection 24-0159-2112 item 5 and item 6 5 / 6 M20 x 1.5 straight fill connection...

- Page 58 15. Accessories Accessories, Table 3 of 4 Connection to SKF lubrication types P 203 / P 223 / P 233 / P243 / P 603 / P 653 Installation on the filling hose Item Illustration Description Order number Connection fitting assy.

- Page 59 15. Accessories Accessories, Table 4 of 4 Connection to SKF lubrication types P 203 / P 223 / P 233 / P243 / P 603 / P 653 Installation on customer-provided pump Item Illustration Description Order number Fill connection 90°, long...

- Page 60 The Power of Knowledge Engineering Over the course of more than a century, SKF has specialized in five fields of competence and Bearings Lubrication acquired a wide range of application expertise. We utilize this experience to provide innovative Seals and Bearing Systems solutions to OEMs and other manufacturers in practically all industrial sectors worldwide.

Need help?

Do you have a question about the GTP-C and is the answer not in the manual?

Questions and answers